High heat flow anti-gravity heat pipe

A gravitational heat pipe, high-heat technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of limited anti-gravity heat transfer effect, weakening the flow rate of working fluid, limiting heat transfer capacity, etc., to overcome the structural layout of the equipment. Confinement, strong anti-gravity heat transfer effect, flexible arrangement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

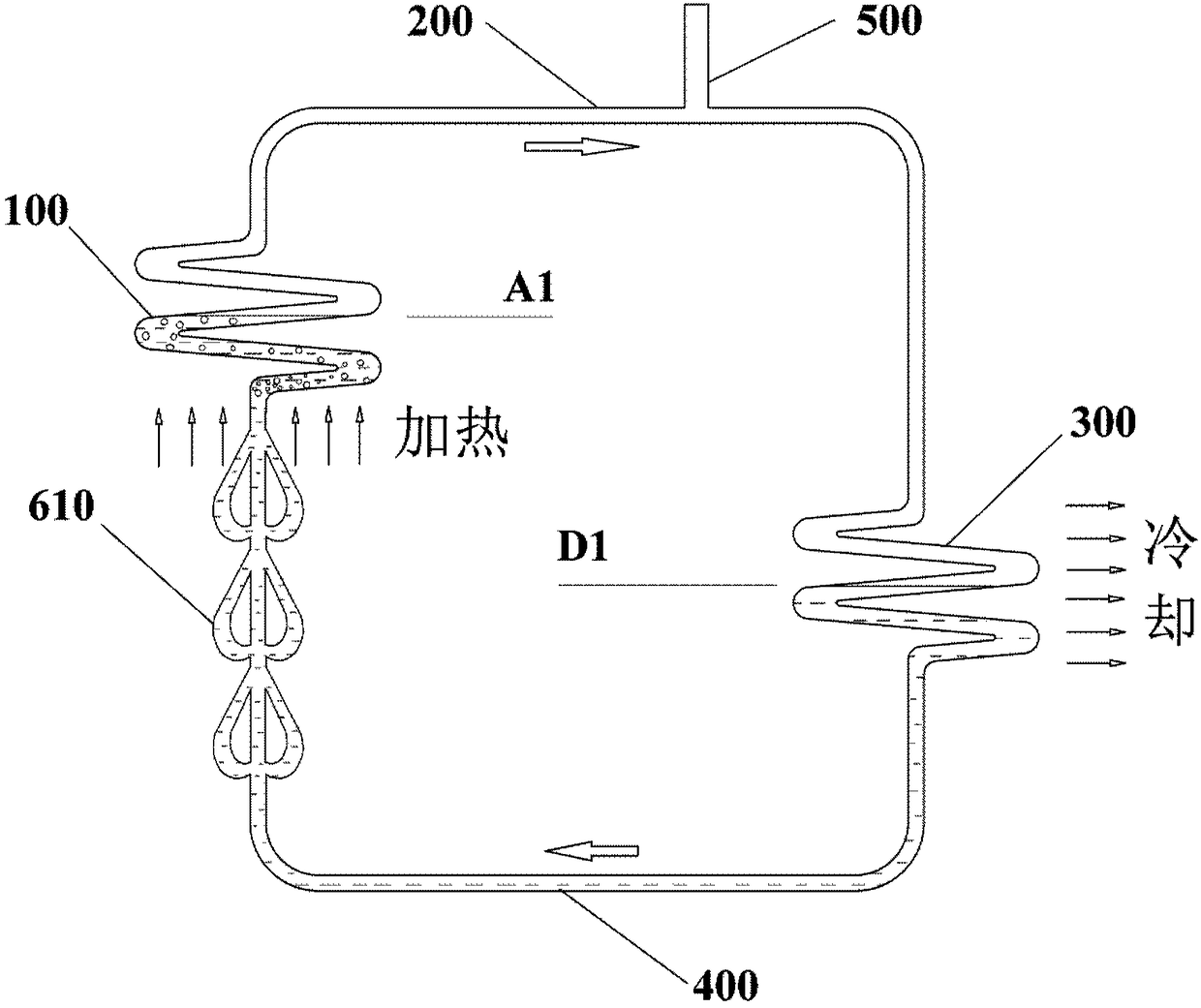

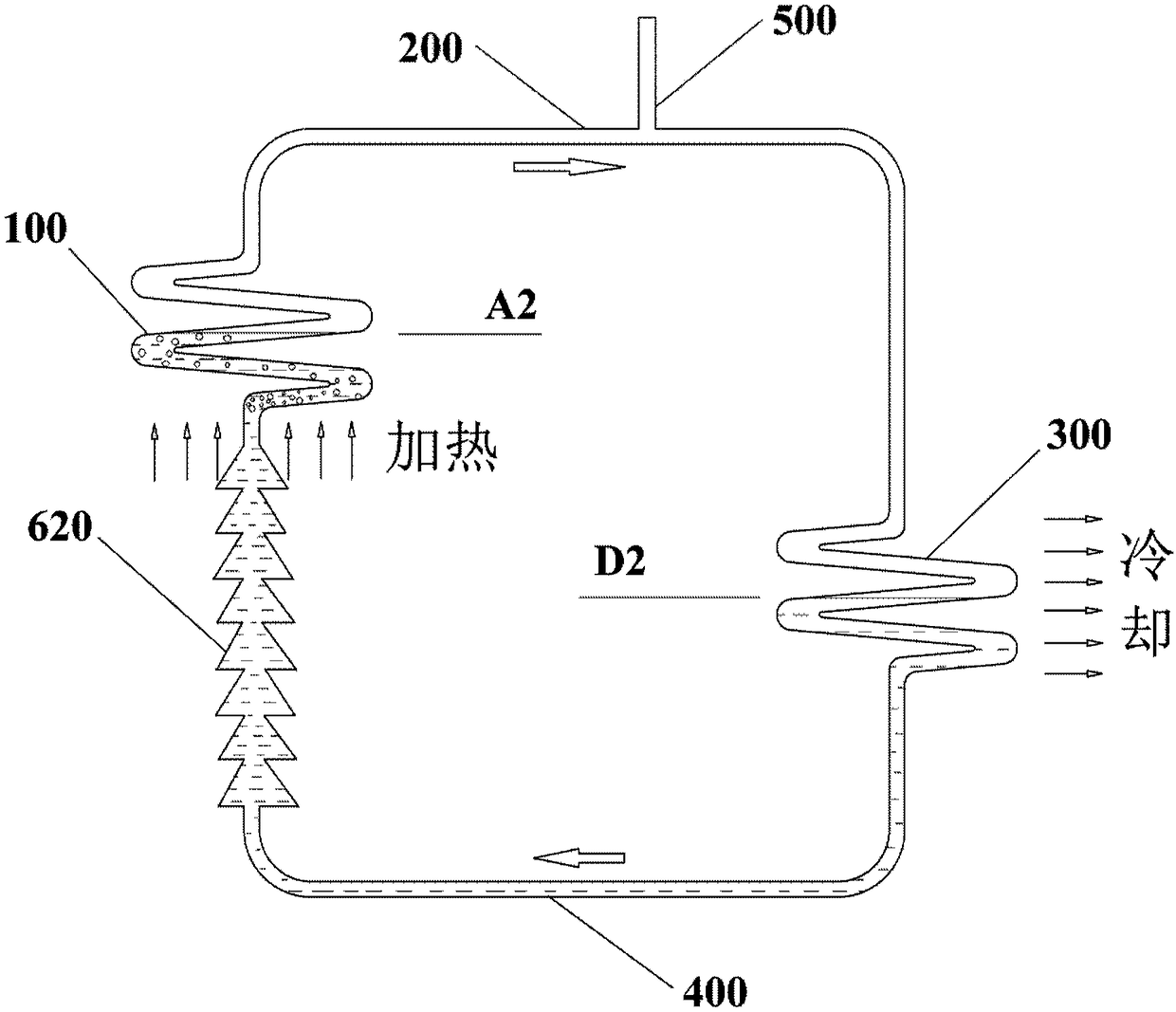

