Patents

Literature

36results about How to "Large magnetocaloric effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

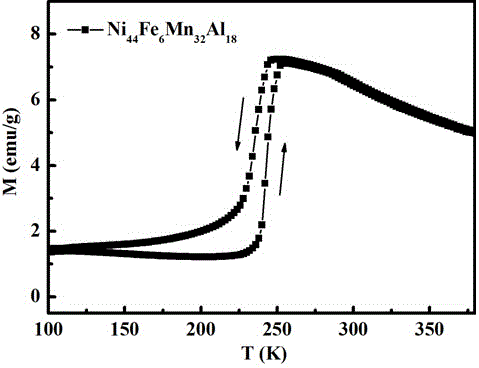

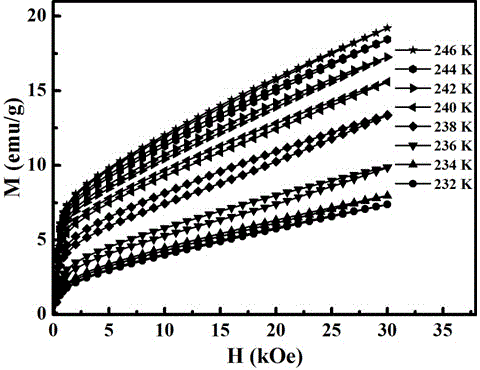

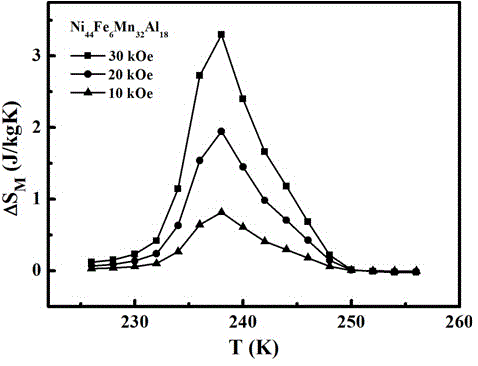

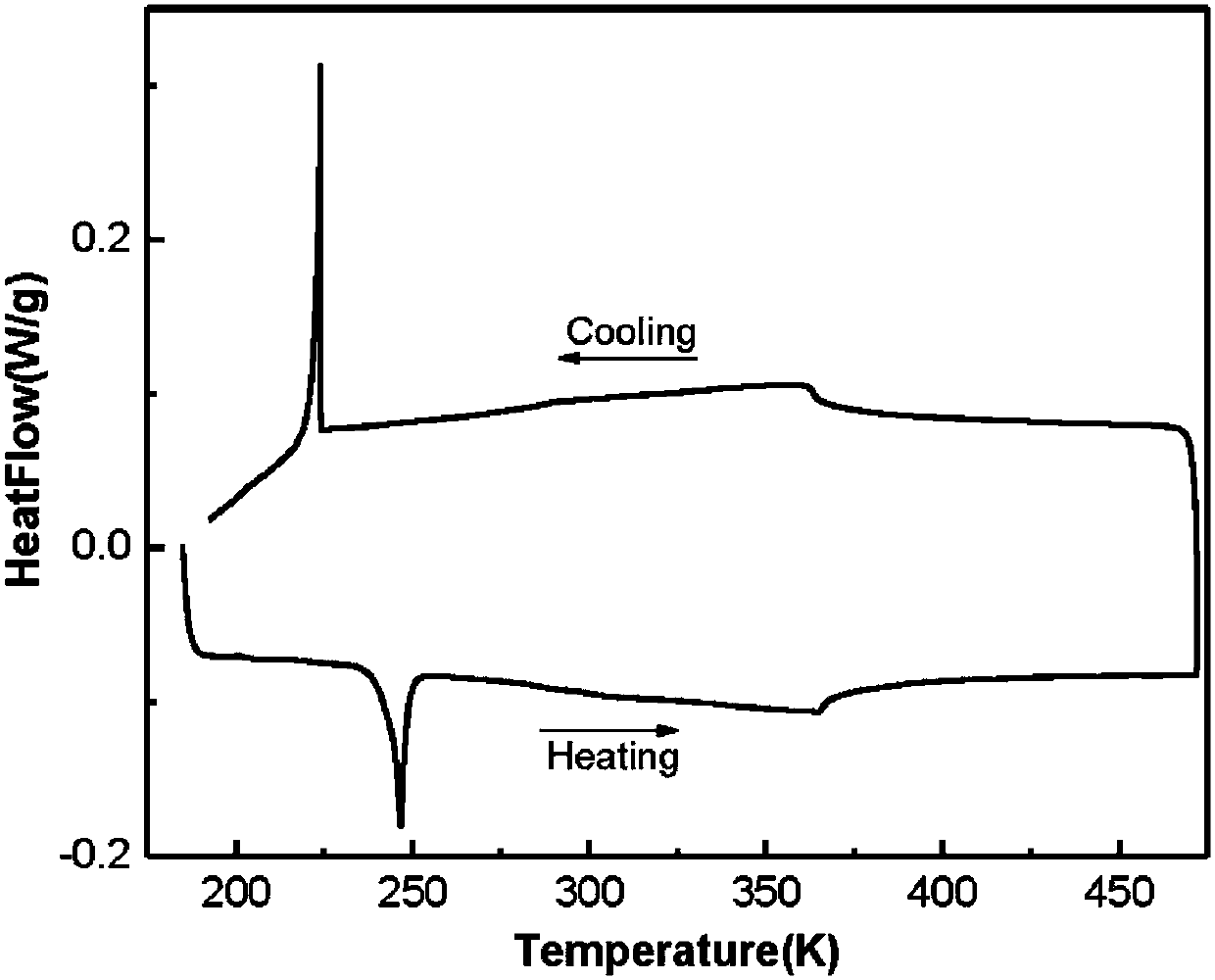

