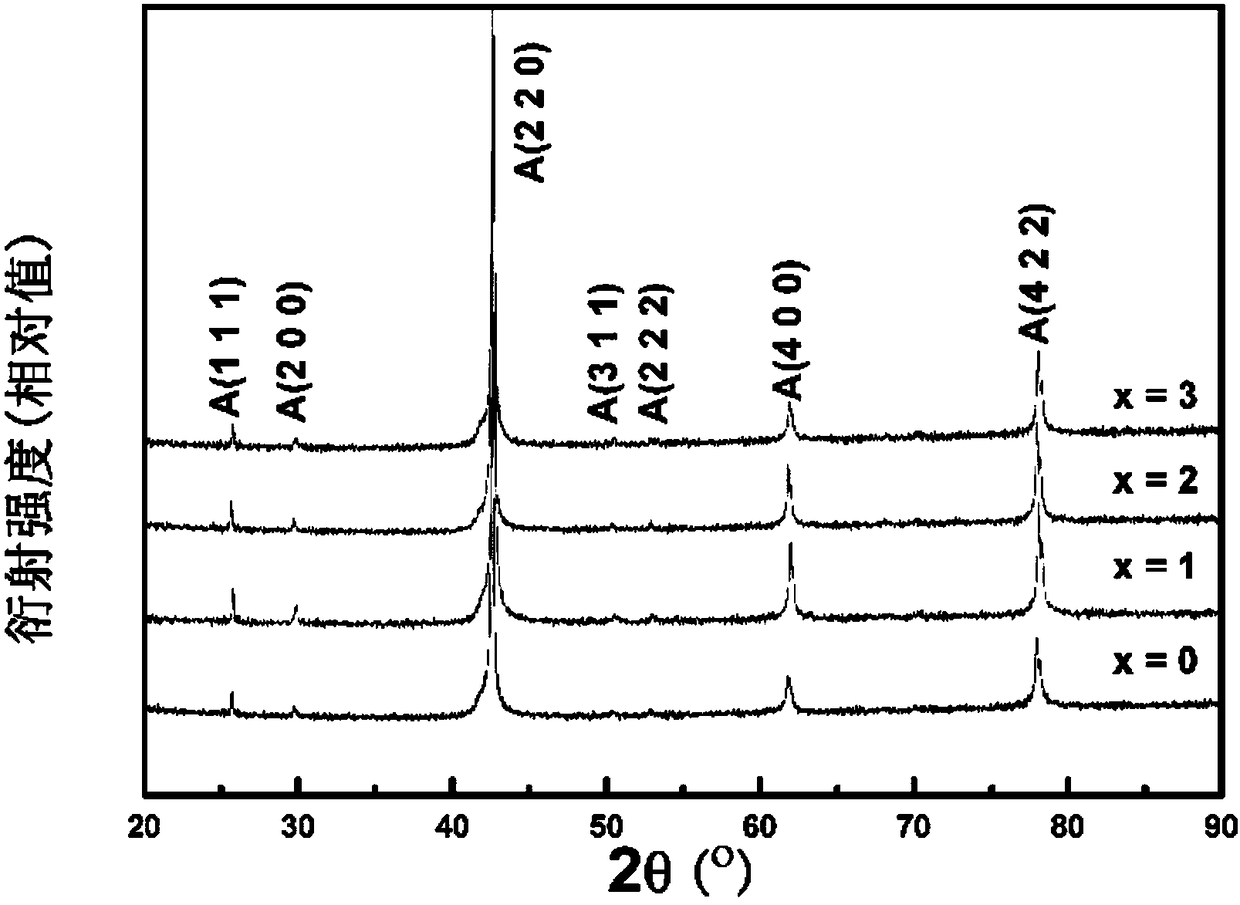

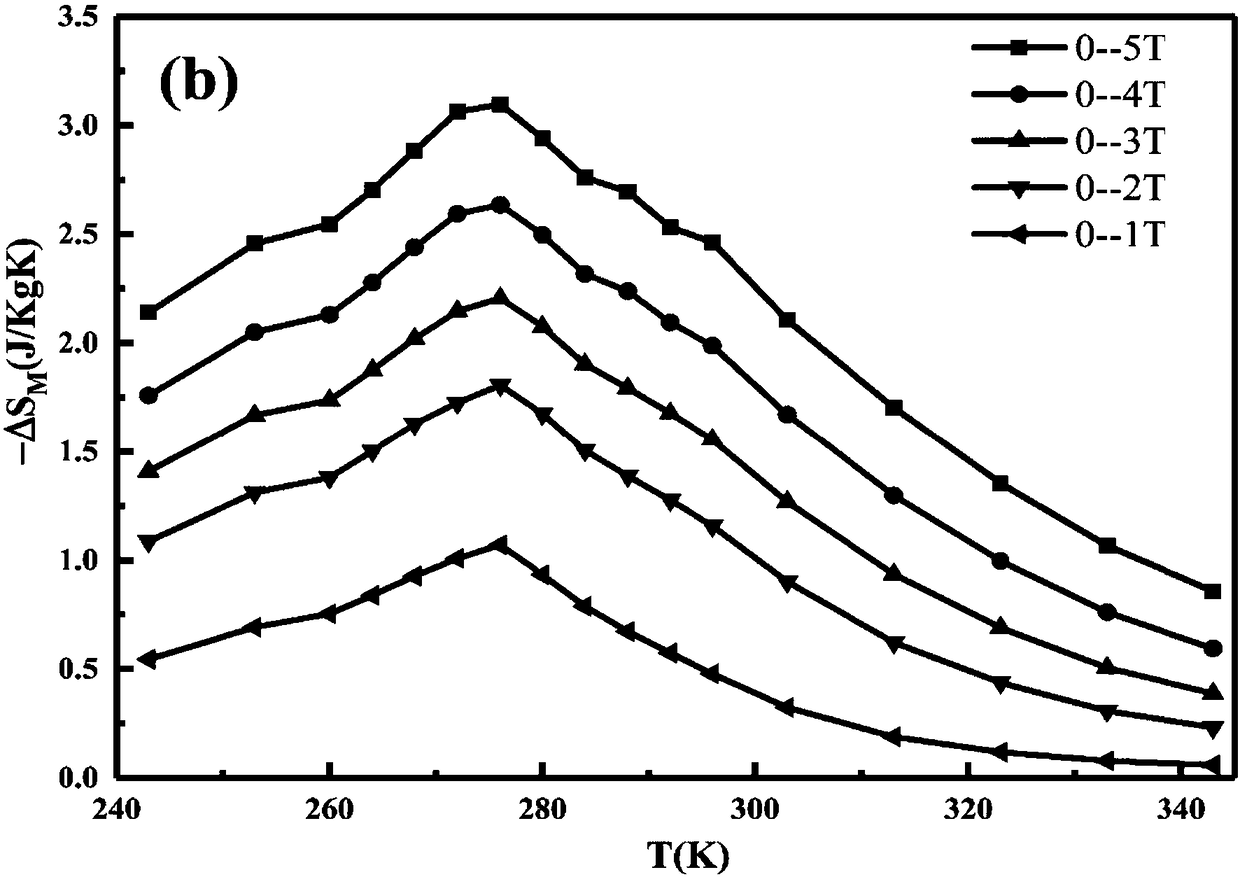

Ni-Co-Mn-Sn magnetic refrigeration material and preparation method thereof

A ni-co-mn-sn, magnetic refrigeration material technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problems of limited practical application, pulverization, low Curie temperature, etc., to improve the working range And magnetocaloric properties, increase the saturation magnetization, the effect of smooth magnetic entropy curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

