Compounds with large magnetic entropy changes and their preparation

A compound and magnetic entropy change technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problems of restricting magnetic refrigeration, difficulty in large-scale production, and insufficient high magnetic entropy change, and achieve adjustable Curie temperature and manufacturing process Simple, the effect of increasing magnetic entropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Raw materials such as nickel, manganese, gallium, etc. are classified into chemical components Ni 51.5 mn 22.7 Ga 25.8 Proportion (electron concentration is 7.513), put into vacuum electric arc furnace, induction furnace or other smelting furnace, vacuumize to 10 -1 or above, pass in argon gas, and obtain a compound with uniform composition after repeated melting and cooling. The compound obtained by smelting was homogenized at 900°C for 72 hours, and then annealed at 700°C for 60 hours. In order to prevent sample oxidation, the homogenization treatment and annealing process can be carried out under vacuum or argon protection. The sample was proved by X-ray diffraction to be a non-modulated square structure, belonging to the martensitic phase. SQUID was used to measure the magnetization curve as a function of temperature. The compound obtained through the above steps has a Curie temperature of -77°C. The calculation results show that the magnetic entropy becomes 4...

Embodiment 2

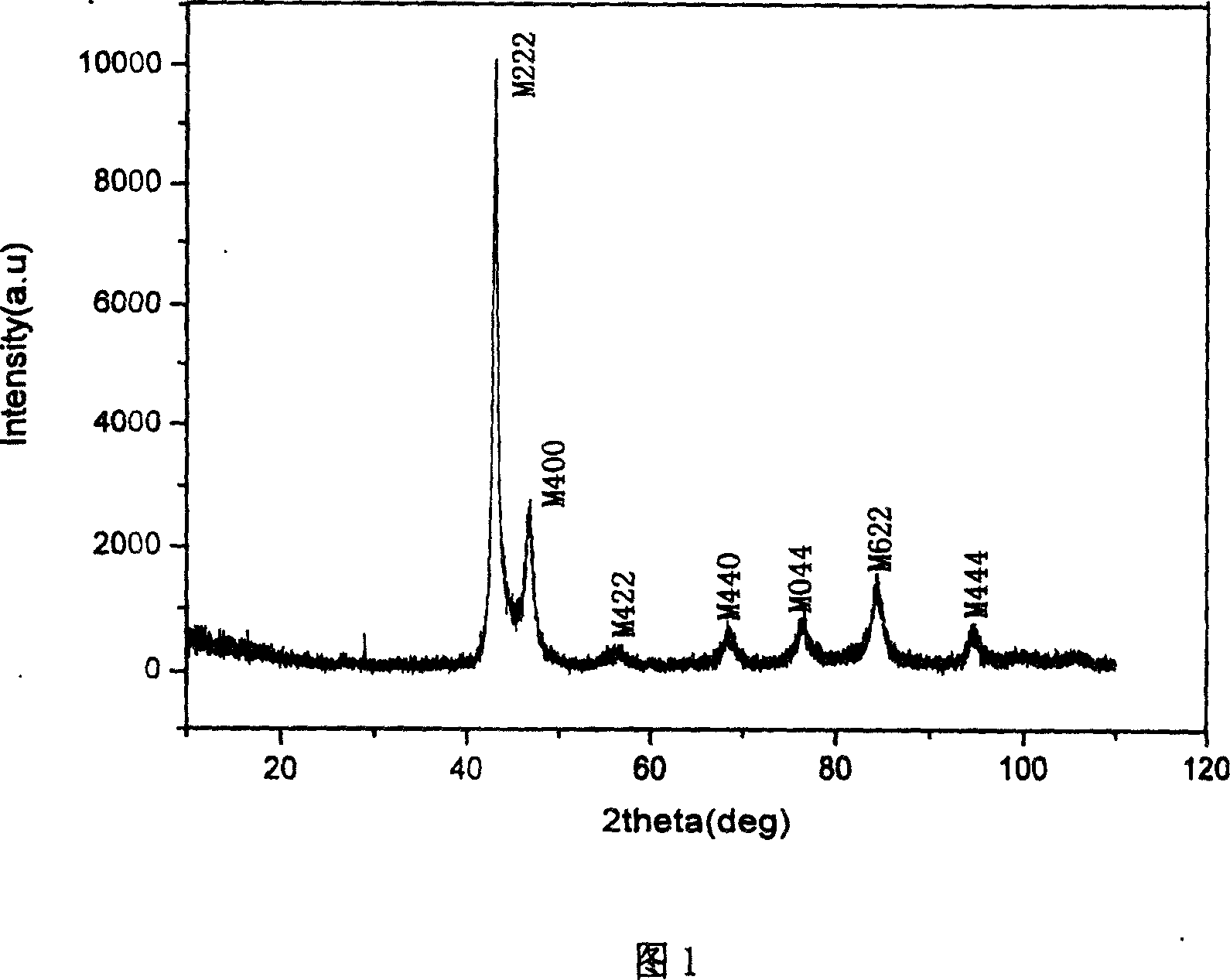

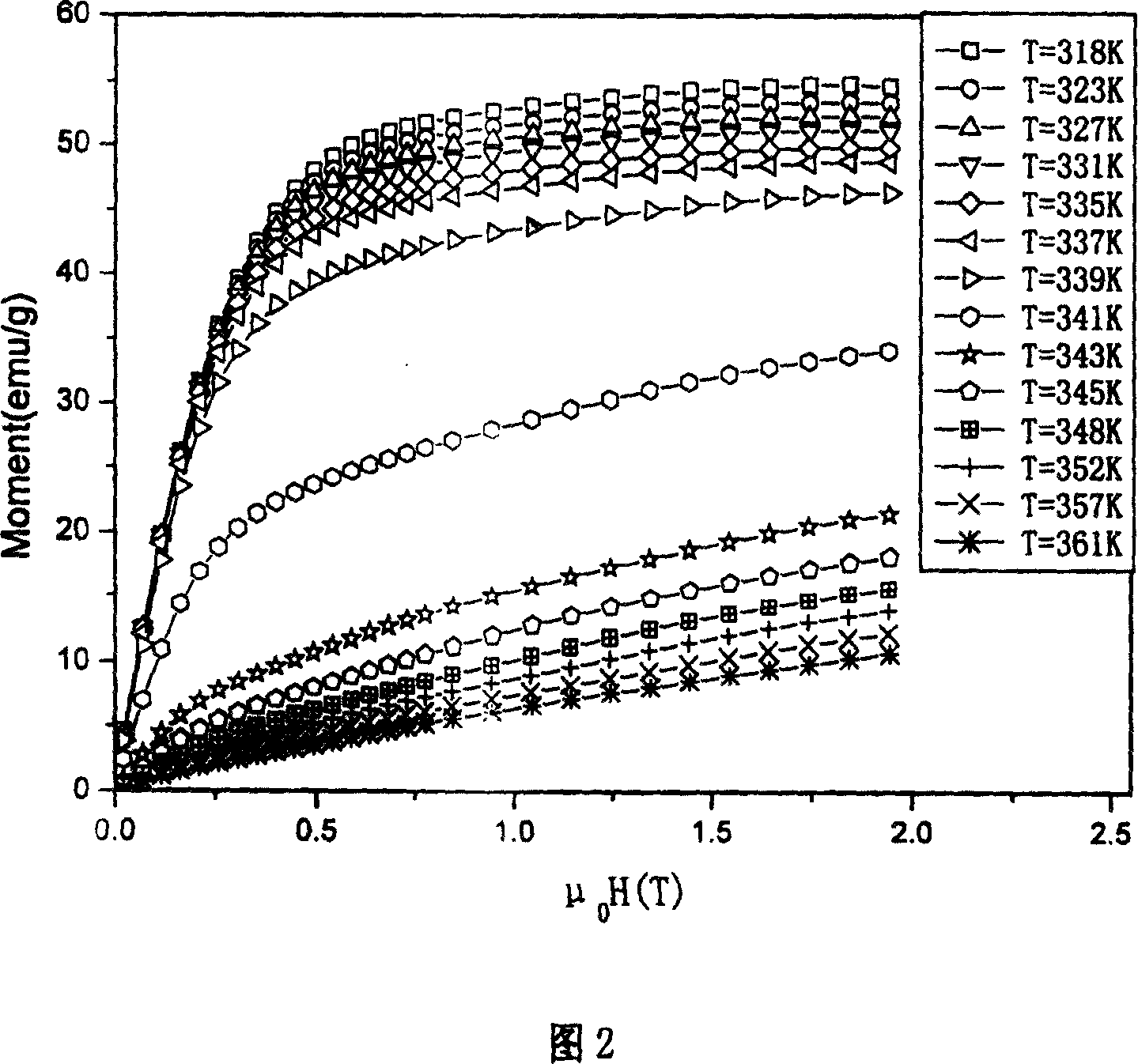

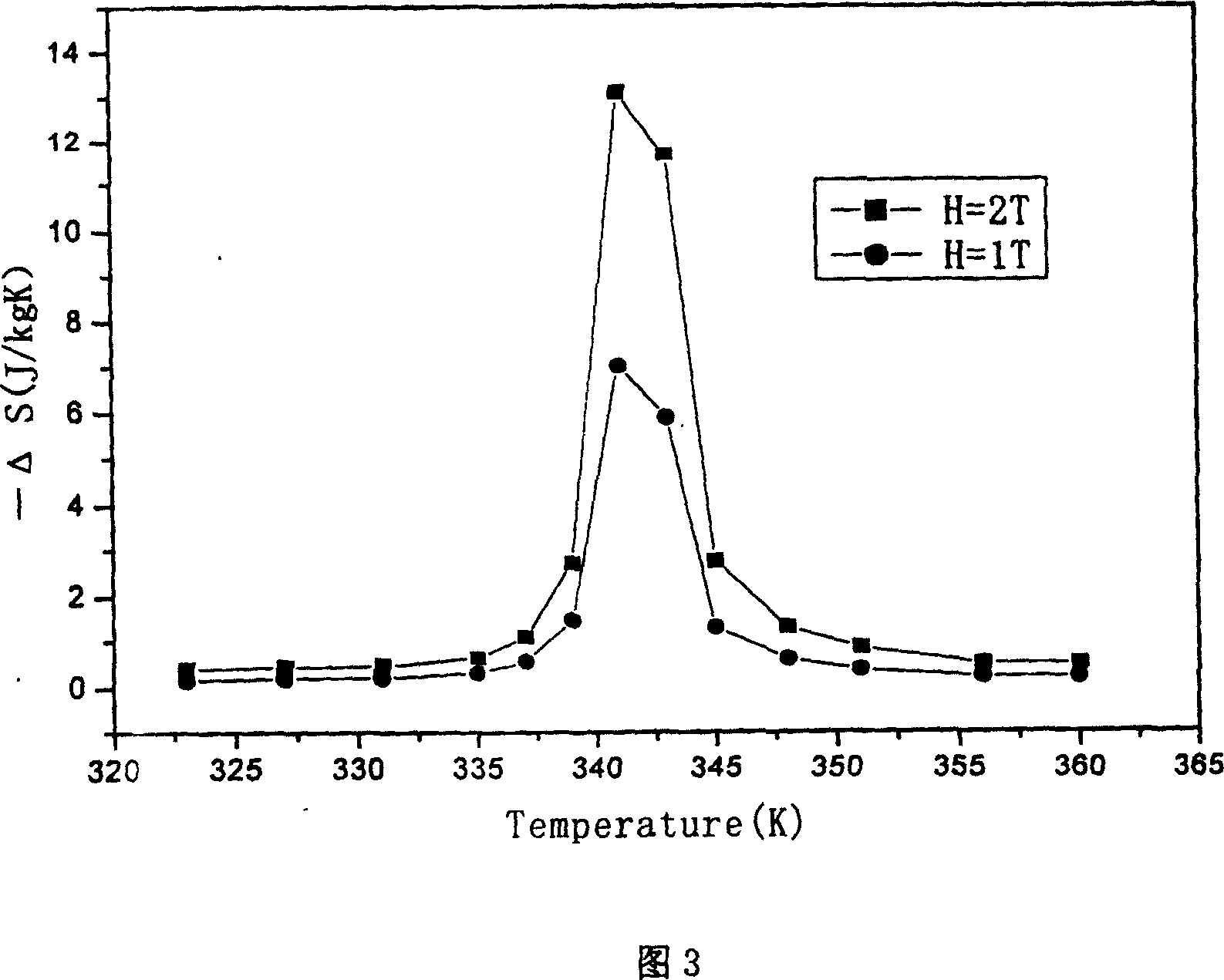

[0022] Raw materials such as nickel, manganese, gallium, etc. are classified into chemical components Ni 54.9 mn 20.5 Ga 24.6 Proportion (electron concentration is 7.663), put into vacuum electric arc furnace, induction furnace or other smelting furnace, vacuumize to 10 -1 or above, pass in argon gas, and obtain a compound with uniform composition after repeated melting and cooling. The compound obtained by smelting was homogenized at 1050°C for 48 hours, and then annealed at 650°C for 72 hours. In order to prevent sample oxidation, the homogenization treatment and annealing process can be carried out under vacuum or argon protection. The sample prepared in this way is proved by X-ray diffraction to have a non-modulated square structure and belongs to the martensitic phase (see Figure 1). The isothermal magnetization curve near the phase transition temperature was measured using a vibrating sample magnetometer LakeShore-7410 (see Figure 2). The compound obtained through t...

Embodiment 3

[0024] Raw materials such as nickel, manganese, gallium, etc. are classified into chemical components Ni 55.5 mn 19.8 Ga 24.7 Proportion (electron concentration is 7.677), put into vacuum electric arc furnace, induction furnace or other smelting furnace, vacuumize to 10 -1 or above, pass in argon gas, and obtain a compound with uniform composition after repeated melting and cooling. The compound obtained by smelting was homogenized at 950°C for 72 hours, and then annealed at 750°C for 48 hours. In order to prevent sample oxidation, the homogenization treatment and annealing process can be carried out under vacuum or argon protection. The sample prepared in this way is proved by X-ray diffraction to have a non-modulated square structure and belongs to the martensitic phase (see Figure 4). The isothermal magnetization curve near the phase transition temperature was measured using a vibrating sample magnetometer LakeShore-7410 (see Figure 5). The compound obtained through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com