Ni-Fe-Mn-Al alloy material and preparation method thereof

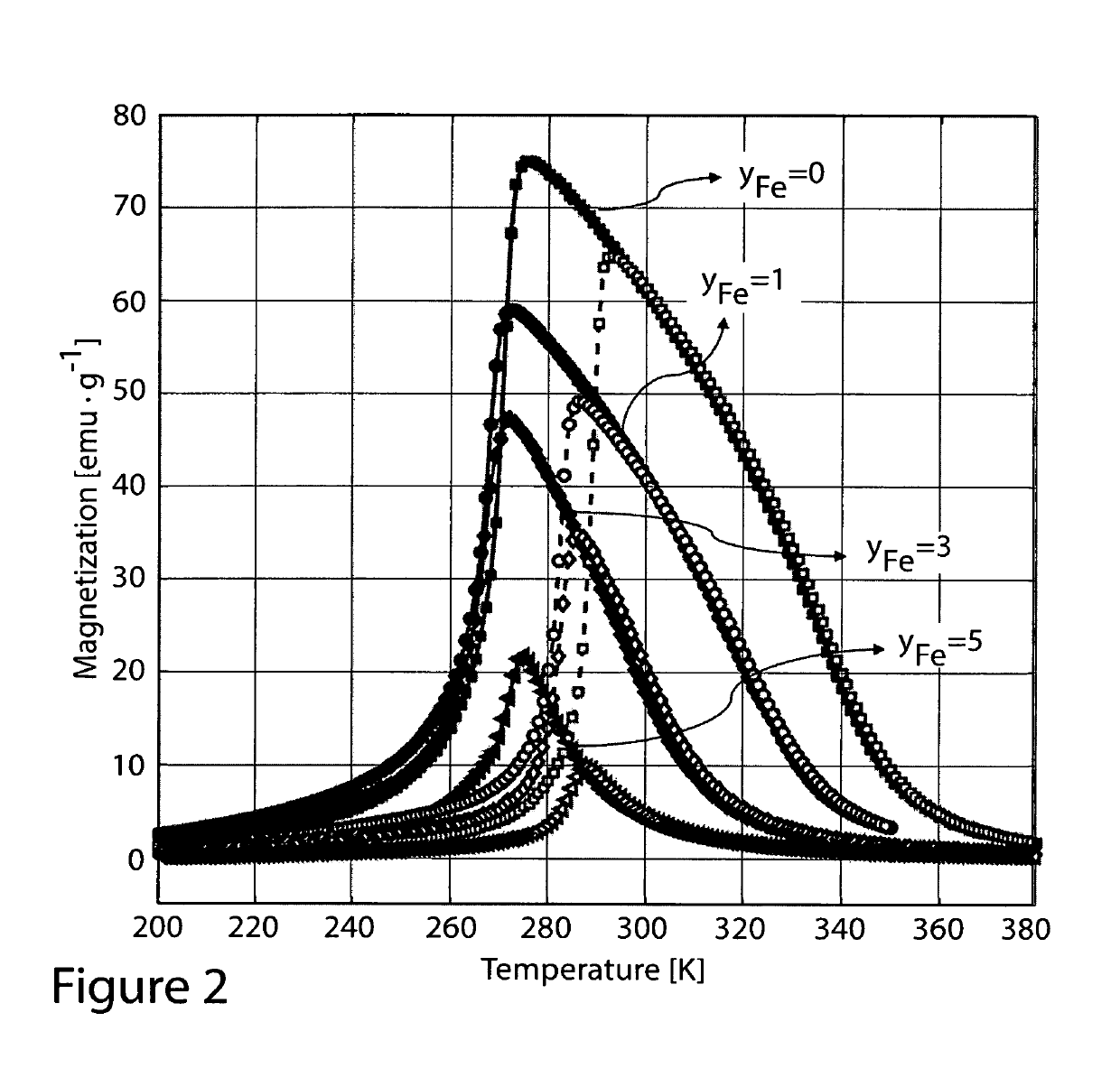

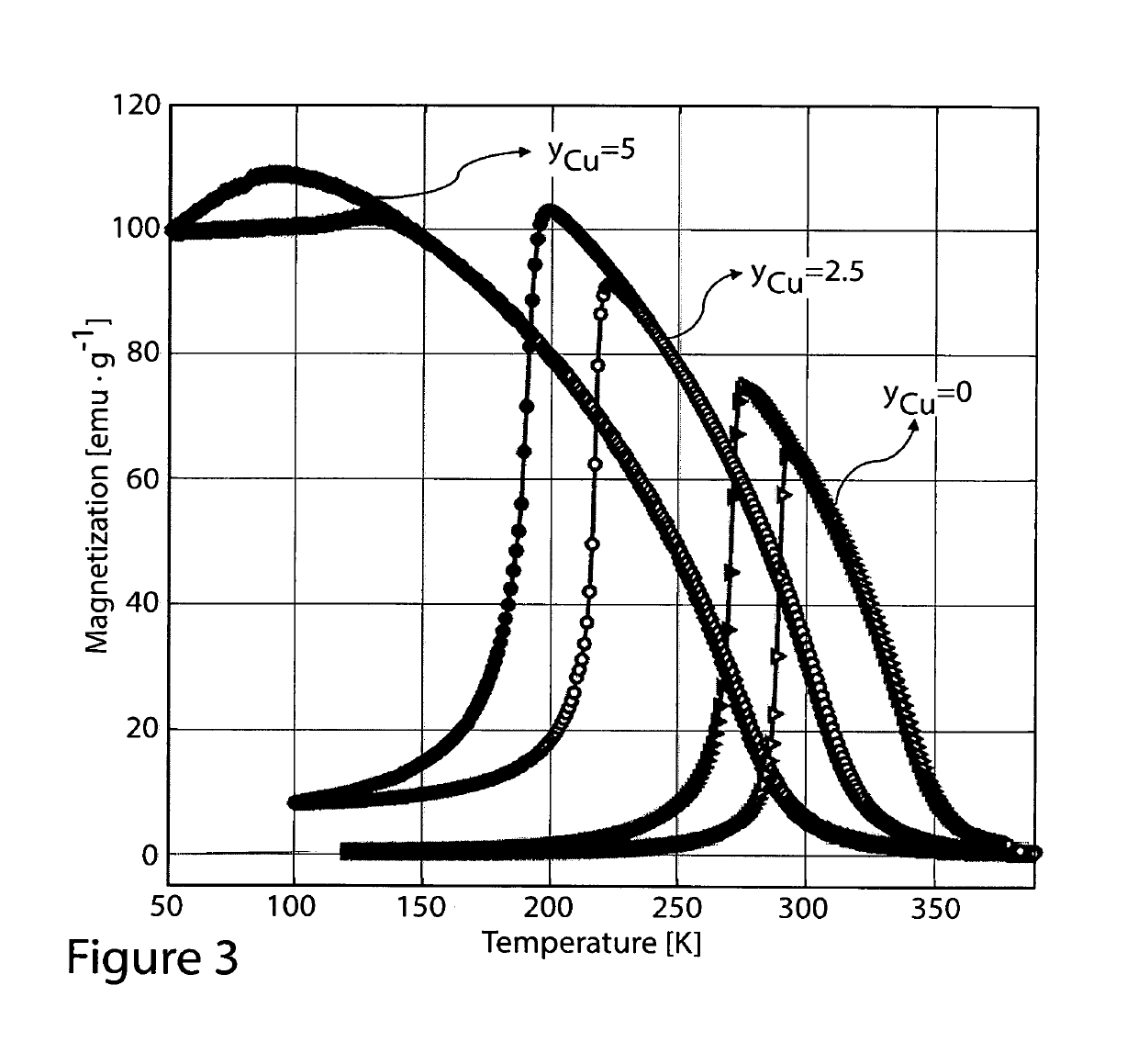

InactiveCN103981397AValence electron reductionLower phase transition temperatureHeat-exchange elementsShape-memory alloyMixed materials

