Patents

Literature

43results about How to "Large magnetic entropy change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

La(fe,si)13-based multi-interstitial atom hydride magnetic refrigeration material with high temperature stability and large magnetic entropy change and preparation method thereof

InactiveUS20130200293A1Stable performanceLarge magnetic entropy changeMagnetic paintsInorganic material magnetismRare-earth elementChemistry

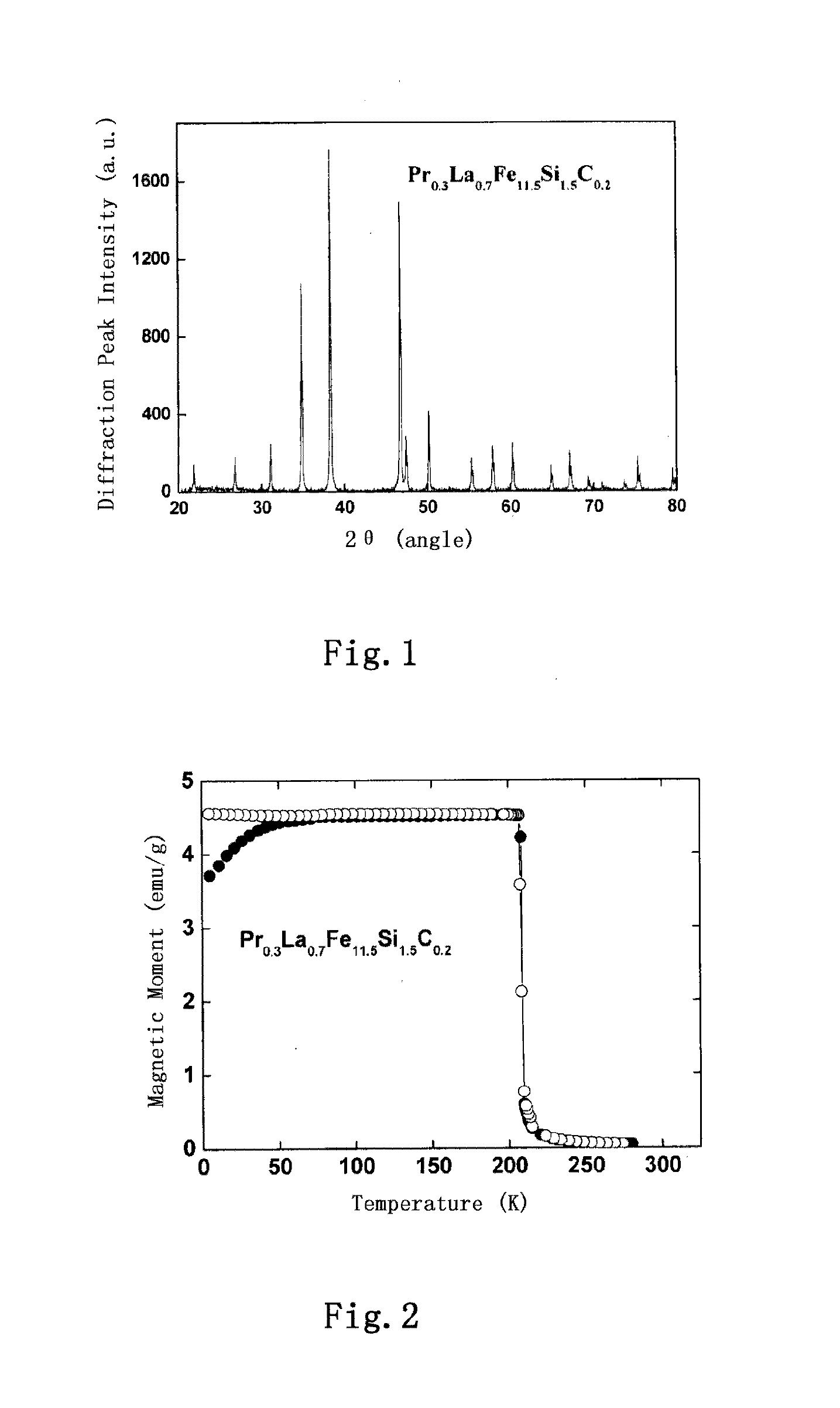

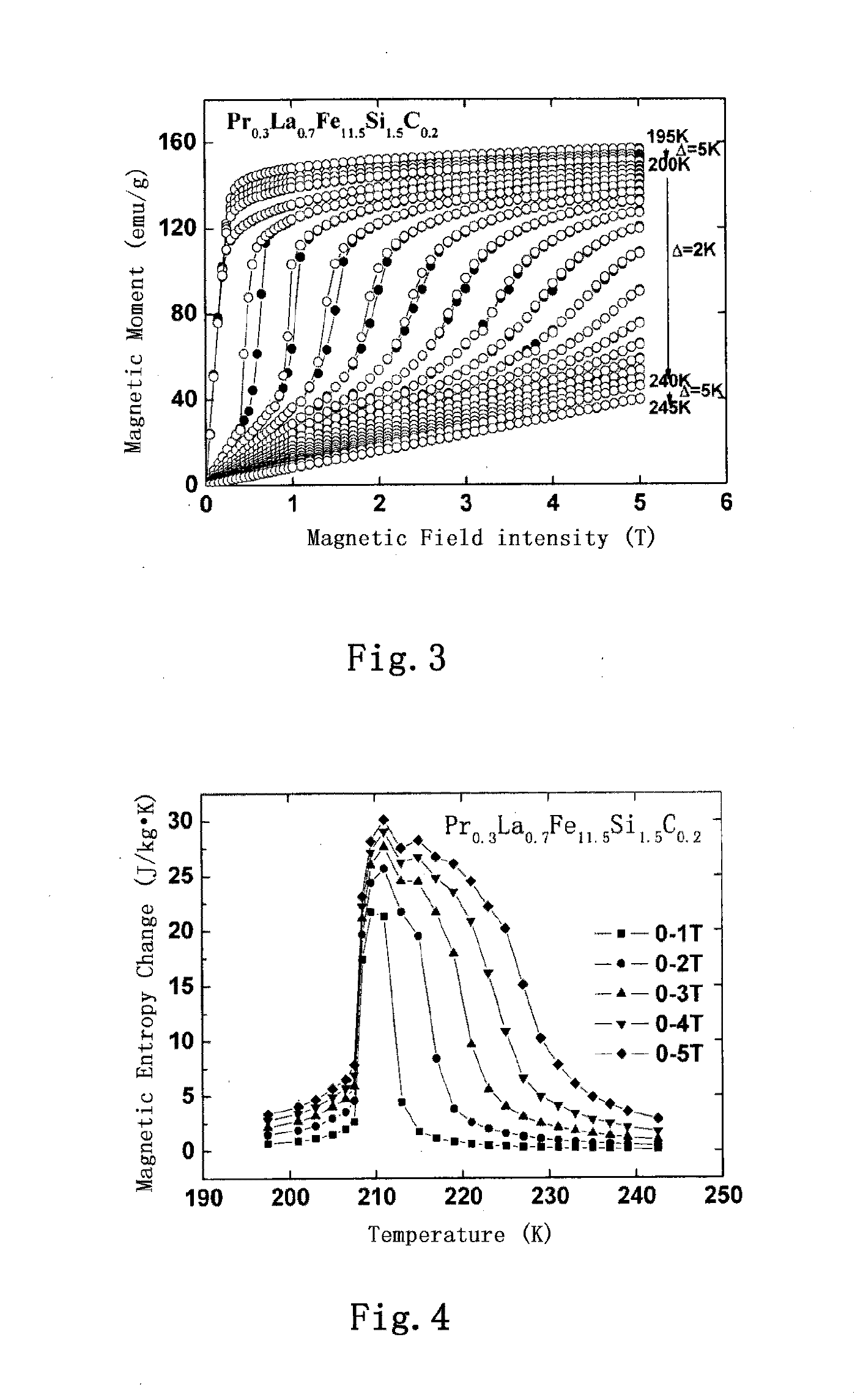

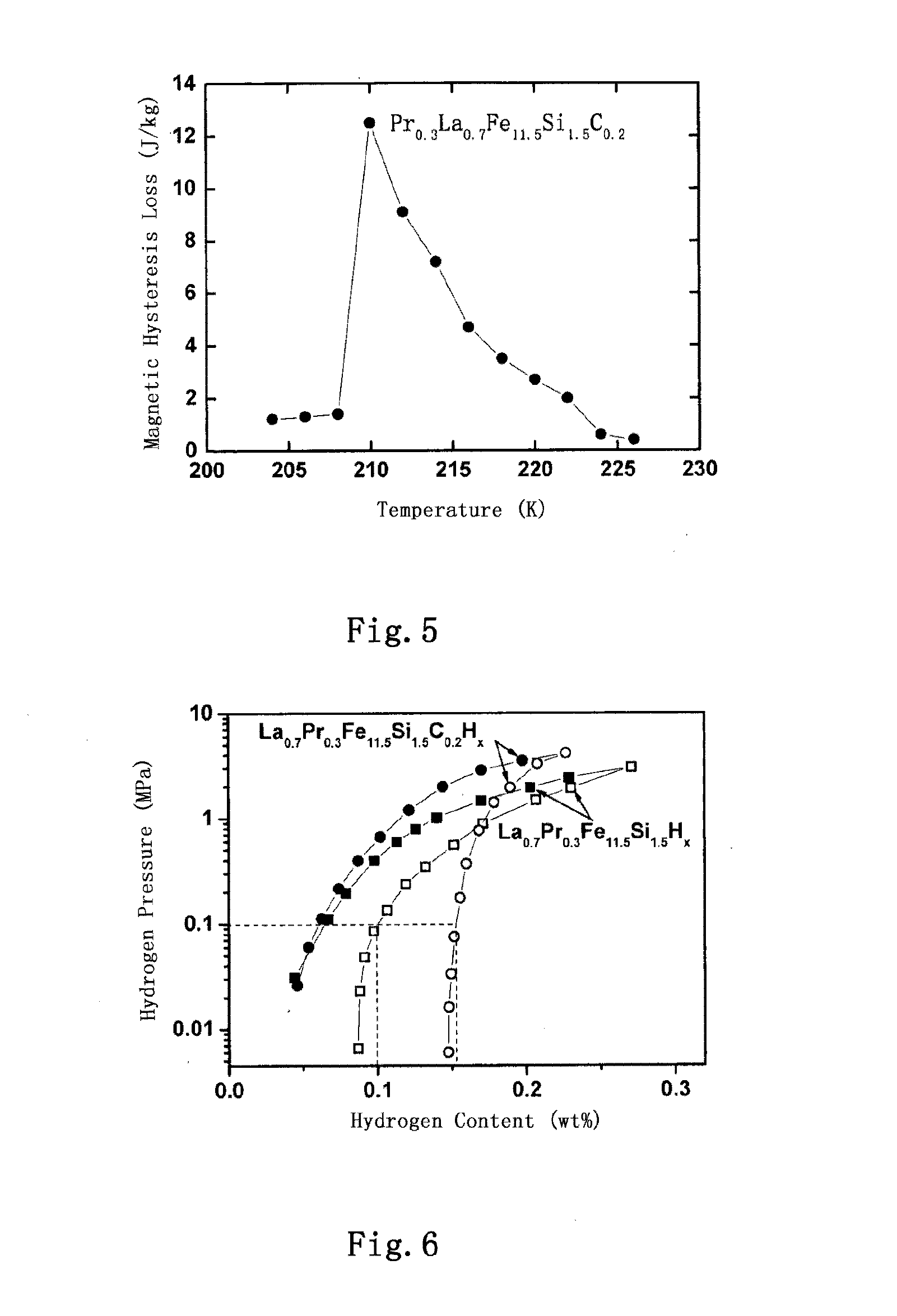

The invention discloses a La(Fe,Si)13-based hydride magnetic refrigeration material comprising multiple interstitial atoms and showing a high-temperature stability and a large magnetic entropy change and the method for preparing the same. By reintroducing interstitial hydrogen atoms into an interstitial master alloy La1-aRaFe13-bSibXc through a hydrogen absorption process, a compound with a chemical formula of La1-aRaFe13-bSibXcHd and a cubic NaZn13-type structure is prepared, wherein R is one or a combination of more than one rare-earth element, X is one or more C, B and the like or their combinations. A desired amount of hydrogen is obtained through a single hydrogen absorption process by means of controlling the hydrogen pressure, temperature and period in the process of hydrogen absorption. The compound can be stable under normal pressure, at a temperature of room temperature to 350° C., that is, the hydrogen atoms can still exist stably in the interstices. The Curie temperature of the compound can be adjusted continuously with a wide range of 180K to 360K by changing its composition. The magnetic entropy change that is more than 2 folds of that of Gd can be obtained around room temperature, and the magnetic hysteresis loss vanishes. In view of the above, this material is a desired magnetic refrigeration material applied at room temperature.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

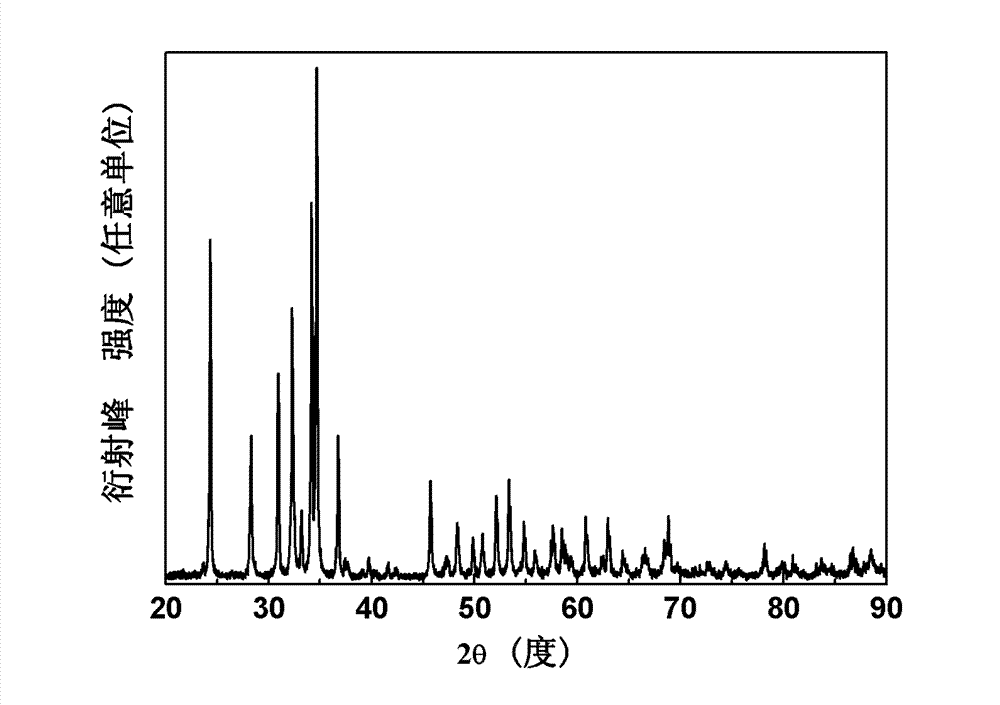

Rare earth-chrome-silicone-based magnetic refrigerating material and preparation method thereof

ActiveCN102383018ALarge magnetic entropy changeHigh magnetic refrigeration capacityHeat-exchange elementsChromiumMetal

The invention relates to a rare earth-chrome-silicone-based magnetic refrigerating material and a preparation method thereof. The chemical general formula of the magnetic material is R-Cr2-Si2, wherein R is rare earth metal Er, Gd or Dy; and the magnetic material has a body-centered ThCr2Si2 tetragonal lattice structure. The preparation method comprises the following steps of: firstly, mixing therare earth metal Er, Gd or Dy, Cr and Si in a certain ratio to obtain a mixture serving as raw materials; secondly, putting the raw materials into a melting container, and repeatedly melting under the protection of argon gas to obtain an alloy cast ingot with uniform components; thirdly, sealing the melted alloy cast ingot into a vacuum quartz container, and annealing at high temperature; and finally, quickly cooling to normal temperature to obtain a finished product. The preparation method is simple, low in cost and applicable to industrialization; and the prepared magnetic material has excellent magnetic and thermal reversibility.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

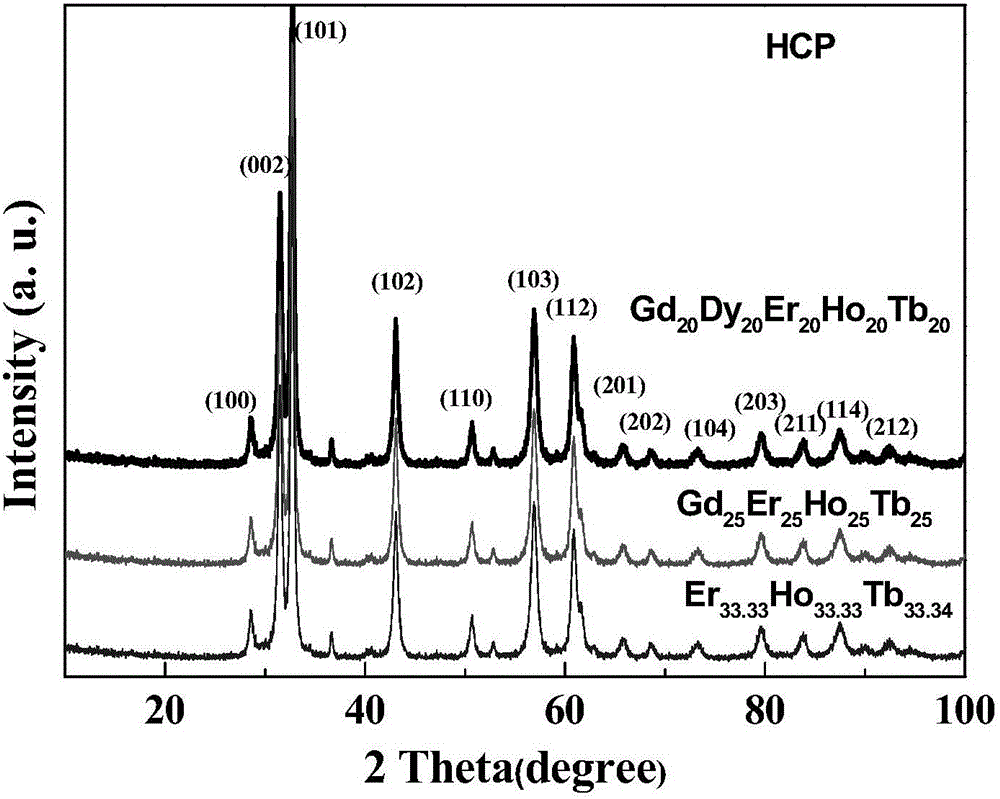

Magnetic refrigeration HoxTbyMz high-entropy alloy and preparation method thereof

The invention belongs to the field of magnetic refrigeration alloys in high-entropy materials, and relates to a magnetic refrigeration HoxTbyMz high-entropy alloy and a preparation method thereof. The high-entropy alloy has a chemical formula of HoxTbyMz; the atomic percents of all components are as follows: x not more than 35 and not less than 5, y not more than 35 and not less than 5, wherein M is one or more in Gd, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Dy, Er, Tm, Yb, Lu and Y, Z not more than 90 and not less than 30, and x+y+z=100; and the high-entropy alloy material is formed under general vacuum suction casting conditions, is low in heat hysteresis effect, has magnetic entropy change even exceeding metal Gd and high magnetic refrigeration capacity, can reach a highest refrigeration temperature section of 190 K, and is an excellent magnetic refrigeration material near the room-temperature range. The high-entropy alloy is broad in application prospect and unique in purpose in such daily life goods with high quantity and wide application as household magnetic refrigerators and household magnetic air conditioners and in the national defense field.

