An automatic washing and drying machine

An automatic flushing, all-in-one technology, applied in separation methods, filtration separation, dispersed particle separation, etc., can solve the problems of long flushing time, low work efficiency, and large physical exertion of workers, to prevent secondary pollution, prevent clogging, The effect of improving usability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

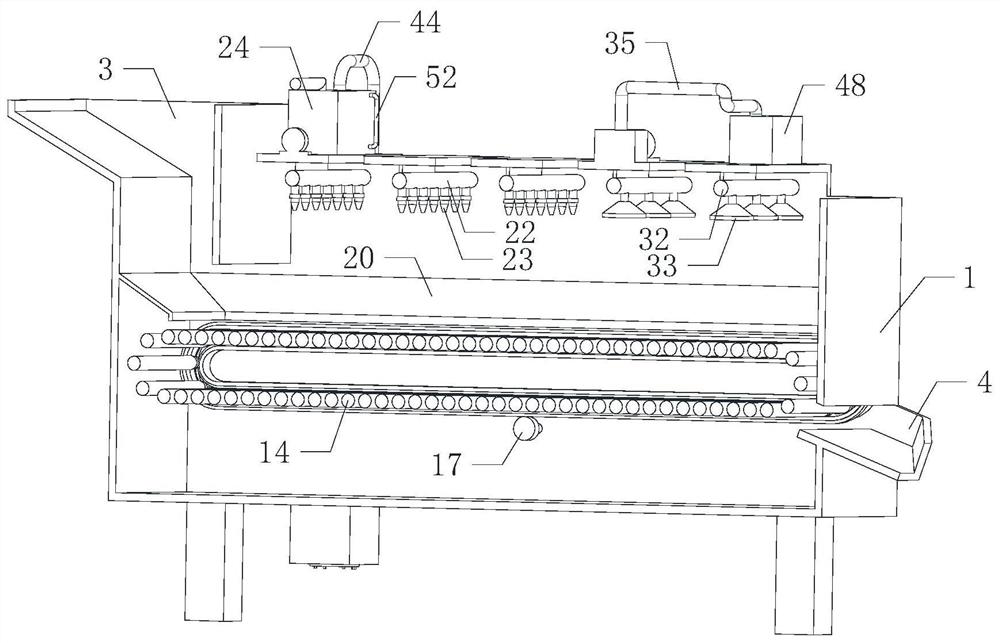

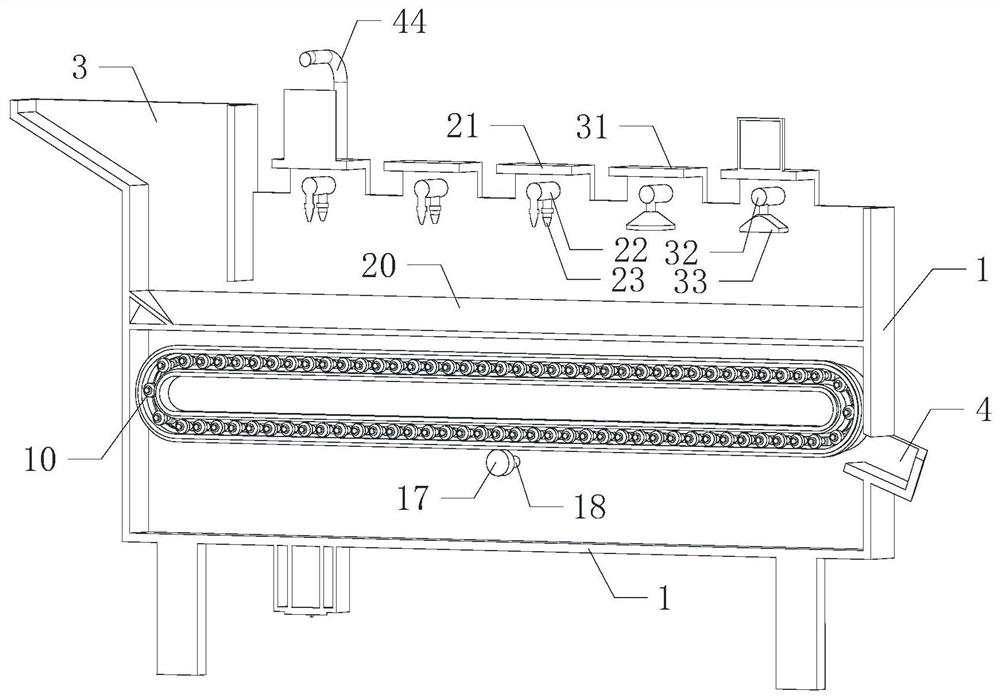

[0022] Such as Figure 1 to Figure 7 As shown, an automatic flushing and air-drying integrated machine of the present invention, when it is working, turns on the power motor 19, the power motor 19 drives the power gear 17 to rotate through the power shaft 18, and the power gear 17 drives the synchronous external toothed belt 16 to perform rotary motion, The synchronous external toothed belt 16 rotates through the synchronous internal toothed belt 15, the inner wall of the synchronous internal toothed belt 15 meshes with the outer walls of multiple sets of synchronous gears 10, and the outer walls of multiple sets of synchronous gears 10 mesh with the outer walls of the syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com