Double-station anti-gravity casting machine of large copper alloy propeller for ship

An anti-gravity casting and copper alloy technology is applied in the field of double-station anti-gravity casting machines for copper alloy propellers for large ships, which can solve the problems of low yield of large copper alloy propellers, single function of anti-gravity casting machines, and low mechanical properties. problems, to achieve the effects of improved mechanical properties, improved tensile strength, and improved process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

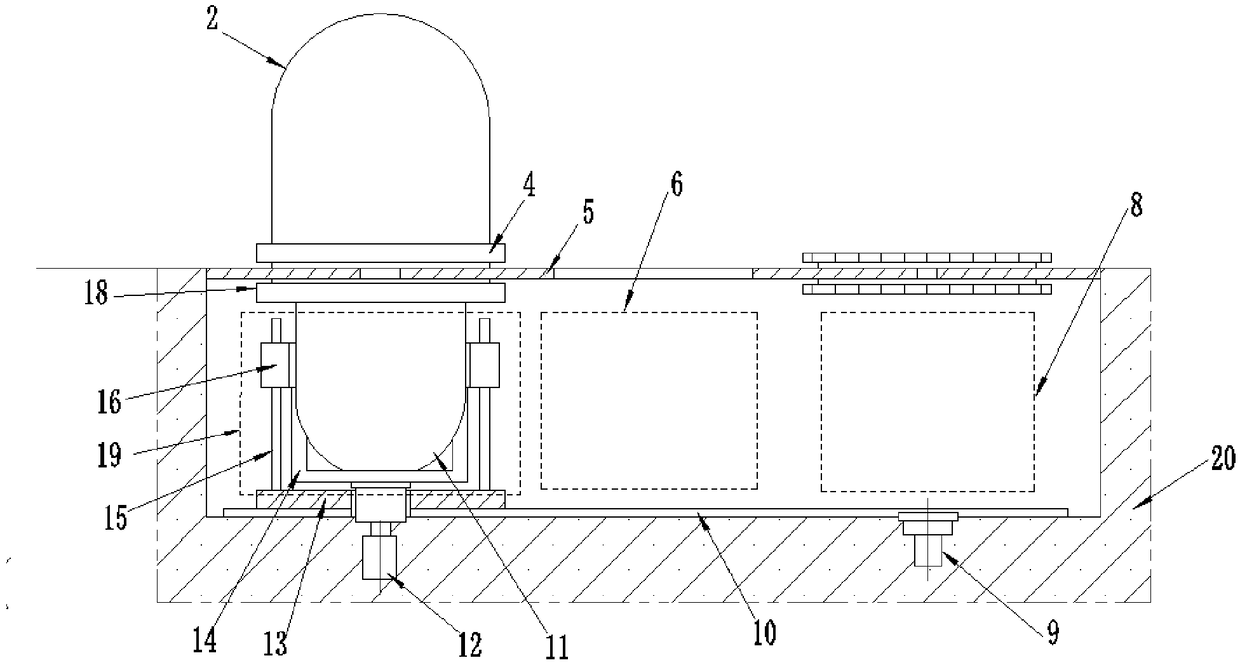

[0047] Specific implementation mode one: combine figure 1 Describe this embodiment, the casting machine main body 20 of the copper alloy propeller double-station anti-gravity casting machine for large ships in this embodiment is a box structure; the box top surface of the casting machine main body 20 is the working platform 5; the inside of the casting machine main body 20 There are copper water packaging unloading station 6, low pressure casting station 8 and differential pressure casting station 19, differential pressure casting station 19 is set on the left side of copper water packaging unloading station 6, low pressure casting station 8 is set on the copper water The right side of packaging and unloading station 6;

[0048] A differential pressure casting solution exchange hole is provided on the working platform 5 corresponding to the center of the differential pressure casting station 19; a low pressure casting solution exchange hole is provided on the working platform ...

