A nonlinear pressure control system for differential pressure casting of complex metal components

A differential pressure casting and metal component technology, applied in the field of nonlinear pressure control system, can solve the problems of poor forming quality of complex metal components, avoid churning and splashing, solve poor forming quality, and eliminate shrinkage cavities and shrinkage porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

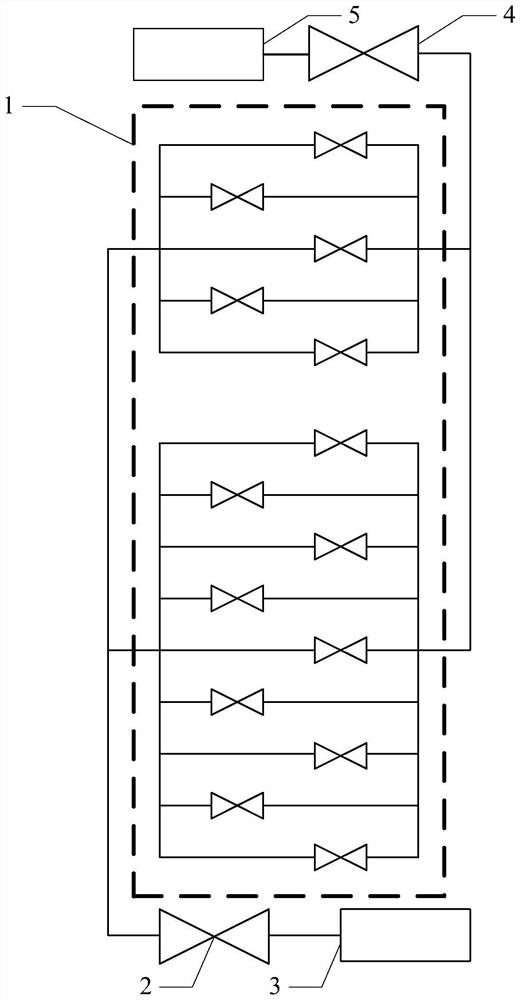

[0028] Embodiment one: combine below figure 1 and figure 2 This embodiment will be described in detail.

[0029] The non-linear pressure control system for differential pressure casting of complex metal components described in this embodiment is used in conjunction with differential pressure casting equipment, and the differential pressure casting equipment includes an upper pressure cylinder and a lower pressure cylinder 5;

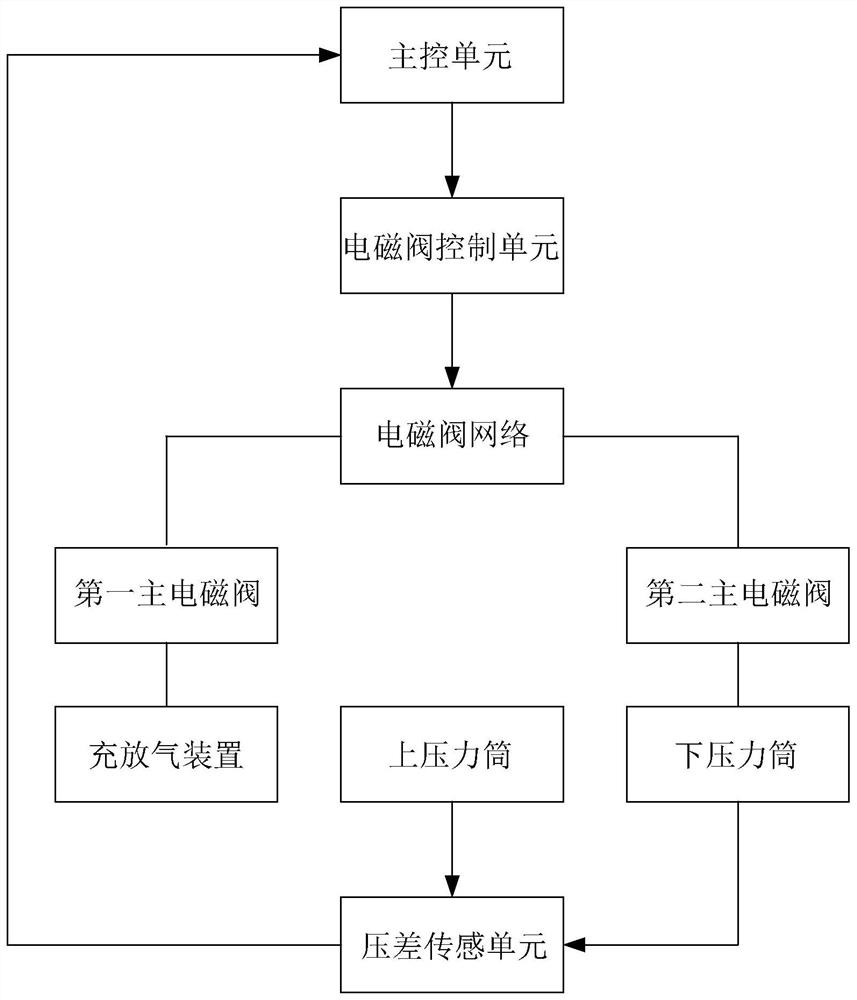

[0030] The nonlinear pressurization control system includes a main control unit, a solenoid valve control unit, a solenoid valve network 1 and a differential pressure sensing unit;

