Method for V-method shaping anti-gravity pouring of aluminum alloy casting

A technology of anti-gravity pouring and aluminum alloy castings, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. Excellent quality, good internal quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

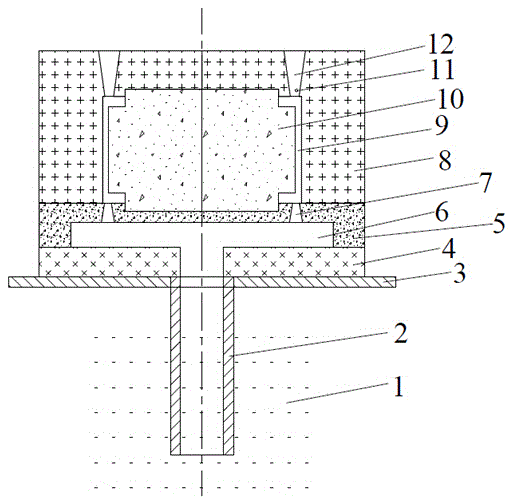

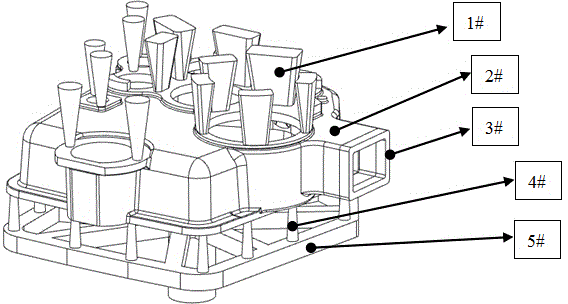

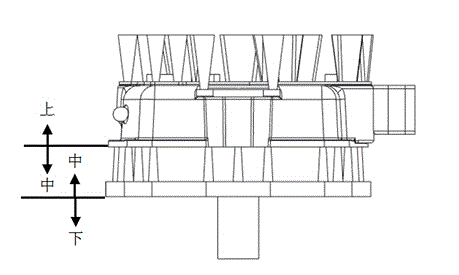

[0027] Take the V-method molding 8 low-pressure pouring of a box aluminum casting 9 as an example, see figure 2 and image 3 shown.

[0028] (1) Model preparation: The outer skin of the casting 9 adopts the V method model, and the model is placed on a negative pressure box with a hollow structure and an air extraction hole. The model has the shape of the aluminum casting 9 of the box and has an air extraction hole. When the vacuum acts, these The holes help keep the membrane snug on the model. Casting 9 sand core adopts aluminum core box structure model.

[0029] (2) Heating film: Place the EVA film under the baking film device and heat it quickly. The heating temperature is 80-120°C, and the mirror surface of the EVA film will sag by 300mm-500mm.

[0030] (3) Coating: Cover the heated EVA film with drooping mirror surface on the model with the shape of the part and with air holes, and vacuum pump (vacuum degree 0.03-0.05MPa) to make the EVA film closely adhere to the mode...

Embodiment 2

[0044] Take the low-pressure pouring of the V method shape 8 of a barrel-shaped aluminum casting 9 as an example, see Figure 4 shown.

[0045] (1) Model preparation: The outer skin of the casting 9 adopts the V method model, and the model is placed on a negative pressure box with a hollow structure and an air extraction hole. The model has the shape of a barrel aluminum casting and has an air extraction hole. When the vacuum acts, these holes have Helps keep the film tight to the model. Casting 9 sand core adopts aluminum core box structure model.

[0046] (2) Heating film: Place the EVA film under the film baker and heat it quickly. The heating temperature is 80-110°C, and the mirror surface of the EVA film will sag by 300mm-500mm.

[0047] (3) Coating: Cover the heated EVA film with drooping mirror surface on the model with the shape of the part and with air holes, and vacuum pump (vacuum degree 0.03-0.05MPa) to make the EVA film closely adhere to the model. Secure the 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com