Heat fin

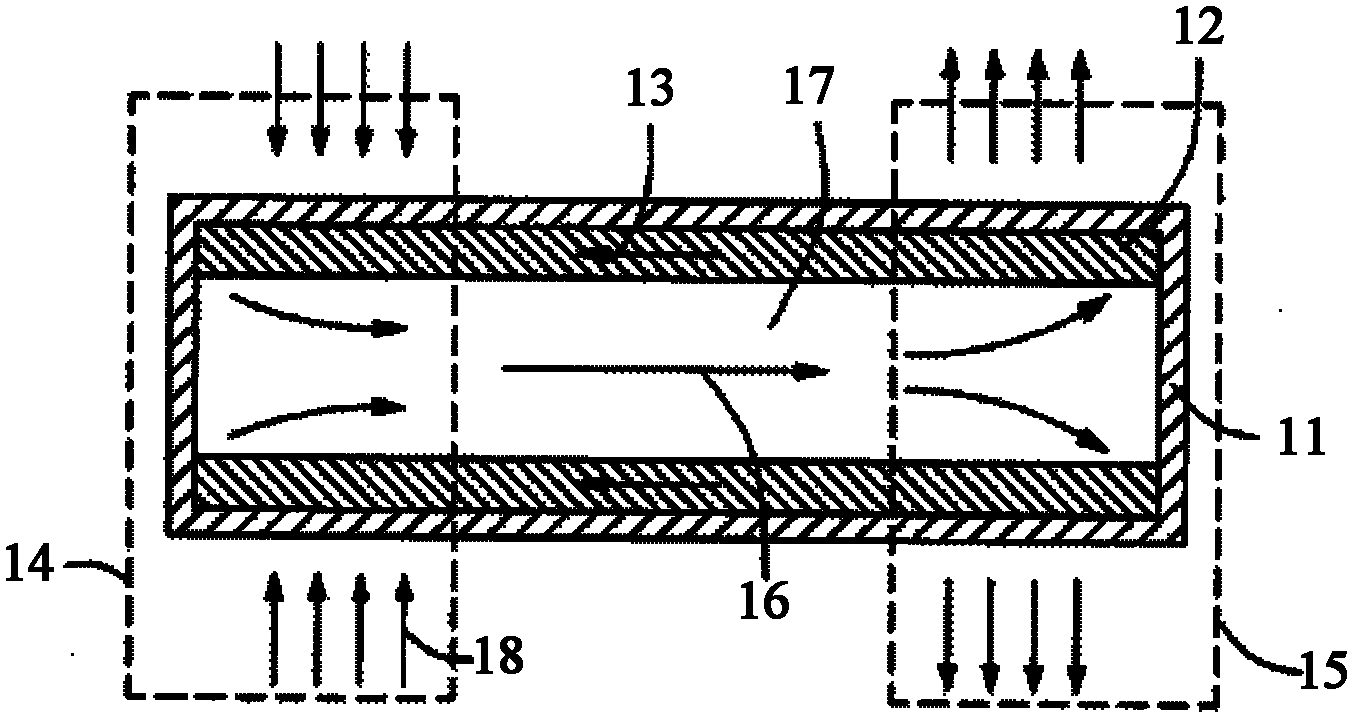

A thermal fin, side panel technology applied to thermal fins. It can solve the problems of long distance and low heat transfer limit of the vapor chamber, and achieve the effect of wide reflow width, favorable for divergence and condensation, and high heat flux density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the present invention is not limited to the following specific embodiments, and those skilled in the art should understand the present invention from the spirit embodied in the following embodiments, and each technical term can be made the broadest based on the spirit of the present invention. understanding. The same or similar components in the figures are denoted by the same reference numerals.