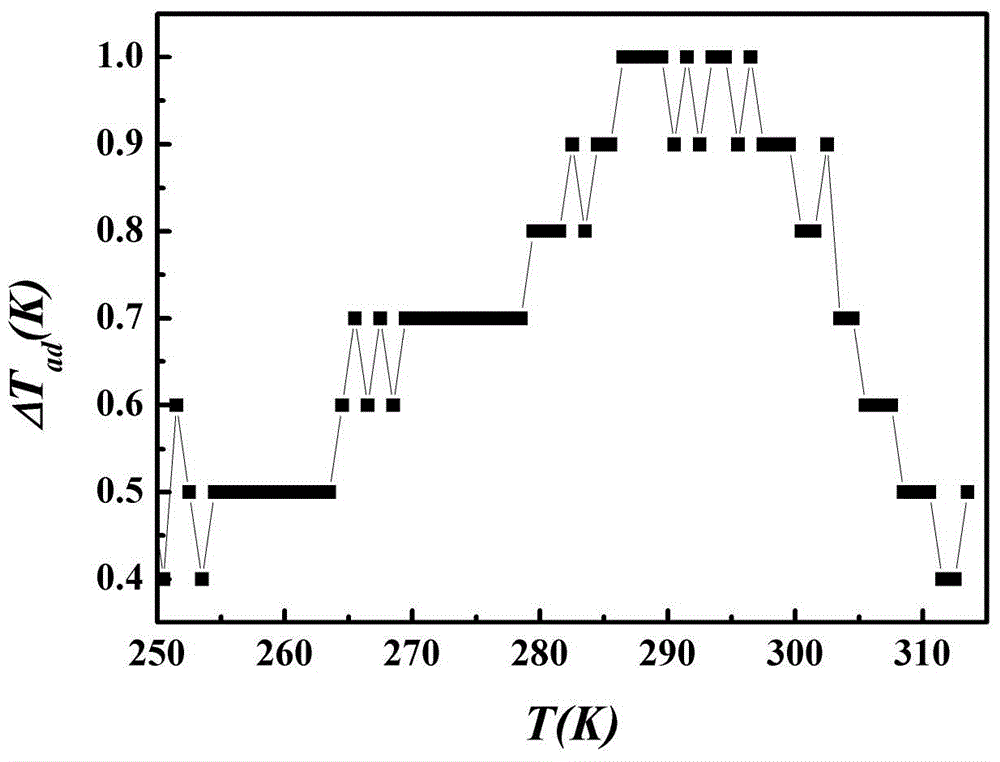

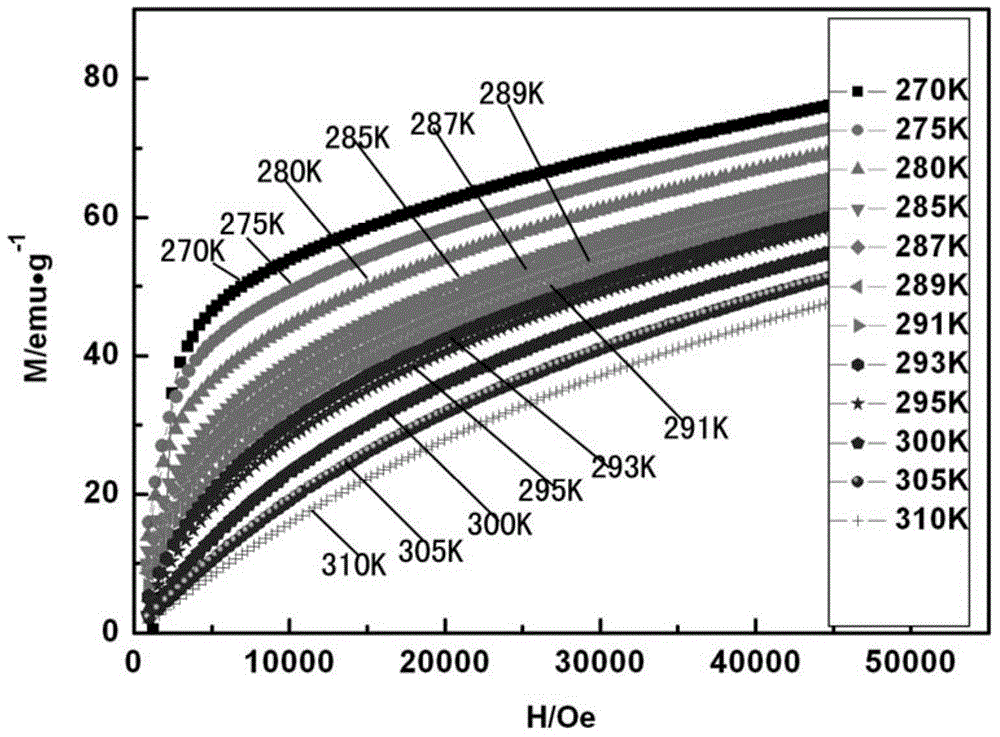

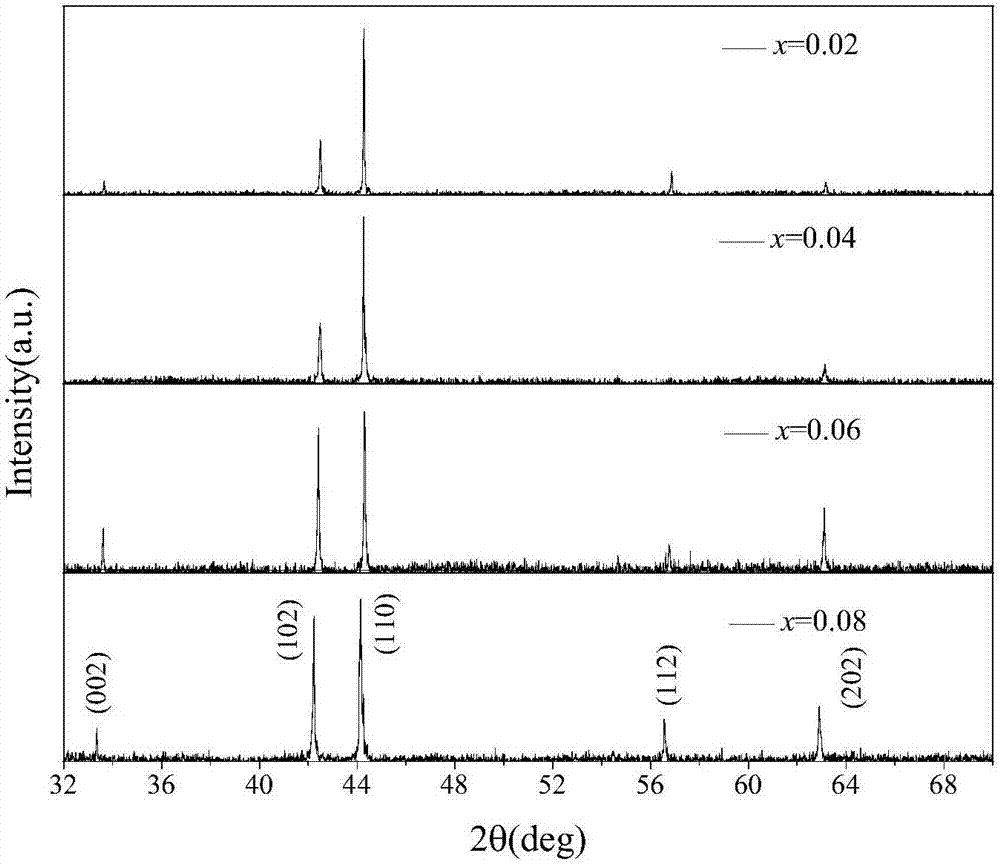

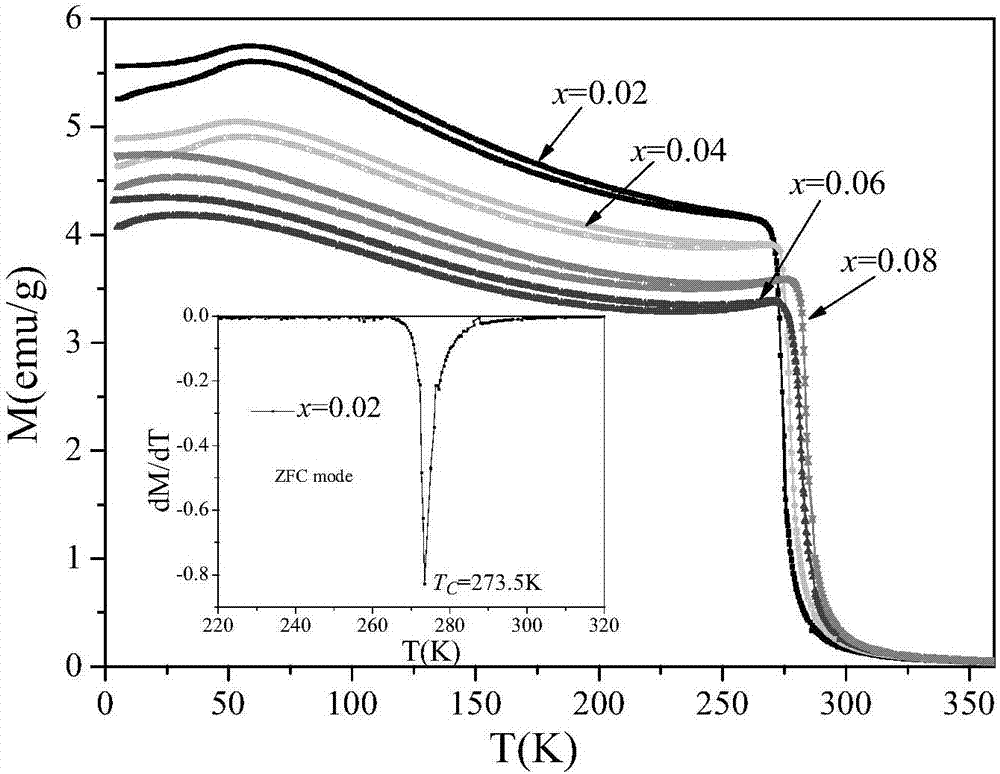

The invention provides a Ni-Fe-Mn-Al alloy material, which has a chemical formula of Ni<50-x>Fe<x>Mn<50-y>Al<y> (2=<x=<9, 16<=y<=18). The preparation comprises the following steps: (1) weighting pure elements according to the ratio of the chemical formula, mixing the pure elements together; (2) placing the mixed material in a water-cooling copper crucible, and repeatedly smelting the mixed material through a conventional electric arch smelting method so as to obtain a uniform alloy casting ingot. The obtained polycrystalline casting ingot can be made into Ni<50-x>Fe<x>Mn<50-y>Al<y> rapidly-quenched strips with a certain texture through a melt quick quenching method. Compared to that of the conventional Ni-Mn base ferromagnetic shape-memory alloy, the binding strength among the crystals of the Ni-Fe-Mn-Al alloy is higher, and thus the mechanical property of the Ni-Fe-Mn-Al alloy is better. The Ni-Fe-Mn-Al alloy is prepared through a conventional method, the raw materials are cheap, and furthermore, the Ni-Fe-Mn-Al alloy has a strong magneto-thermal effect under a low magnetic field, so the Ni-Fe-Mn-Al alloy can be applied to the magnetic refrigeration field.