Owner:UNIV OF SCI & TECH BEIJING

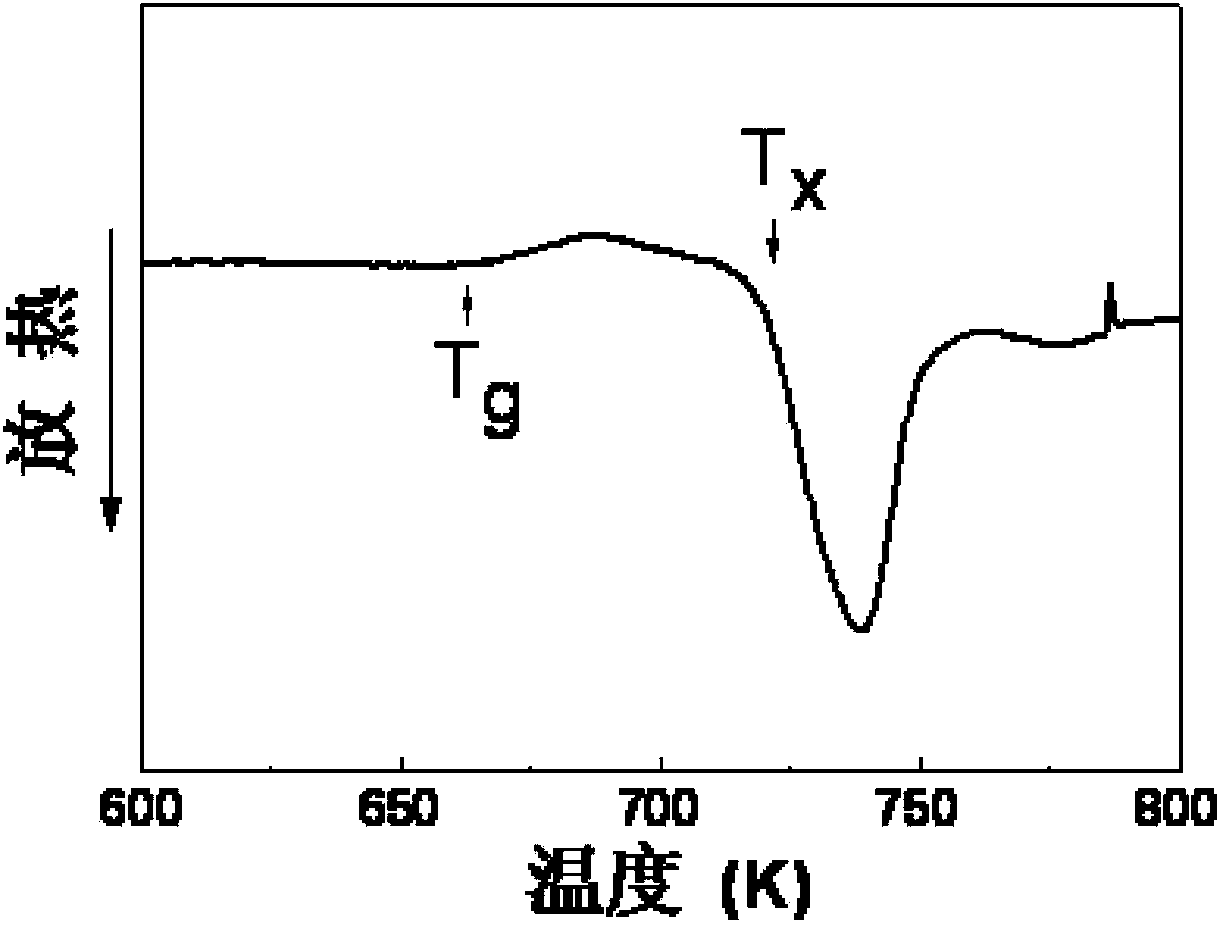

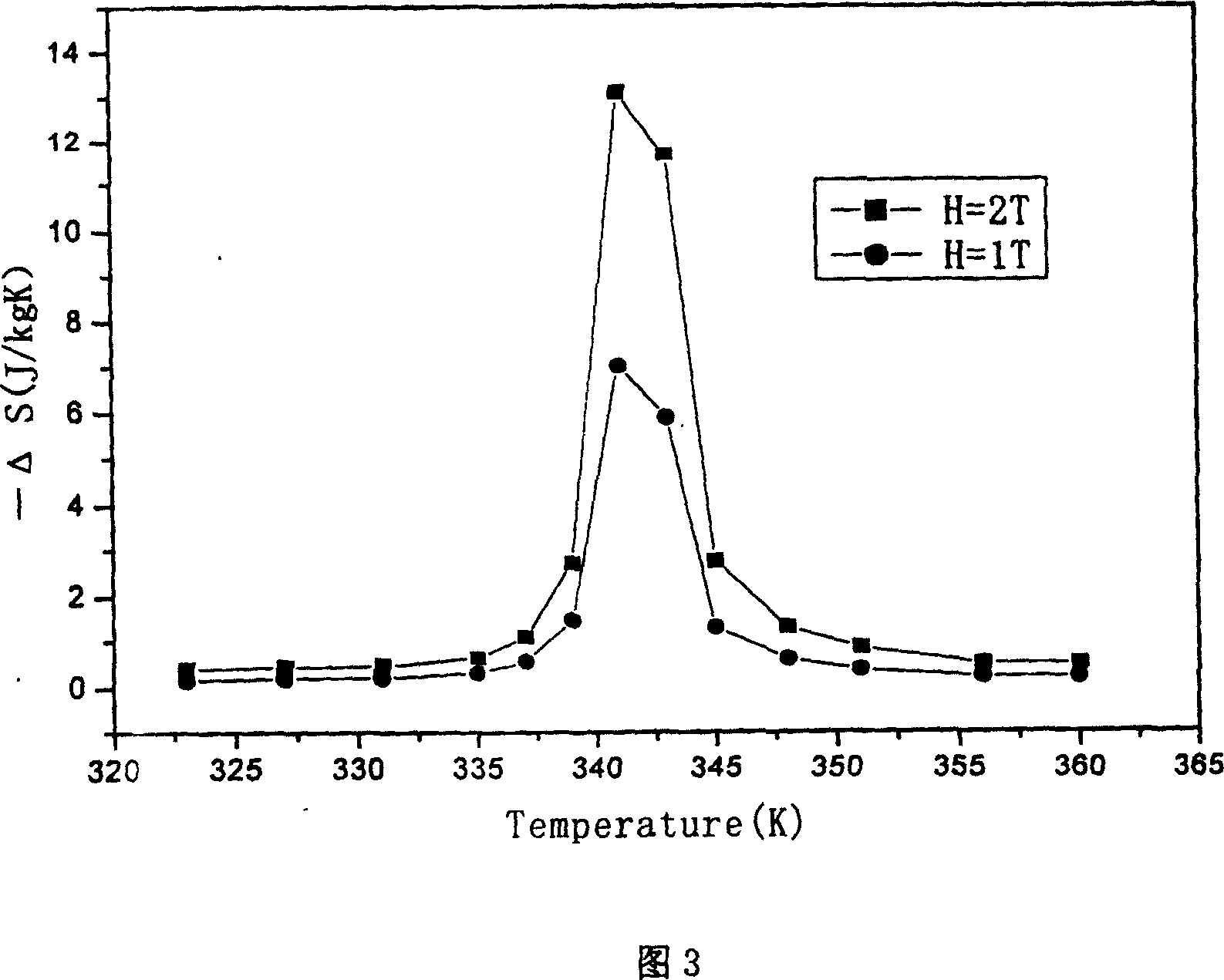

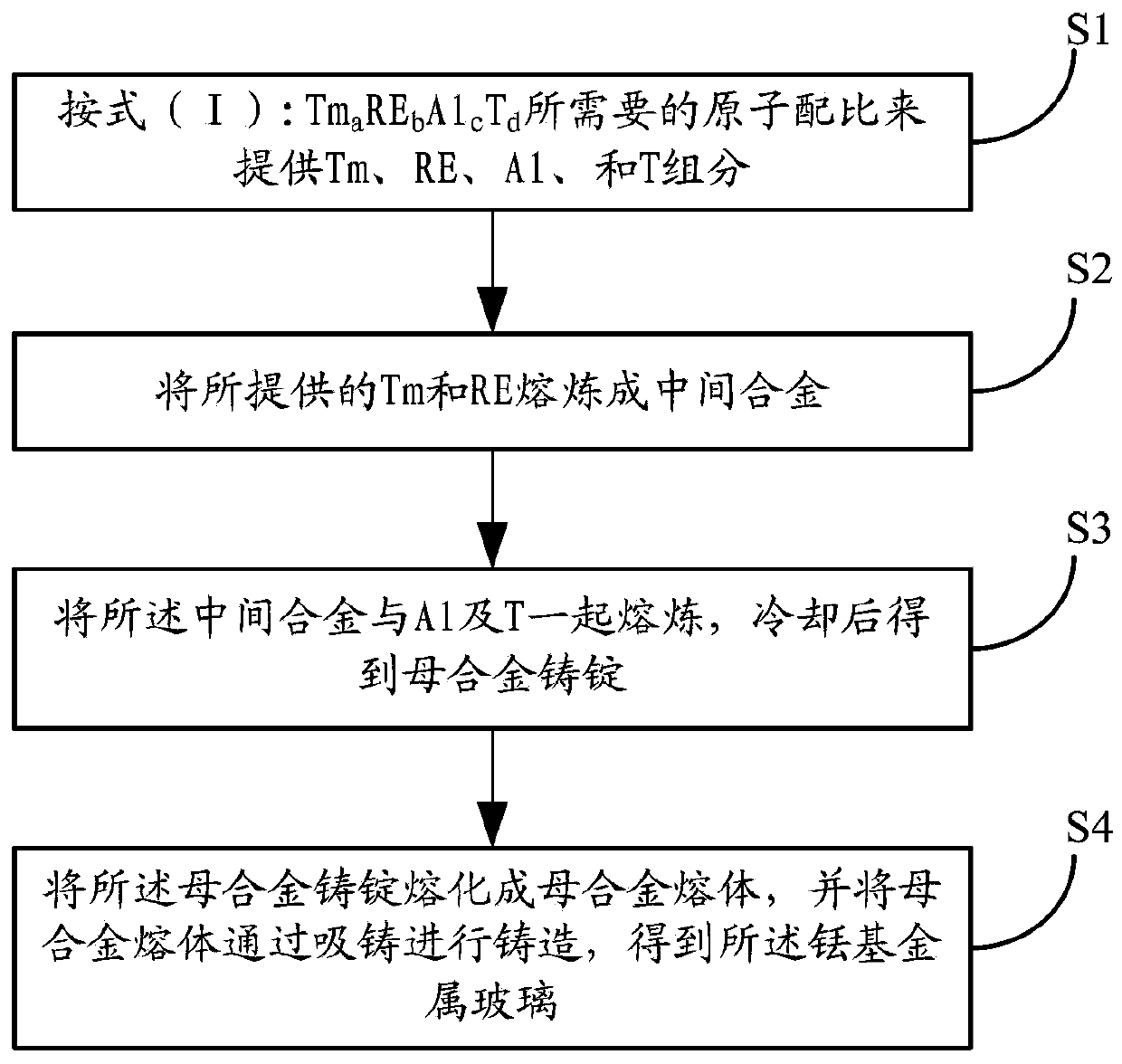

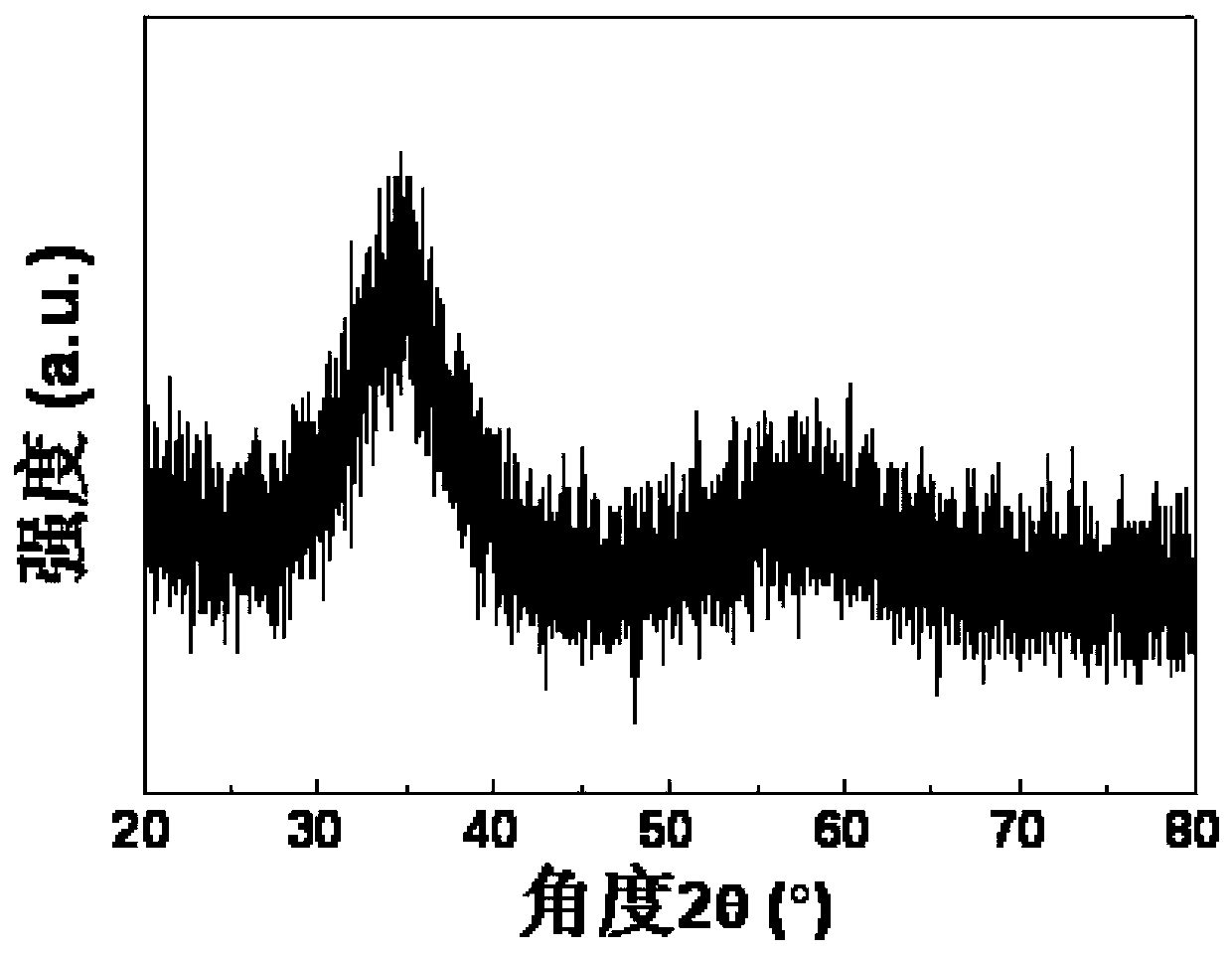

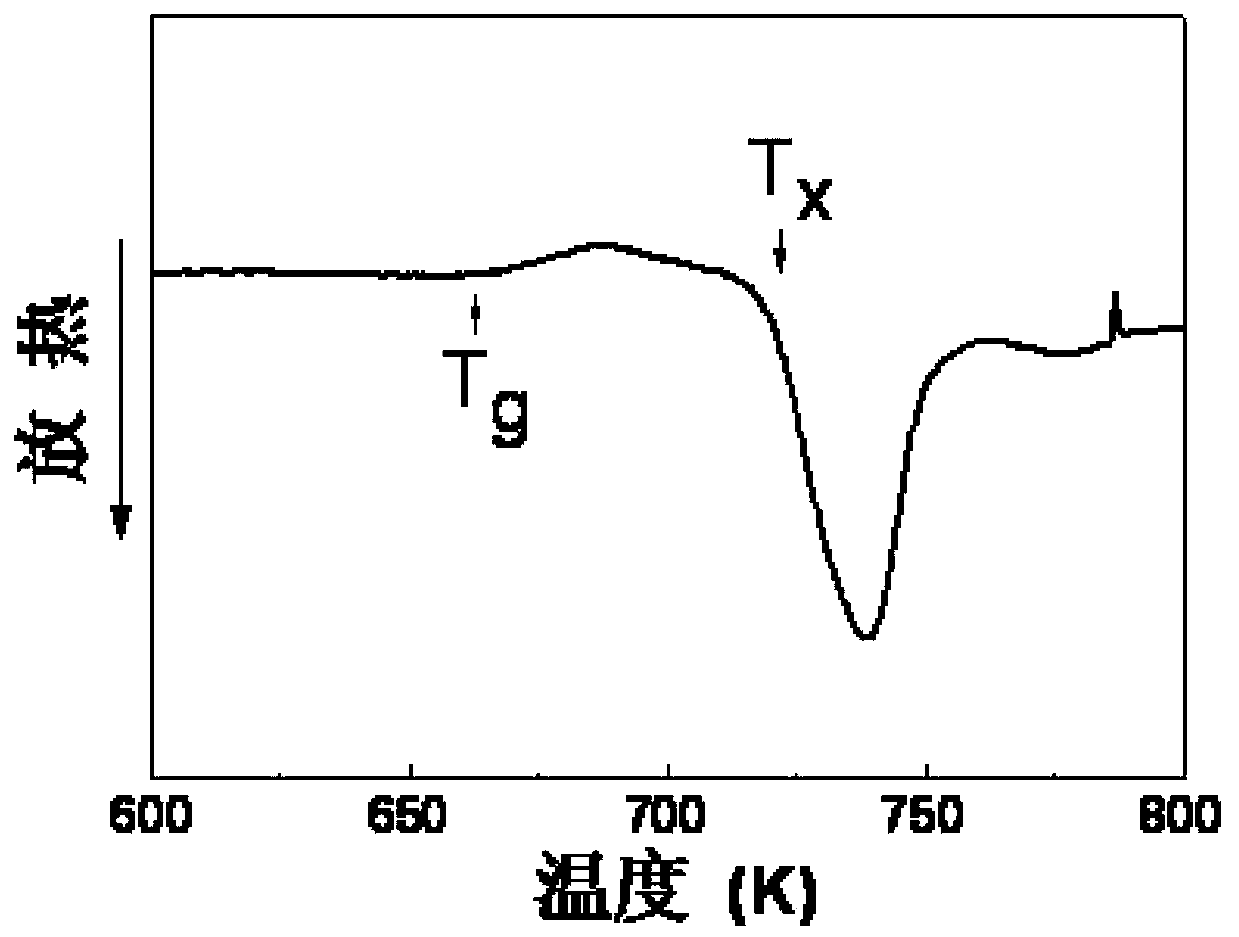

Thulium-based metal glass, preparation method and application thereof

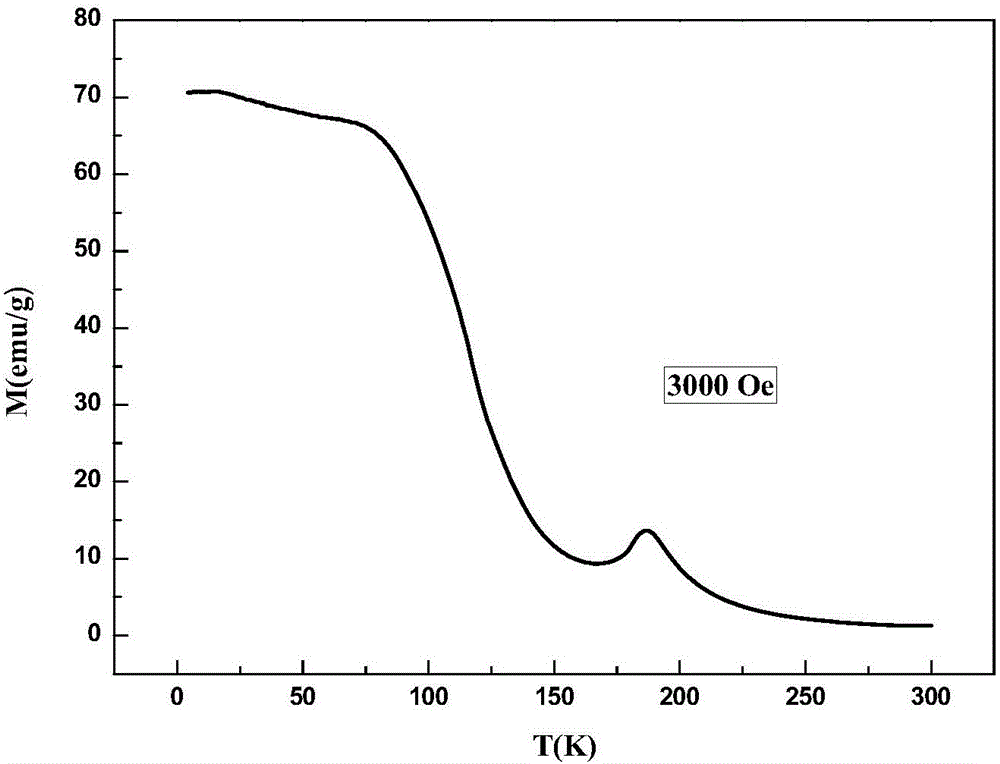

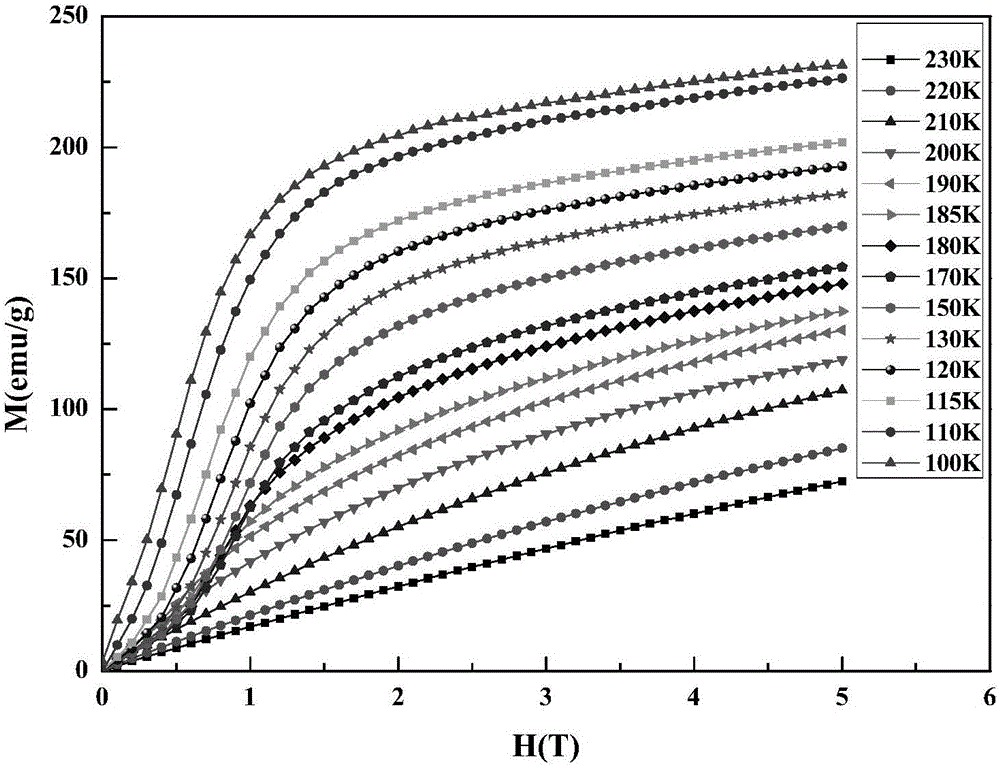

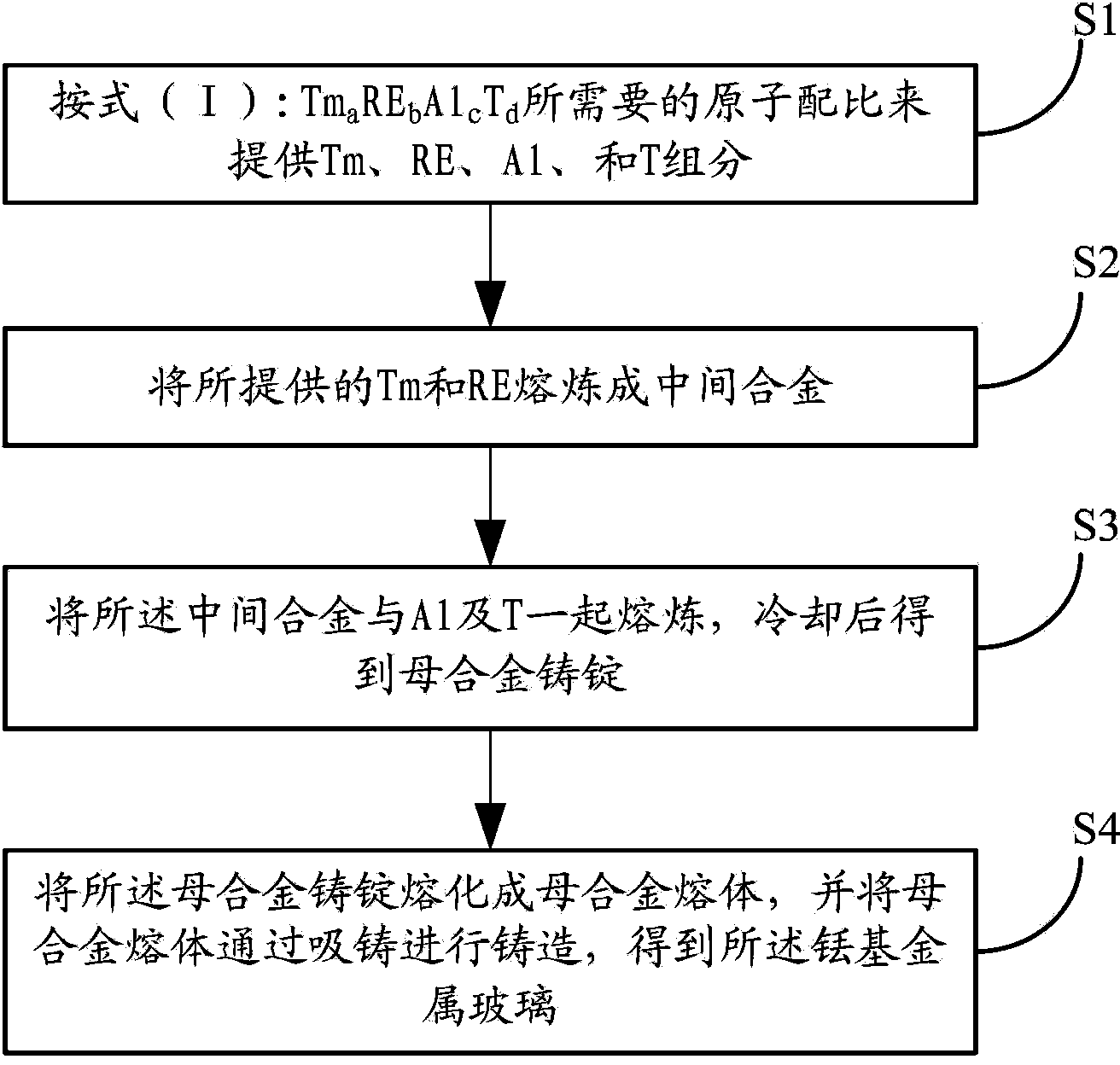

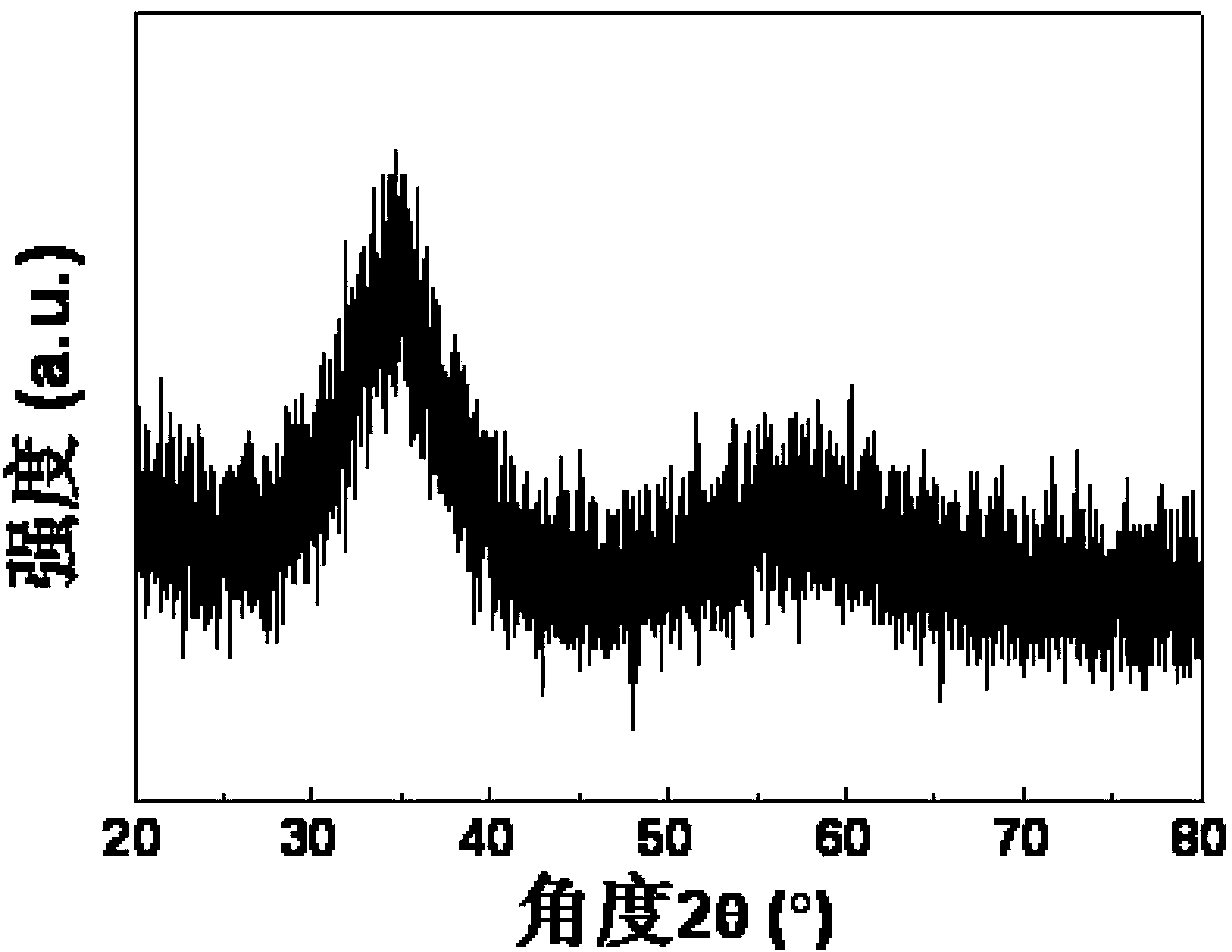

ActiveCN103668008AMagnetic transition temperature range is wideLow critical cooling rateRare-earth elementThulium

The invention discloses thulium-based metal glass, a preparation method and an application thereof. Based on thulium as the major component, the formula of the thulium-based metal glass is shown in a formula (I), RE represents one or more rare earth elements selected from Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho and Er; T represents Co or Ni; a, b, c and d represent atomic percents of elements, wherein a is greater than or equal to 30 and less than or equal to 60, b is greater than or equal to 5 and less than or equal to 30, c is greater than or equal to 20 and less than or equal to 25, d is greater than or equal to 15 and less than or equal to 25, (a+b) is greater than or equal to 50 and less than or equal to 60, and (a+b+c+d) is equal to 100. According to the thulium-based metal glass disclosed by the invention, on the one hand, the amorphous forming ability can be modulated by changing RE and T, and on the other hand, the temperature interval of the thulium-based metal glass on magnetic transformation can be modulated to expand the magnetic transformation area, so that the thulium-based metal glass has great magnetocaloric effect in a wider temperature interval. TmaREbALcTd(I).

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

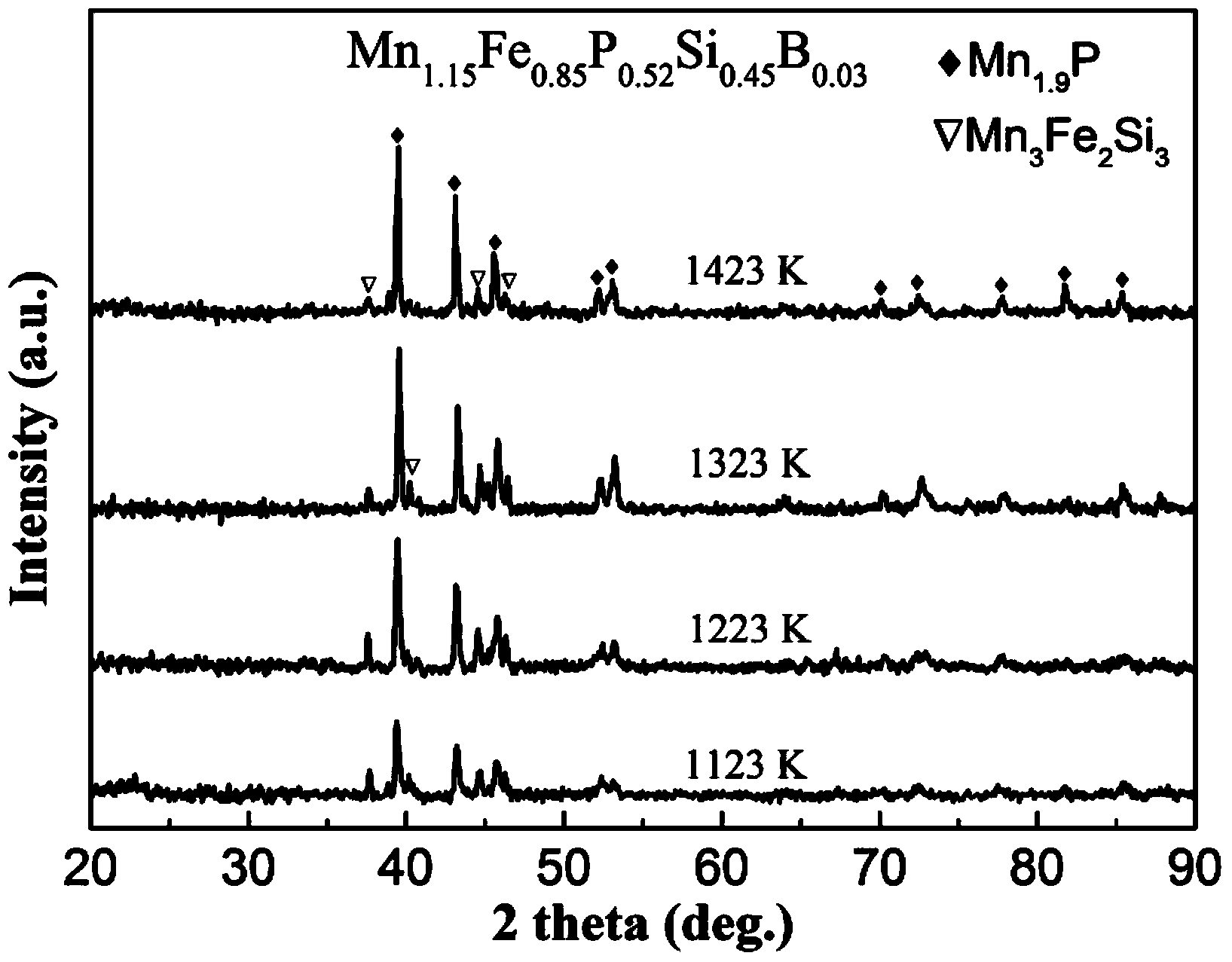

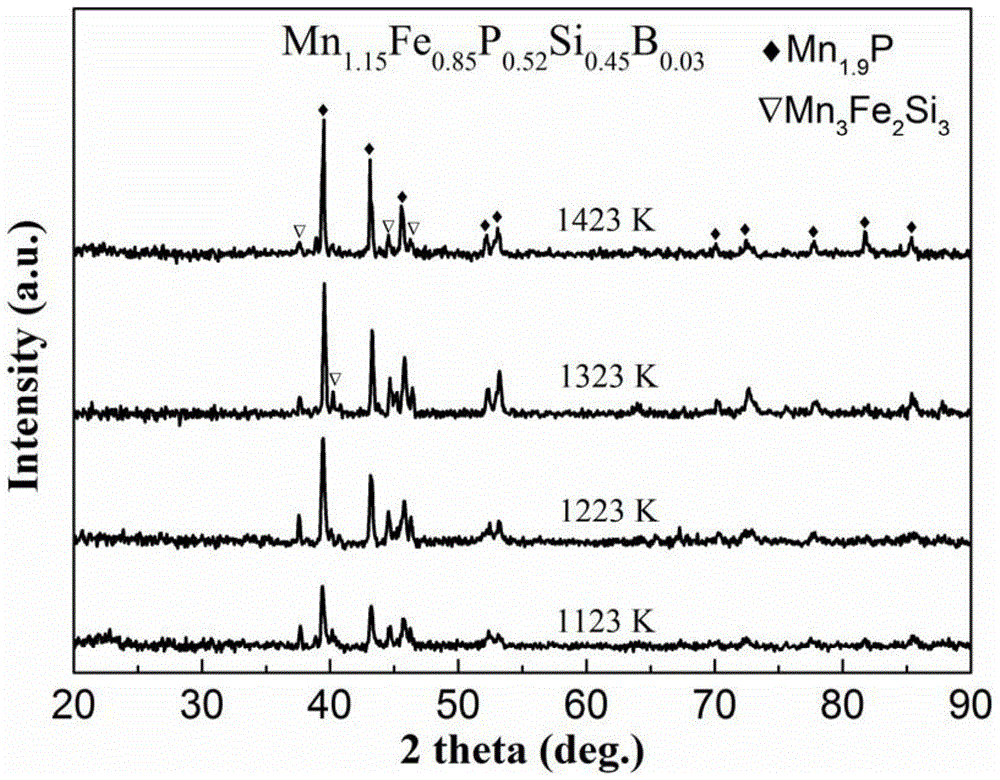

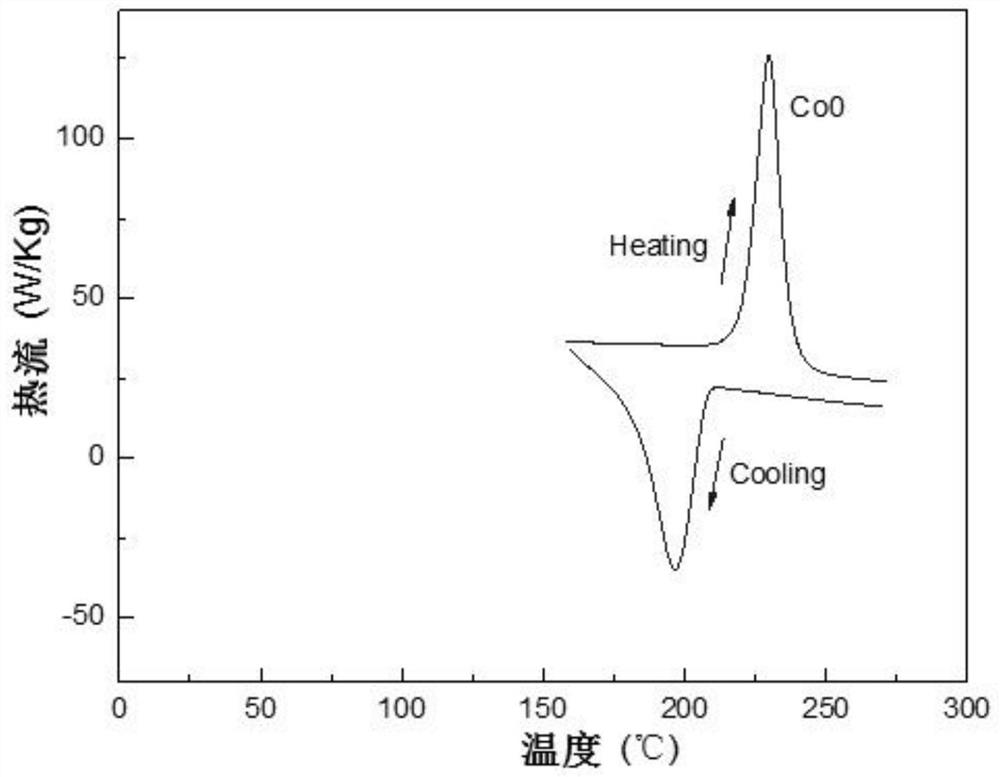

Mn-Fe-P-Si magnetic refrigeration material and preparation method thereof

InactiveCN104357727AWide variety of sourcesLow priceHeat-exchange elementsElectric arc furnaceHigh density

The invention belongs to the field of magnetic refrigeration materials, and discloses an Mn-Fe-P-Si magnetic refrigeration material and a preparation method thereof. The material composition is selectively Mn1.15Fe0.85P0.52Si0.45B0.03. The preparation method comprises the following steps: (1) mixing Mn sheets, Fe blocks, FeP blocks, Si blocks and B blocks after weighing according to the mass percentages of elements in a chemical formula, wherein 5% of balance is added to the Mn; (2) putting raw materials prepared in the step (1) into a vacuum electric arc furnace, and utilizing high-purity argon gas shield for smelting to obtain an alloy pig; (3) breaking up the alloy pig, putting into a vacuum rapid quenching furnace for smelting alloy, and carrying out copper mold casting; (4) sealing the copper mold casting alloy into a quartz tube, vacuumizing to below 10<-4> Pa, carrying out annealing treatment, and then rapidly quenching into cold water to obtain the magnetic refrigeration material. The mn-Fe-P-Si magnetic refrigeration material is simple in technology, low in cost, and the magnetic refrigeration material with high density and excellent magnetocaloric effect can be obtained.