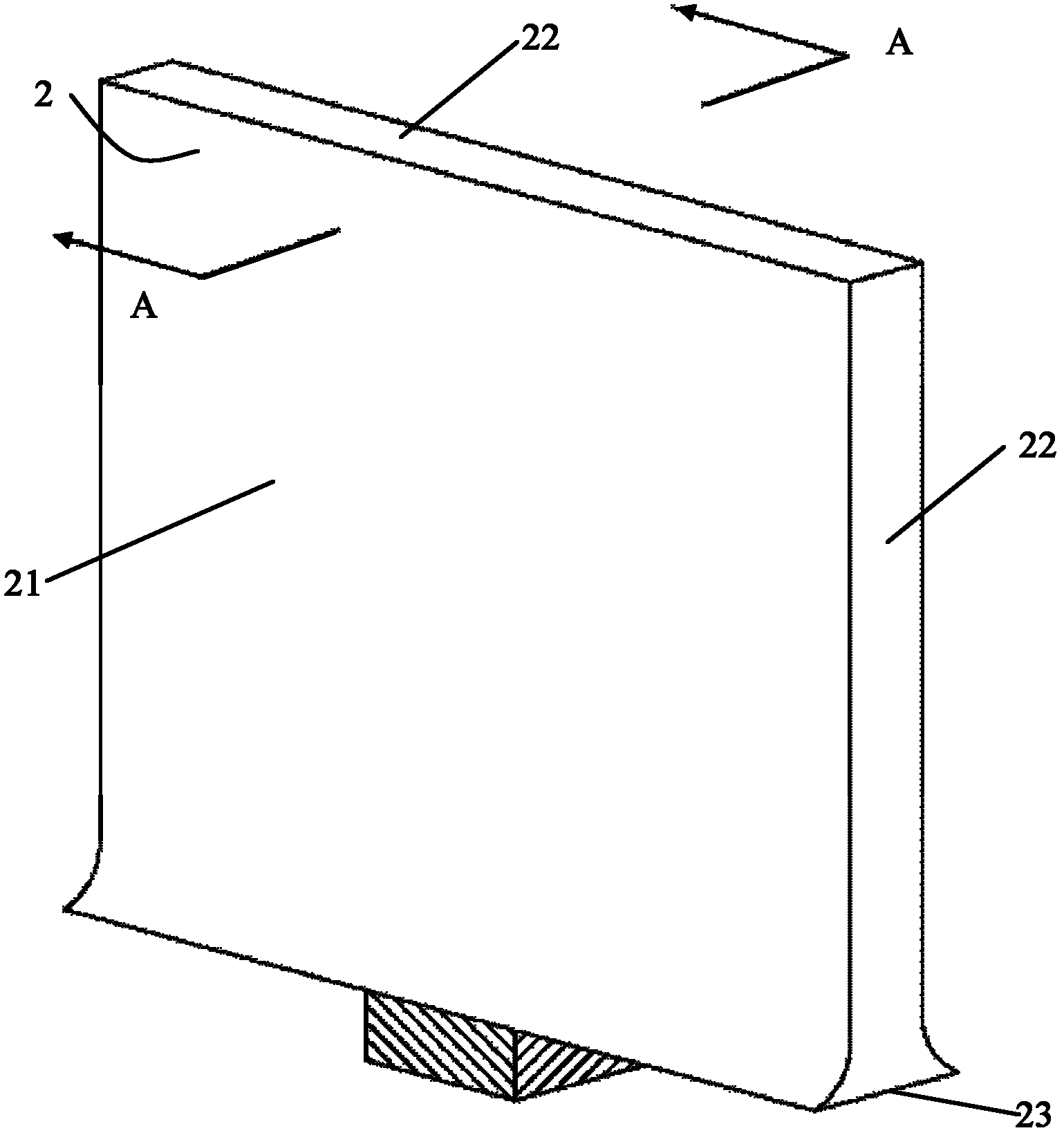

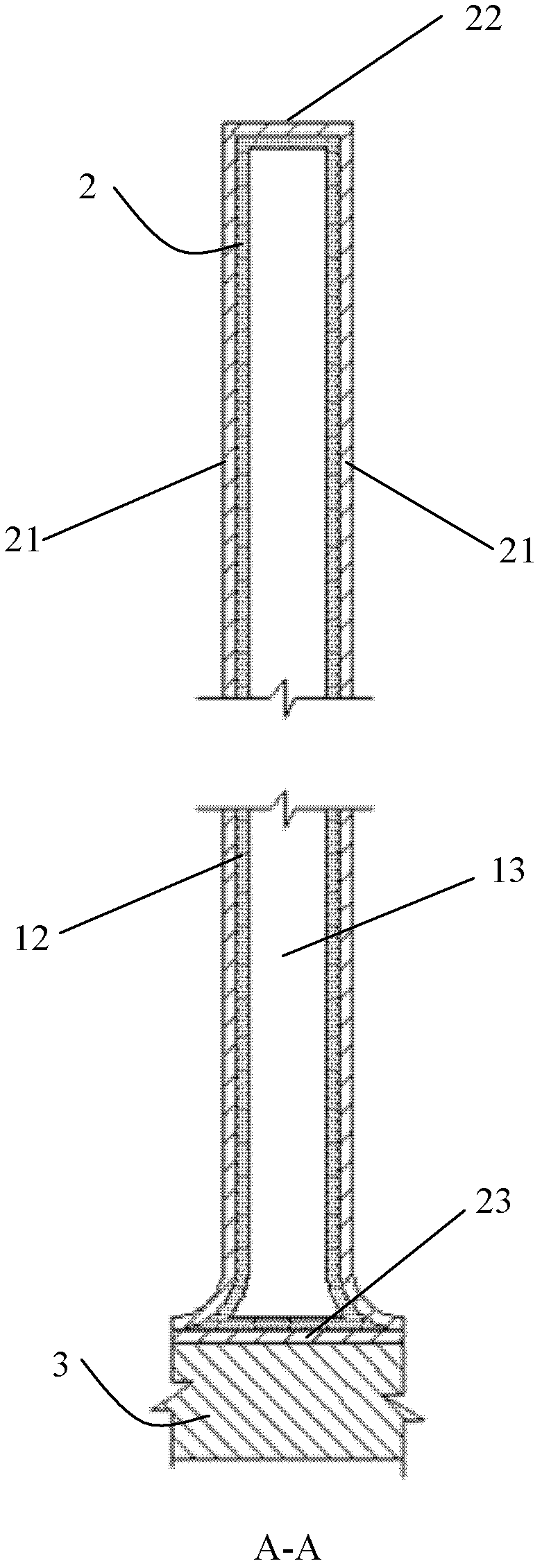

[0037] figure 2 , image 3 The first embodiment of the present invention is shown, as shown in the figure, the heat fin of the present invention includes two side panels 21 forming a hollow plate-shaped casing 2 and frames 22, 23 connecting the two side panels 21, tightly The capillary structure layer 12 attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com