Liquid metal pulse heat pipe

A liquid metal and pulse heat pipe technology, applied in the field of heat pipes, can solve the problems of large calorific value, low heat transfer limit of heat pipes, and low heat transfer efficiency of heat pipes, and achieve the effect of wide working temperature range and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

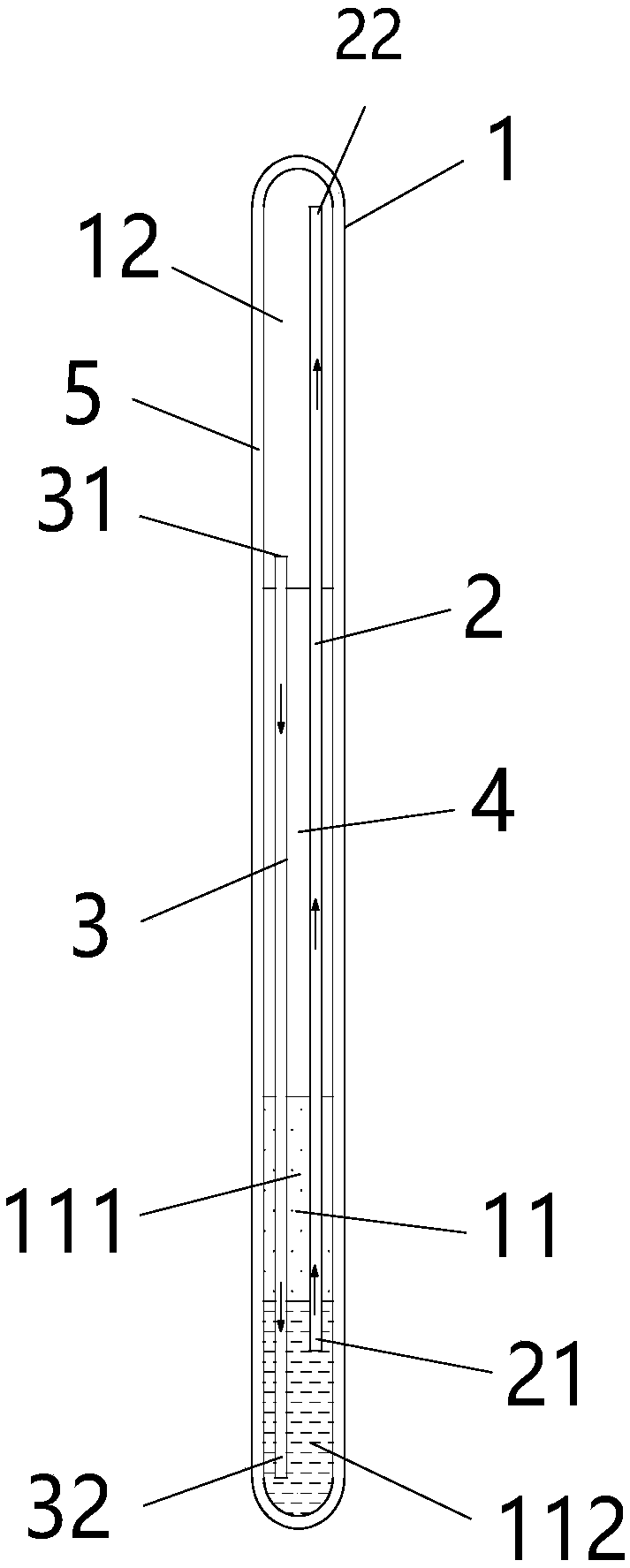

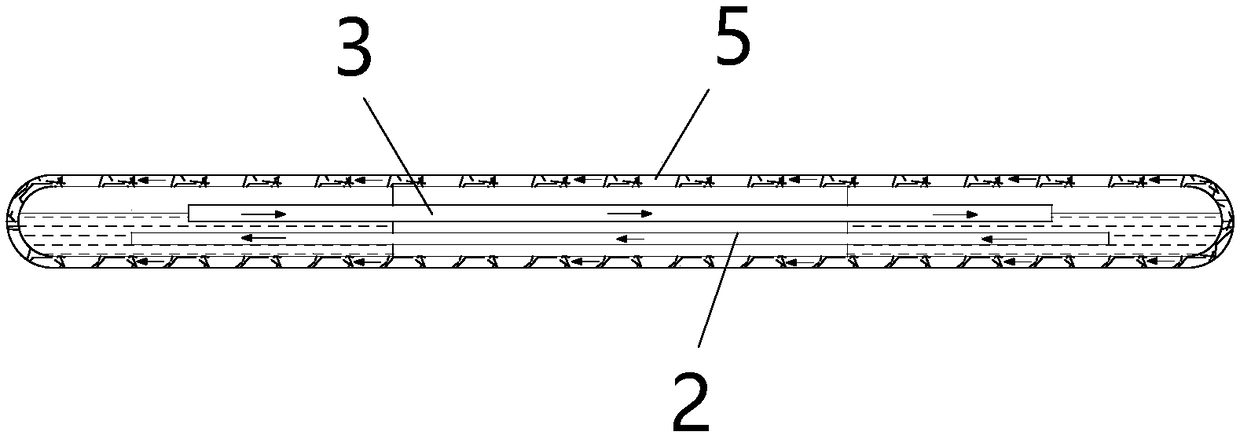

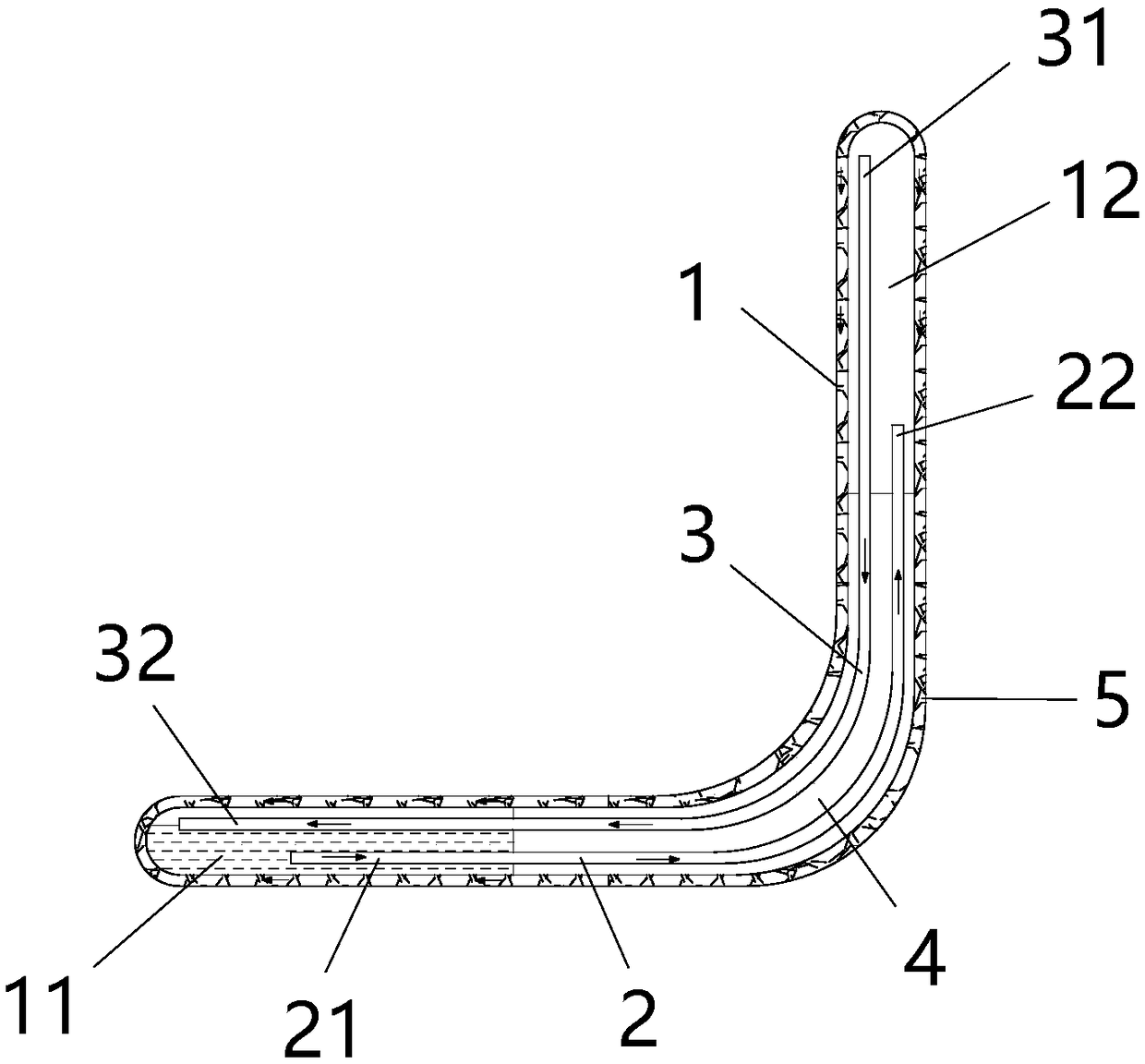

[0032] Such as figure 1 As shown, the figure schematically shows that the liquid metal pulse heat pipe includes a pipe body 1 , an ascending pipe 2 and a return pipe 3 .

[0033] In the embodiment of the present application, a heating chamber 11 and a heat dissipation chamber 12 which are independent of each other are sequentially constructed inside the pipe body 1 from bottom to top. Boiling point working medium 111 and liquid metal 112.

[0034] The ascending pipe 2 is arranged inside the pipe body 1 and runs through the heating chamber 11 and the heat dissipation chamber 12 .

[0035] The return pipe 3 is arranged inside the pipe body 1 and runs through the heating chamber 11 and the heat dissipation chamber 12, wherein the return pipe 3 and the ascending pipe 2 are spaced apart, and the heating chamber 11 is heating, so that the low-boiling point working fluid 111 is heated and evaporated into a gaseous working medium, and the liquid metal 112 and the gaseous working med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com