Owner:SOUTH CHINA UNIV OF TECH

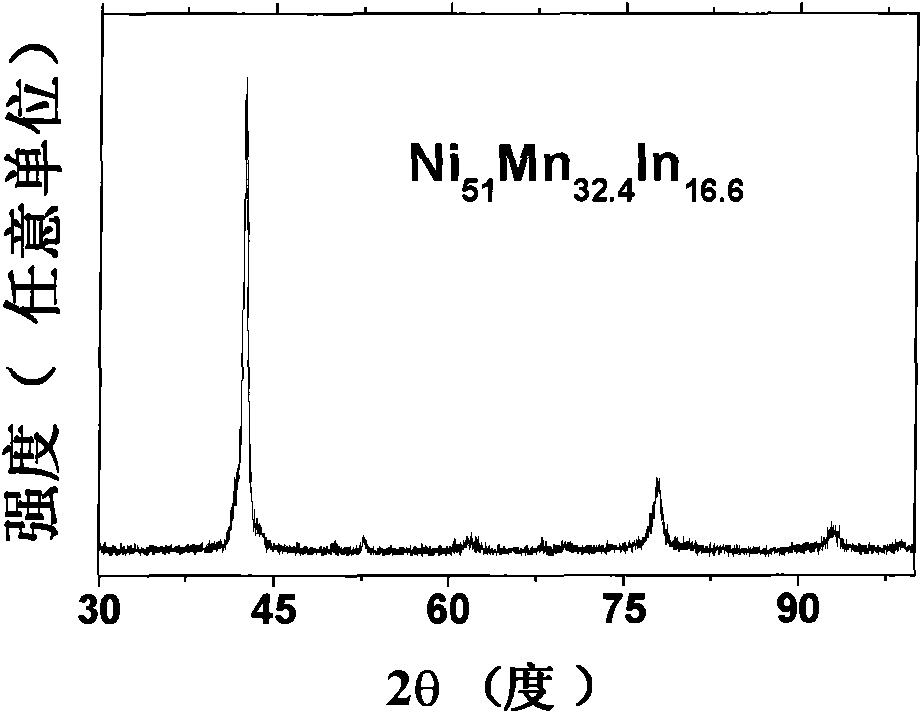

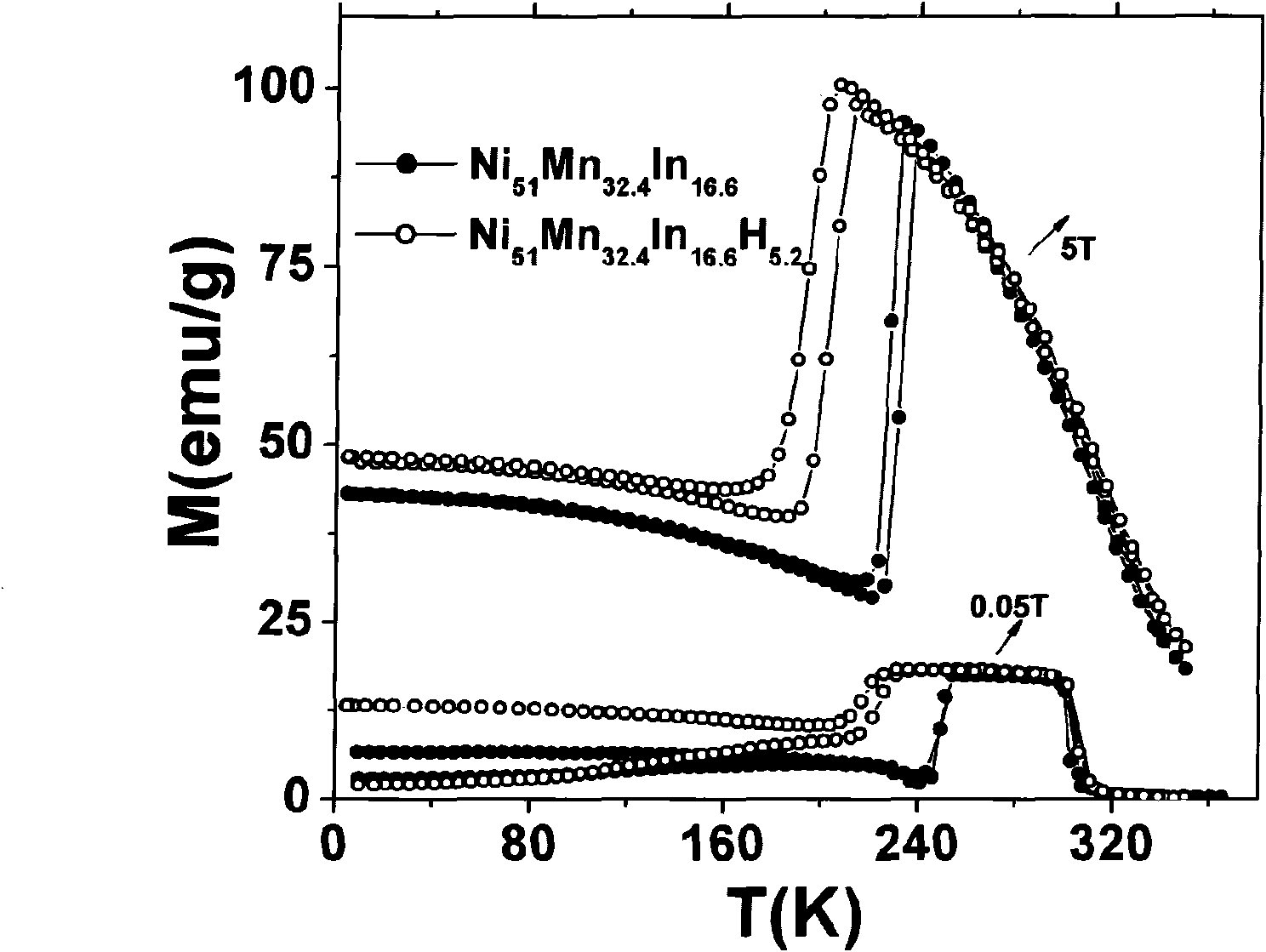

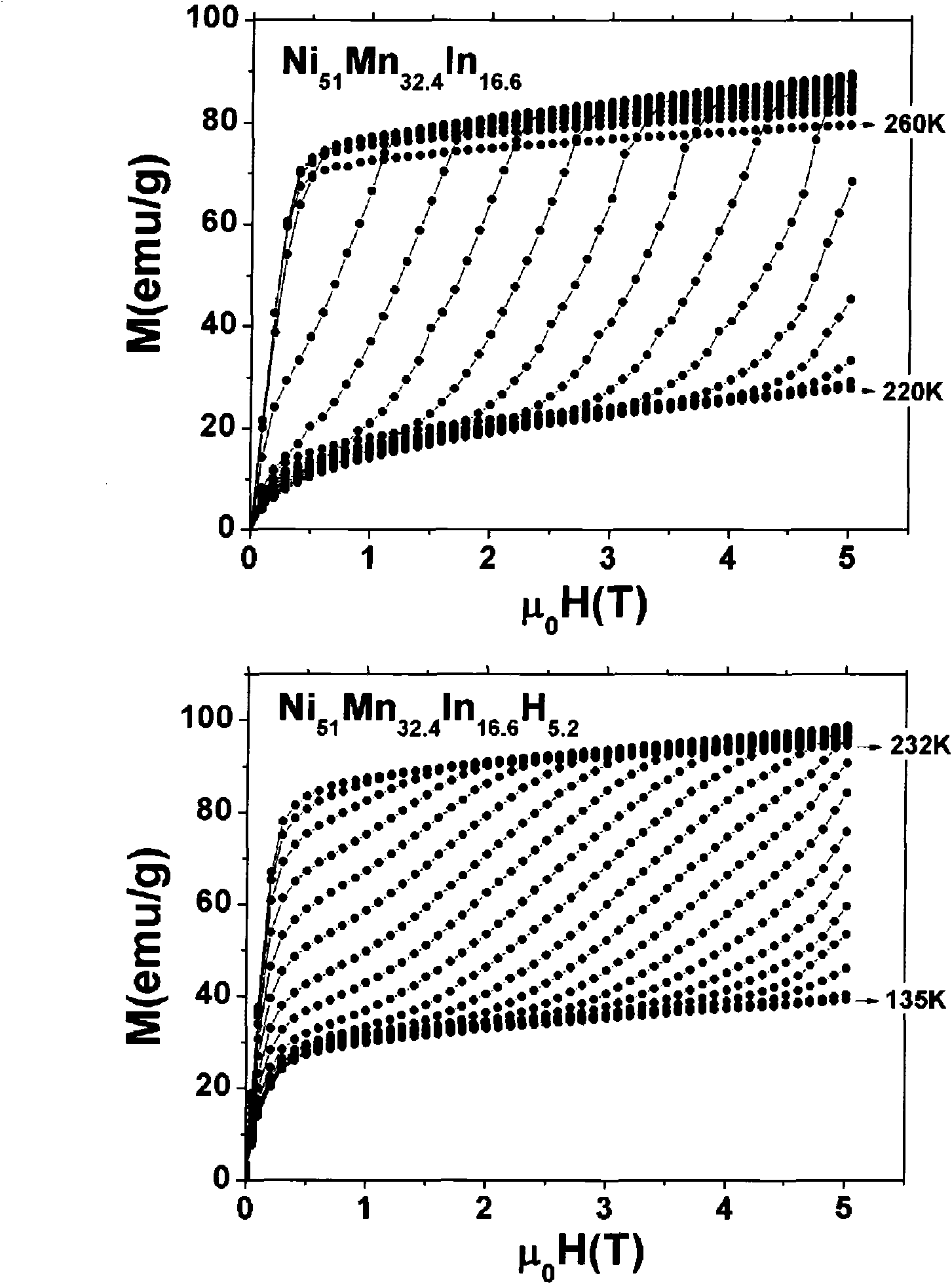

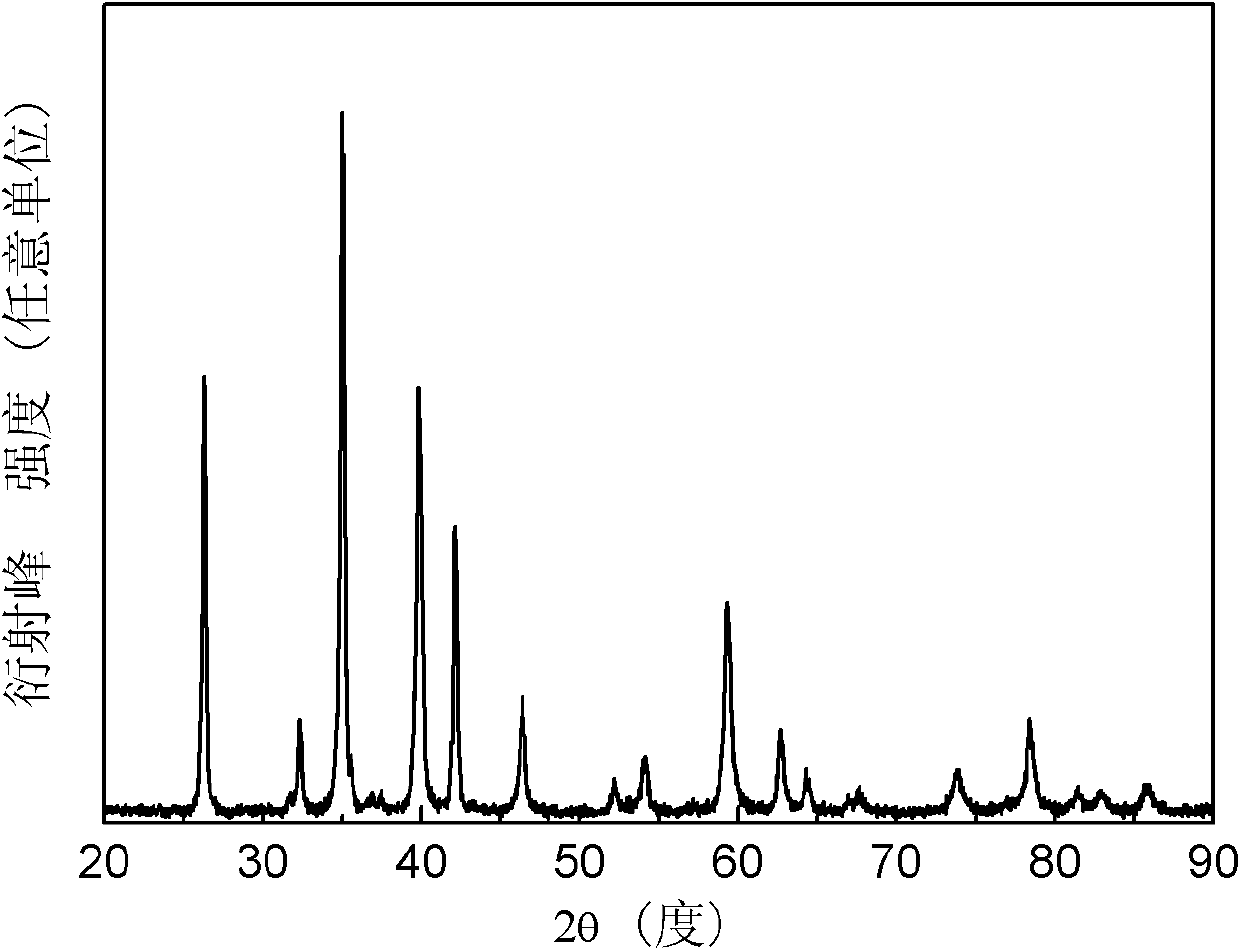

Hydrogenated NiMn-based alloy magnetic refrigeration material and preparation method and use thereof

InactiveCN101923933ALarge magnetic entropy changeHigh magnetic entropy changeMagnetic materialsHeat-exchange elementsHydrogen pressureAlloy

The invention provides a hydrogenated NiMn-based alloy magnetic refrigeration material with big magnetic entropy change. The magnetic refrigeration material has a chemical general formula of NixMnyMzHalpha, and a NixMnyMz alloy before hydrogen absorption has L21 Heusler (Heusler) type structure, wherein M is the combination of one or more of the following elements in any ratio: In, Sb, Sn and Ga. The invention also provides a method for preparing the material, which comprises the following steps of: firstly, smelting and annealing to prepare a NixMnyMz single-phase alloy; then annealing to prepare a NixMnyMzHalpha hydride under hydrogen pressure; and regulating the hydrogen content in the alloy by controlling the hydrogen pressure, the annealing temperature and time. The introduction of a hydrogen atom makes the martensite phase transformation temperature move to low temperature. Therefore, huge magnetic entropy change occurs in a controllable temperature region, the magnetic entropy amplitude is higher than Gd, and the material is an ideal magnetic refrigeration material in a high-temperature region even in a room temperature region.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Rare earth-iron-silicon material for magnetic refrigeration, and preparation method and application thereof

ActiveCN102703037ALarge magnetic entropy changeImprove cooling effectMagnetic materialsHeat-exchange elementsCrystal structureWorking temperature

The invention provides a rare earth-iron-silicon material for magnetic refrigeration, and a preparation method and application thereof. The material is a compound of the following general formula: RFeSi, wherein R is any one element of Gd, Tb, Dy, Ho and Er, or is the combination of Er element and any one element of Gd, Tb, Dy and Ho. The magnetic refrigeration material has a CeFeSi-type square crystal structure. The rare earth-iron-silicon material provided by the invention, especially ErFeSi and (Gd0.8 Er0.2) FeSi presenting relatively large magnetic entropy change near their respective phase transition temperatures and wide working temperature areas, has large magnetic refrigeration capacity and good thermal and magnetic reversibility, and is a very ideal medium and low temperature zone magnetic refrigeration material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

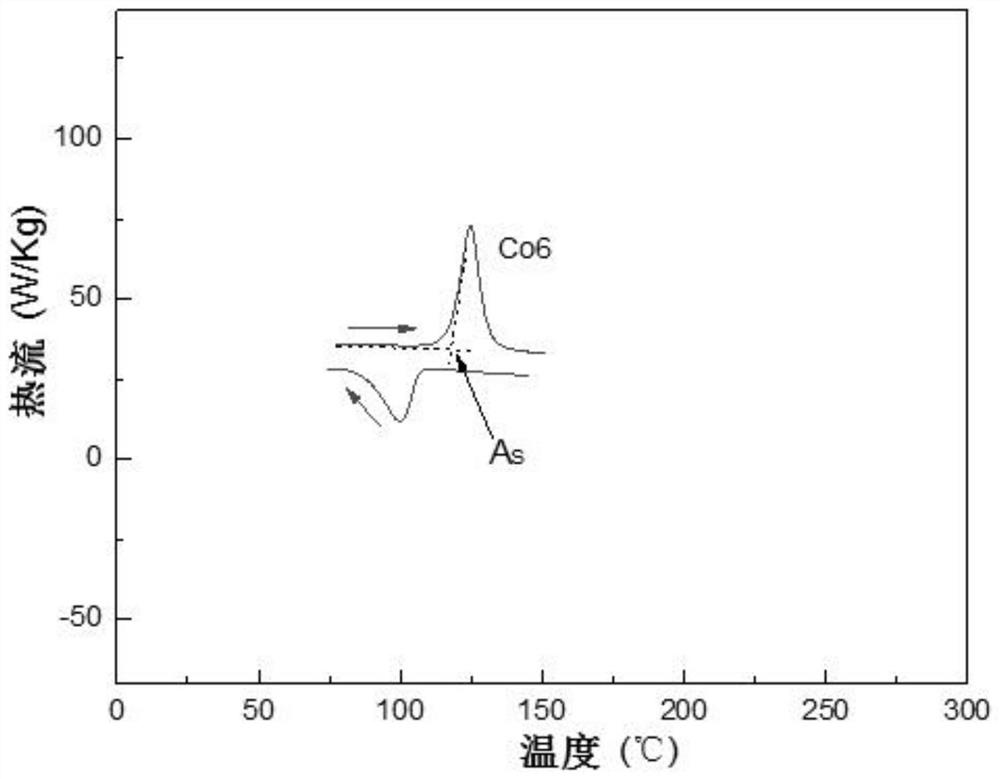

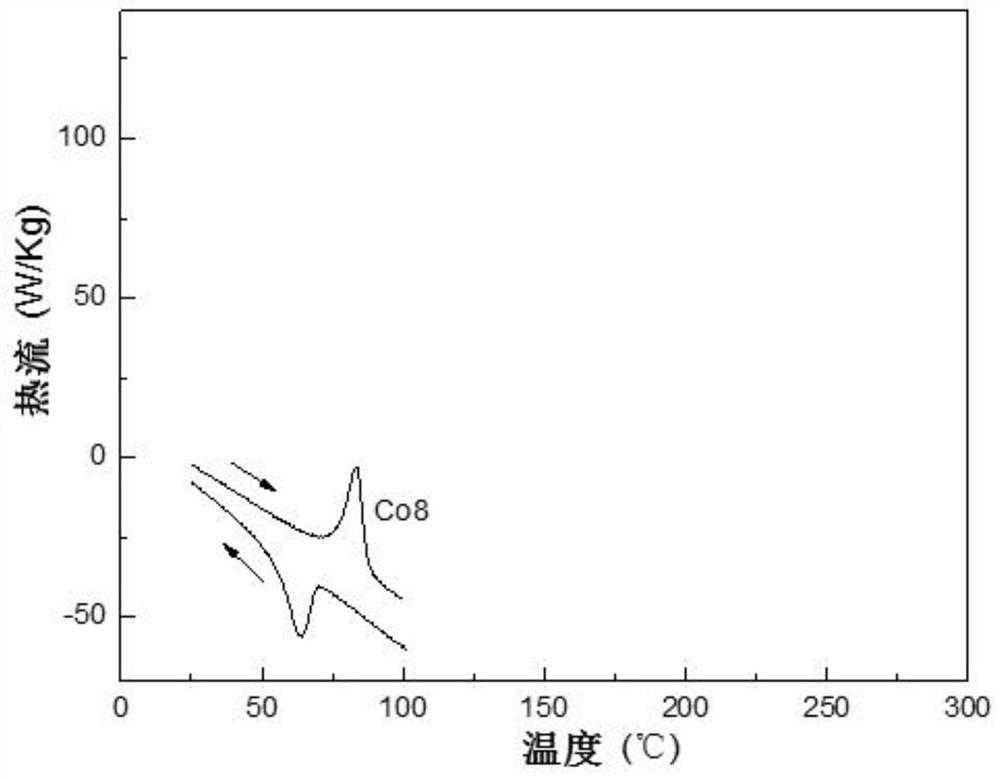

High-temperature high-toughness Ni-Co-Mn-Sn-Cu alloy with high magnetocaloric effect, preparation method, and application thereof

InactiveCN110423934AIncrease working temperatureImprove mechanical propertiesInorganic material magnetismCoils manufactureShape-memory alloyAlloy

The invention relates to a high-temperature high-toughness Ni-Co-Mn-Sn-Cu alloy with a high magnetocaloric effect, a preparation method, and application thereof, belongs to the technical field of magnetic materials, and particularly relates to the high-temperature high-toughness Ni-Co-Mn-Sn-Cu alloy with the high magnetocaloric effect, the preparation method, and the application thereof. The invention aims to solve the problems that an existing Ni-Mn-Sn ferromagnetic shape-memory alloy system is high in brittleness and hard to meet the use requirement under high temperature environment. A chemical general formula is Ni48-xCoxMn37Sn9Cu6, wherein x is mole fraction and is larger than 0 and smaller than or equal to 12; and the sum of mole number of elements in the alloy is 100. The method comprises the steps of (1) preparing materials; (2) carrying out electric arc meting; and (3) carrying out homogenization treatment so as to finally obtain an Ni48-xCoxMn37Sn9Cu6 magnetic refrigeration alloy material.

