Alkali metal heat pipe wick and preparation method thereof and heat pipe

An alkali metal and liquid-absorbing core technology, applied in the field of heat transfer, can solve the problems of the maximum heat transfer rate limiting the heat transfer capacity of heat pipes, the capillary heat transfer limit limit of alkali metal heat pipes, etc., to improve the heat transfer limit, increase the capillary limit, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

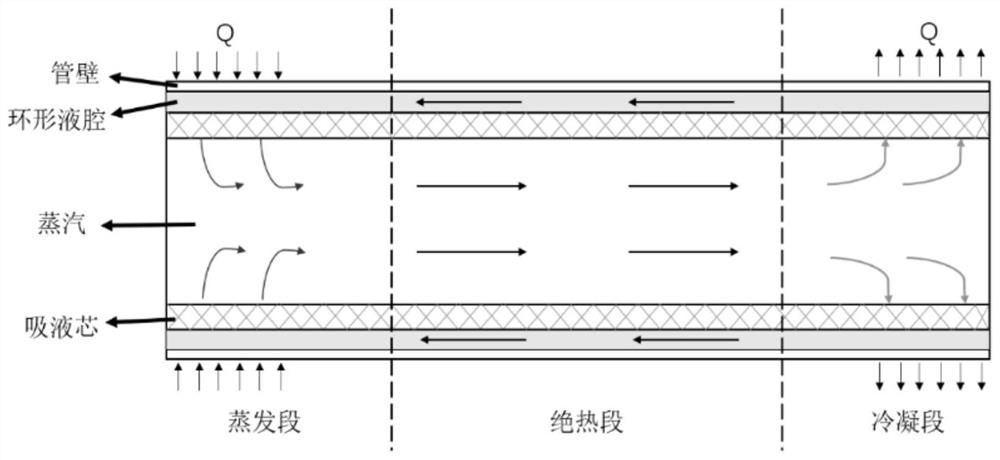

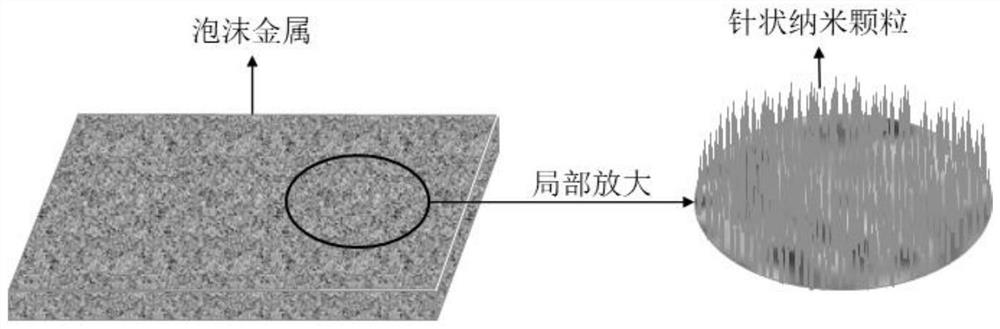

[0051] The alkali metal heat pipe liquid-absorbing core includes metal foam, and the surface of the metal foam is formed with alkali metal needle-like nanoparticles.

[0052] In this embodiment, the metal foam is copper foam of 120 μm, and the specific preparation process of the liquid-absorbing core is as follows:

[0053] Immerse 120 μm copper foam in 2.5 mol L at 70 °C -1 Potassium hydroxide and 0.065mol L -1 Soak in the mixed solution of potassium persulfate for 30 minutes, take out the foamed metal flakes, wash them and bake them in a high-temperature oven at 180°C for 2 hours. The surface of the foamed metal flakes can form needle-like nanostructures, such as figure 2 shown.

[0054] In this embodiment, needle-like nanoparticles with a diameter of 500-800 nm are formed, and the equivalent micropore radius is about 8 um.

Embodiment 2

[0056] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0057] Immerse 120 μm copper foam in 1 mol L at 50 °C -1 Potassium hydroxide and 0.026mol L -1 Soak in a mixed solution of potassium persulfate for 50 minutes.

[0058] In this embodiment, needle-shaped nanoparticles with a diameter of 600-900 nm are formed, and the equivalent micropore radius is about 15 um.

Embodiment 3

[0060] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0061] Immerse 120 μm copper foam in 3 mol L at 80 °C -1 Potassium hydroxide and 0.078mol L -1 Soak in a mixed solution of potassium persulfate for 30 minutes.

[0062] In this embodiment, needle-like nanoparticles with a diameter of 400-700nm can be formed, and the equivalent micropore radius is about 6um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com