[0031] The solenoid valve network 1 includes a first solenoid valve subnetwork and a second solenoid valve subnetwork, and the first solenoid valve subnetwork and the second solenoid valve subnetwork are arranged in parallel;

[0032] The first solenoid valve sub-network includes five solenoid valves connected in parallel with each other, and the second solenoid valve sub...

Embodiment 2

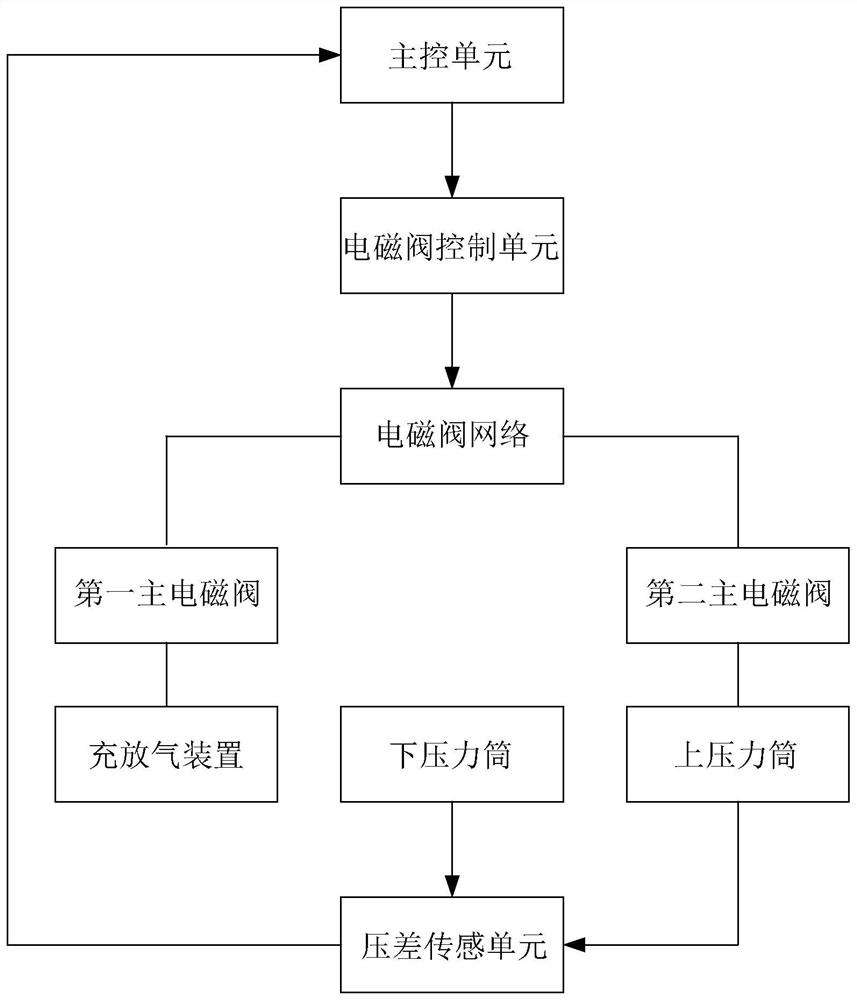

[0045] Embodiment two: combine below image 3 and Figure 4 This embodiment will be described in detail.

[0046] The non-linear pressure control system for differential pressure casting of complex metal components described in this embodiment is used in conjunction with differential pressure casting equipment, and the differential pressure casting equipment includes an upper pressure cylinder 6 and a lower pressure cylinder;

[0047] The nonlinear pressurization control system includes a main control unit, a solenoid valve control unit, a solenoid valve network 1 and a differential pressure sensing unit;

[0048] The solenoid valve network 1 includes a first solenoid valve subnetwork and a second solenoid valve subnetwork, and the first solenoid valve subnetwork and the second solenoid valve subnetwork are arranged in parallel;

[0049] The first solenoid valve sub-network includes five solenoid valves connected in parallel with each other, and the second solenoid valve sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com