Owner:HARBIN UNIV OF SCI & TECH

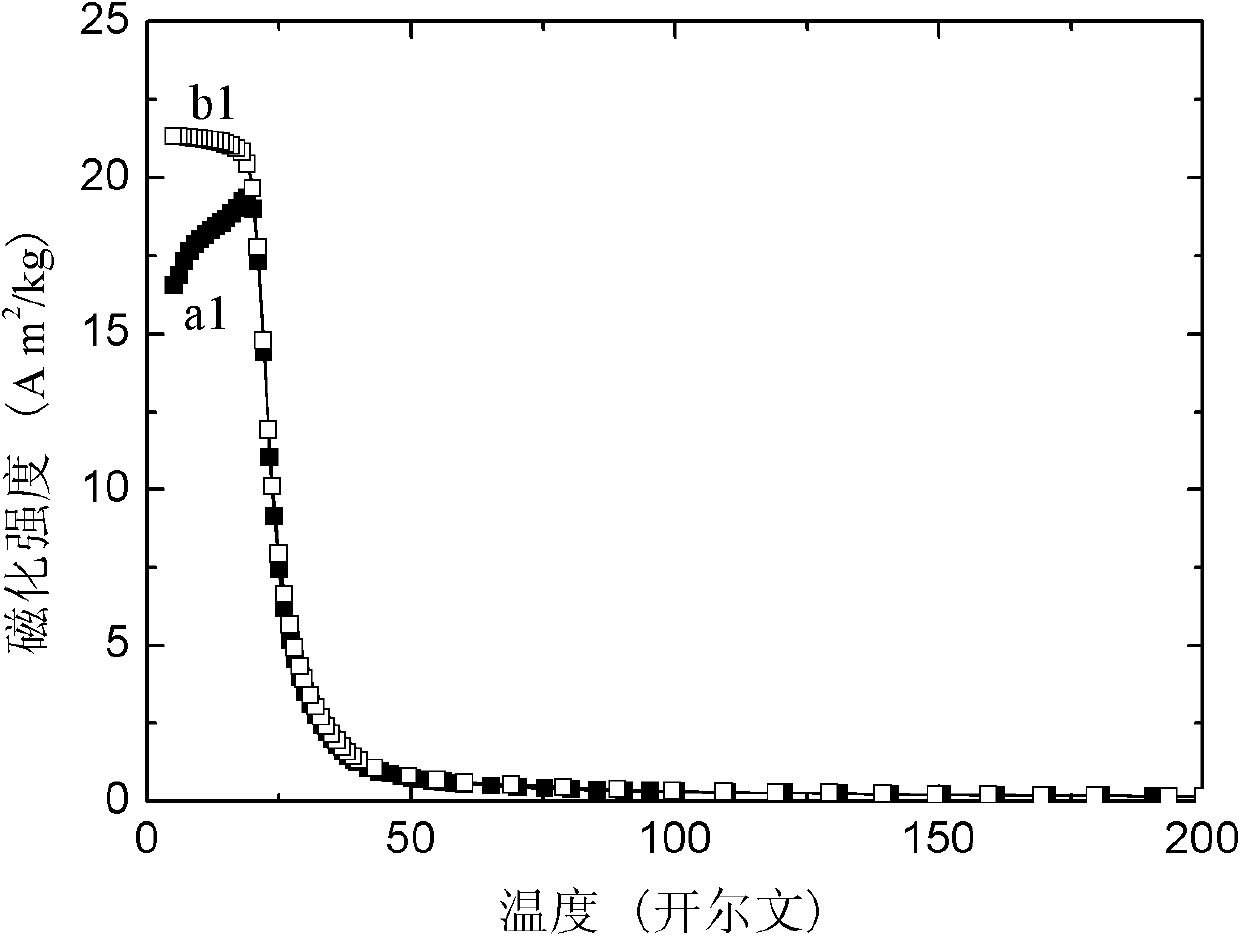

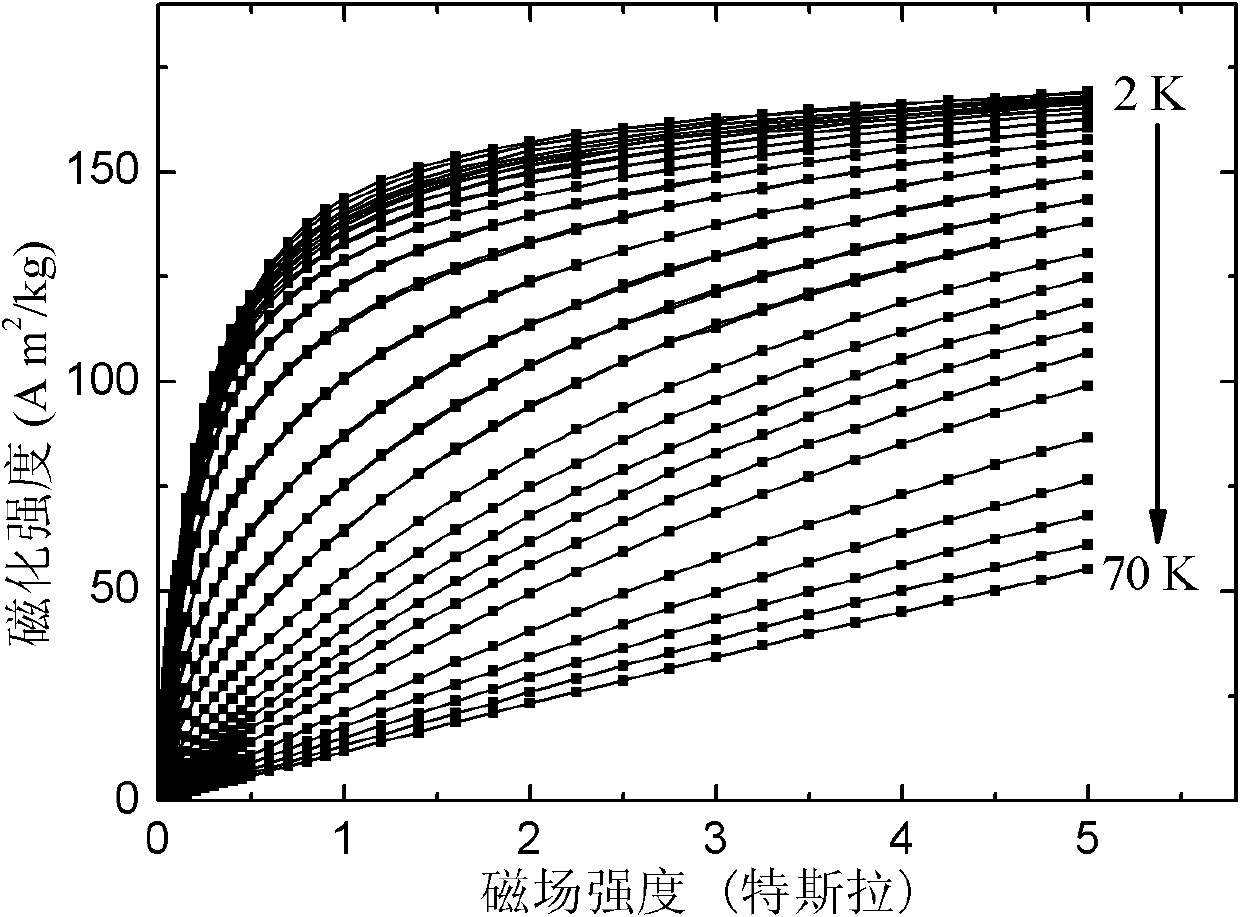

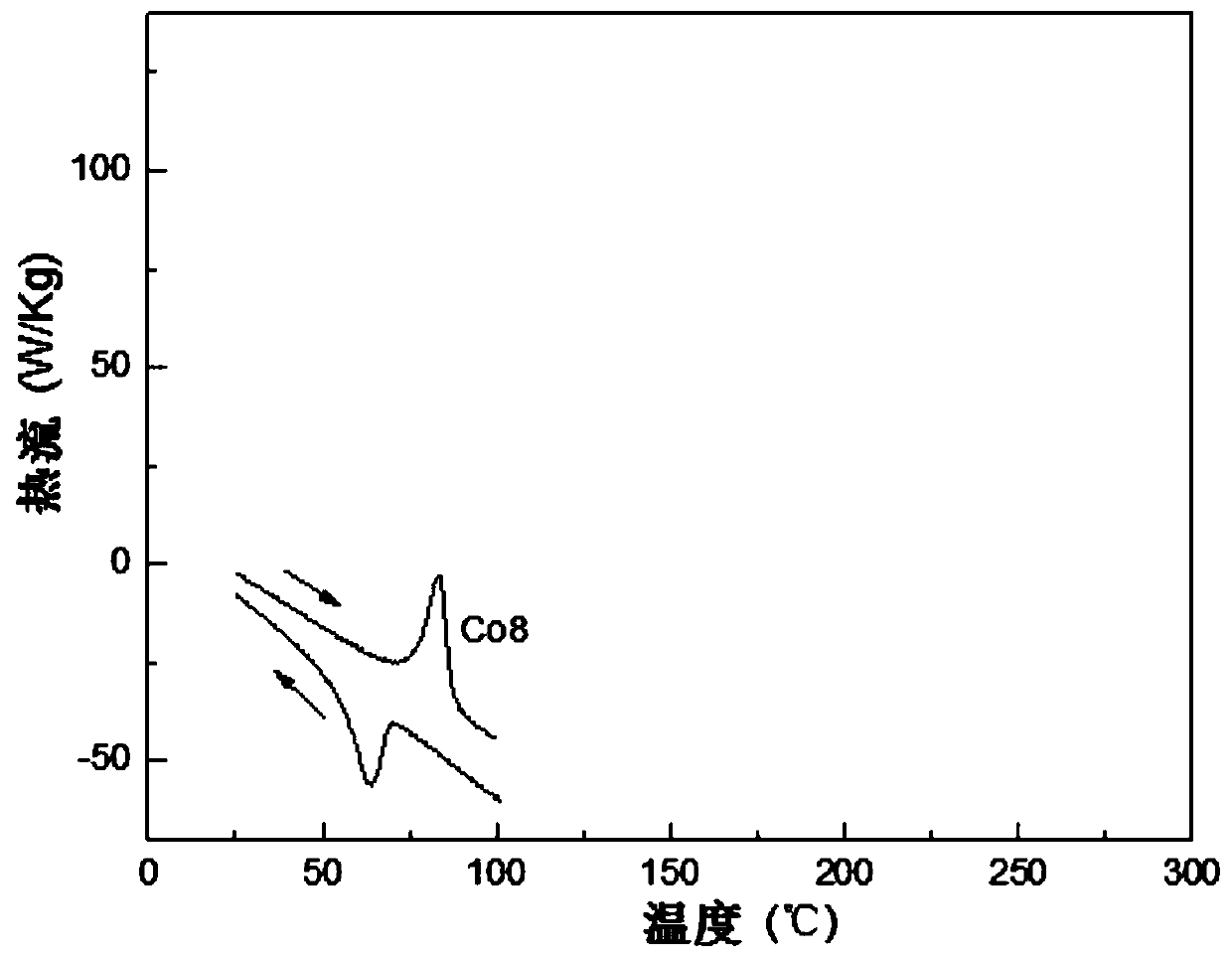

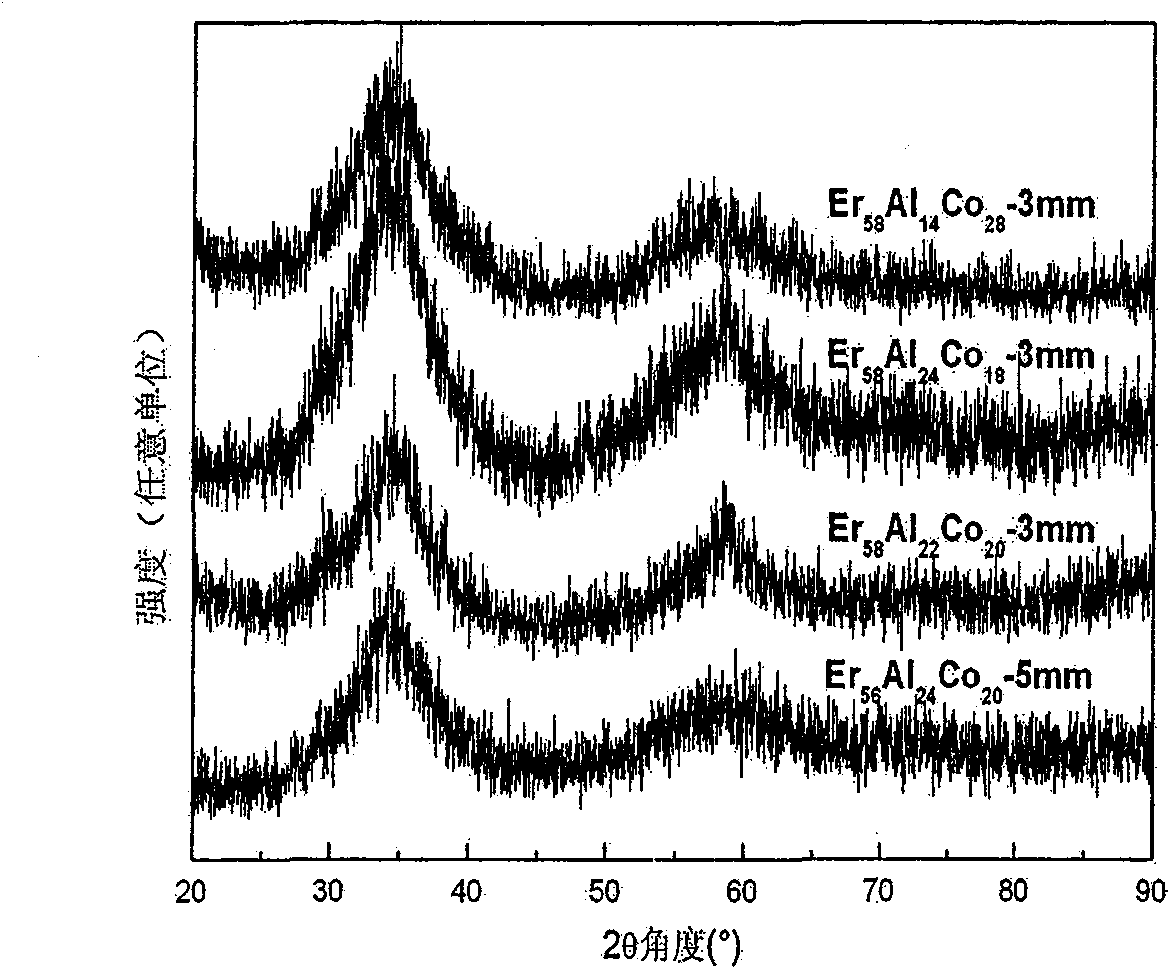

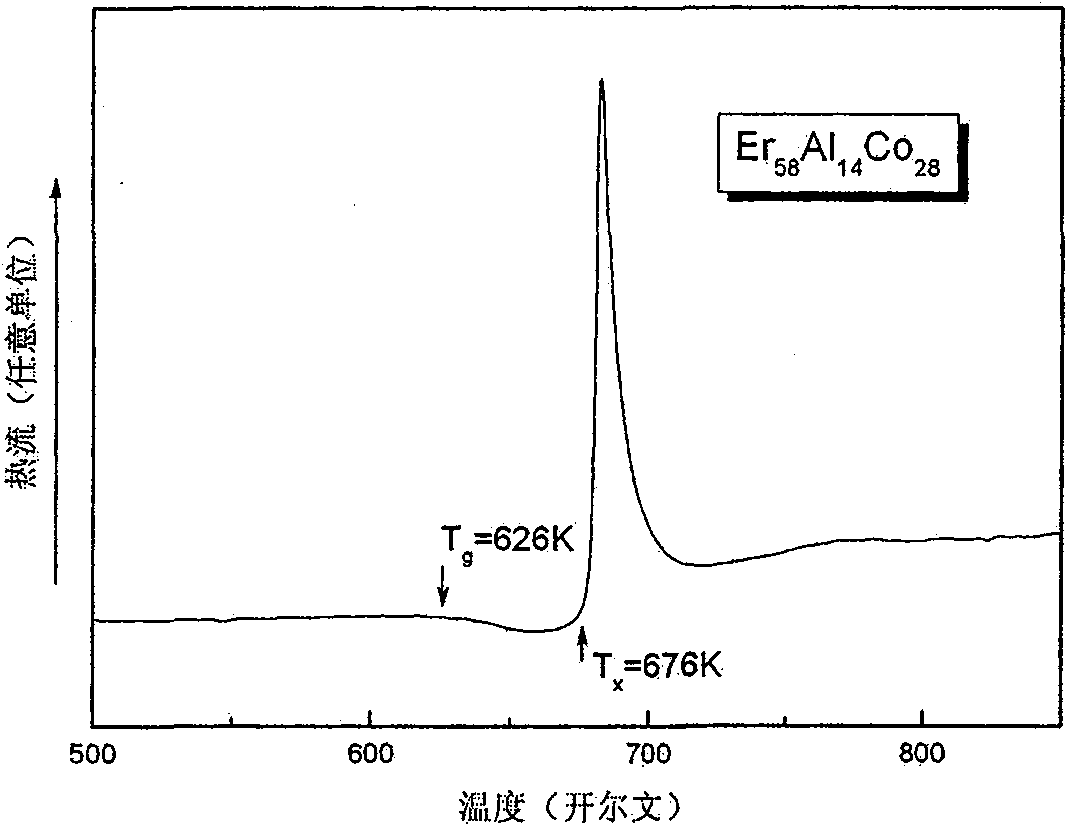

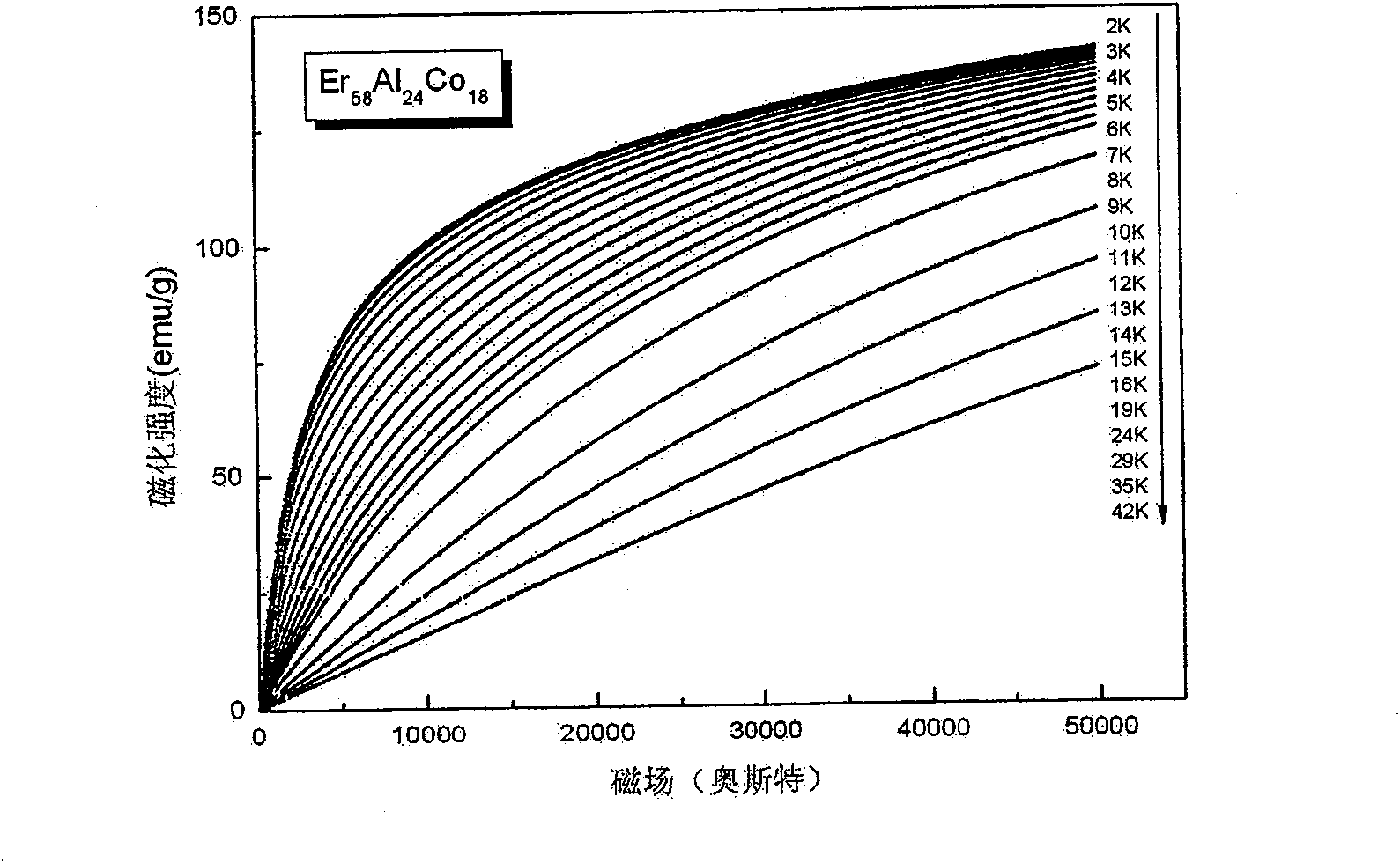

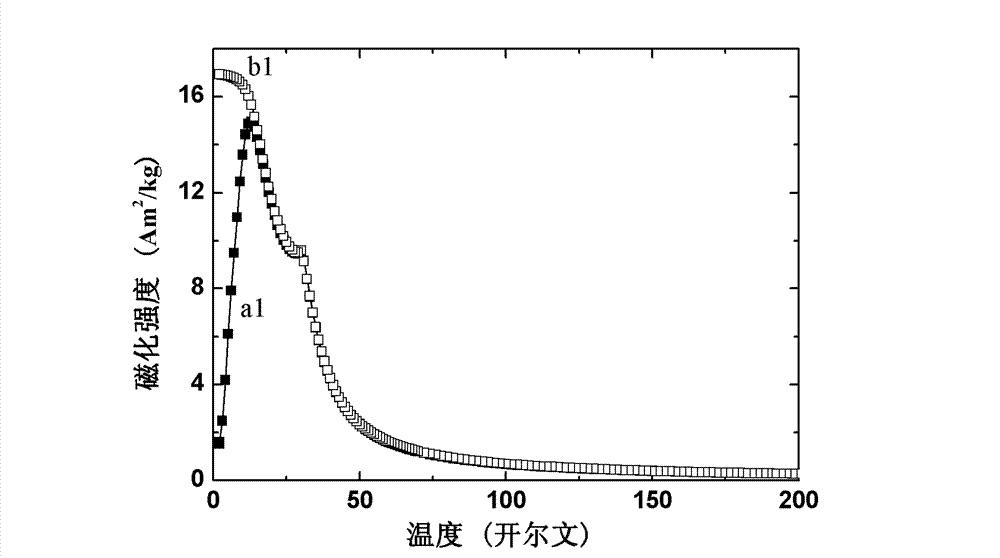

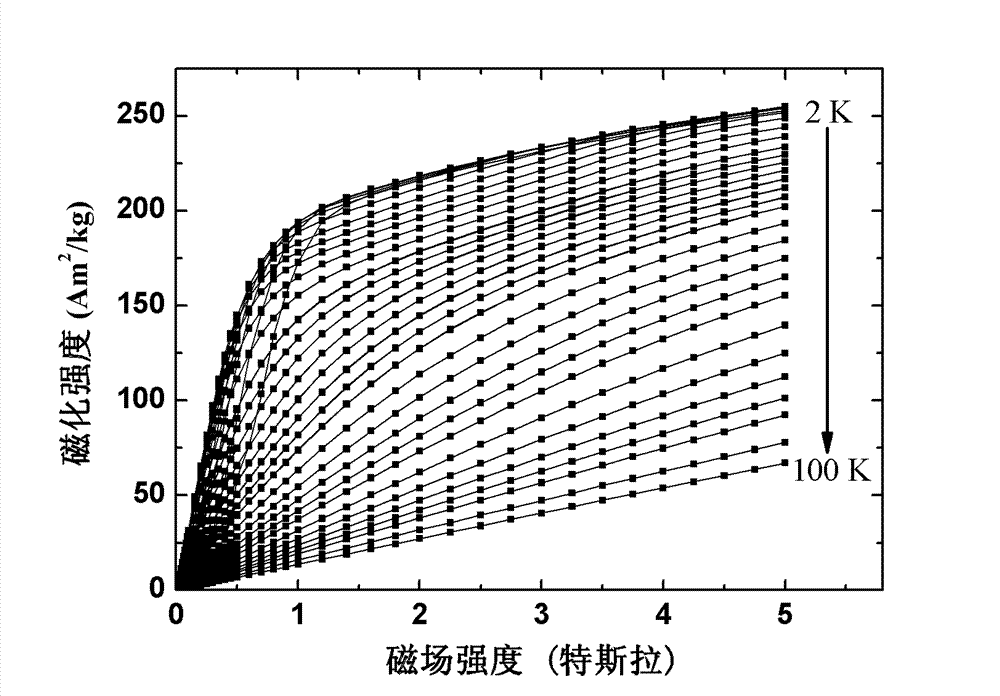

Low-temperature magnetic cooling erbium-based bulk amorphous material

The invention discloses a low-temperature magnetic cooling erbium-based bulk amorphous material and belongs to the field of magnetic cooling alloys of functional materials. The low-temperature magnetic cooling erbium-based bulk amorphous material is characterized by comprising the following chemical components in percentage by atom: 55 to 65 percent of Er, 14 to 24 percent of Al and 18 to 28 percent of Co. The material can form bulk amorphous alloys under a common suction casting condition, has magnetic entropy change and magnetic cooling capability higher than those of metal Er, has a cost price lower than magnetic cooling materials such as Er-based crystalline and giant magnetic material Gd5Si2Ge2, of the same magnetic entropy change and magnetic cooling capability and is a high quality magnetic cooling material in a 2 to 50 K range.

Owner:UNIV OF SCI & TECH BEIJING

Rare earth-aluminum material used for magnetic refrigeration, and preparation method and application thereof

InactiveCN102899548ALarge magnetic entropy changeImprove cooling effectHeat-exchange elementsRare earthWorking temperature

The invention provides a rare earth-aluminum material used for magnetic refrigeration, and a preparation method and an application thereof. The material is a compound having the following general formula R3Al2, wherein R represents any one element of Gd, Tb, Dy, Ho and Er or a combination of Ho element and any one of Gd, Tb, Dy and Er. The magnetic refrigeration material has a Zr3Al2 type tetragonal crystal structure. The rare earth-aluminum material provided by the invention, particularly Ho3Al2 has an antiferromagnetic-ferromagnetic phase transition and a ferromagnetic-paramagnetic phase transition, presents a relatively large magnetic entropy change and a wide working temperature zone nearby a phase-transition temperature. The rare earth-aluminum material has a relatively large magnetic refrigeration capacity and good thermal reversibility and magnetic reversibility, and is a very ideal magnetic refrigeration material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