Owner:TAIYUAN UNIV OF TECH

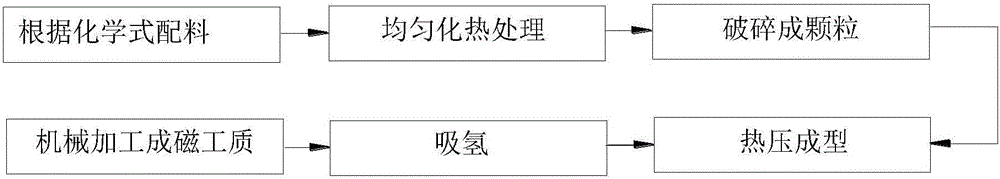

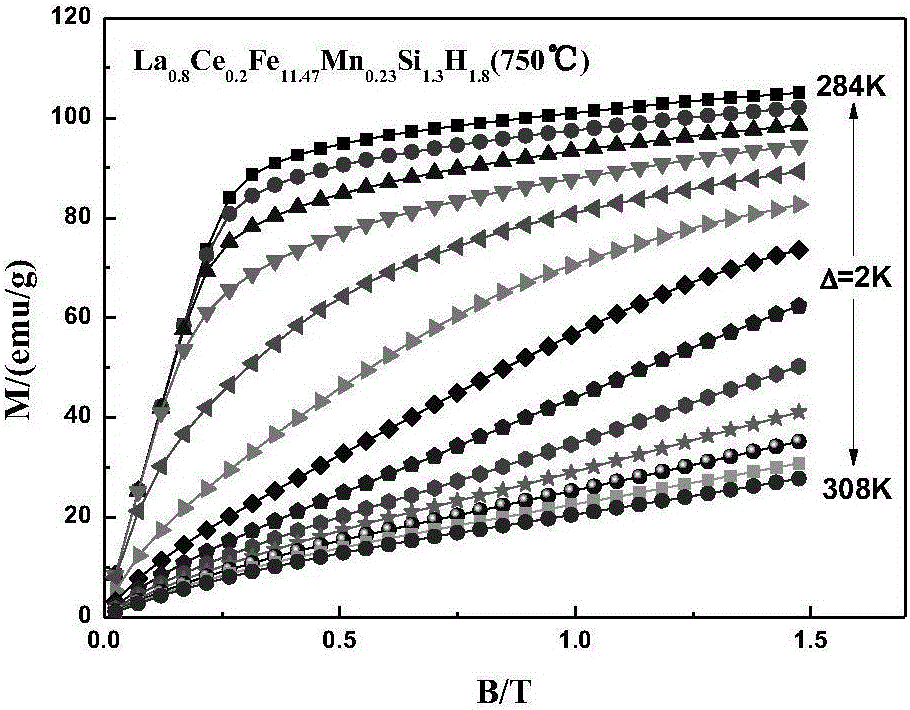

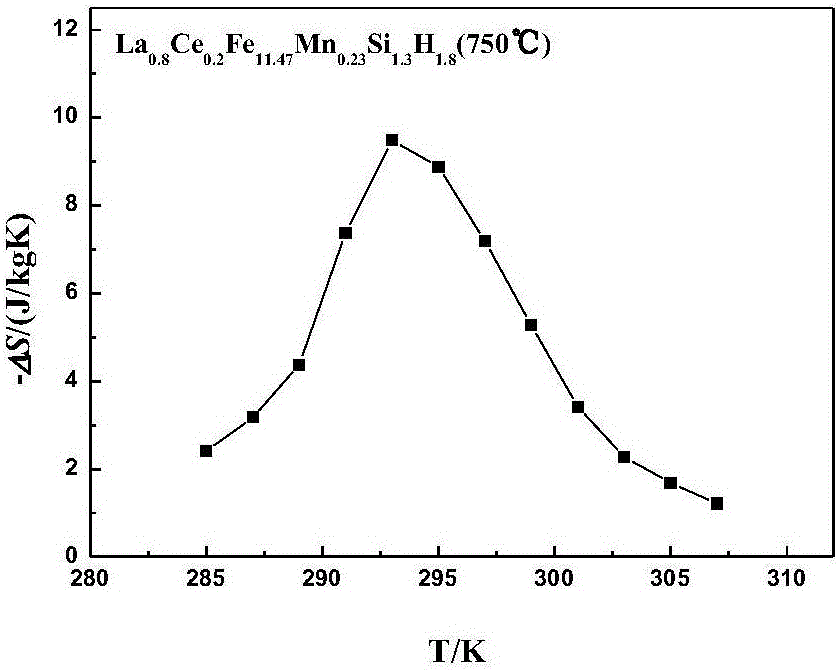

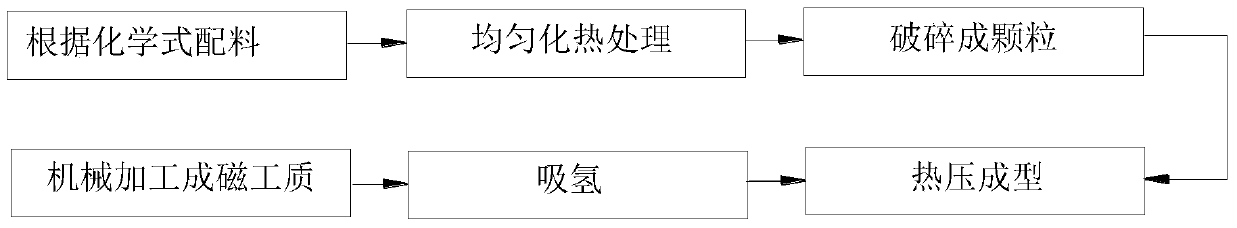

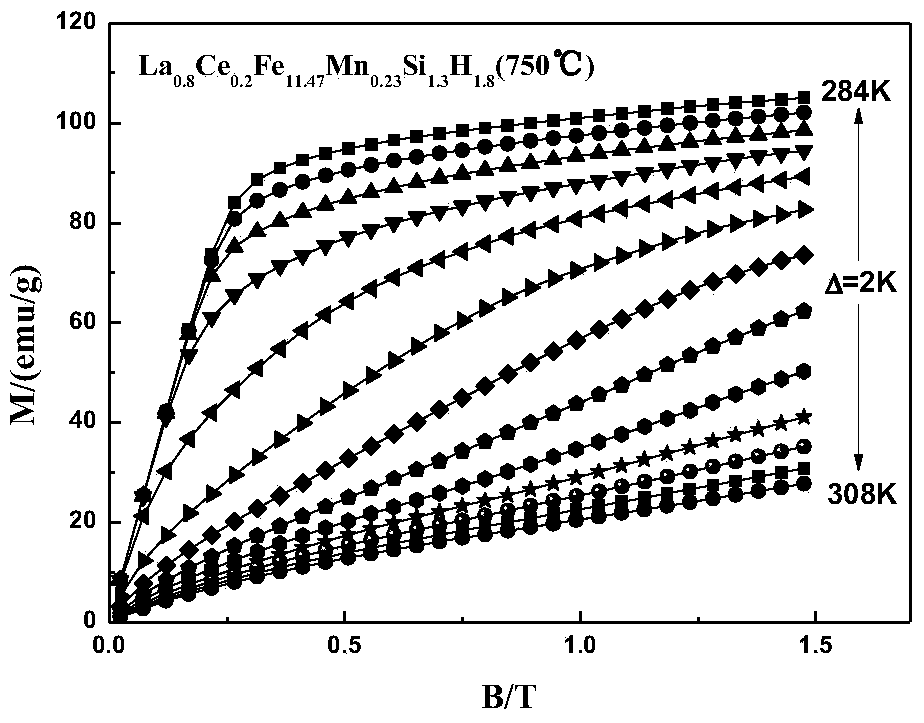

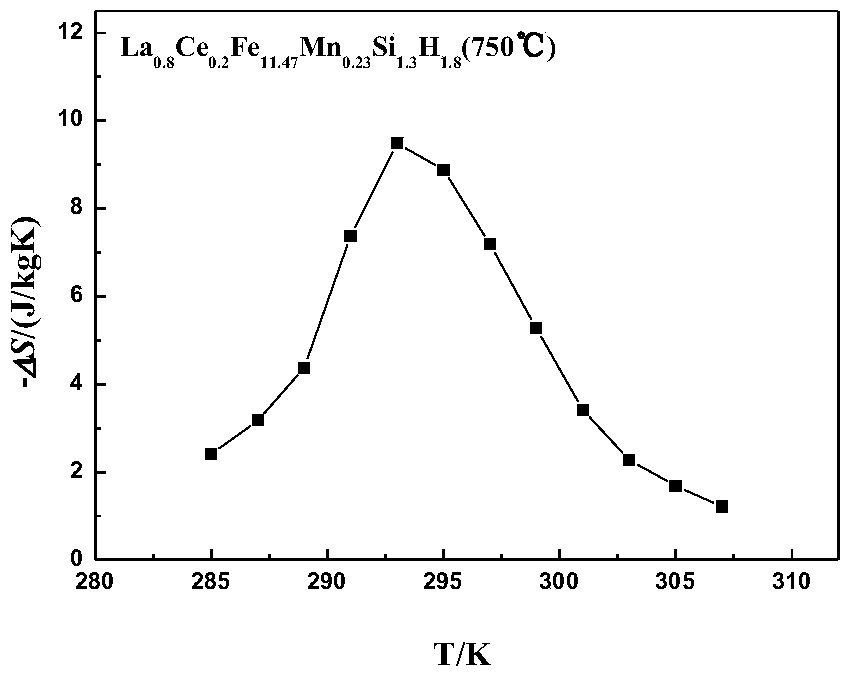

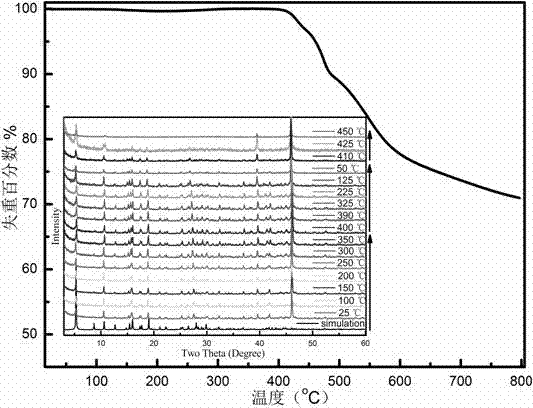

Lanthanum-iron-silicon-based hydride magnetic refrigerant, preparation method of lanthanum-iron-silicon-based hydride magnetic refrigerant and magnetic refrigerator

ActiveCN105957672AAvoid introducingMeet the use requirementsInorganic material magnetismRare-earth elementAdhesive

The invention discloses a lanthanum-iron-silicon-based hydride magnetic refrigerant, a preparation method of the lanthanum-iron-silicon-based hydride magnetic refrigerant and a magnetic refrigerator. The chemical formula of the lanthanum-iron-silicon-based hydride magnetic refrigerant is La1-aRa(Fe1-b-cMbSic)13Hd, wherein R represents one or a composition of a plurality types of the following rare earth elements: Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc and Y; a value range of a is 0 to 0.5; M represents one or a composition of a plurality of types of Ti, V, Cr, Mn, Co, Ni, Cu, Zn and Ga; a value range of b is 0.005 to 0.05; a value range of c is 0.069 to 0.162; and a value range of d is 0 to 2. The lanthanum-iron-silicon-based hydride magnetic refrigerant provided by the invention is formed into a block by adopting a hot pressing molding process, introduction of impurity constituents such as an adhesive and the like is avoided, a