Gd-based amorphous nanocrystal composite with high Curie temperature and refrigerating capacity and preparation method of Gd-based amorphous nanocrystal composite

A technology of amorphous, nanocrystalline and cooling capacity, applied in the field of Gd-based amorphous and nanocrystalline composite materials and its preparation, can solve the problems of limiting the application of magnetic refrigeration materials, difficult to balance, high Curie temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

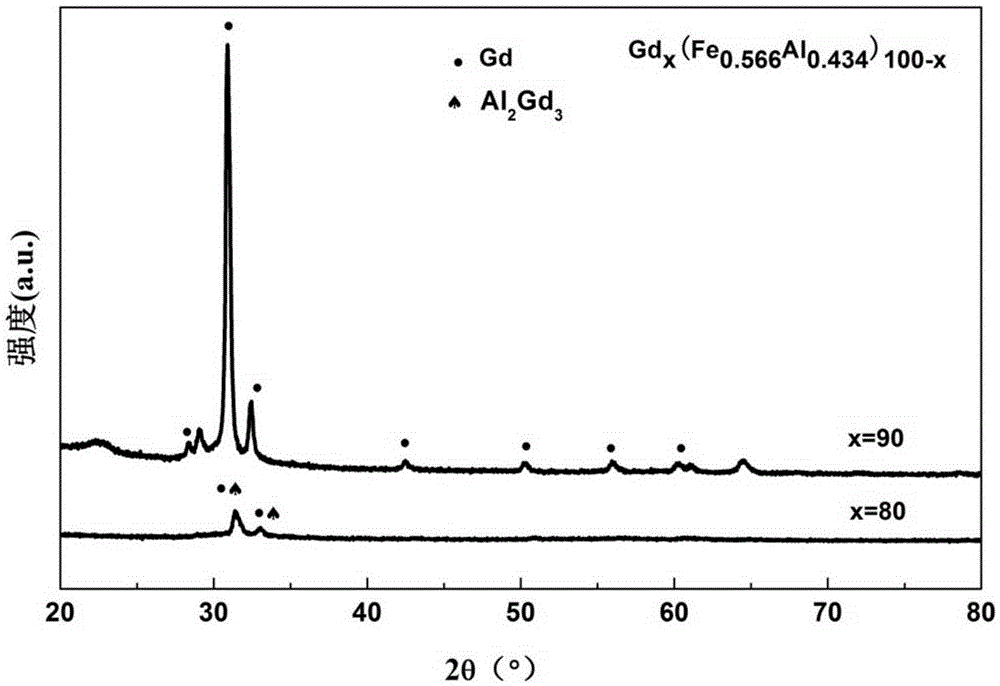

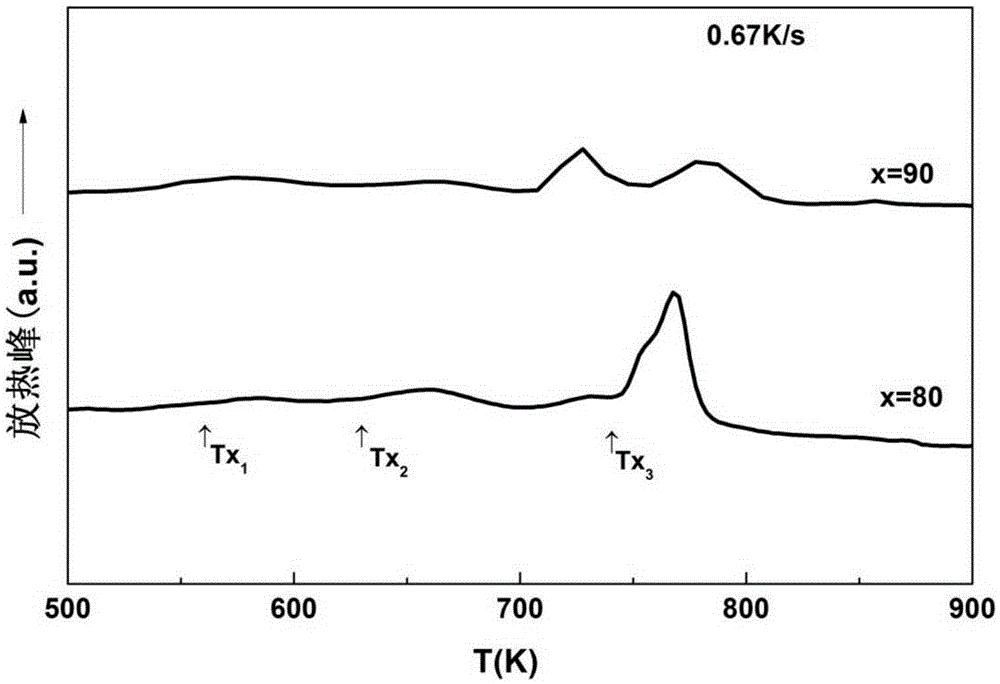

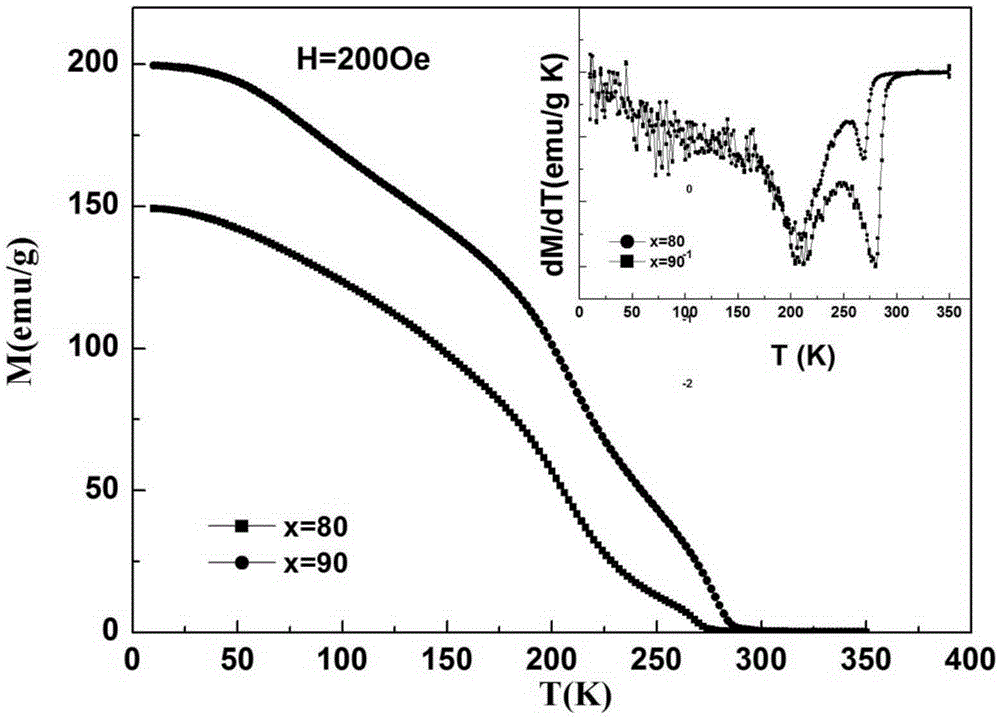

[0029] In this embodiment, the molecular formula of the amorphous nanocrystalline composite material is Gd 80 Fe 11.3 Al 8.7 .

[0030] The amorphous-nanocrystalline composite Gd 80 Fe 11.3 Al 8.7 The preparation includes the following steps:

[0031] Step 1: Elements Gd, Fe and Al with a purity of 99.99% or more are separated according to Gd 80 Fe 11.3 Al 8.7 The atomic ratio of each element in the sample is evenly mixed to obtain the raw material, and the total weight of the raw material is 20g;

[0032] Step 2: Put the raw materials prepared in step 1 into a non-consumable vacuum arc melting furnace, use Ti to absorb oxygen, and pump low vacuum and high vacuum to 7×10 -4Pa; then fill the furnace cavity with high-purity argon to clean it, use high-purity argon of 0.5-0.7 atmospheres as a protective gas, repeat the smelting for 6 times, and obtain a master alloy ingot with uniform composition after cooling;

[0033] Step 3: Grinding the master alloy ingot obtained i...

Embodiment 2

[0039] In this embodiment, the molecular formula of the amorphous nanocrystalline composite material is Gd 90 Fe 5.7 al 4.3 .

[0040] The amorphous-nanocrystalline composite Gd 90 Fe 5.7 al 4.3 The preparation includes the following steps:

[0041] Step 1: Elements Gd, Fe and Al with a purity of 99.99% or more are separated according to Gd 90 Fe 5.7 al 4.3 The atomic ratio of each element in the sample is evenly mixed to obtain the raw material, and the total weight of the raw material is 20g;

[0042] Step 2: Put the raw materials prepared in step 1 into a non-consumable vacuum arc melting furnace, use Ti to absorb oxygen, and use mechanical pump and molecular pump to pump high vacuum to 7×10 -4 Pa; then fill in high-purity argon to clean the furnace cavity three times, fill in high-purity argon with a pressure of about 0.5-0.7 atmospheres as a protective gas, repeat smelting for 6 times, and obtain an alloy ingot with uniform composition after cooling;

[0043] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Maximum magnetic entropy change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com