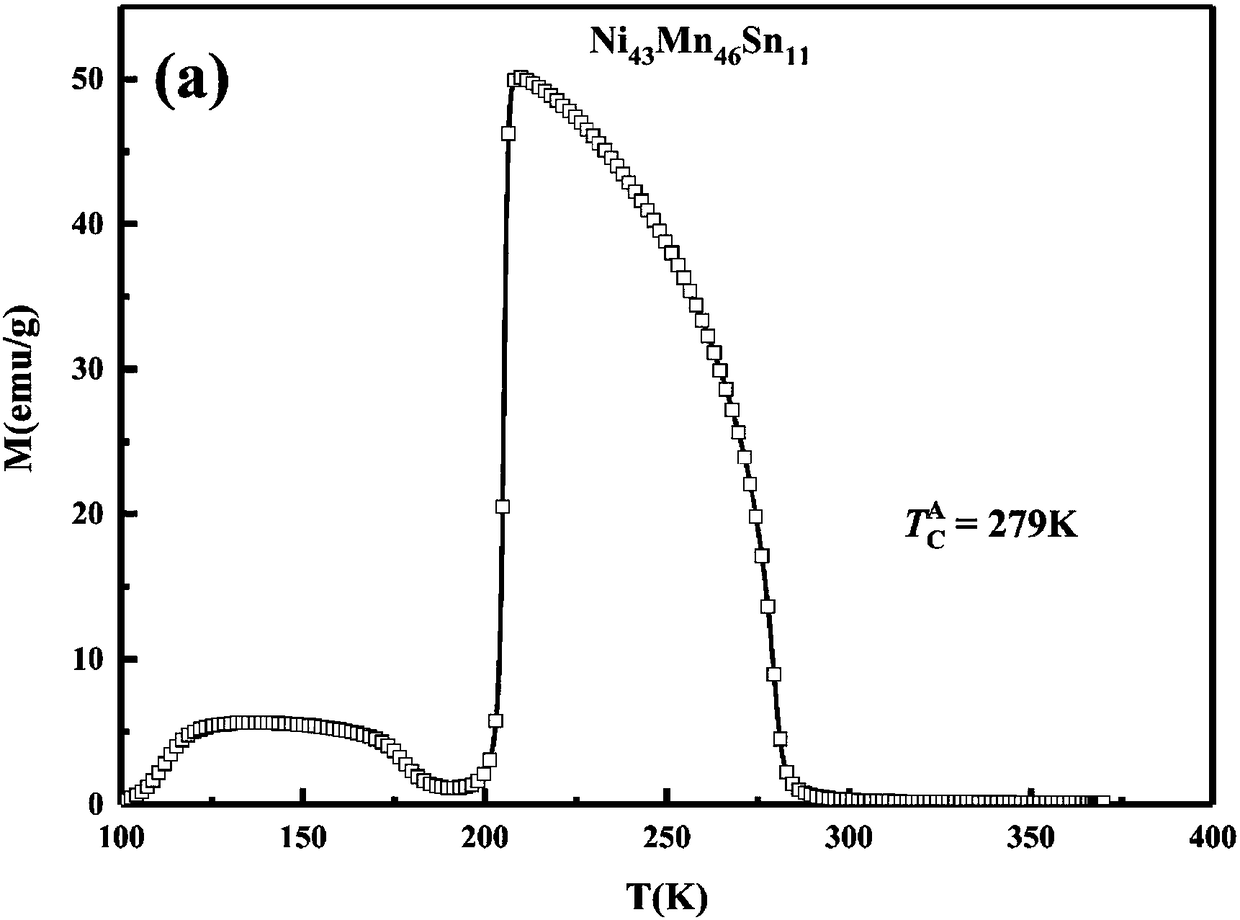

Embodiment 1

[0041] Step 1: Ni, Mn, Sn are weighed and mixed according to the molar ratio of elements Ni:Mn:Sn=43:46:11, and Mn is added with a balance of 1.5% of its mass;

[0042] Step 2: Put the raw materials configured in step 1 into the vacuum electric arc furnace, and vacuumize to 10 -3 Pa, after cleaning the furnace with high-purity argon, fill it with 0.04MPa high-purity argon, and repeat the melting for 5 times under the protection of high-purity argon to obtain a button-shaped alloy ingot with uniform composition.

[0043] Step 3: After simple mechanical crushing of the alloy ingot prepared in Step 2, put it into a quartz nozzle, fix the quartz tube in the induction coil, and evacuate to 10 -4 Pa, after cleaning the furnace with high-purity argon, fill it with high-purity argon with a pressure difference of 0.08MPa, and perform single-roll melt rapid quenching under its protection, and the tangential linear speed of the copper roll is 20m / s.

[0044] Step 4: Seal the strip sample ...

Embodiment 2

[0049] Step 1: Ni, Mn, Co, Sn are weighed and mixed according to the molar ratio of elements Ni: Co: Mn: Sn = 42:1:46:11, and Mn is added with a balance of 1.5% of its mass;

[0050] Step 2: Put the raw materials configured in step 1 into the vacuum electric arc furnace, and vacuumize to 10 -3 Pa, after cleaning the furnace with high-purity argon, fill it with 0.04MPa high-purity argon, and repeat the melting for 5 times under the protection of high-purity argon to obtain a button-shaped alloy ingot with uniform composition.

[0051] Step 3: After simple mechanical crushing of the alloy ingot prepared in Step 2, put it into a quartz nozzle, fix the quartz tube in the induction coil, and evacuate to 10 -4 Pa, after cleaning the furnace with high-purity argon, fill it with high-purity argon with a pressure difference of 0.08MPa, and perform single-roll melt rapid quenching under its protection, and the tangential linear speed of the copper roll is 20m / s.

[0052] Step 4: Seal t...

Embodiment 3

[0057] Step 1: Ni, Mn, Co, Sn are weighed and mixed according to the molar ratio of elements Ni: Co: Mn: Sn = 41:2:46:11, and Mn is added with a balance of 1.5% of its mass;

[0058] Step 2: Put the raw materials configured in step 1 into the vacuum electric arc furnace, and vacuumize to 10 -3 Pa, after cleaning the furnace with high-purity argon, fill it with 0.04MPa high-purity argon, and repeat the melting for 5 times under the protection of high-purity argon to obtain a button-shaped alloy ingot with uniform composition.

[0059] Step 3: After simple mechanical crushing of the alloy ingot prepared in Step 2, put it into a quartz nozzle, fix the quartz tube in the induction coil, and evacuate to 10 -4 Pa, after cleaning the furnace with high-purity argon, fill it with high-purity argon with a pressure difference of 0.08MPa, and perform single-roll melt rapid quenching under its protection, and the tangential linear speed of the copper roll is 20m / s.

[0060] Step 4: Seal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Maximum magnetic entropy change | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com