Preparation method for manganese-ferrum-phosphorus-silicon magnetic cooling alloy

A magnetic refrigeration and phosphorus-silicon technology, which is applied in the field of preparation of manganese-iron-phosphorus-silicon magnetic refrigeration alloys, can solve problems such as unfavorable environmental protection, difficulty in synthesizing manganese-iron-phosphorus-silicon materials, and difficulty in solving manganese-iron-phosphorus-silicon materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

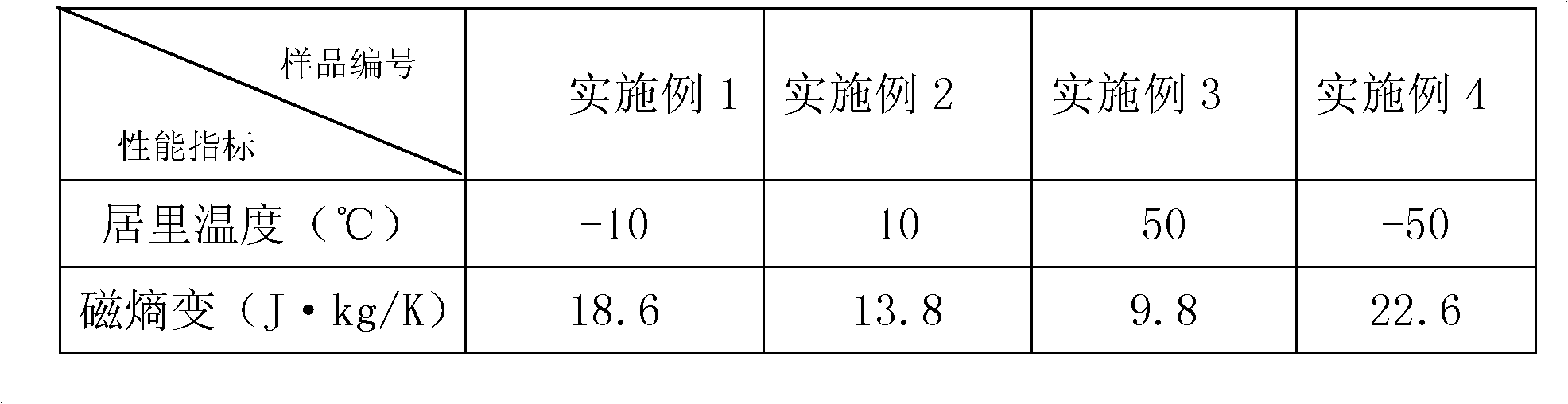

Embodiment 1

[0012] Manganese, iron, phosphorus, silicon four powder raw materials according to Mn 1.2 Fe 0.8 P 0.6 Si 0.4 The nominal composition (molar ratio) ratio of the mixed powder is subjected to high-energy ball milling, and the technological conditions of the ball milling are: the ball-to-material ratio is 1:10, and the ball-milling time is 2 hours. Spark plasma sintering is carried out on the powder after ball milling under the condition of vacuum, and the technological conditions of sintering are: temperature 920° C., time 5 minutes, pressure 30 MPa. The sintered manganese-iron-phosphorus-silicon alloy block is subjected to heat treatment under the protection of argon, and the process conditions of the heat treatment are: temperature 850° C., time 36 hours. Finally, a manganese-iron-phosphorus-silicon alloy with excellent magnetocaloric properties is obtained.

Embodiment 2

[0014] Manganese, iron, phosphorus, silicon four powder raw materials according to Mn 1.1 Fe 0.9 P 0.5 Si 0.5 The nominal composition (molar ratio) ratio of the mixed powder is subjected to high-energy ball milling, and the technological conditions of the ball milling are: the ball-to-material ratio is 1:10, and the ball-milling time is 2 hours. Spark plasma sintering is carried out on the powder after ball milling under the condition of vacuum, and the technological conditions of sintering are: temperature 940° C., time 3 minutes, pressure 30 MPa. The manganese-iron-phosphorus-silicon alloy block obtained by sintering is subjected to heat treatment under the protection of argon, and the process conditions of the heat treatment are: temperature 875° C., time 24 hours. Finally, a manganese-iron-phosphorus-silicon alloy with excellent magnetocaloric properties is obtained.

Embodiment 3

[0016] Manganese, iron, phosphorus, silicon four powder raw materials according to Mn 1.05 Fe 0.95 P 0.4 Si 0.6 The nominal composition (molar ratio) ratio of the mixed powder is subjected to high-energy ball milling, and the technological conditions of the ball milling are: the ball-to-material ratio is 1:10, and the ball-milling time is 2 hours. Spark plasma sintering is carried out on the powder after ball milling under the condition of vacuum, and the technological conditions of sintering are: temperature 930° C., time 4 minutes, pressure 30 MPa. The sintered manganese-iron-phosphorus-silicon alloy block is subjected to heat treatment under the protection of argon, and the heat treatment process conditions are: temperature 900° C., time 12 hours. Finally, a manganese-iron-phosphorus-silicon alloy with excellent magnetocaloric properties is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com