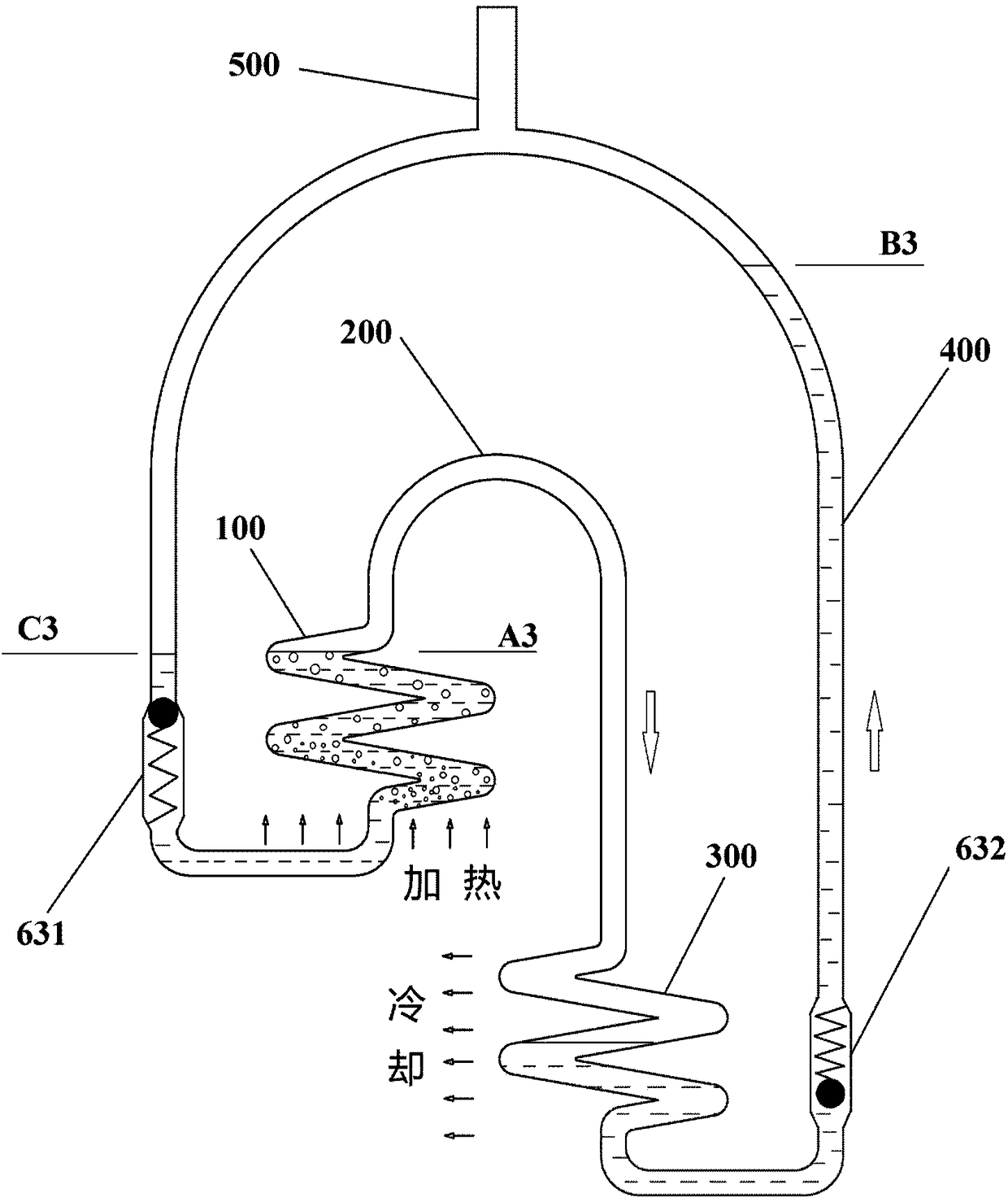

[0028] The present disclosure provides a high heat flow anti-gravity heat pipe. On the basis of retaining the traditional heat pipe evaporation and condensation heat exchange mechanism, the capillary core structure that hinders the flow of working fluid is eliminated. , the highest heat flux density load of high heat flow anti-gravity heat pipe can reach 1000W / cm 2 It can significantly improve the heat transfer capacity, especially suitable for large heat flow and long-distance heat transfer. This disclosure directly uses the saturation pressure difference accompanied by the temperature difference between the cold and hot ends as the driving force, and utilizes the asymmetrical flow path formed by flow direction guide devices such as Tesla valves, multi-section reducing pipes, one-way valves, and float valves. The structure promotes the one-way flow of the working fluid, which can achieve a stronger anti-gravity heat transfer effect. In addition, the heat pipe of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com