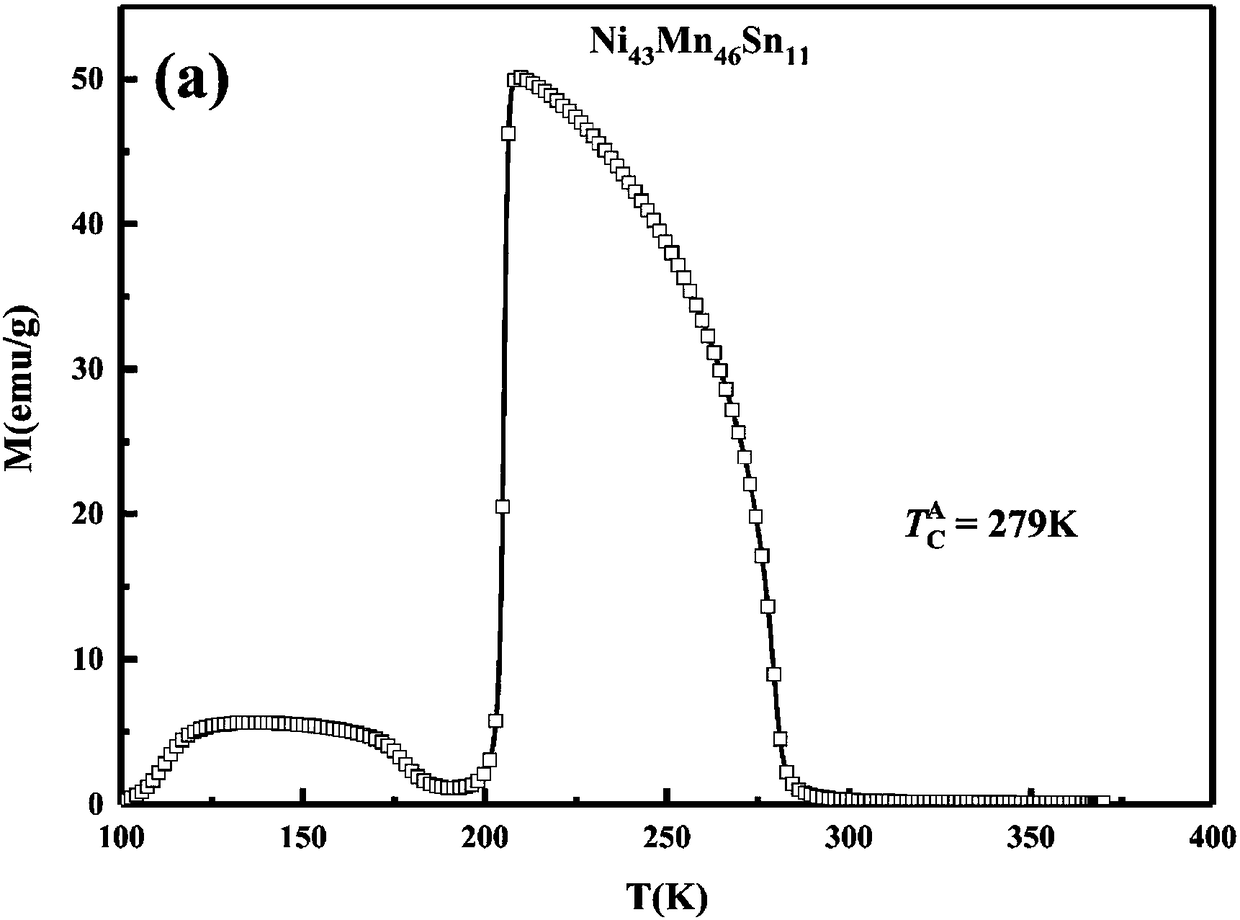

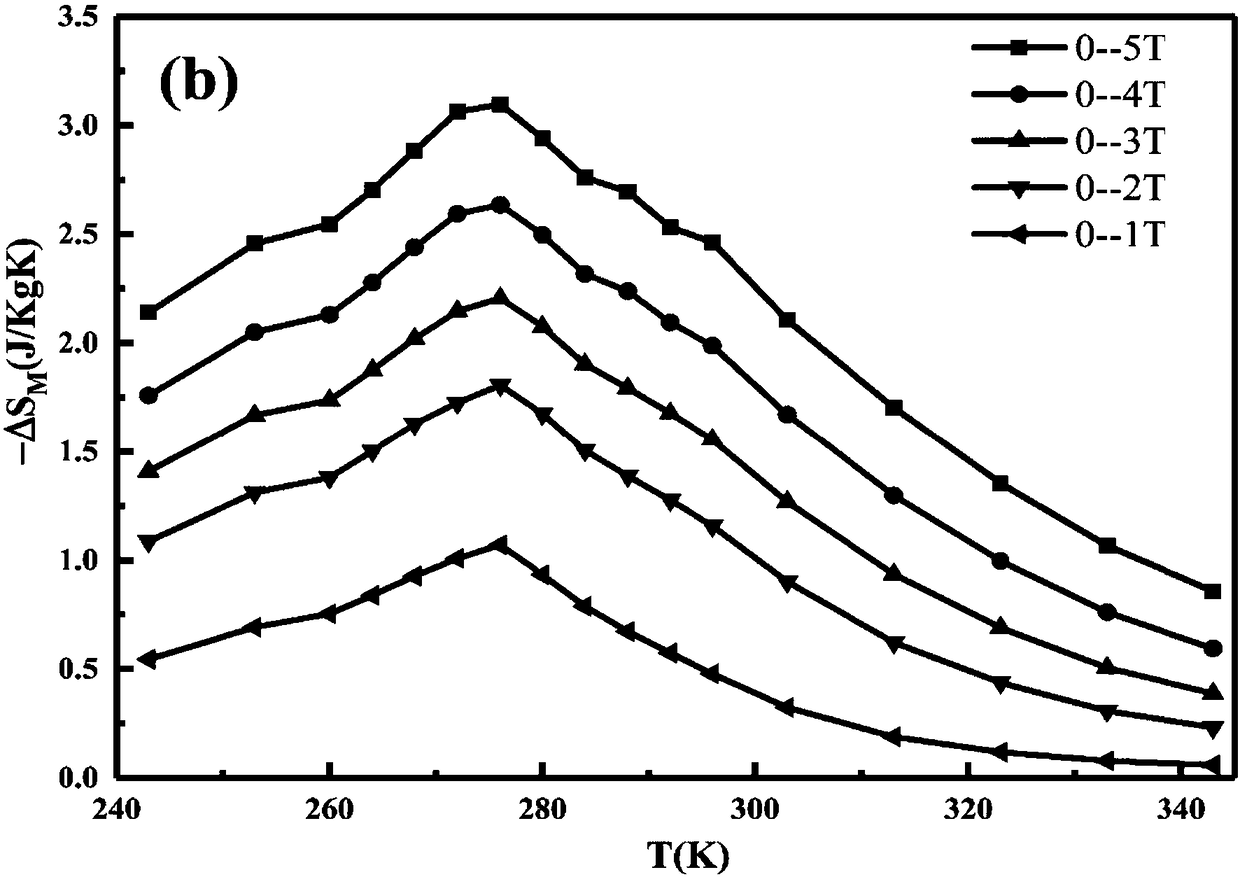

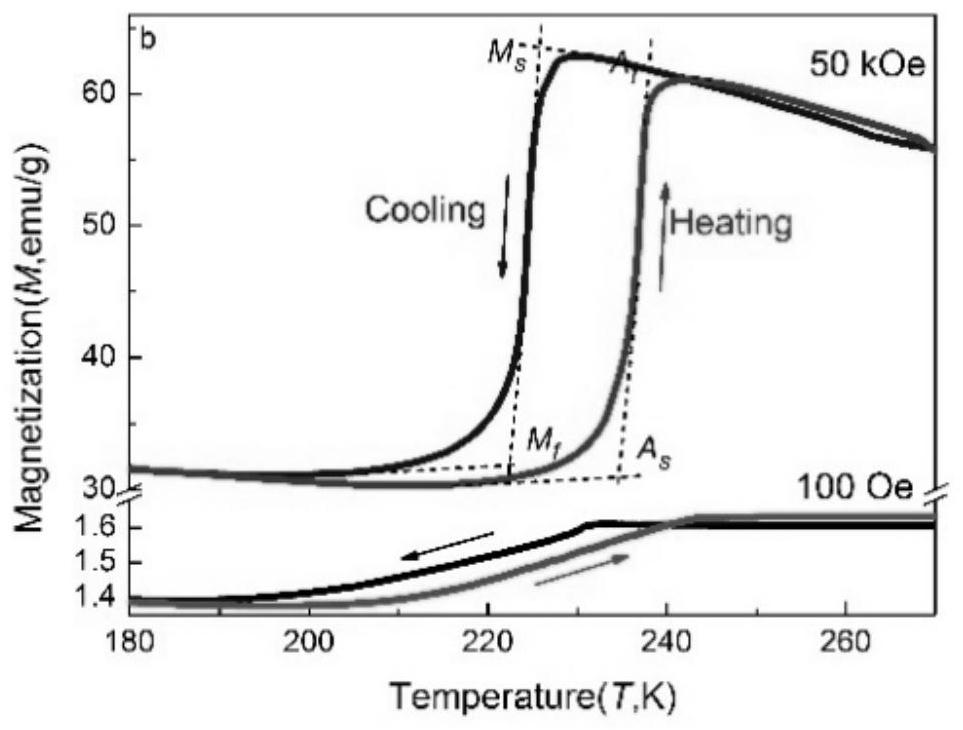

Ni-Co-Mn-Sn magnetic refrigeration material and preparation method thereof

ActiveCN108330372ALarge magnetic entropy changeThe magnetic entropy curve is flatInorganic material magnetismCo elementMagnetic refrigeration

The invention discloses a Ni-Co-Mn-Sn magnetic refrigeration material and a preparation method of the Ni-Co-Mn-Sn magnetic refrigeration material. The chemical formula of the material is Ni43-xCoxMn46Sn11, wherein x is larger than or equal to 0 and is smaller than or equal to 3. The method comprises the following steps that 1, metal raw materials are weighed in proportion, and Mn with the certainmargin is added; 2, the mixed raw materials are repeatedly molten under argon protection, and an alloy cast ingot with uniform ingredients is obtained; and 3, the alloy is subjected to solution rapidquenching under argon protection, and the Ni-Co-Mn-Sn magnetic refrigeration material is obtained. By adding the Co element into an alloy thin belt, the saturation magnetization of austenite and the Curie temperature of alloy are improved, and the alloy belt material has the good thermomagnetic property at the room temperature. The material shows second-order phase change in the magnetization process, heat stagnation and magnetic stagnation are almost avoided, the preparation process is simple, the cost is low, and the material is suitable for industrial production and practical application.

Owner:SOUTH CHINA UNIV OF TECH

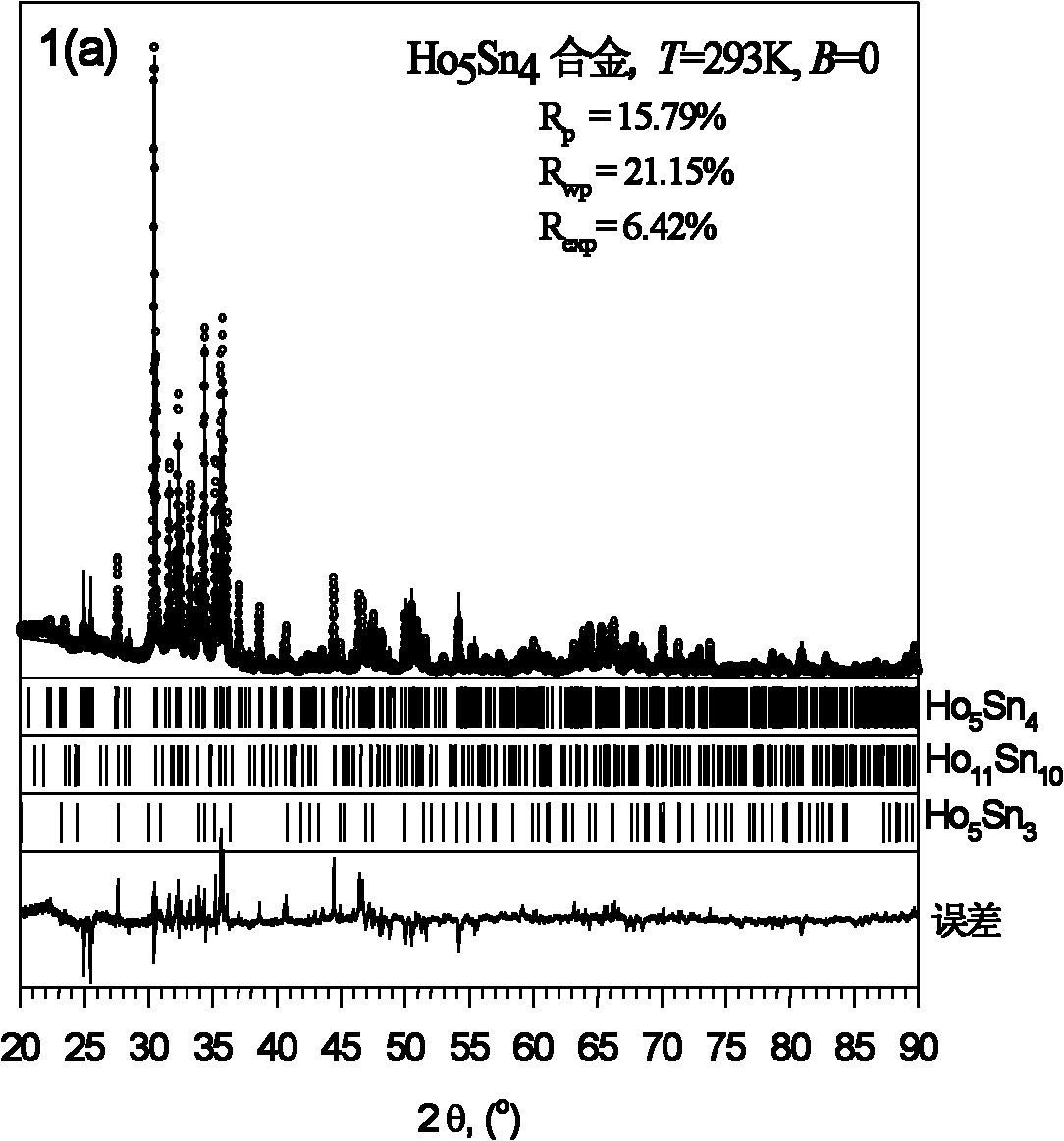

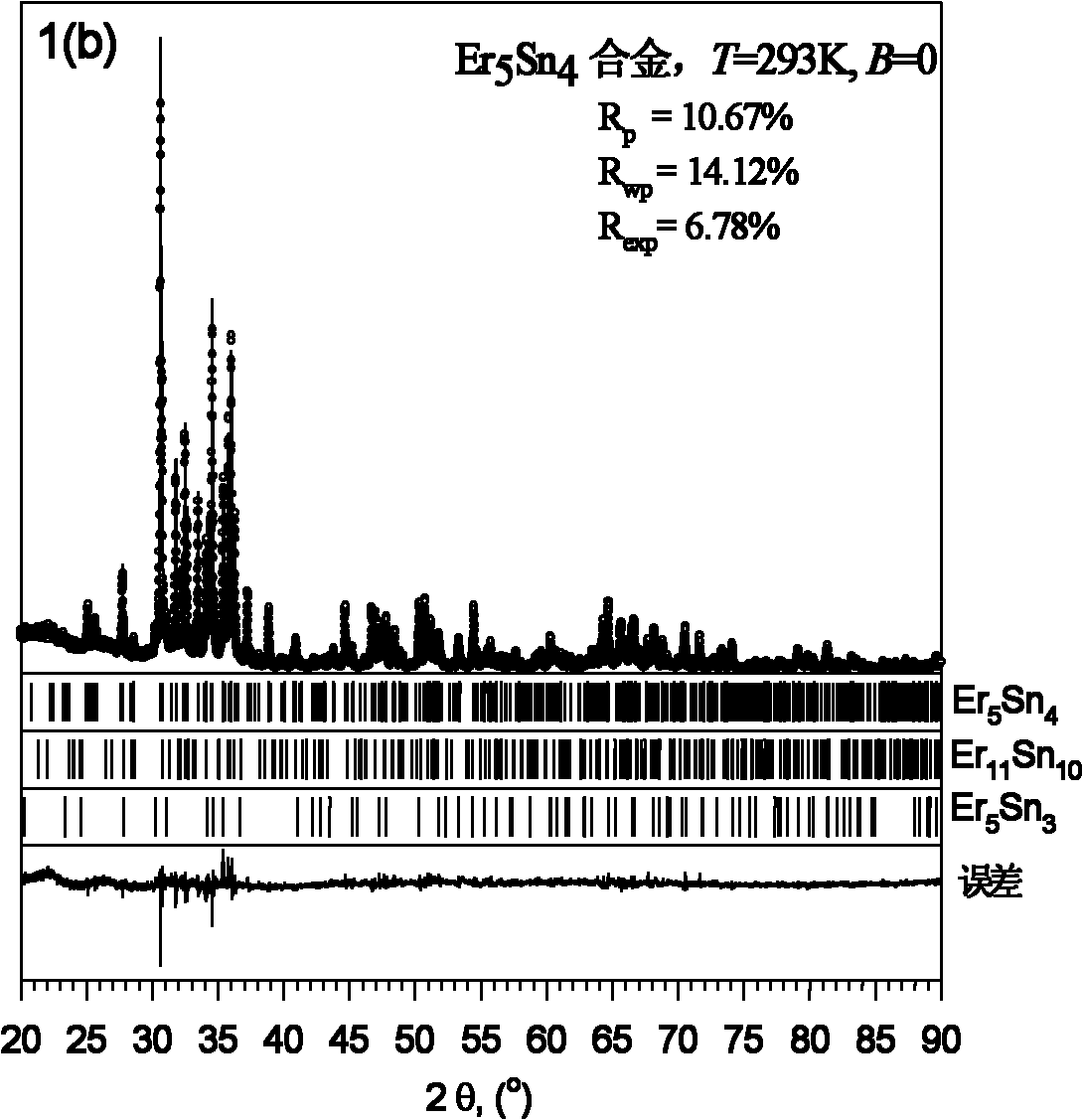

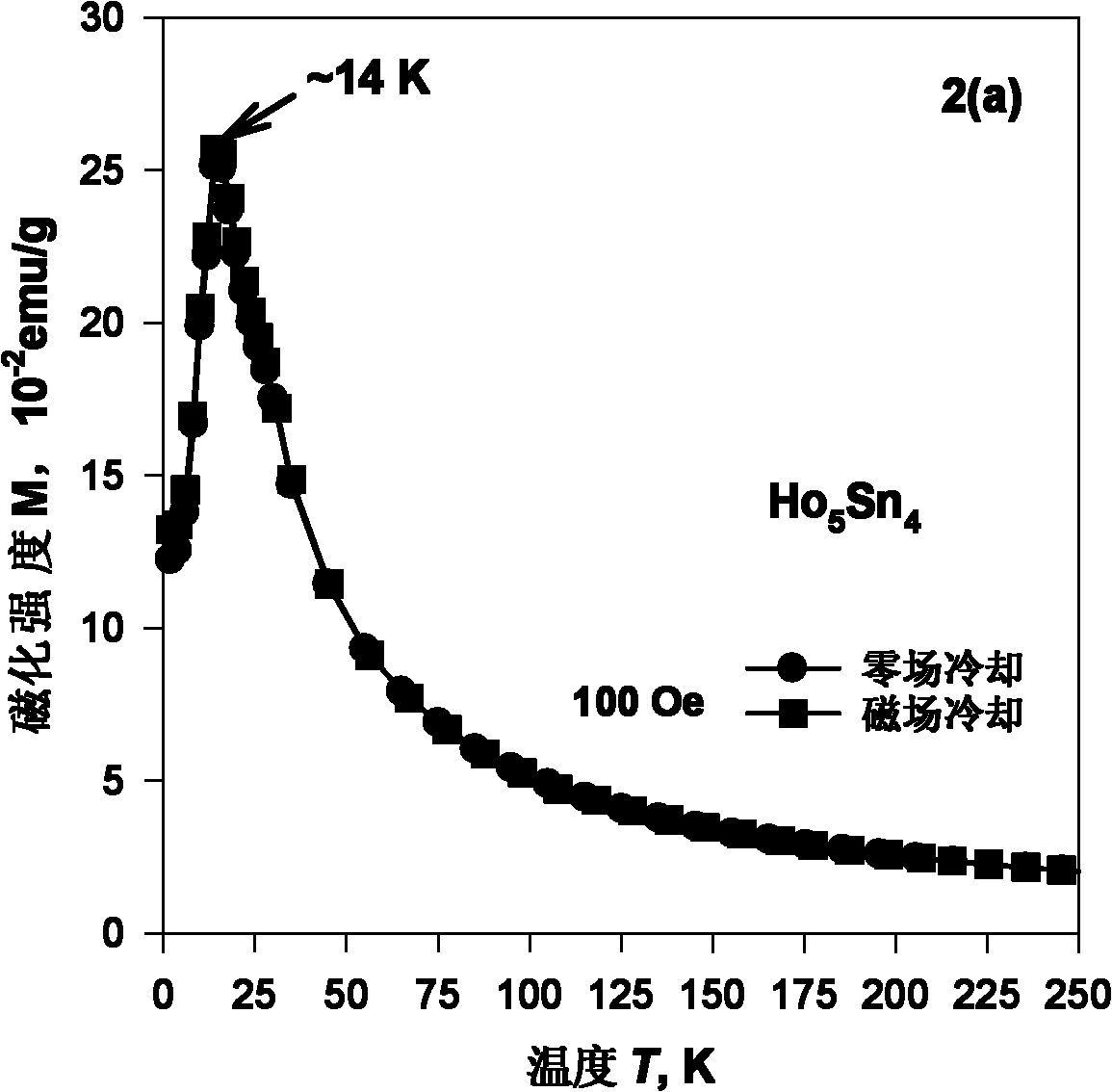

Rare earth tin-based low-temperature magnetic refrigeration material and preparation method thereof

The invention relates to the field of magnetic materials, and discloses a rare earth tin-based low-temperature magnetic refrigeration material. A general chemical formula of the magnetic refrigeration material is R5Sn4; and in the formula, R is Ho or Er. A method for preparing the magnetic refrigeration material comprises the following steps of: (1) weighing 60 to 70 mass percent of rare earth metal R and 30 to 40 mass percent of weak metal Sn and mixing; (2) repeatedly smelting mixed raw materials to obtain an alloy cast ingot with uniform ingredients; and (3) annealing the alloy cast ingot under vacuum at the temperature of 1,573K for 24 hours, and cooling in a furnace to obtain the rare earth tin-based low-temperature magnetic refrigeration material R5Sn4. A main raw material Sn adopted by the method is cheap and has abundant reserves in natural world; the prepared product R5Sn4 shows second-order phase transition in the magnetization process; and the preparation method is simple and low in cost, and is suitable for industrialized production.

Owner:SOUTH CHINA UNIV OF TECH

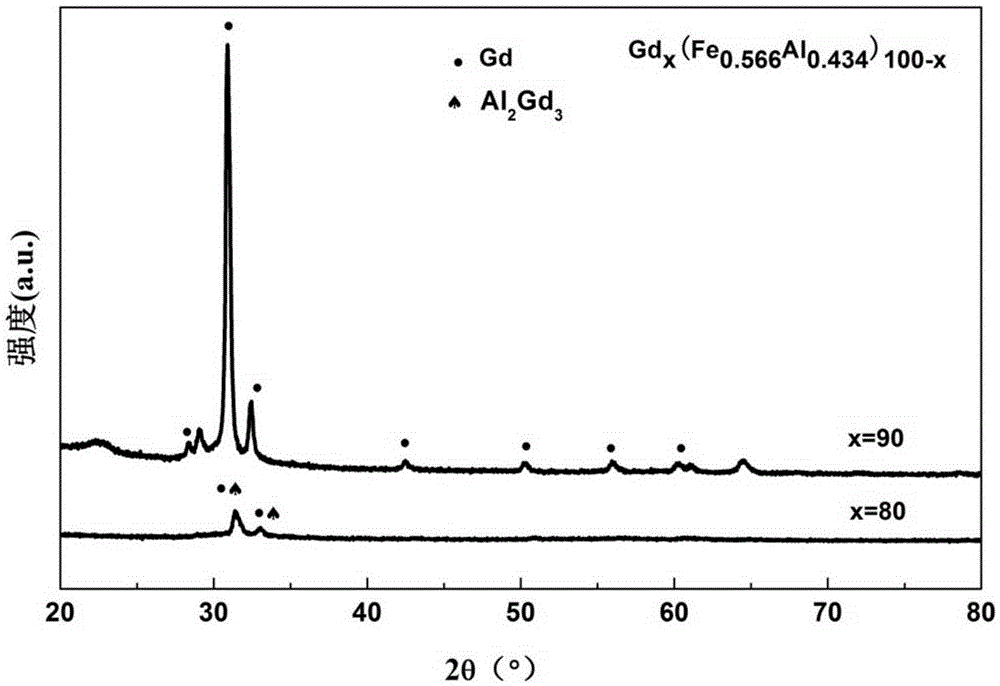

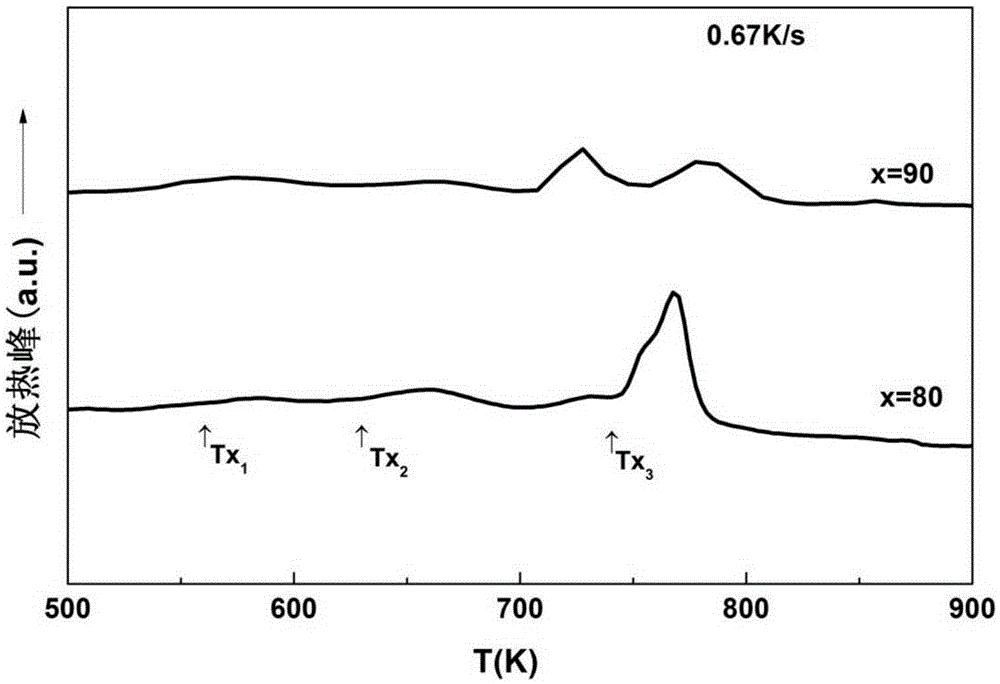

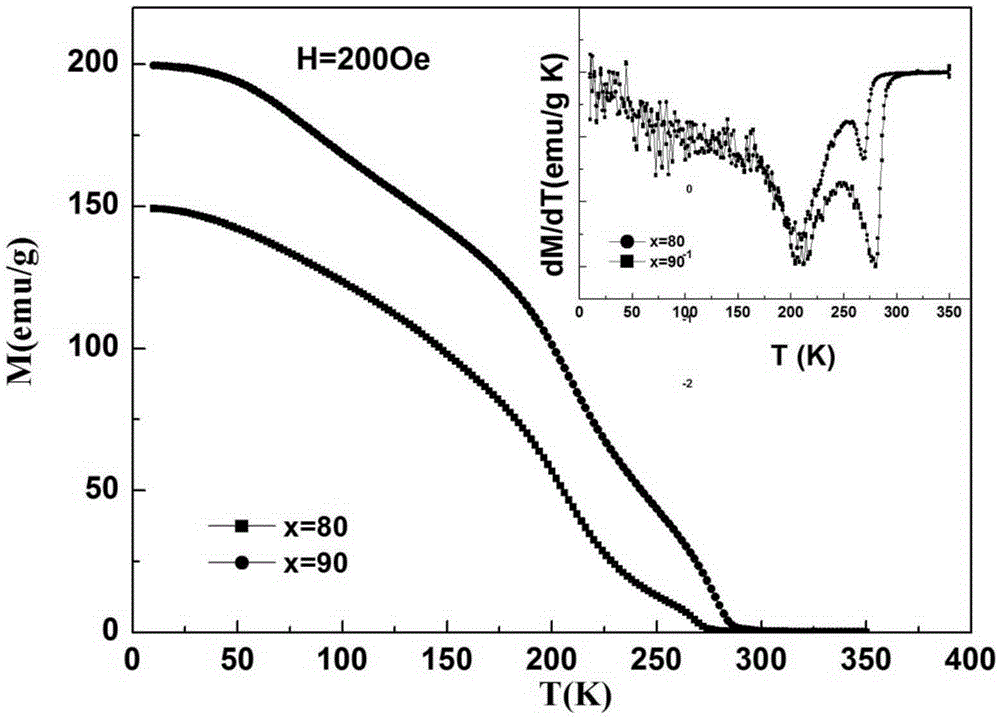

Gd-based amorphous nanocrystal composite with high Curie temperature and refrigerating capacity and preparation method of Gd-based amorphous nanocrystal composite

The invention discloses a Gd-based amorphous nanocrystal composite with high Curie temperature and refrigerating capacity. The chemical formula of the Gd-based amorphous nanocrystal composite is GdaFebAlc, wherein a, b and c refer to atom contents of corresponding elements, a is larger than or equal to 75 and smaller than or equal to 92, b is larger than or equal to 5 and smaller than or equal to 20, c is larger than or equal to 4 and smaller than or equal to 15, and the equation of a+b+c=100 is met. Compared with the prior art, the Gd-based amorphous nanocrystal composite has the high Curie temperature, and meanwhile has the large magnetic entropy change, the Curie temperature of the composite is more than 200 K, the magnetic entropy change under a 5 T magnetic field is larger than 5.0 J / kg / K, the magnetic transition temperature interval is large, and the refrigerating capacity reaches up to 690 J / kg or above. Thus, the composite is a good magnetic refrigeration material and can be applied as a near room temperature magnetic refrigeration working medium.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Rare earth-nickel-boron-carbon based magnetic material for low-temperature magnetic refrigeration and preparation method thereof

InactiveCN102660694ALarge magnetic entropy changeHigh magnetic refrigeration capacityInorganic material magnetismHeat-exchange elementsSpace groupRare earth

The invention relates to a rare earth-nickel-boron-carbon based magnetic material for low-temperature magnetic refrigeration and a preparation method thereof. The magnetic material has the chemical general formula of RNiBC, wherein R is rare earth metals Gd, Tb, Dy or Er, and the magnetic material has the structure of a tetragonal crystal, and belongs to a P4 / nmm space group. The preparation method comprises the following steps of: firstly, mixing rare earth metals Tb, Gd, Dy or Er and Ni, B and C in proportion into raw materials, putting the raw materials in a smelting container, and repeatedly smelting under the protection of argon, to obtain an alloy cast ingot with even components; sealing the smelted alloy cast ingot in a vacuum quartz container, annealing at high temperature, and quickly cooling to normal temperature, to obtain a finished product. The rare earth-nickel-boron-carbon material provided by the invention not only is large in magnetic entropy change nearby the respective phase-transition temperature, but also is good in magnetic / thermal reversible properties, thereby being an ideal low-temperature refrigeration material.

