Gypsum line lamp strip light guide plate mounting equipment

A technology for installing equipment and light guide plates, applied in the field of light guide plates, can solve problems such as the length of the light guide plates, and achieve the effects of low power consumption, uniform light, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

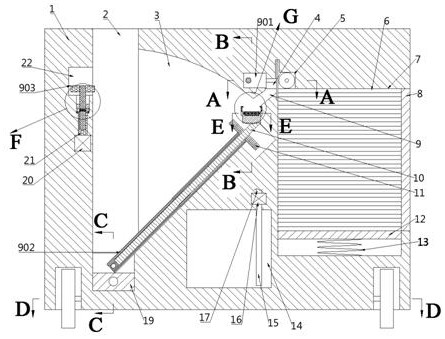

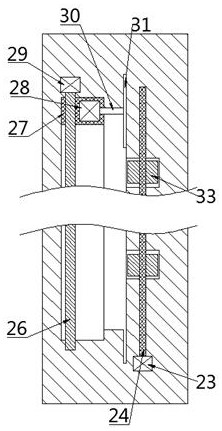

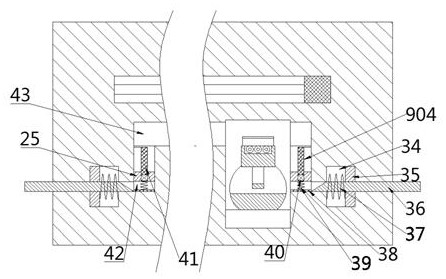

[0020]Bonded belowFigure 1-8The present invention will be described in detail, in which it is convenient for the description, the orientation of the following statement is as follows: The above-mentioned left and right directionsfigure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0021]A plaster line lamp belt light guide plate mounting apparatus according to Figs. 1-8, includes a fuselage 1, a light-conductive plate chamber 7 having an opening to right in the right wall, the light guide plate chamber 7 The right side is provided with a door 8 for closing the light guiding plate chamber 7, and the light guiding plate cavity 7 is fixedly provided with a bottom plate compression spring 13, the bottom plate compression spring 13 away from one end of the bottom wall of the light guide plate chamber 7. The bottom plate 12 is provided, and the top wall of the bottom plate 12 is disposed in contact with a light guide plate 6, and the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com