high thermomagnetic property is kept, the prepared magnetic refrigerant is excellent in mechanical property, the problem of reduction of mechanical properties of pulverization, frangibility and the like of a lanthanum-iron-silicon-based compound after hydrogenation is solved, and performance of the formed magnetic refrigerant can meet the use requirements of the magnetic refrigerator.

Owner:BAOTOU RES INST OF RARE EARTHS

Coated magnetic alloy material and method for the manufacture thereof

InactiveCN102246248AExcellent mechanical propertiesImprove application feasibilityInorganic material magnetismLiquid/solution decomposition chemical coatingCrystal structureMaterial physics

The invention refers to the area of materials science and material physics and relates to a coated magnetic alloy material that can be used, for example, as a magnetic cooling material for cooling purposes. The object of the present invention is to provide a coated magnetic alloy material that exhibits improved mechanical and / or chemical properties. The object is accomplished by a magnetic alloy material having an Na Zn13-type crystalline structure and having a composition according to the formula Ra Fe100-a-x-y-z Tx My Lz, the surface of said alloy material being coated with a material comprising at least one element from the group of Al, Si, C, Sn, Ti, V, Cd, Cr, Mn, W, Co, Ni, Cu, Zn, Pd, Ag, Pt, Au or combinations thereof. The object is further achieved by a method in which the magnetic alloy material is coated by way of fluid phase processes.