specific Embodiment approach 2

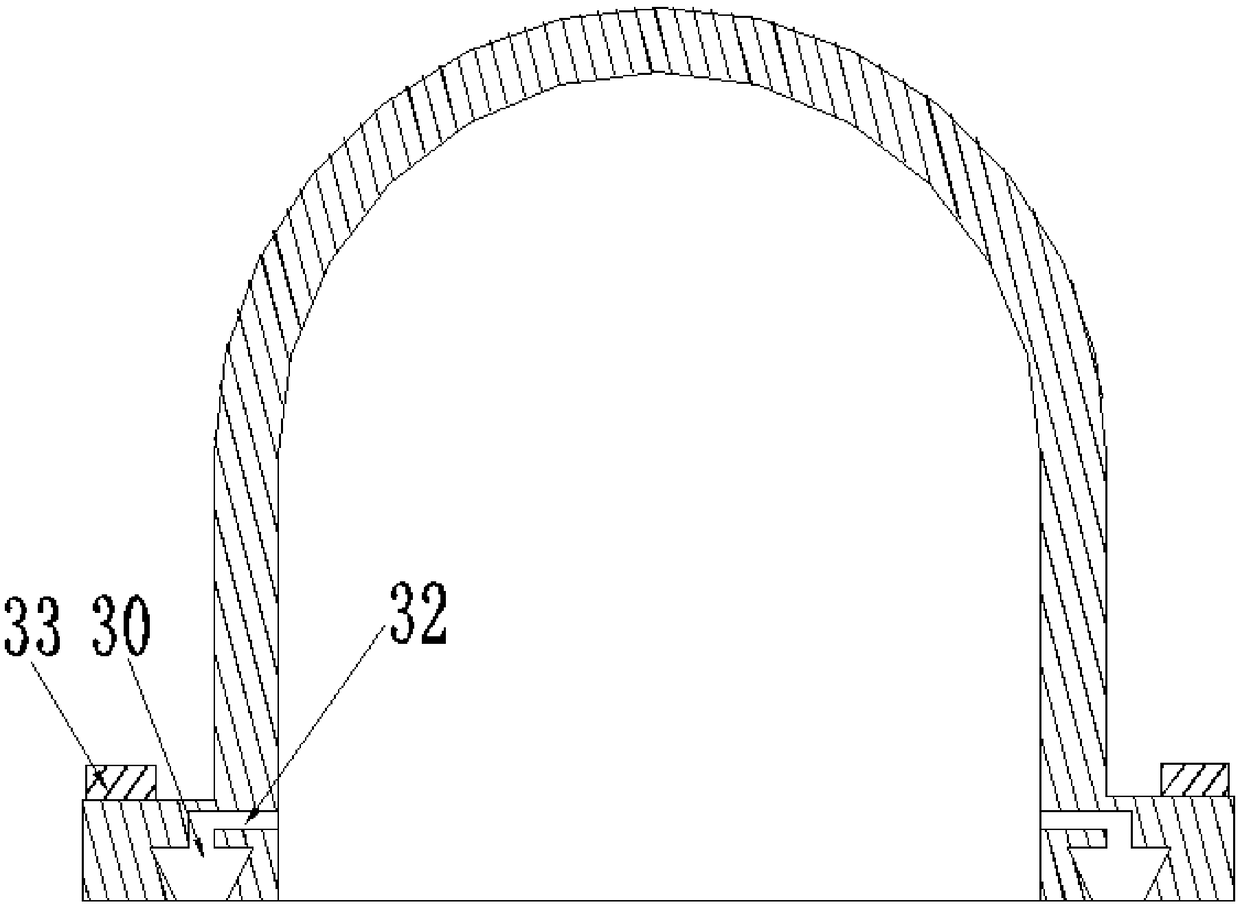

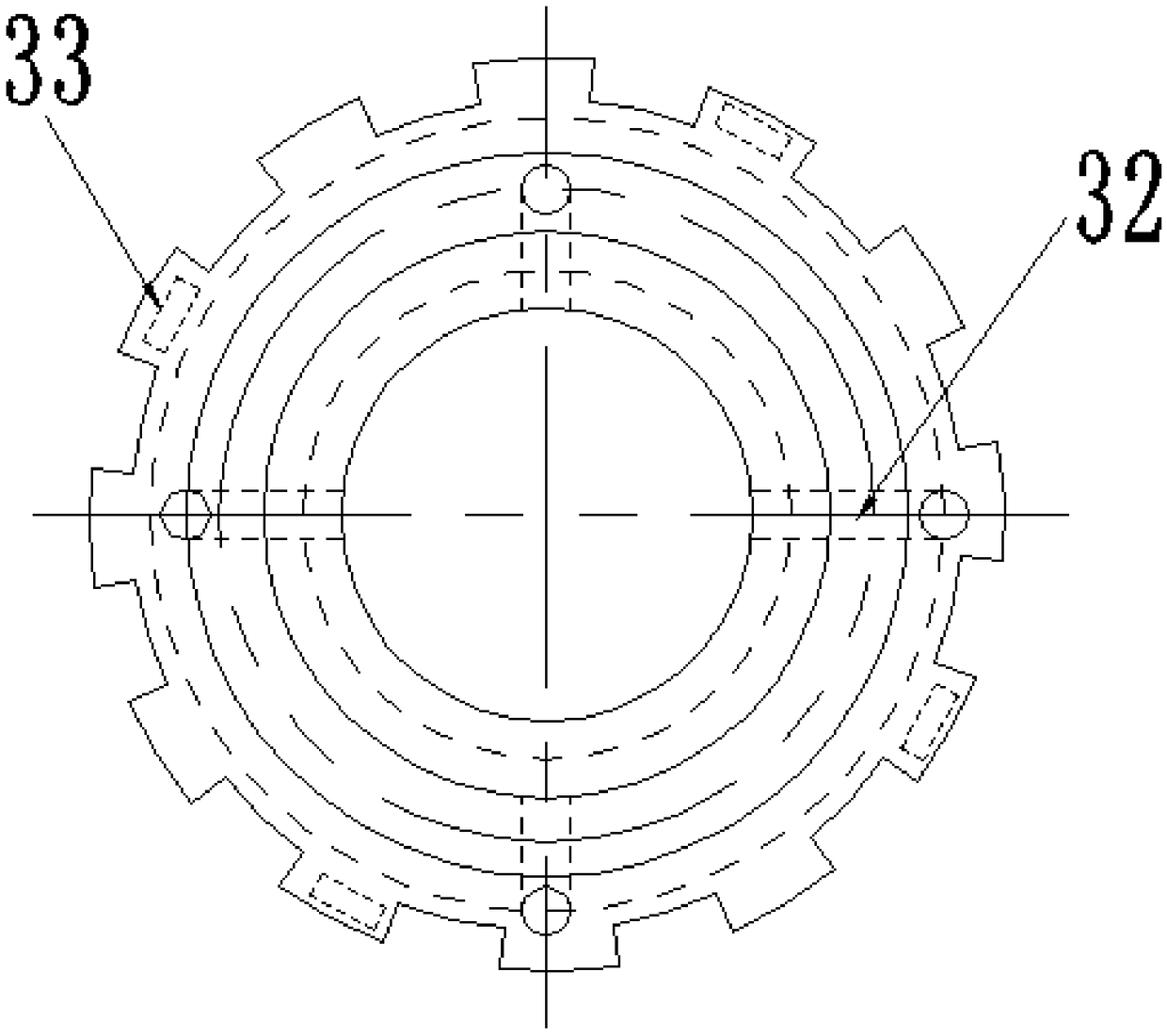

[0056] Specific implementation mode two: combination Figure 4~6 This embodiment is described. The difference between this embodiment and the first embodiment is that the mouth of the upper working tank 2 is set downwards, and the flange end surface of the mouth of the upper working tank 2 is provided with an inverted ladder-type sealing groove 30, which is inverted. The trapezoidal sealing groove 30 communicates with the interior of the upper working tank 2 through several air ducts 32 arranged in the side wall of the upper working tank 2, and an inverted trapezoidal sealing rubber sealing ring 31 is arranged in the inverted trapezoidal sealing groove 30; A tooth-shaped outer edge is provided, and several wedge irons 33 are arranged on the upper surface of the tooth-shaped outer edge; the upper working tank locking ring 4 is annular, and a rectangular groove is opened on the annular inner peripheral surface of the upper working tank locking ring 4 , the two groove walls of th...

specific Embodiment approach 3

[0057] Specific implementation mode three: combination Figure 4~6 Describe this implementation mode, the difference between this implementation mode and specific implementation mode 1 or 2 is:

[0058] The connection method between the upper working tank 2 and the connecting flange 21 of the upper working tank is as follows: when the upper working tank 2 is connected with the connecting flange 21 of the upper working tank, the toothed outer edge of the upper working tank 2 and the connecting flange of the upper working tank The toothed end face of 21 is set correspondingly, and one of the toothed groove walls of the rectangular groove of the locking ring 4 of the upper working tank passes through the toothed outer edge of the tank mouth of the upper working tank 2 and the toothed end face of the connecting flange 21 of the upper working tank , and then start the locking oil cylinder 41, the locking oil cylinder 41 drives the upper working tank locking ring 4 to rotate through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com