Owner:HANGZHOU DIANZI UNIV

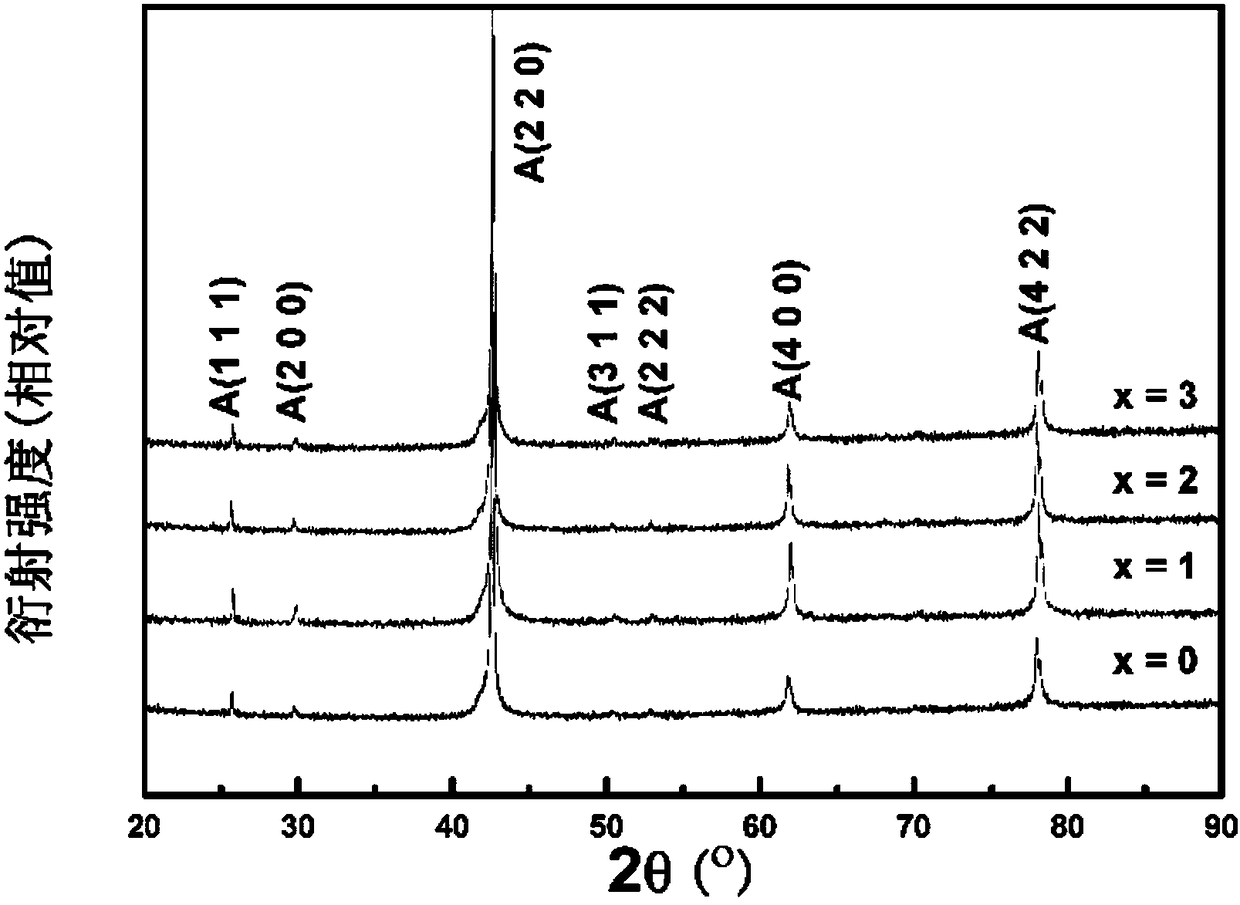

Gadolinium-based high-entropy perovskite oxide magnetic refrigeration material and preparation method thereof

PendingCN113963881ASimple equipmentThe preparation process is stableInorganic material magnetismInductances/transformers/magnets manufactureDistillationPerovskite (structure)

The invention relates to a gadolinium-based high-entropy perovskite oxide magnetic refrigeration material and a preparation method thereof, the chemical general formula of the magnetic refrigeration material is GdXO3, X is at least four elements of transition metals Cr, Mn, Fe, Co, Ni or Al, the molar content range of each component element is 10-30%, and the total content is 100%. The material has a perovskite structure, the space group is Pbnm, and the disordered arrangement of transition metal ions has typical high-entropy characteristics. The preparation method mainly comprises the following steps: dissolving rare earth salt and metal salt which are mixed according to an equal ratio in water, the molar mass ratio of ions being 1: 1; adding citric acid into the obtained salt solution, heating, preserving heat, and fully stirring the mixture to form sol; drying the sol by distillation to obtain gel; calcining the gel to obtain a sinter; and tabletting and molding the sinter, performing sintering at high temperature, and performing cooling to obtain a finished product. The gadolinium-based high-entropy perovskite oxide material prepared by the method can be applied to the field of low-temperature region magnetic refrigeration, and is low in raw material price, simple in equipment, simple and reliable in process and suitable for industrial production.

Owner:SHANGHAI UNIV

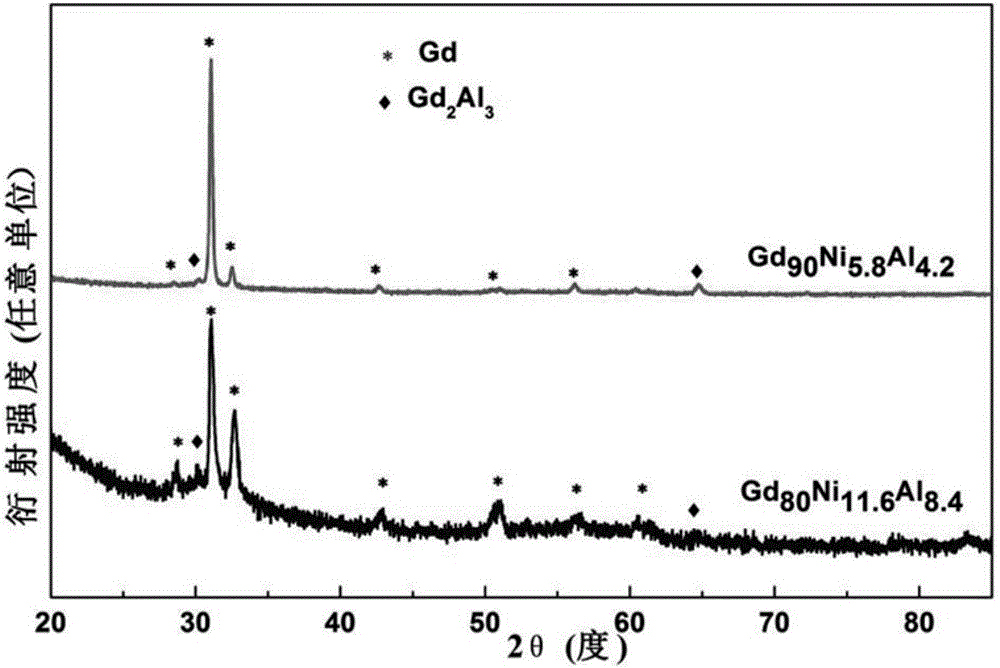

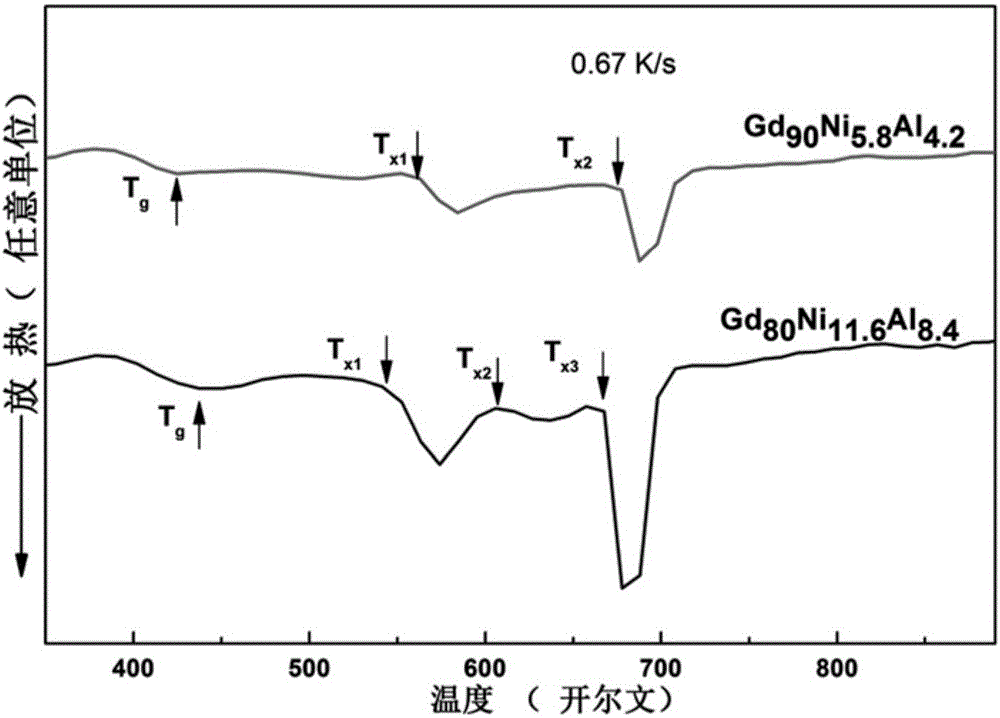

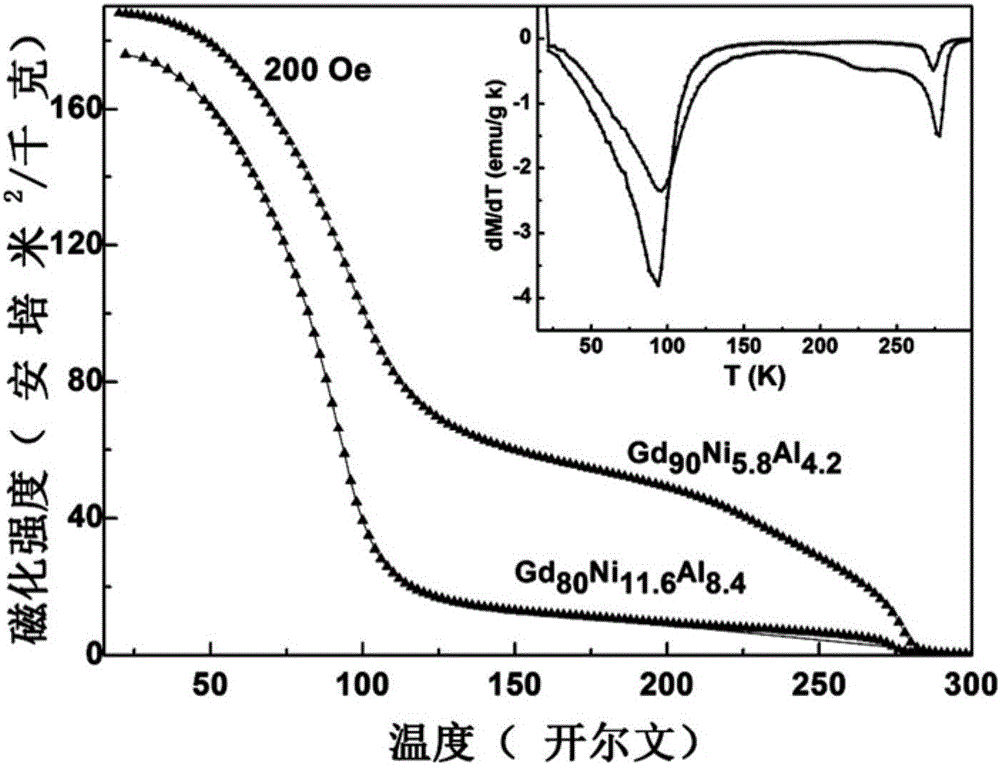

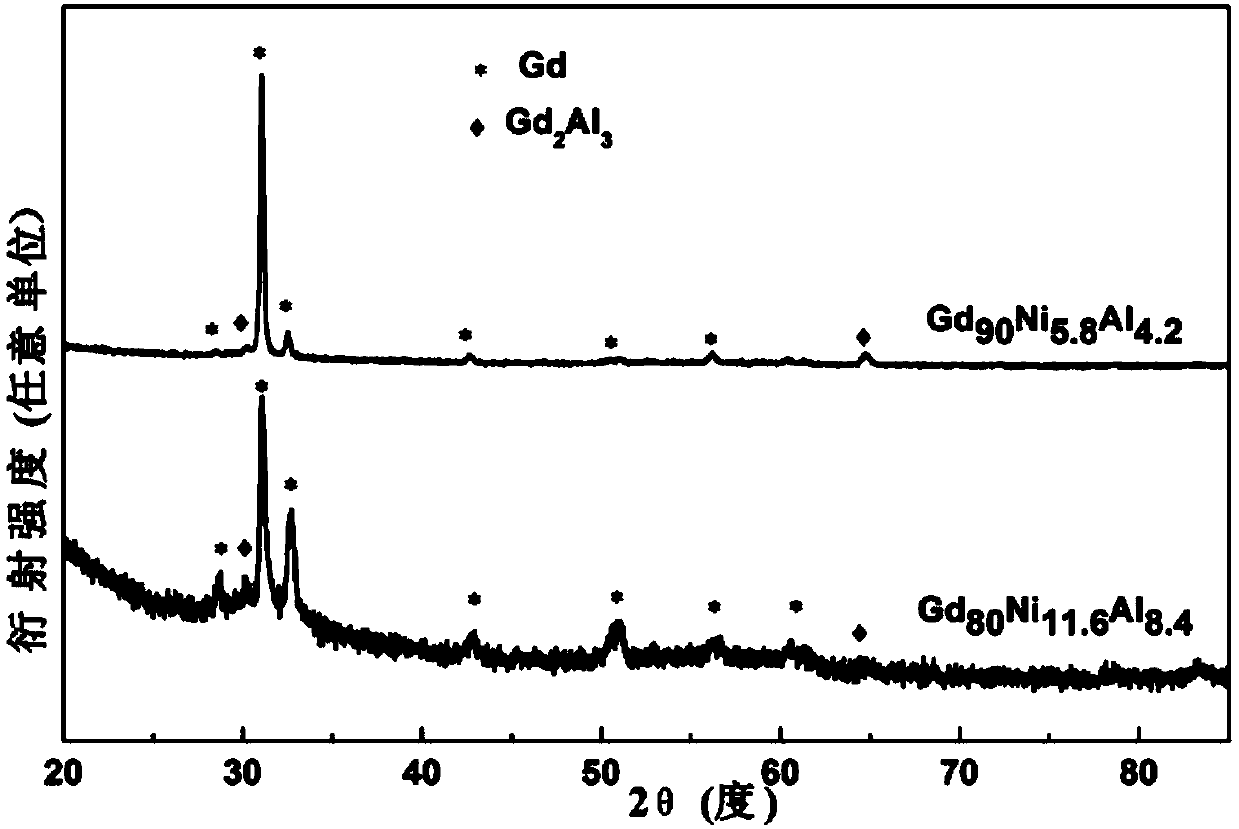

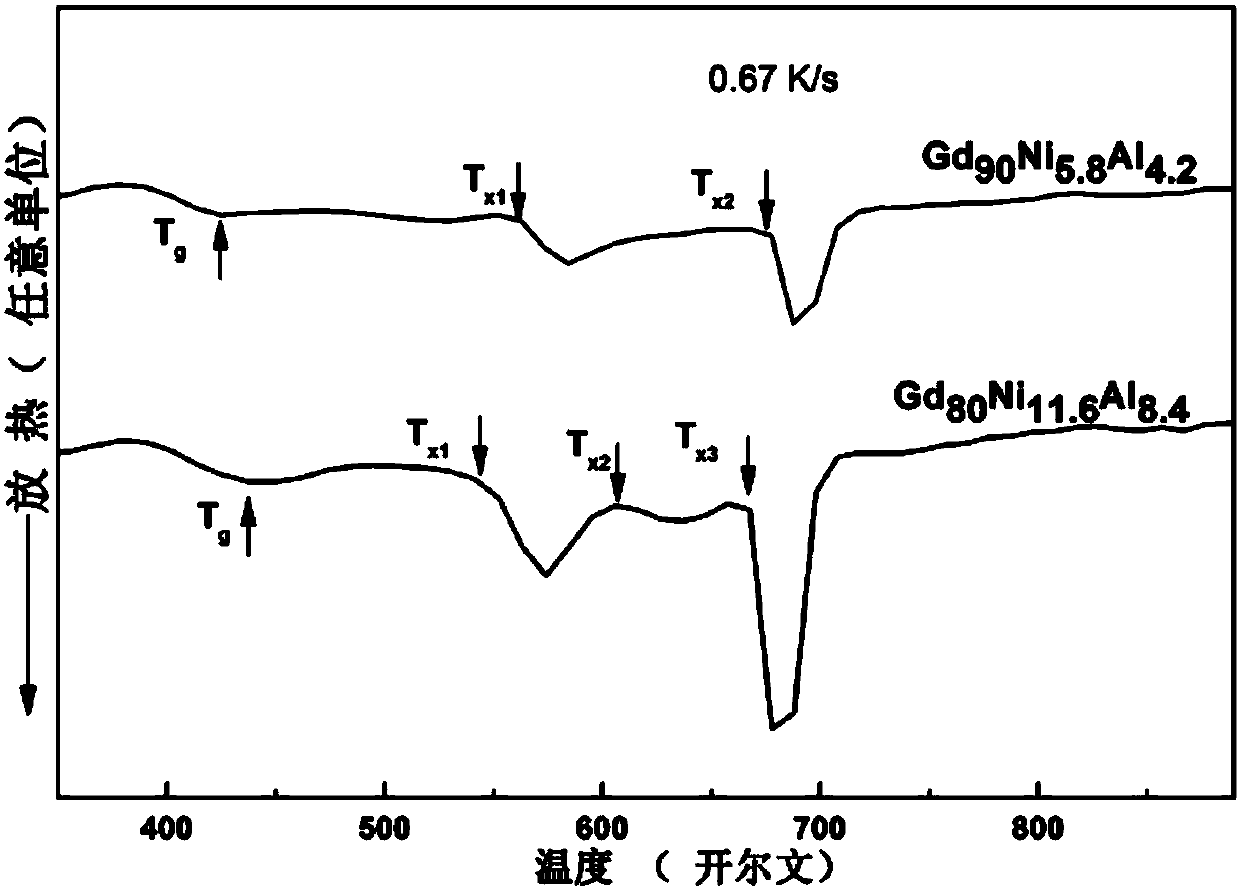

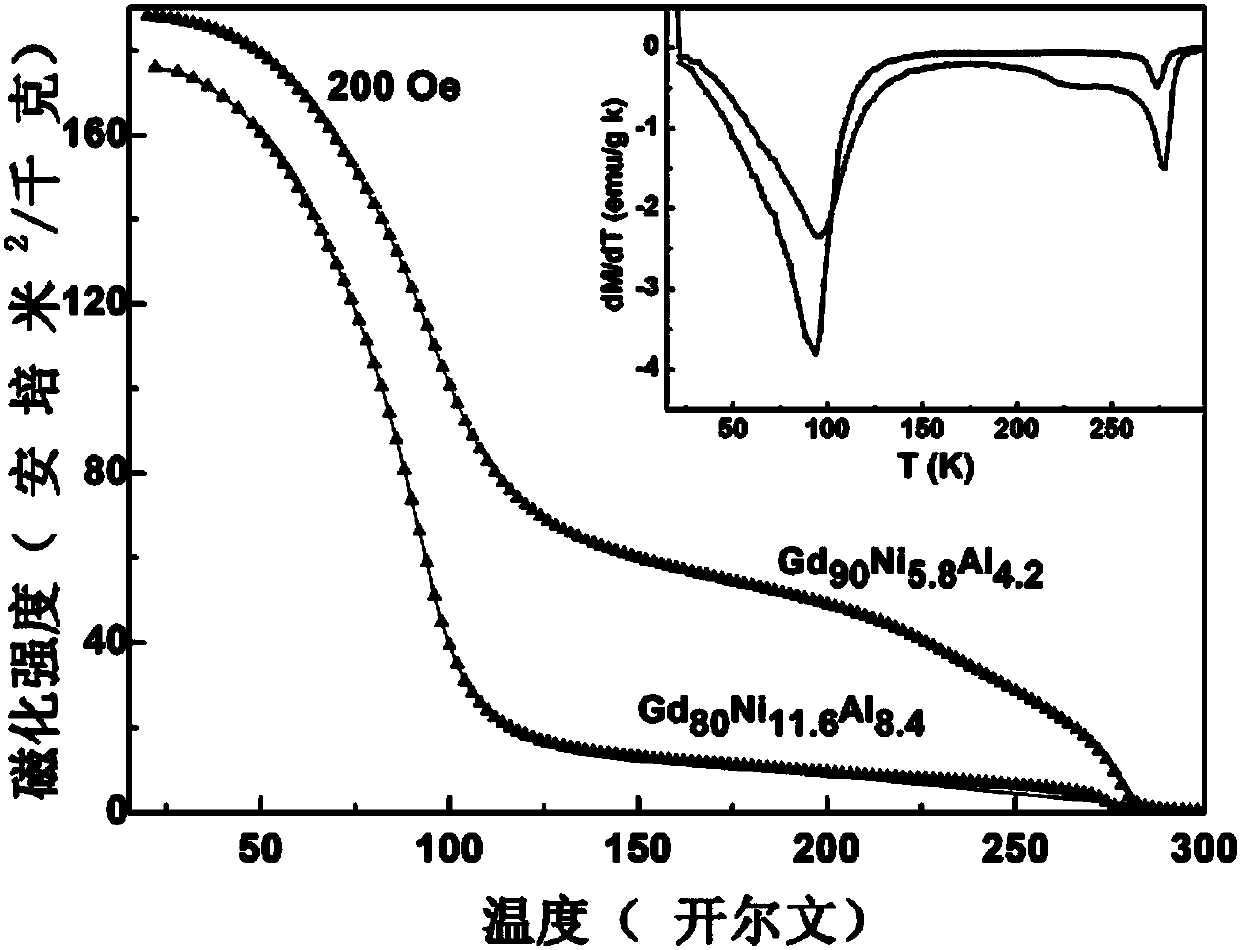

Gd-Ni-Al-based amorphous and nanocrystalline composite material and preparation method thereof

InactiveCN105970118AExpand the range of refrigeration applicationsGuaranteed heat recovery balanceHeat-exchange elementsRefrigeration temperatureMagnetic refrigeration

The invention discloses a Gd-Ni-Al-based amorphous and nanocrystalline composite material. The molecular formula of the Gd-Ni-Al-based amorphous and nanocrystalline composite material is GdaNibAlc, wherein a, b and c represent atom contents of corresponding elements, 80<=a<=90, 5.8<=b<=11.6, 4.2<=c<=8.4, and the equation that a+b+c=100 is satisfied. The Gd-Ni-Al-based amorphous and nanocrystalline composite material is of an amorphous / nanocrystalline complex phase structure and has two refrigeration temperature zones and one or two magnetic entropy change platforms, the high-temperature magnetic order temperature is 270 K or above, and the magnetic entropy change under a 5T magnetic field can reach 6.7 J / kg / K. Because magnetic transition temperature intervals are wide, the refrigeration capacity reaches up to 640 J / kg or above, and the Gd-Ni-Al-based amorphous and nanocrystalline composite material is a good magnetic refrigeration material and can be used as a magnetic refrigeration working material in the two intervals of the two refrigeration temperature zones.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

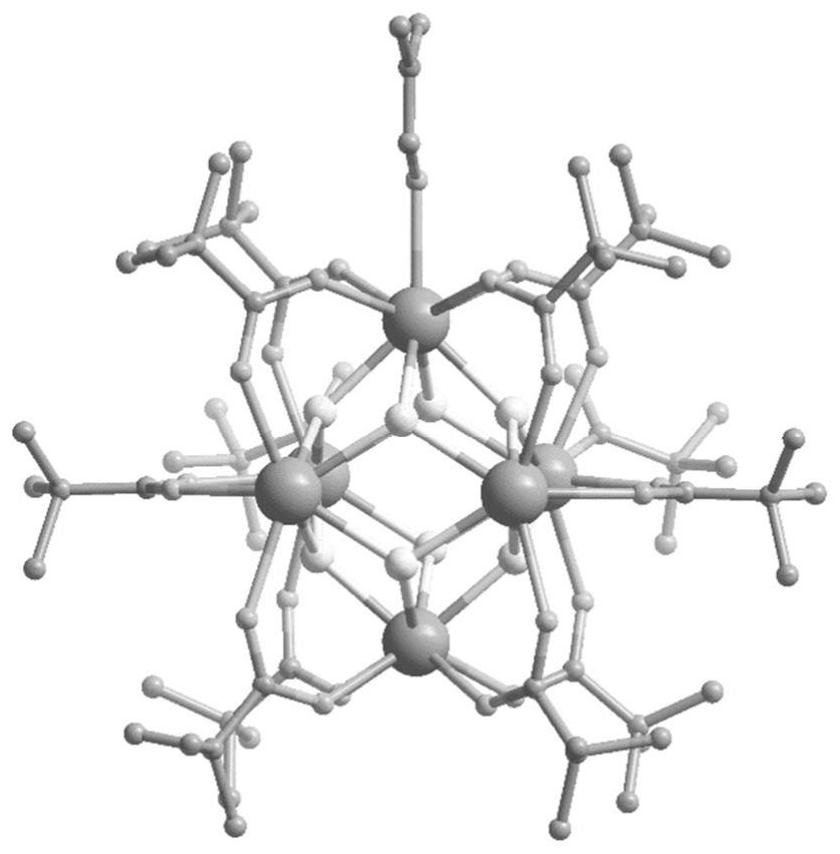

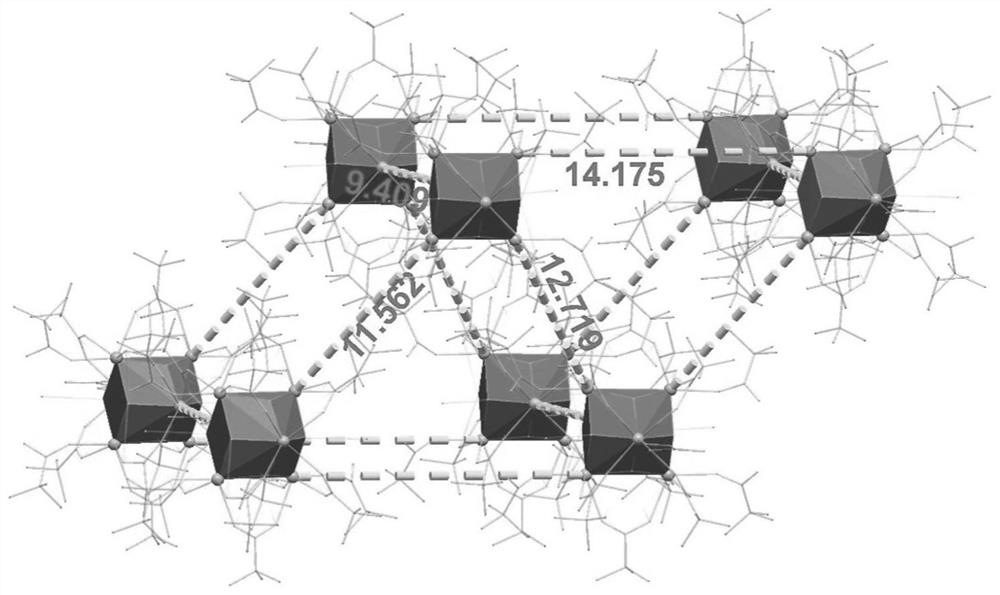

Fluorine-bridged rare earth molecular cluster magnetic refrigeration material and preparation method thereof

ActiveCN111292909BLarge magnetic entropy changeHigh magnetic entropy changeGroup 3/13 organic compounds without C-metal linkagesInorganic material magnetismMagnetic exchangeOrganic solvent

The invention discloses a fluorine bridged rare earth molecular cluster magnetic refrigeration material and a preparation method thereof. By adopting a solvothermal synthesis method, an air-stable fluorine bridged rare earth molecular cluster magnet is obtained through the reaction of a rare earth metal salt and a fluorine source. Refrigeration material, the unique weak ferromagnetic exchange makes the magnetic entropy change more difficult to saturate under low temperature and low field, and the magnetic refrigeration effect is better. The magnetic refrigeration material of fluorine bridged rare earth molecular cluster is a cluster compound, which is soluble in organic solvents, easy to process, and easy to combine with other materials or refrigeration sites, which can accurately reduce the specified temperature. The temperature in the region has a large magnetic entropy change in the low temperature region, which is an ideal material for low-temperature magnetic refrigeration materials. Due to the weak ferromagnetic exchange between rare earth ions in the cluster compound, the magnetic entropy change of the material at low temperature and low magnetic field is caused. high.

