Ni-co-mn-sn-cu alloy with high temperature, high toughness and large magnetocaloric effect, preparation method and application thereof

A technology of ni48-xcoxmn37sn9cu6 and magnetocaloric effect is applied in the field of preparing Ni-Co-Mn-Sn-Cu alloys with high temperature, high toughness and large magnetocaloric effect, which can solve the problems of high brittleness, and achieve the improvement of fracture strength, plasticity, and improvement. Effect of saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

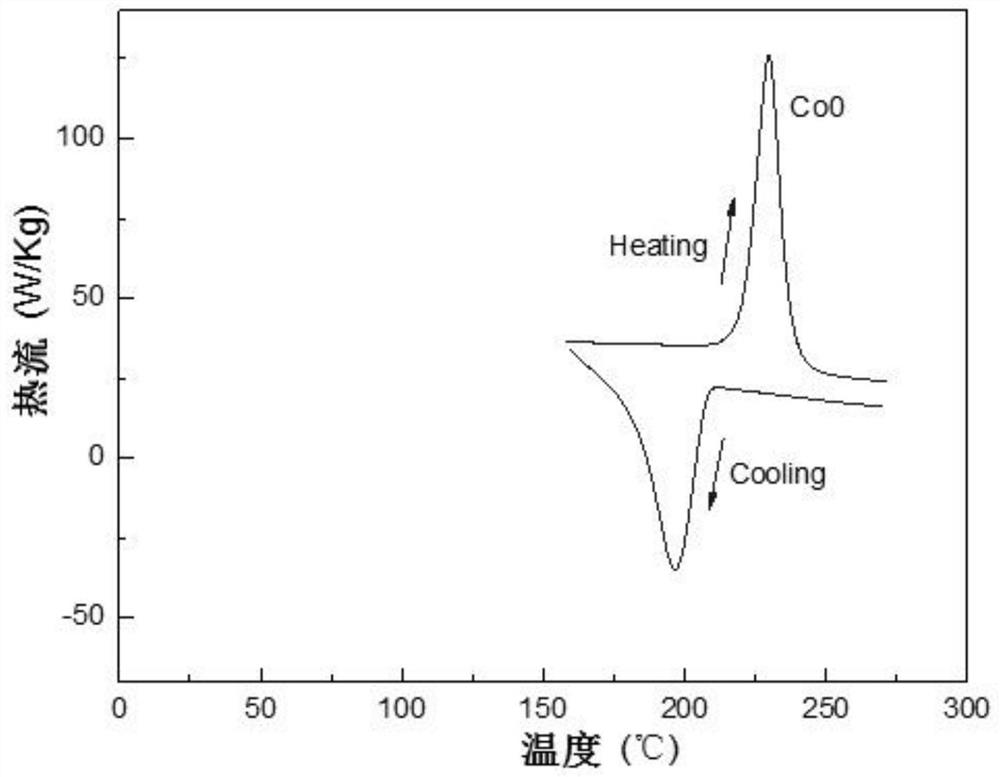

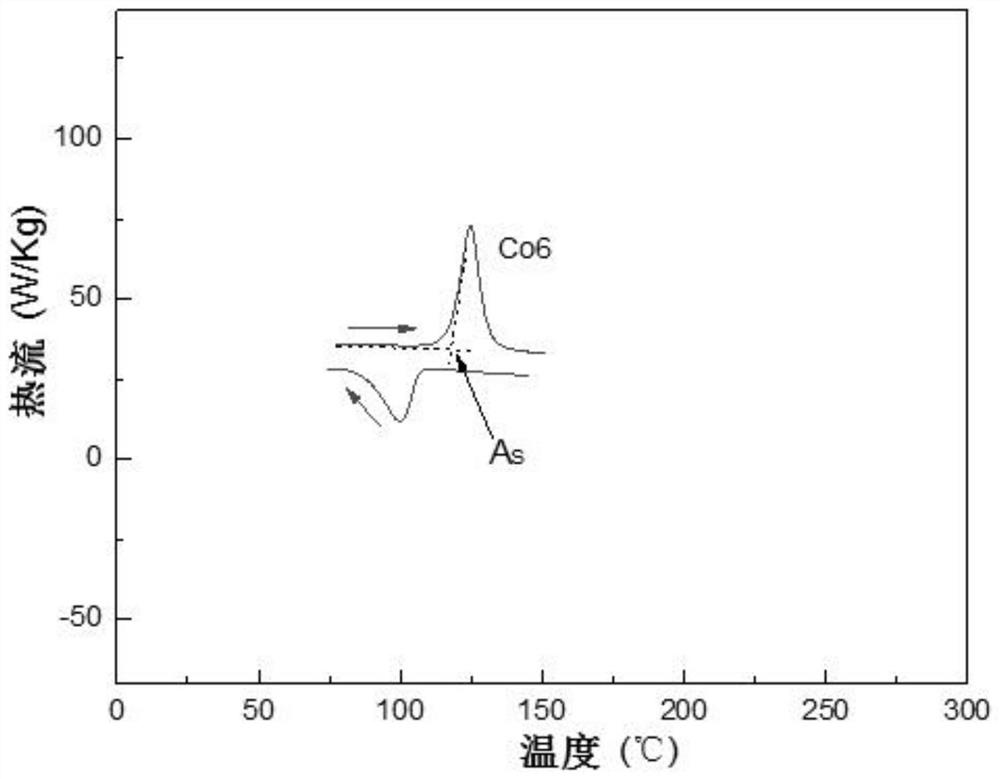

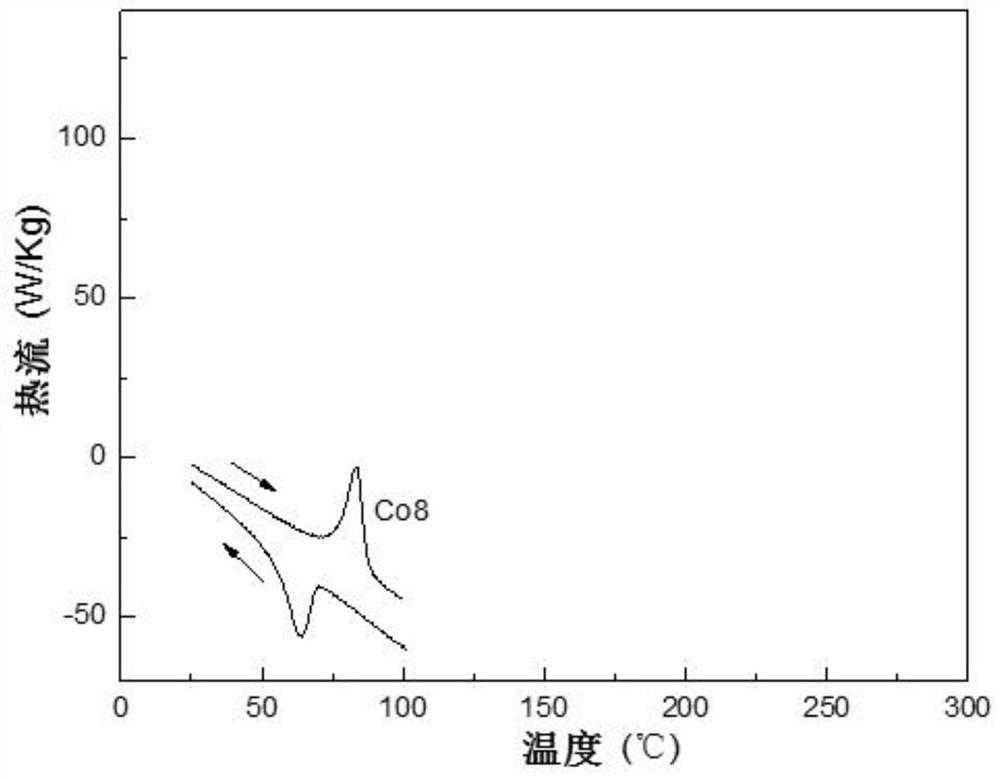

[0022] Specific Embodiment 1: In this embodiment, a Ni-Co-Mn-Sn-Cu alloy with high temperature, high toughness and large magnetocaloric effect has a general chemical formula of Ni 48-x co x mn 37 sn 9 Cu 6 , wherein x is the mole fraction, 0<x≤12 and the sum of the moles of elements in the alloy is 100.

specific Embodiment approach 2

[0023] Specific embodiment two: In this embodiment, a method for preparing a Ni-Co-Mn-Sn-Cu alloy with high temperature, high toughness and large magnetocaloric effect is completed according to the following steps:

[0024] 1. Material preparation: Ni according to the general chemical formula 48-x co x mn 37 sn 9 Cu 6 Perform batching, wherein x is the mole fraction, 0<x≤12 and the sum of the moles of elements in the alloy is 100, respectively weighing nickel block, manganese block, tin block, cobalt block and copper block as raw materials;

[0025] 2. Place the raw materials weighed in step 1 in a smelting crucible, and carry out arc melting to obtain Ni-Co-Mn-Sn-Cu button ingot;

[0026] 3. Mechanically polish the Ni-Co-Mn-Sn-Cu button ingot to remove surface impurities, then clean it with acetone for 2 to 3 times and then with alcohol for 2 to 3 times and seal it in a vacuum of 10 -3 In the quartz tube of Pa, keep warm at 1073K for 36-48h for homogenization treatment, ...

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step one, according to the general chemical formula, it is Ni 48-x co x mn 37 sn 9 Cu 6 Carry out batching, wherein x is mole fraction, x=6. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strain | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com