Owner:西安交通大学深圳研究院 +1

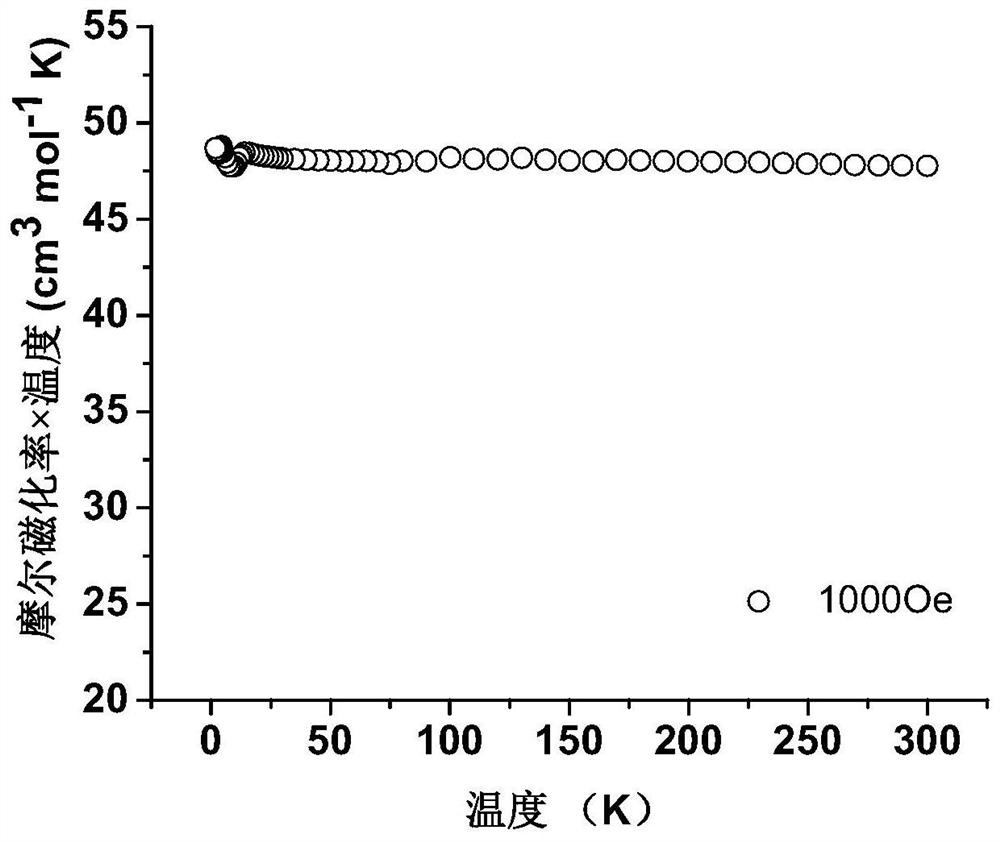

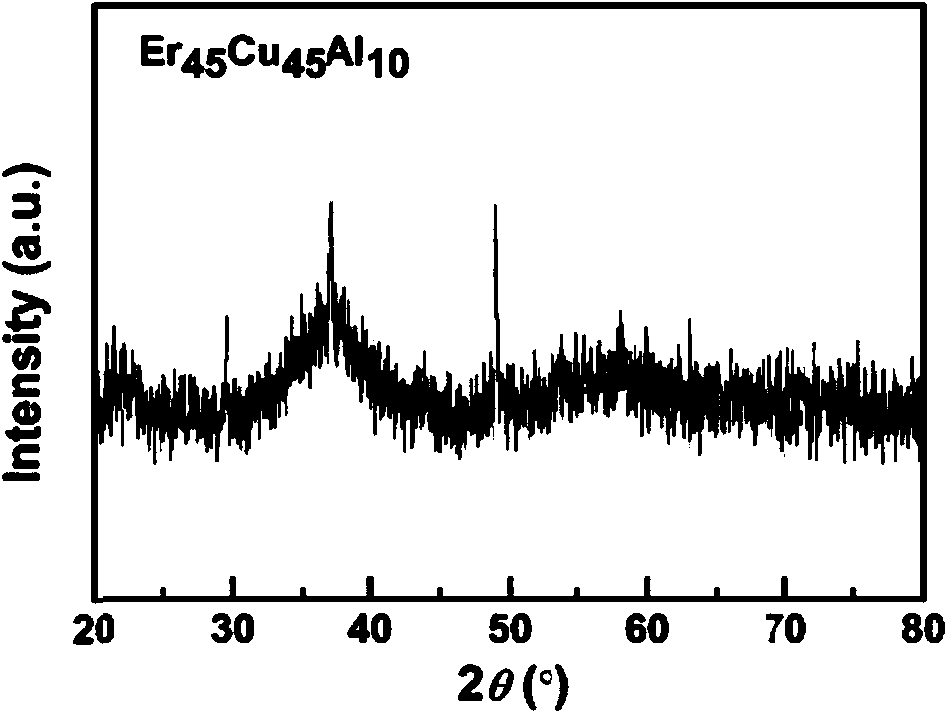

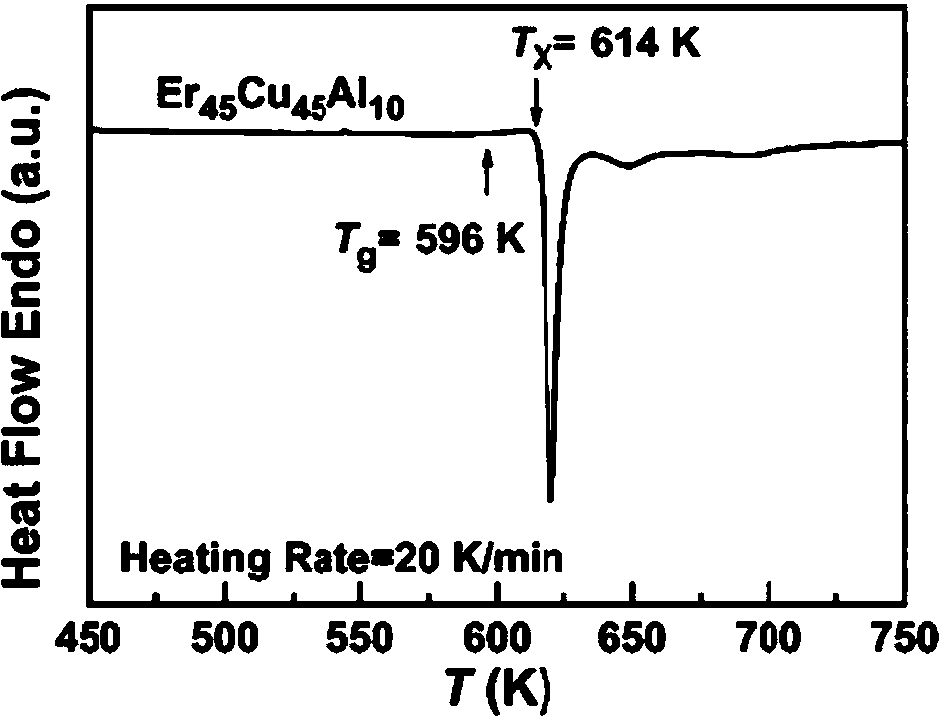

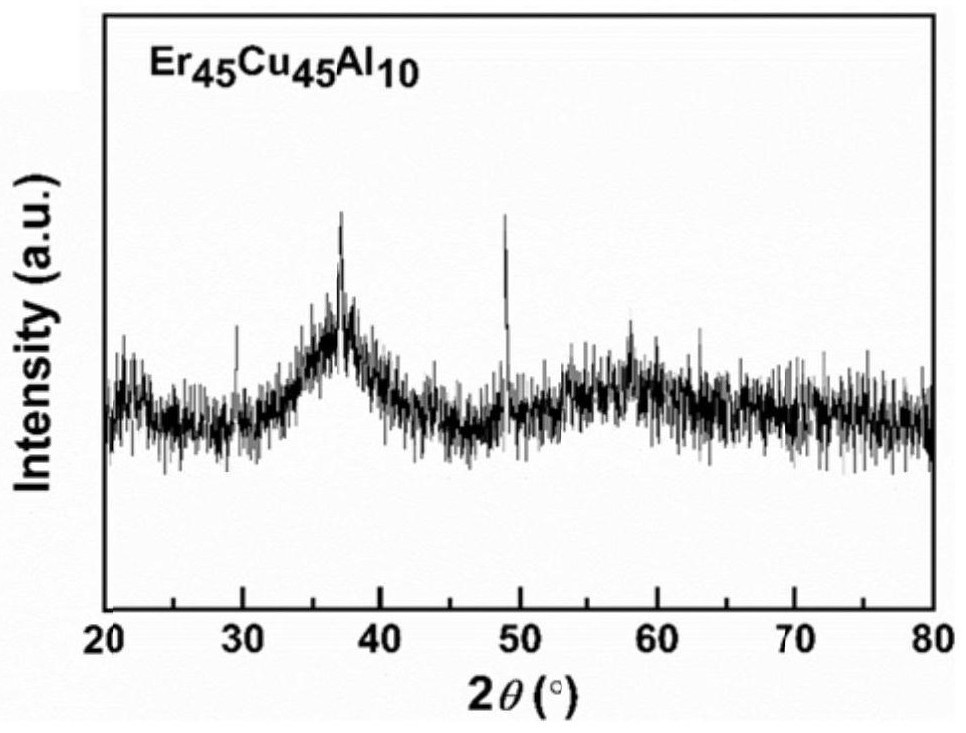

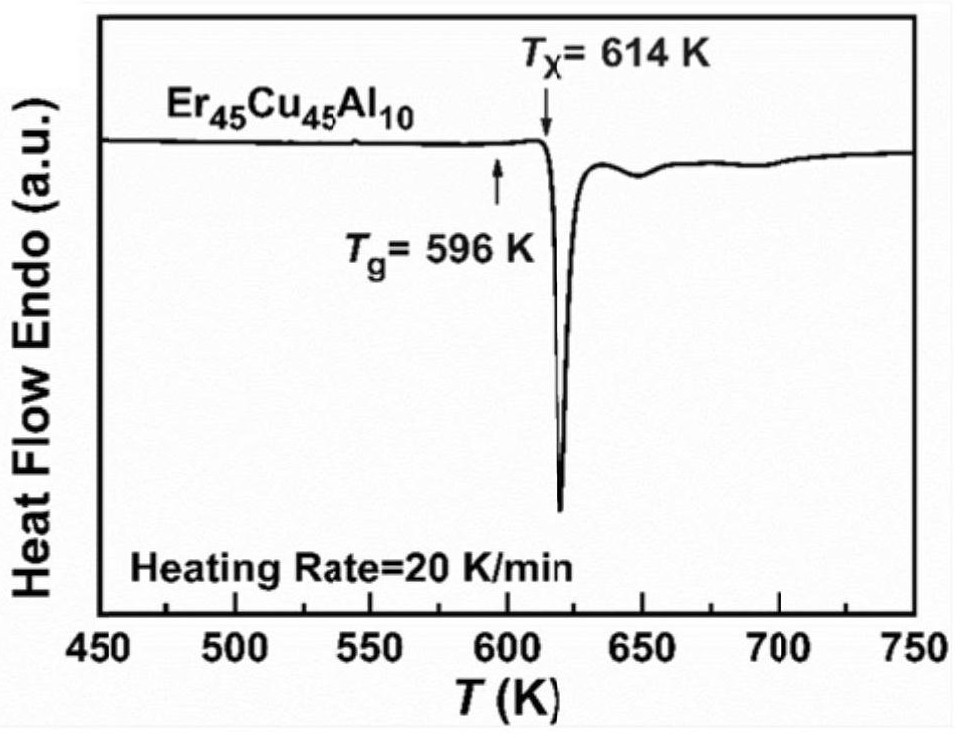

Amorphous composite not containing Fe, Co and Ni and preparation method and application of amorphous composite

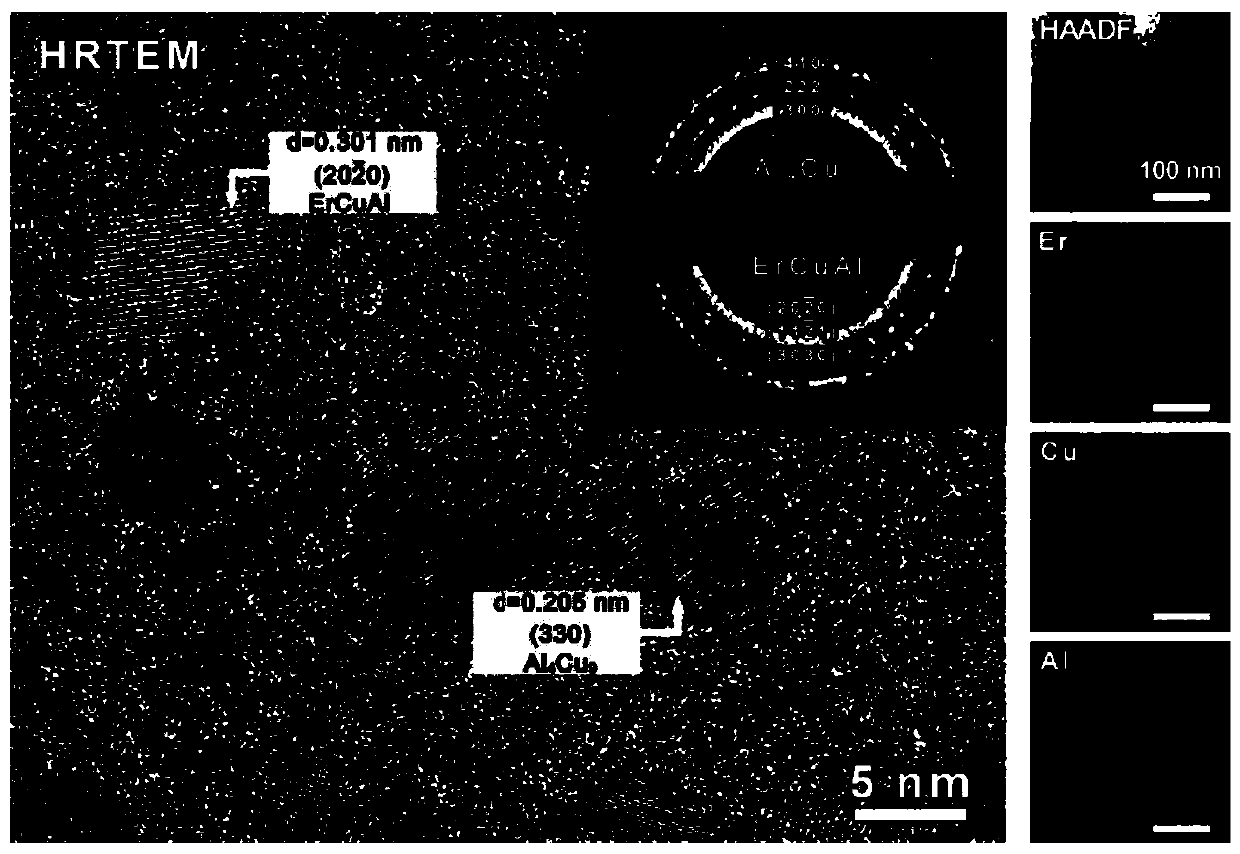

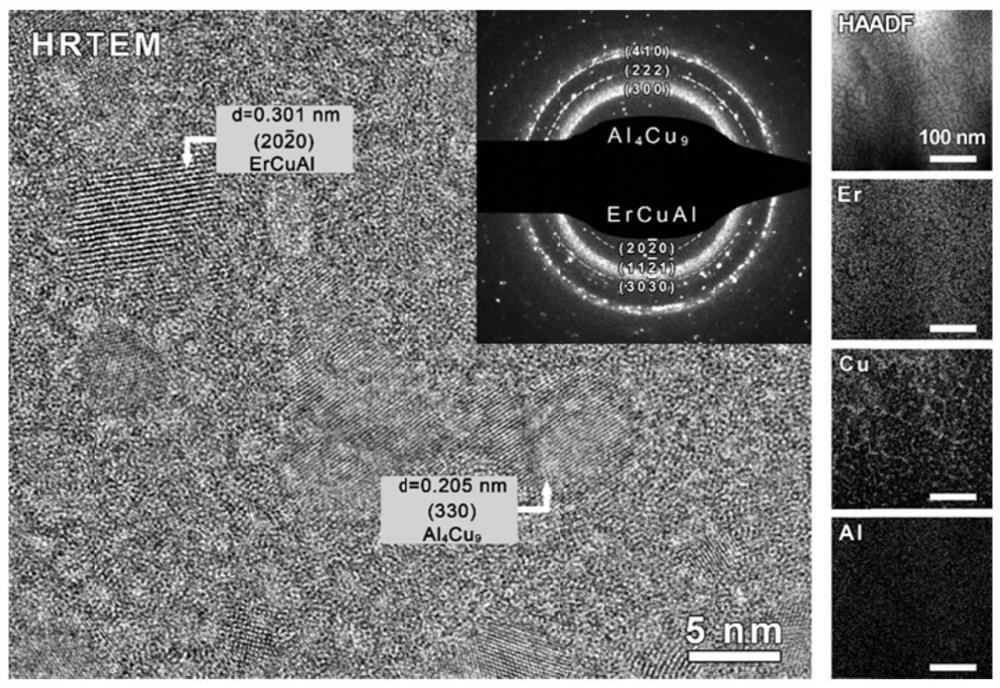

ActiveCN110983207AExcellent magnetocaloric performanceLow costRare-earth elementElectric arc furnace

The invention discloses an amorphous composite not containing Fe, Co and Ni. The chemical formula is (Er0.5Cu0.5)100-xAlx, wherein x is larger than or equal to 10 or smaller than or equal to 20. The invention further provides a preparation method of the amorphous composite. The preparation method includes the steps that (1), metal Er, metal Cu and metal Al are put in an electric arc furnace in proportion, the metal is smelted uniformly, and after the metal is cooled, a mother alloy cast ingot is obtained; and (2), the mother alloy cast ingot is re-melted into mother alloy melt, the mother alloy melt is sprayed to the surface of a rotating copper roller and subjected to shock cooling, and the strip-shaped amorphous composite is obtained. The invention further discloses application of the amorphous composite as a magnetic refrigerant material. As the amorphous composite does not contain elements such as the Fe, the Co and the Ni with a strong antiferromagnetic coupling effect with the Er, the amorphous composite has more excellent magnetothermal performance, a large magnetothermal effect can be achieved with small rare earth elements, and meanwhile the material cost is reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

RE4TCd magnetic refrigeration material and preparation method thereof

ActiveCN114561580AReduce volatilityUniform tissueTransportation and packagingMetal-working apparatusRare-earth elementMischmetal

The invention discloses an RE4TCd magnetic refrigeration material. RE is one or a mixture of two of rare earth elements Dy, Ho and Tm, and T is one or a mixture of two of transition metal elements Ni and Cu. The invention also discloses a preparation method of the RE4TCd magnetic refrigeration material, which comprises the following steps: mixing and melting the rare earth metal and the transition metal into an RE4T alloy ingot, crushing the RE4T alloy ingot, mixing the crushed RE4T alloy ingot with Cd powder, sintering in a sealed mold at high pressure and low temperature, and carrying out heat treatment to obtain the RE4TCd material. According to the RE4TCd magnetic refrigeration material and the preparation method thereof, the magnetic entropy change value of the RE4TCd magnetic refrigeration material is 16.4-25.8 J / kg K under the magnetic field change of 0-5, the RE4TCd magnetic refrigeration material has large magnetic entropy change, and the application range of the low-temperature magnetic refrigeration material is widened.

Owner:HANGZHOU DIANZI UNIV

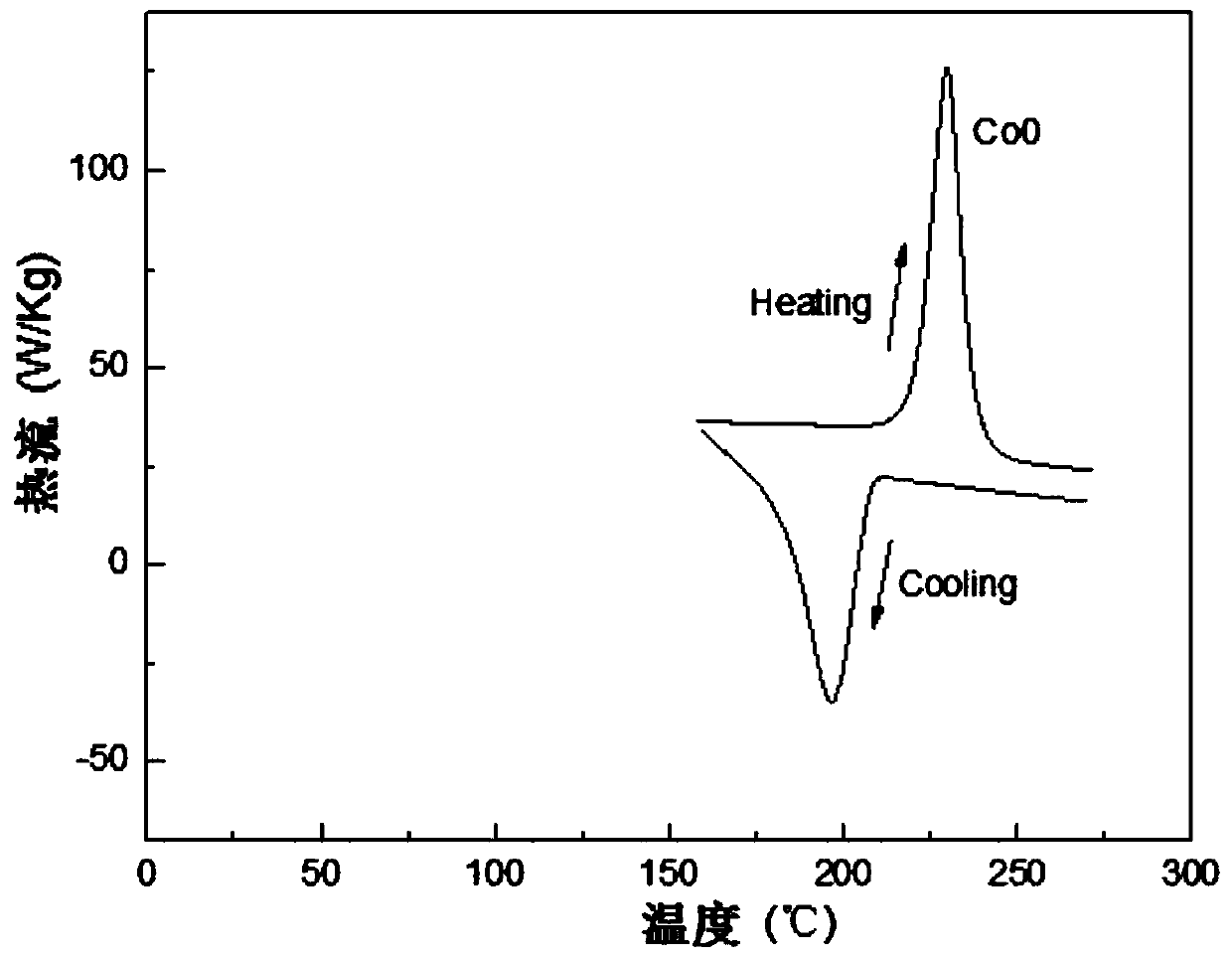

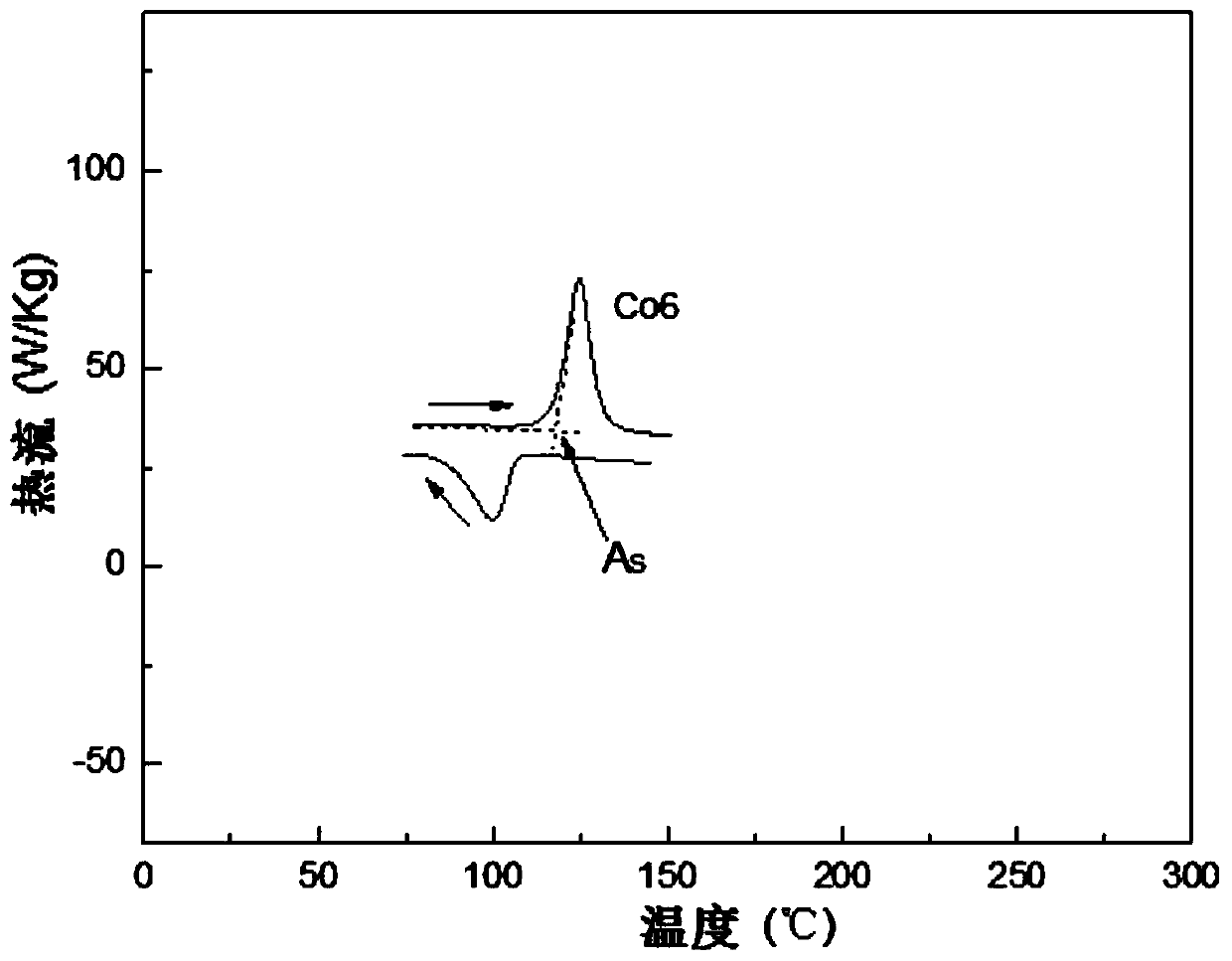

Preparation method for europium-based low-temperature magnetic refrigeration material of ThCr2Si2 structure

ActiveCN102383017BLarge magnetic entropy changeHigh magnetic refrigeration capacityHeat-exchange elementsRare earthCrystal structure

The invention relates to a europium-based low-temperature magnetic refrigeration material of a ThCr2Si2 structure and a preparation method for the europium-based low-temperature magnetic refrigeration material. The chemical general formula of the magnetic material is Eu-T-X, wherein T is Fe or Cu, and X is P or As; and the magnetic material has body-centered ThCr2Si2 tetragonal crystal structure.The method comprises the following steps of: mixing rare-earth metallic europium, transition metal and nonmetal in a ratio to form a raw material, wherein the transition metal is Fe or Cu, and the nonmetal is P or As; putting the raw material into a quartz container, vacuumizing, closing, heating the quartz container to the temperature of between 400 and 450 DEG C, preserving heat, continuously heating the quartz container to the temperature of between 800 and 900 DEG C, and preserving heat; and performing pressure molding on the product after cooling, performing high-temperature annealing and cooling, and thus obtaining a finished product. By adopting the method of slow heating and step-by-step reaction, volatilization of P or As is effectively overcome. The method is simple in process and is easily implemented, and the prepared magnetic refrigeration material has good magnetic and thermal reversible properties.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

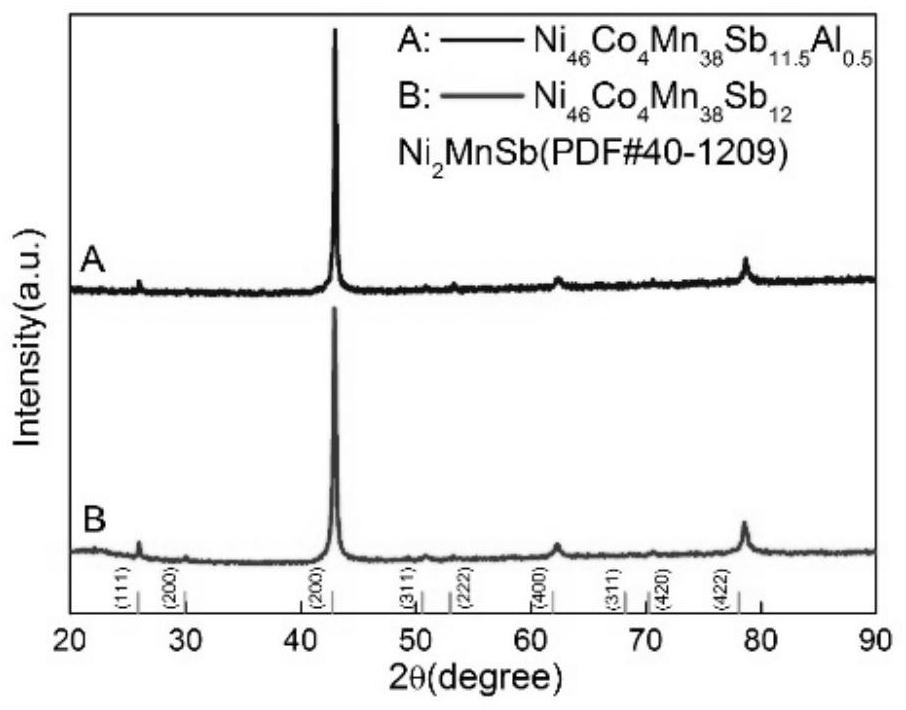

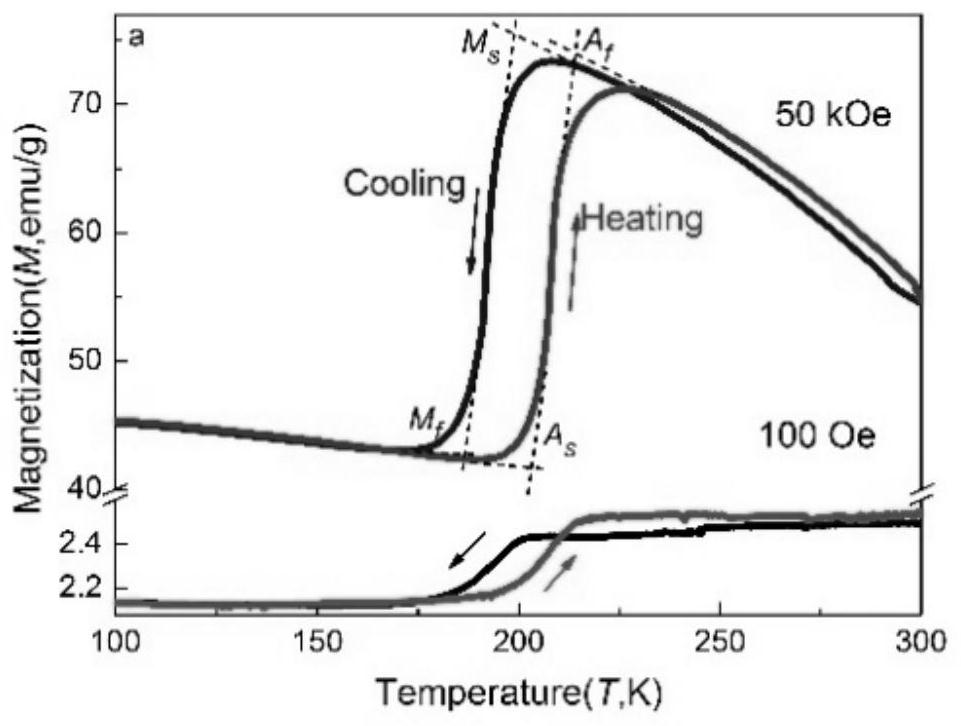

A kind of ni-co-mn-sb-al magnetic refrigeration material and preparation method thereof

InactiveCN109881074BLarge magnetic entropy changeHigh magnetic entropy changeInorganic material magnetismCooling effectMagneto

A kind of Ni-Co-Mn-Sb-Al magnetic refrigeration alloy material and preparation method thereof, the chemical general formula of described Ni-Co-Mn-Sb-Al material is Ni 46 co 4 mn 38 Sb 12‑x Al x , where 0≤x≤0.5. In the invention, the as-cast alloy ingot is prepared through raw material proportioning, repeated vacuum arc melting, and annealing treatment, thereby preparing a Ni-Co-Mn-Sb-Al magnetic refrigeration alloy block. The magnetic refrigeration material prepared by the invention has large magnetic entropy, good refrigeration effect, good mechanical properties, easy processing, simple and easy preparation method and good application prospect.

Owner:HUBEI UNIV +1

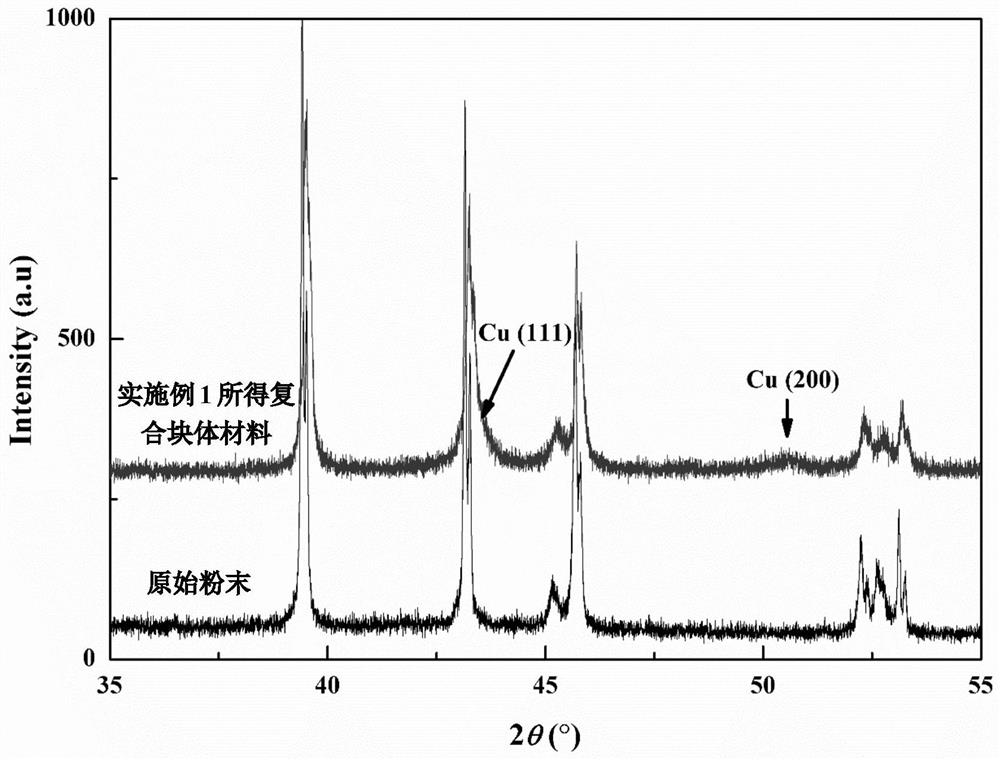

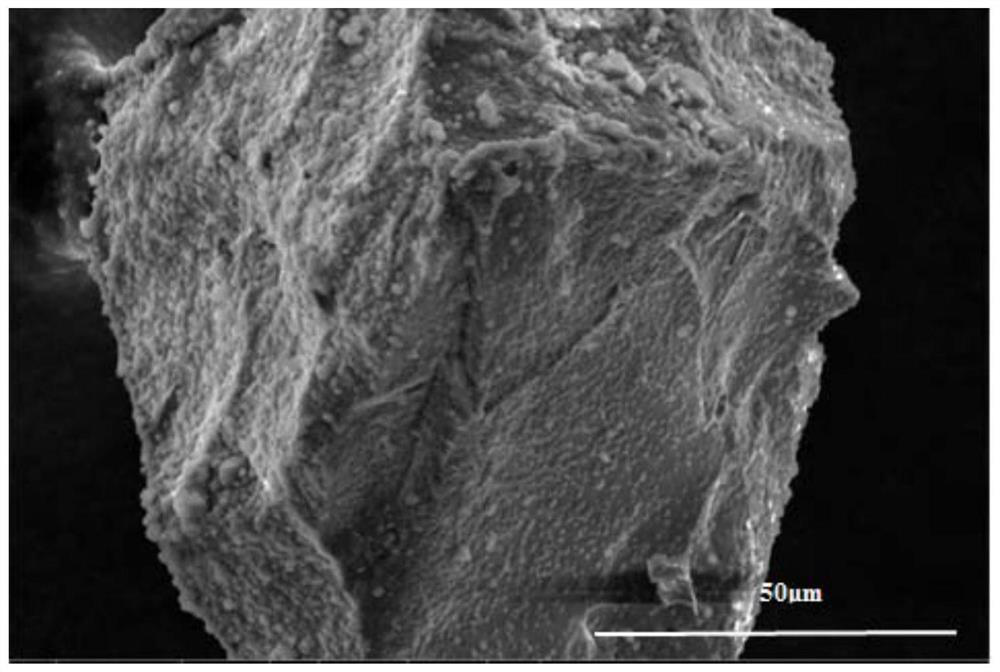

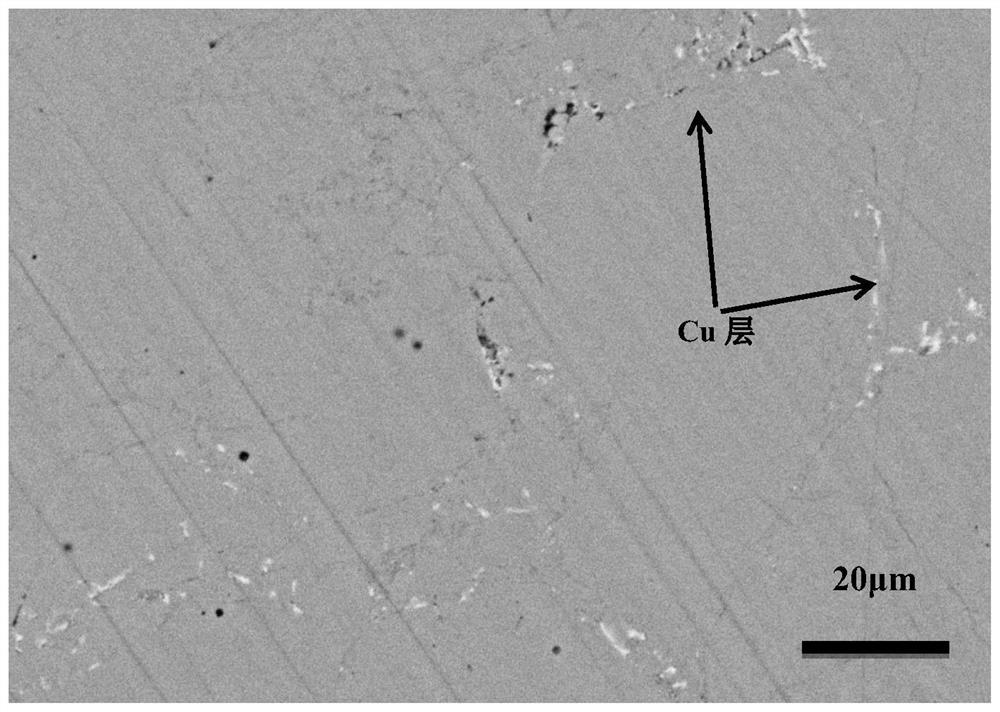

A kind of preparation method of mnfepsi-based magnetic refrigeration composite material

ActiveCN110684909BHigh thermal conductivityHigh magnetic entropy changeMachines using electric/magnetic effectsSustainable buildingsMagnetic refrigerationCopper sulfate

Owner:NANJING UNIV OF SCI & TECH +1

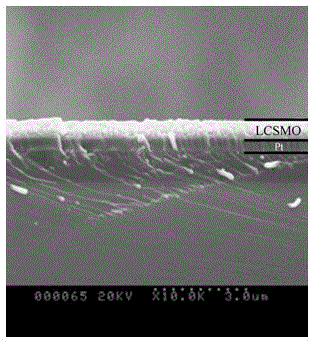

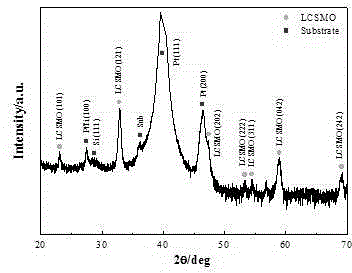

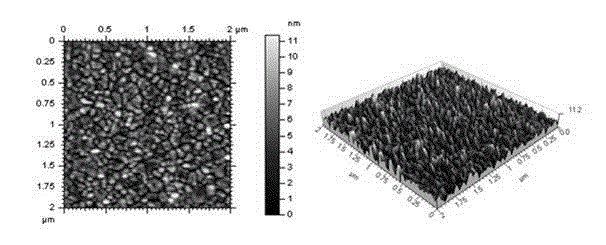

A preparation method of la0.7ca0.25sr0.05mno3 ferromagnetic film

Owner:JILIN NORMAL UNIV

A kind of amorphous composite material not containing Fe, Co, Ni and its preparation method and application

ActiveCN110983207BLarge magnetocaloric effectLarge magnetic entropy changeRare-earth elementElectric arc furnace

The invention discloses an amorphous composite material not containing Fe, Co, Ni, the chemical formula is (Er 0.5 Cu 0.5 ) 100‑x al x , where 10≤x≤20. The present invention also provides the preparation method of the amorphous composite material, comprising the steps of: (1) putting metal Er, Cu and Al in an electric arc furnace in proportion, melting evenly, and obtaining a master alloy ingot after cooling; (2) ) re-melting the master alloy ingot into a master alloy melt, spraying the master alloy melt onto the surface of a rotating copper roller, and quenching to obtain a strip-shaped amorphous composite material. The invention also discloses the application of the amorphous composite material as a magnetic refrigerant material. Because the amorphous composite material of the present invention does not contain elements having strong antiferromagnetic coupling effects with Er such as Fe, Co, Ni, etc., it has more excellent magneto-caloric properties, and can realize larger magneto-caloric properties with less rare earth elements. Magnetocaloric effect, while saving material cost.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of mn-fe-p-si magnetic refrigeration material and preparation method thereof

The invention belongs to the field of magnetic refrigeration materials, and discloses an Mn-Fe-P-Si magnetic refrigeration material and a preparation method thereof. The material composition is selectively Mn1.15Fe0.85P0.52Si0.45B0.03. The preparation method comprises the following steps: (1) mixing Mn sheets, Fe blocks, FeP blocks, Si blocks and B blocks after weighing according to the mass percentages of elements in a chemical formula, wherein 5% of balance is added to the Mn; (2) putting raw materials prepared in the step (1) into a vacuum electric arc furnace, and utilizing high-purity argon gas shield for smelting to obtain an alloy pig; (3) breaking up the alloy pig, putting into a vacuum rapid quenching furnace for smelting alloy, and carrying out copper mold casting; (4) sealing the copper mold casting alloy into a quartz tube, vacuumizing to below 10<-4> Pa, carrying out annealing treatment, and then rapidly quenching into cold water to obtain the magnetic refrigeration material. The mn-Fe-P-Si magnetic refrigeration material is simple in technology, low in cost, and the magnetic refrigeration material with high density and excellent magnetocaloric effect can be obtained.

Owner:SOUTH CHINA UNIV OF TECH

A kind of gd-ni-al based amorphous nanocrystalline composite material and preparation method thereof

InactiveCN105970118BExpand the range of refrigeration applicationsGuaranteed heat recovery balanceHeat-exchange elementsRefrigeration temperatureMagnetic refrigeration

The invention discloses a Gd-Ni-Al-based amorphous and nanocrystalline composite material. The molecular formula of the Gd-Ni-Al-based amorphous and nanocrystalline composite material is GdaNibAlc, wherein a, b and c represent atom contents of corresponding elements, 80<=a<=90, 5.8<=b<=11.6, 4.2<=c<=8.4, and the equation that a+b+c=100 is satisfied. The Gd-Ni-Al-based amorphous and nanocrystalline composite material is of an amorphous / nanocrystalline complex phase structure and has two refrigeration temperature zones and one or two magnetic entropy change platforms, the high-temperature magnetic order temperature is 270 K or above, and the magnetic entropy change under a 5T magnetic field can reach 6.7 J / kg / K. Because magnetic transition temperature intervals are wide, the refrigeration capacity reaches up to 640 J / kg or above, and the Gd-Ni-Al-based amorphous and nanocrystalline composite material is a good magnetic refrigeration material and can be used as a magnetic refrigeration working material in the two intervals of the two refrigeration temperature zones.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Ni-co-mn-sn-cu alloy with high temperature, high toughness and large magnetocaloric effect, preparation method and application thereof

InactiveCN110423934BIncrease working temperatureImprove mechanical propertiesInorganic material magnetismCoils manufactureMagnetic refrigerationToughness

The invention relates to a high-temperature high-toughness Ni-Co-Mn-Sn-Cu alloy with a high magnetocaloric effect, a preparation method, and application thereof, belongs to the technical field of magnetic materials, and particularly relates to the high-temperature high-toughness Ni-Co-Mn-Sn-Cu alloy with the high magnetocaloric effect, the preparation method, and the application thereof. The invention aims to solve the problems that an existing Ni-Mn-Sn ferromagnetic shape-memory alloy system is high in brittleness and hard to meet the use requirement under high temperature environment. A chemical general formula is Ni48-xCoxMn37Sn9Cu6, wherein x is mole fraction and is larger than 0 and smaller than or equal to 12; and the sum of mole number of elements in the alloy is 100. The method comprises the steps of (1) preparing materials; (2) carrying out electric arc meting; and (3) carrying out homogenization treatment so as to finally obtain an Ni48-xCoxMn37Sn9Cu6 magnetic refrigeration alloy material.

Owner:HARBIN UNIV OF SCI & TECH

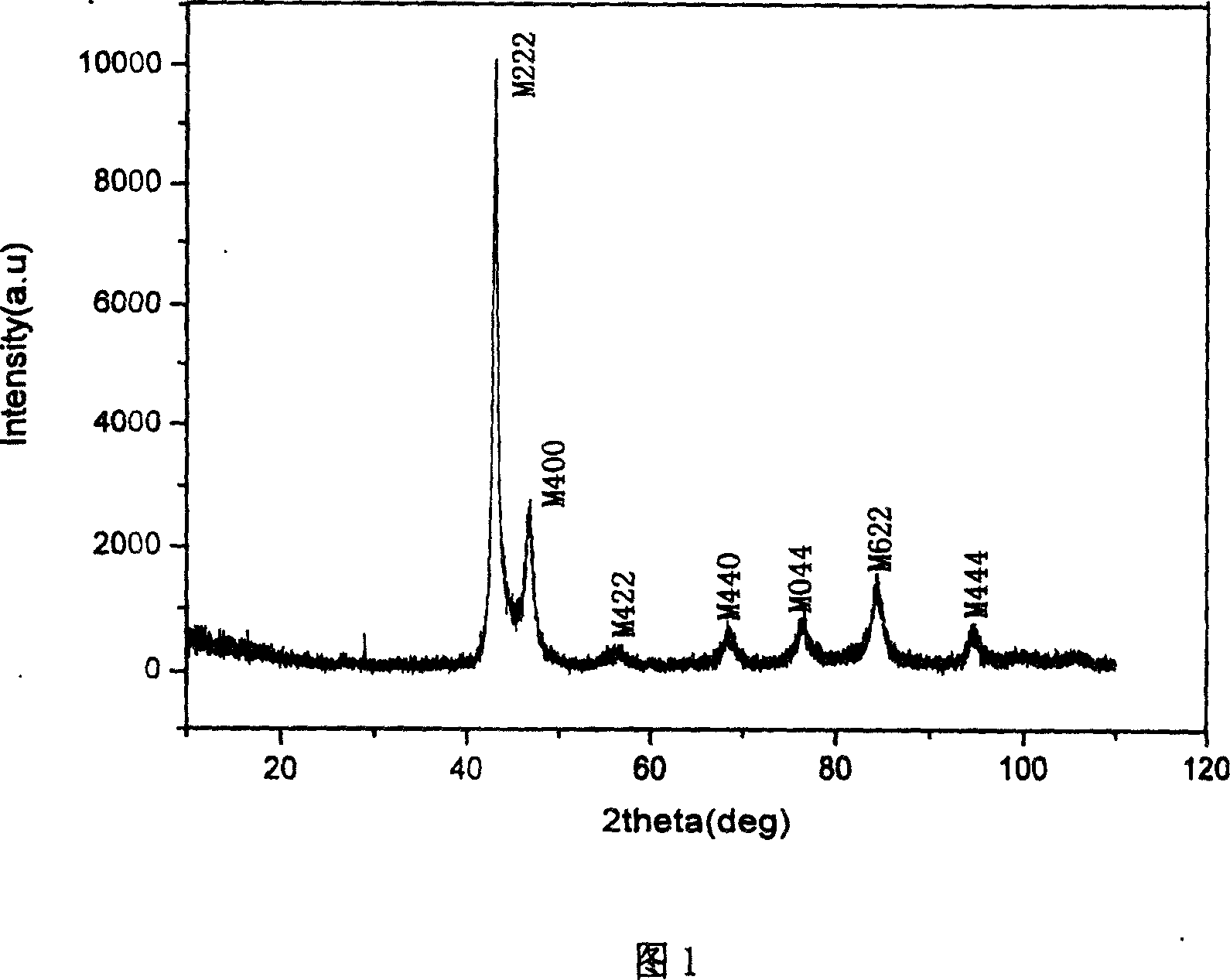

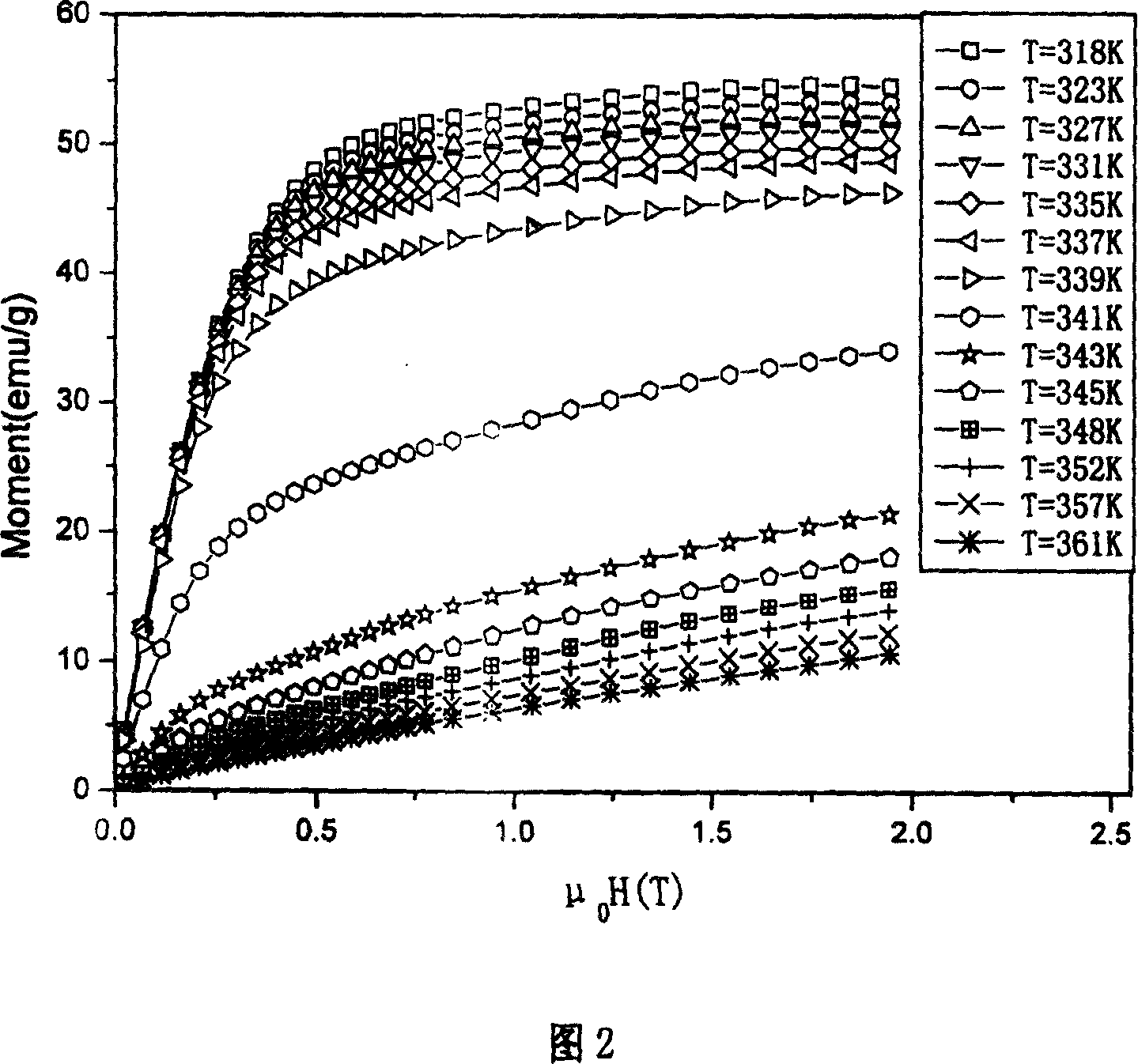

Compounds with large magnetic entropy changes and their preparation

InactiveCN1304615CSimple preparation processLarge magnetic entropy changeMagnetic materialsThermoelectric devicesElectric arc furnaceManganese

Owner:UNIV OF SCI & TECH BEIJING

Thulium-based metallic glass, preparation method and application

ActiveCN103668008BMagnetic transition temperature range is wideLow critical cooling rateRare-earth elementMagnetic transitions

The invention discloses a thulium-based metallic glass and its preparation method and application. The thulium-based metallic glass is mainly composed of thulium, and its composition is shown in formula (I), wherein, RE means selected from Ce, Pr, Nd, One or more rare earth elements in Sm, Gd, Tb, Dy, Ho and Er; T represents Co or Ni; a, b, c, d represent the atomic percentage of each element, 30≤a≤60, 5≤ b≤30, 20≤c≤25, 15≤d≤25, 50≤a+b≤60 and a+b+c+d=100. According to the thulium-based metallic glass of the present invention, the change of RE and T can modulate the amorphous forming ability on the one hand, and on the other hand can modulate the temperature range in which the magnetic transition of the thulium-based metallic glass occurs, broaden the magnetic transition region, and make it work in a wider range. It has a large magnetocaloric effect in the temperature range. TmaREbAlcTd (I).

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

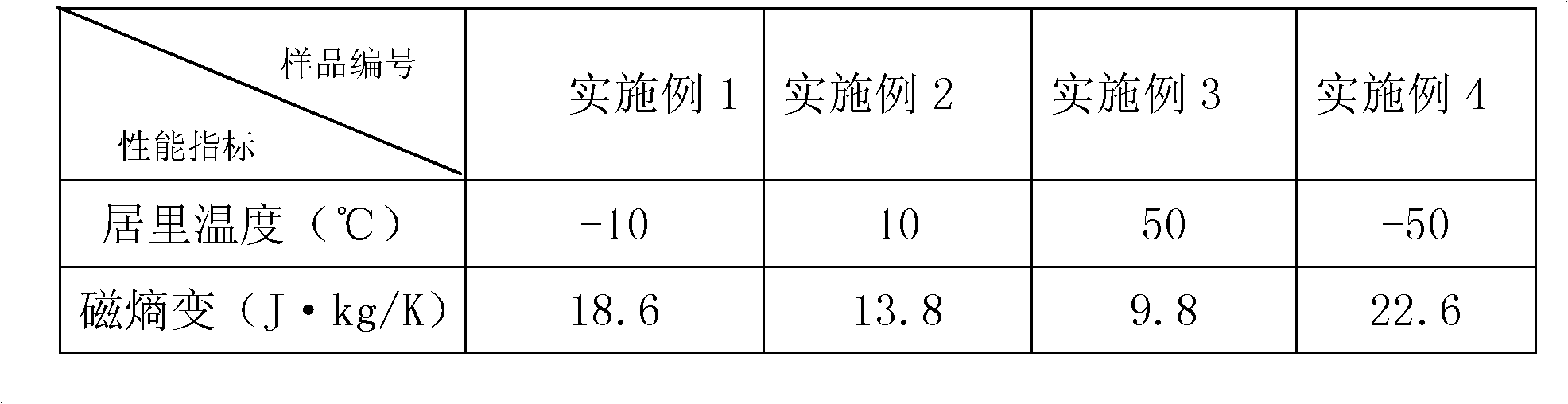

Preparation method for manganese-ferrum-phosphorus-silicon magnetic cooling alloy

A preparation method for manganese-ferrum-phosphorus-silicon magnetic cooling alloy belongs to the technical field of magnetic material preparation. At first, manganese powder, ferrum powder, phosphorus powder and silicon powder, which serve as raw materials, are mixed according to the mole ratio of 2-x : x : 1-y : y to obtain a nominal composition: Mn2-xFexP1-ySiy, wherein x is larger than or equal to 0.8 and less than or equal to 1.0, and y is larger than or equal to 0.4 and less than or equal to 0.6; then, the high energy ball milling is conducted and the spark plasma sintering is performed under vacuum so as to obtain a manganese-ferrum-phosphorus-silicon alloy block body; and finally, the obtained manganese-ferrum-phosphorus-silicon alloy block body is subjected to heat treatment under the protection of argon so as to obtain the manganese-ferrum-phosphorus-silicon magnetic cooling alloy with an excellent magnetocaloric property. The curie temperature of the manganese-ferrum-phosphorus-silicon magnetic cooling alloy is adjusted through regulating the manganese-ferrum ratio and the phosphorus-silicon ratio within the temperature range from 50 DEG C below zero to 50 DEG C; and the obtained manganese-ferrum-phosphorus-silicon alloy has a greater magnetic entropy change under a 2 tesla field, thereby being beneficial to be used in a room-temperature area magnetic cooling technology.

Owner:赣州兮泓永磁技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com