Owner:INST FUER FESTKOERPER & WERKSTOFFORSCHUNG DRESDEN EV

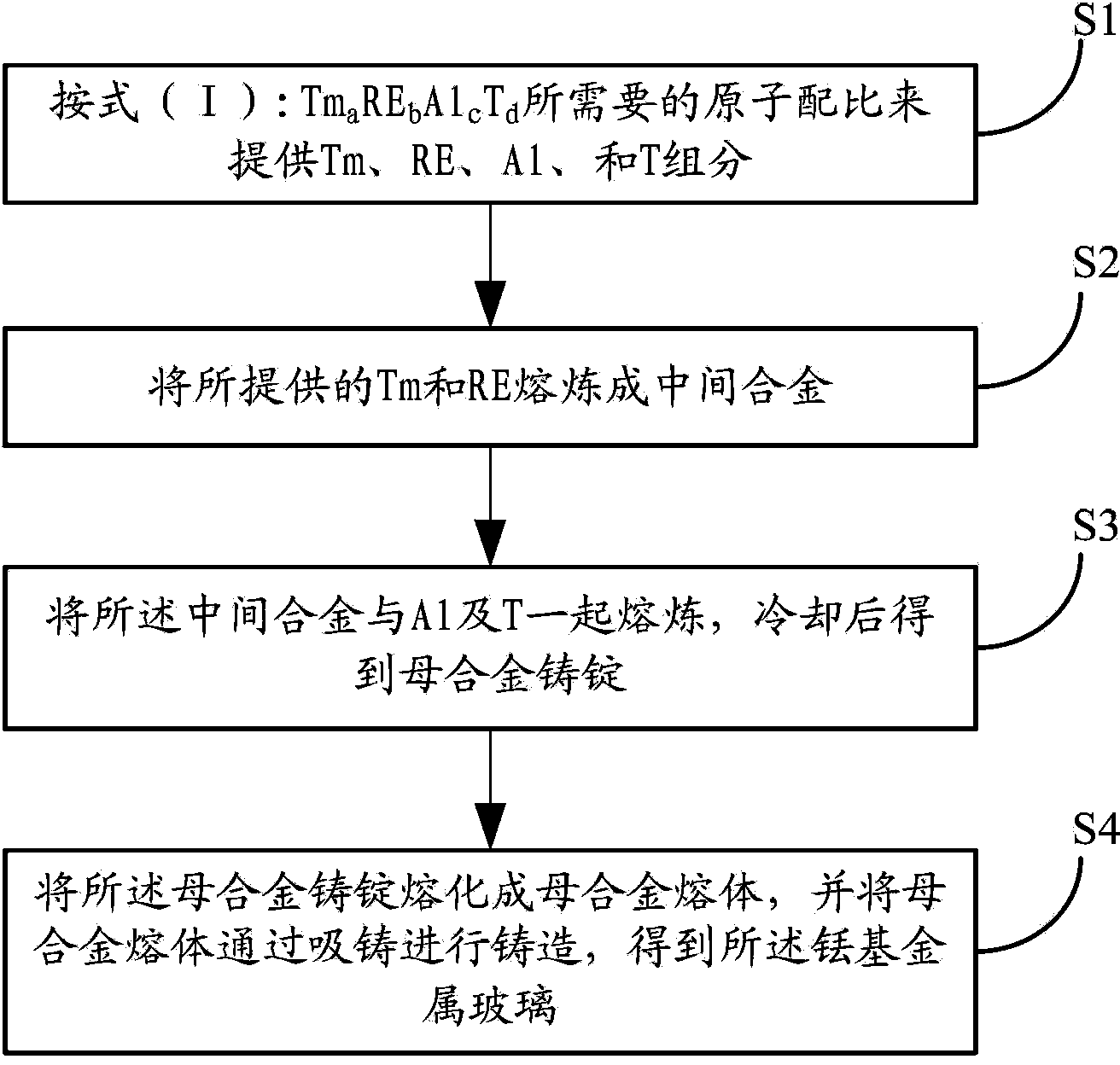

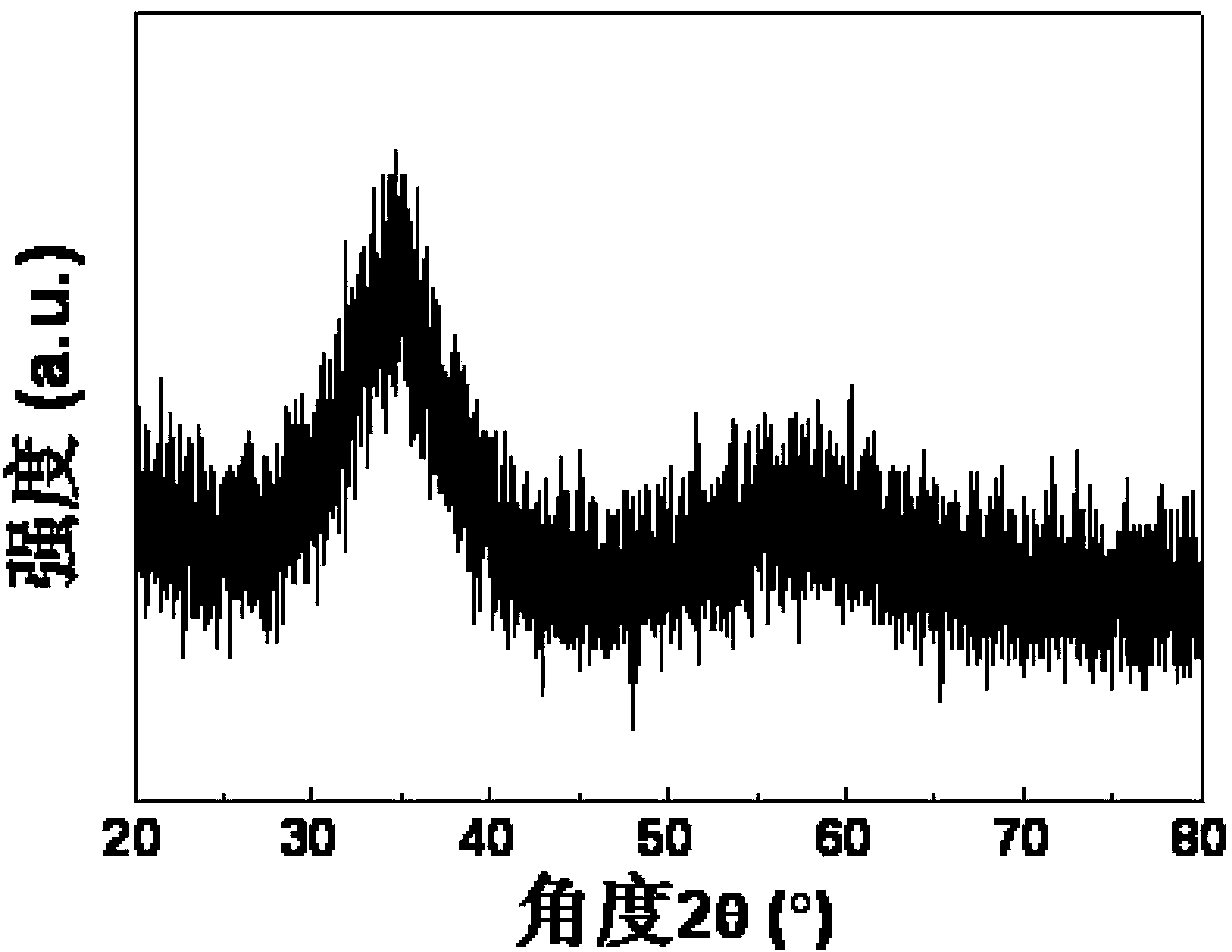

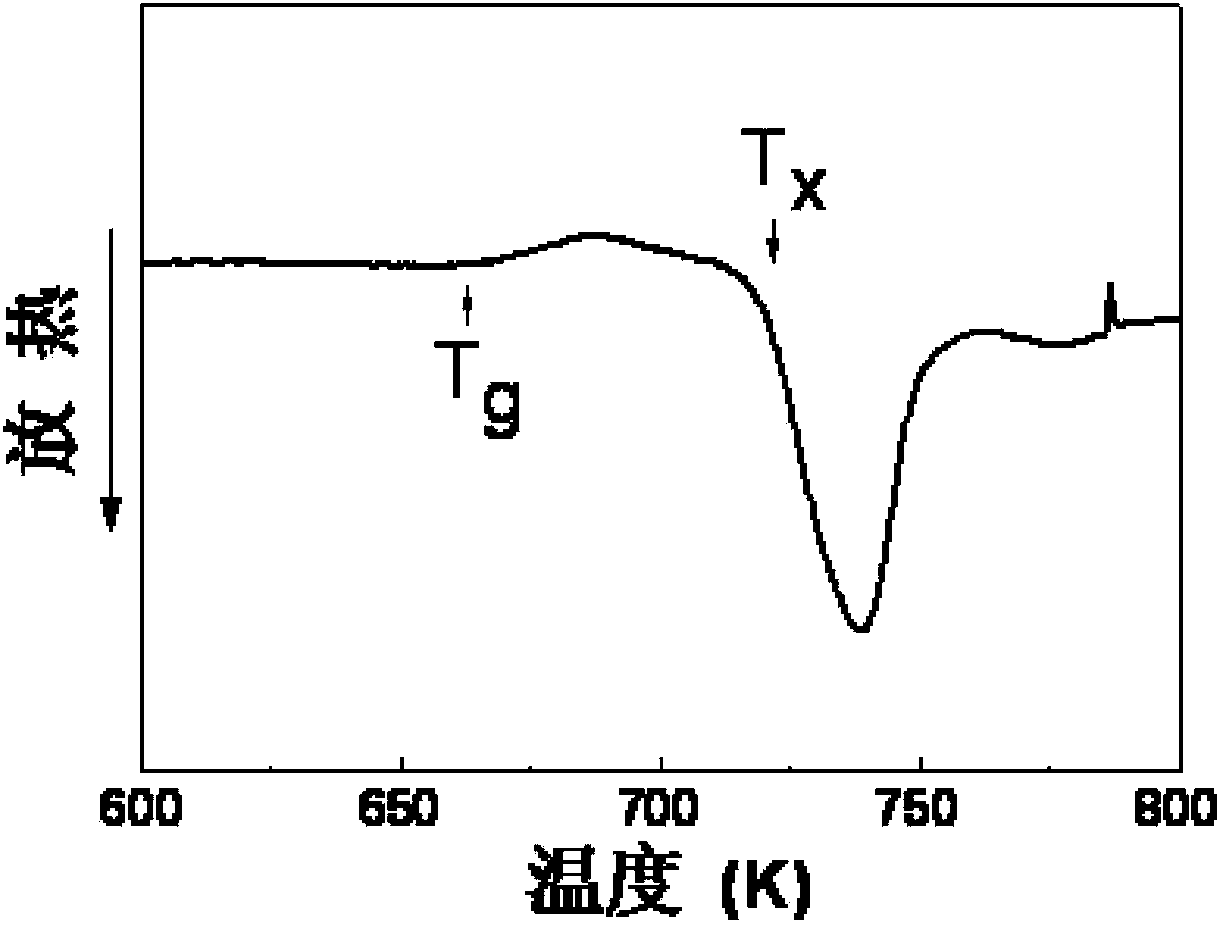

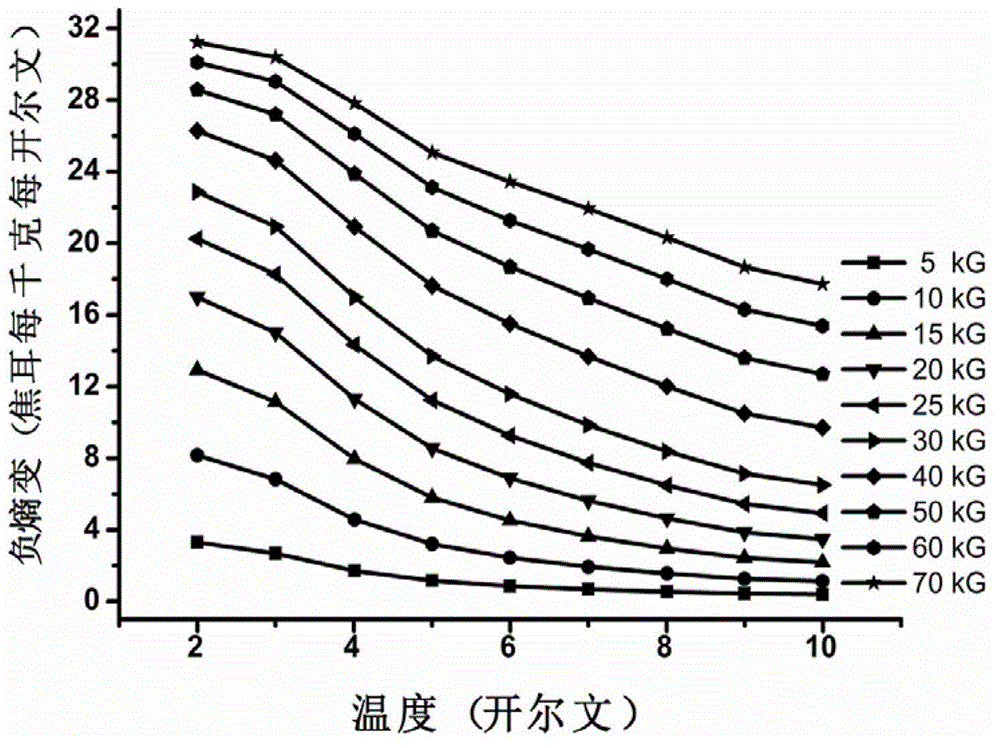

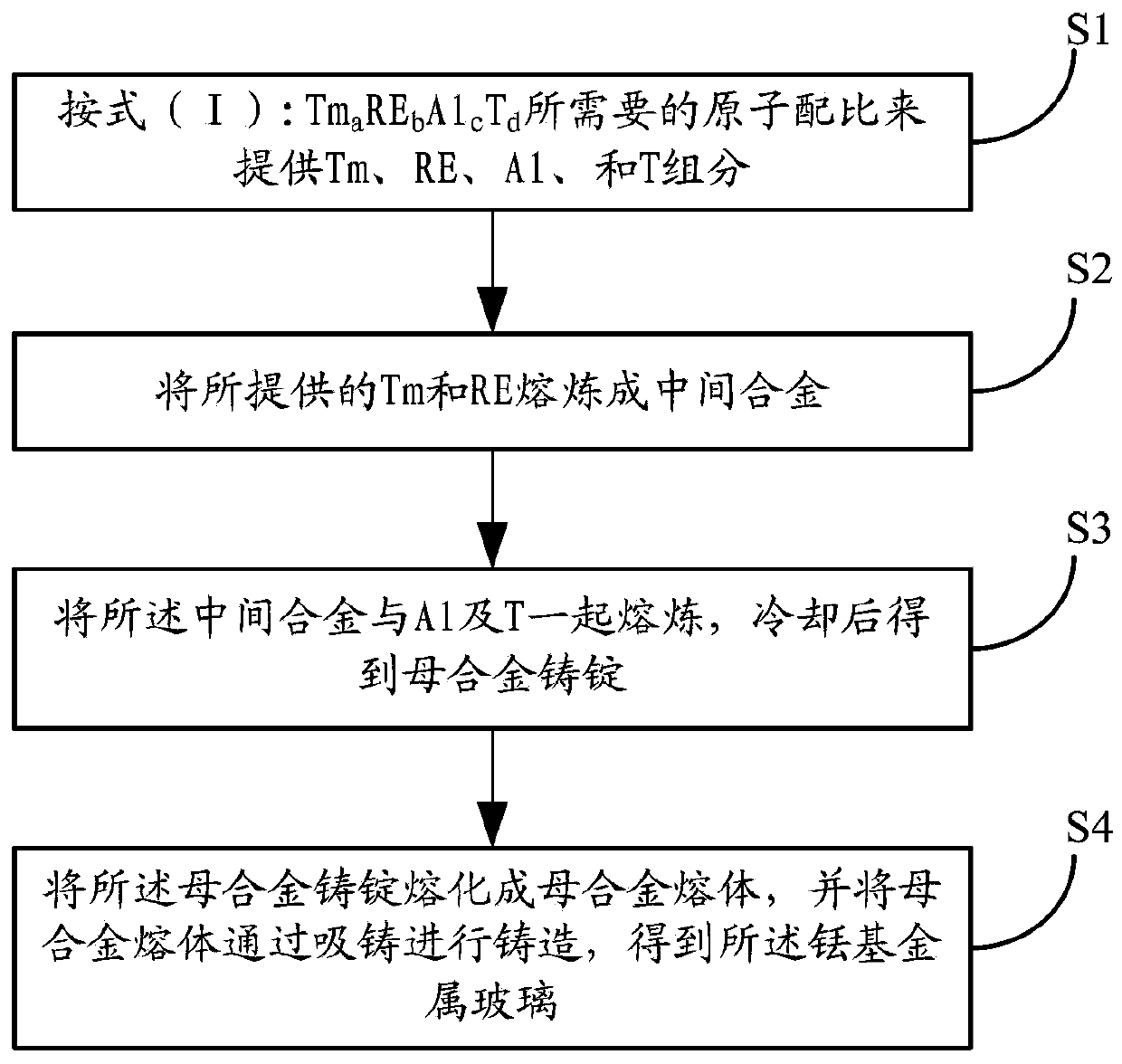

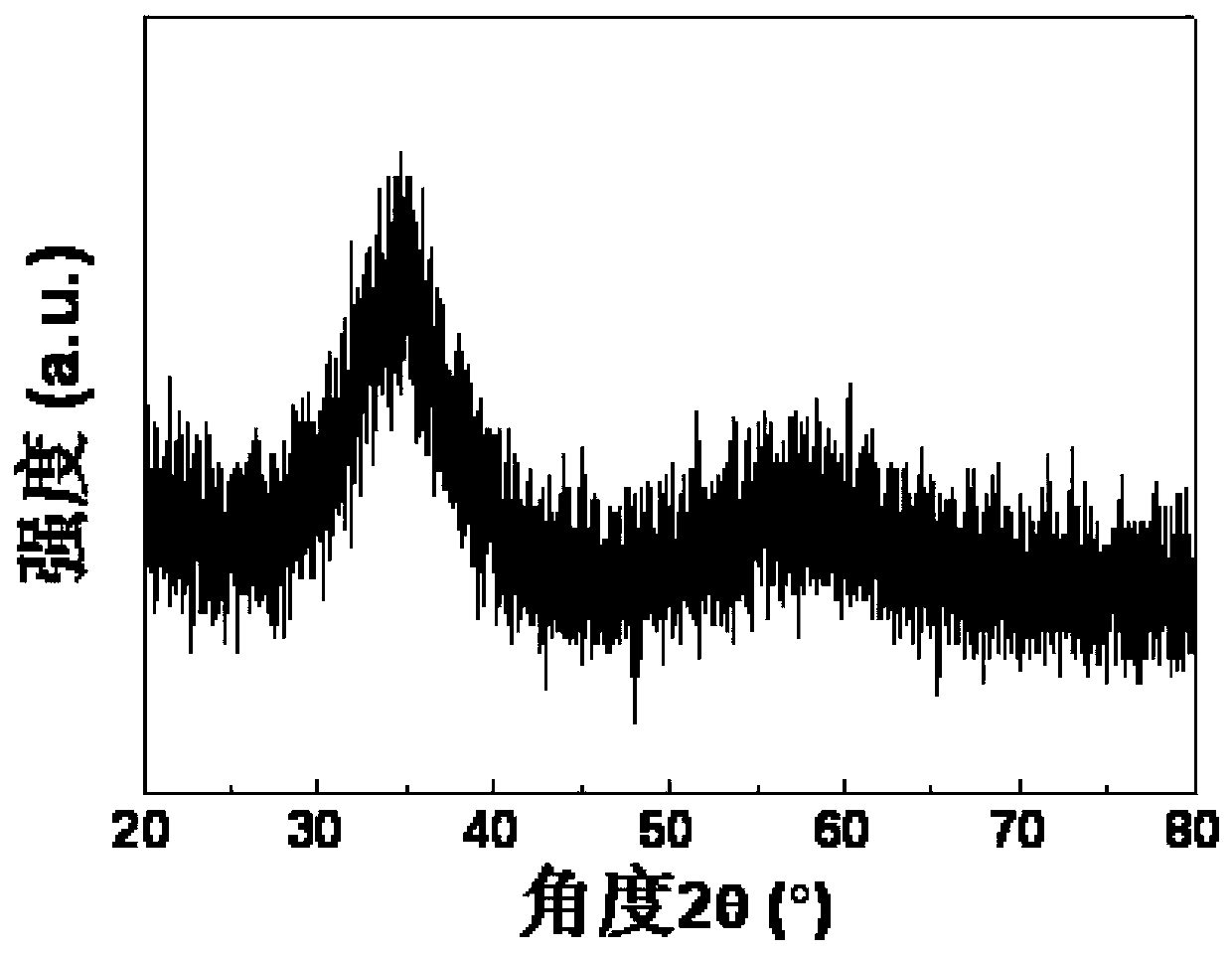

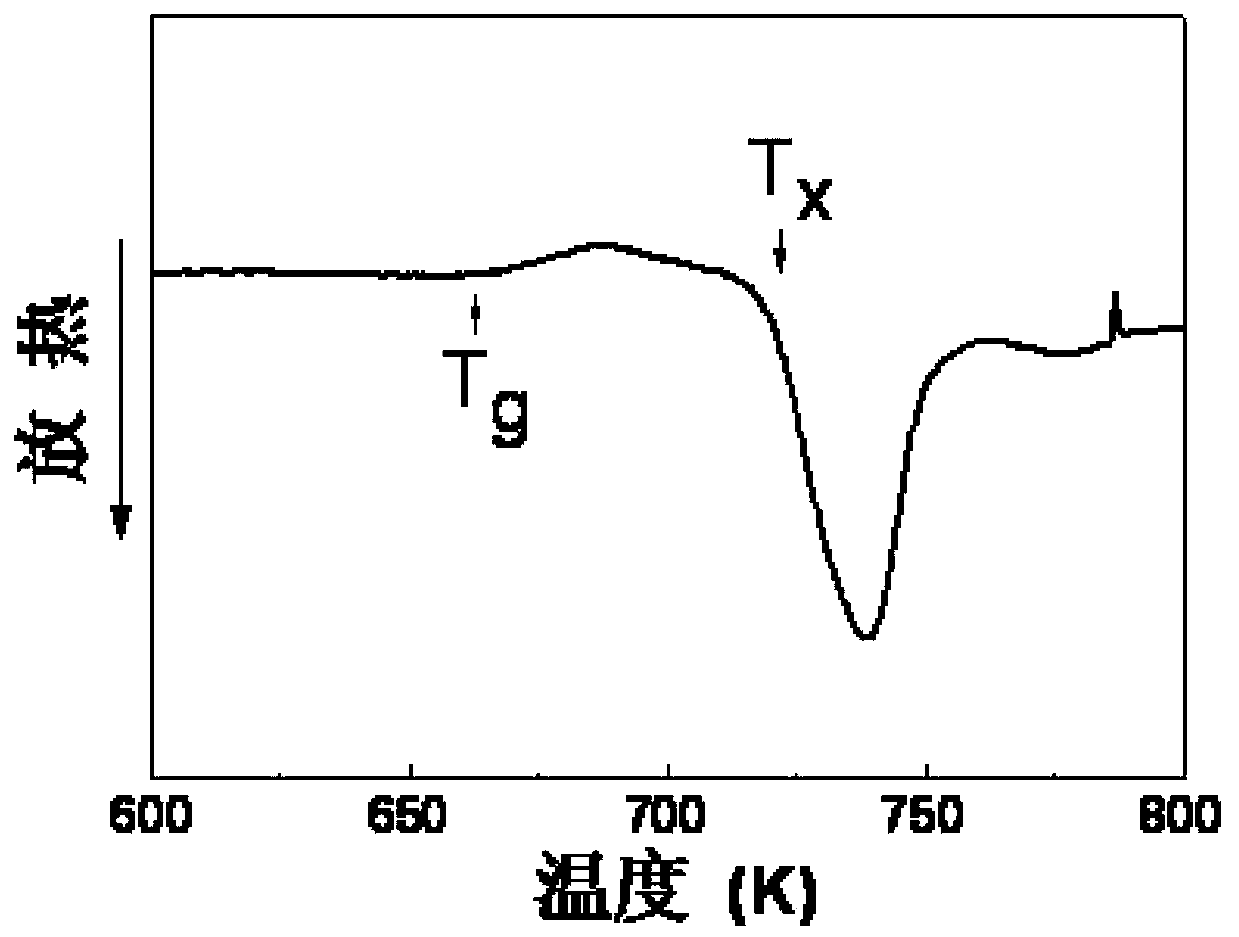

Thulium-based metal glass, preparation method and application thereof

ActiveCN103668008AMagnetic transition temperature range is wideLow critical cooling rateRare-earth elementThulium

The invention discloses thulium-based metal glass, a preparation method and an application thereof. Based on thulium as the major component, the formula of the thulium-based metal glass is shown in a formula (I), RE represents one or more rare earth elements selected from Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho and Er; T represents Co or Ni; a, b, c and d represent atomic percents of elements, wherein a is greater than or equal to 30 and less than or equal to 60, b is greater than or equal to 5 and less than or equal to 30, c is greater than or equal to 20 and less than or equal to 25, d is greater than or equal to 15 and less than or equal to 25, (a+b) is greater than or equal to 50 and less than or equal to 60, and (a+b+c+d) is equal to 100. According to the thulium-based metal glass disclosed by the invention, on the one hand, the amorphous forming ability can be modulated by changing RE and T, and on the other hand, the temperature interval of the thulium-based metal glass on magnetic transformation can be modulated to expand the magnetic transformation area, so that the thulium-based metal glass has great magnetocaloric effect in a wider temperature interval. TmaREbALcTd(I).

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

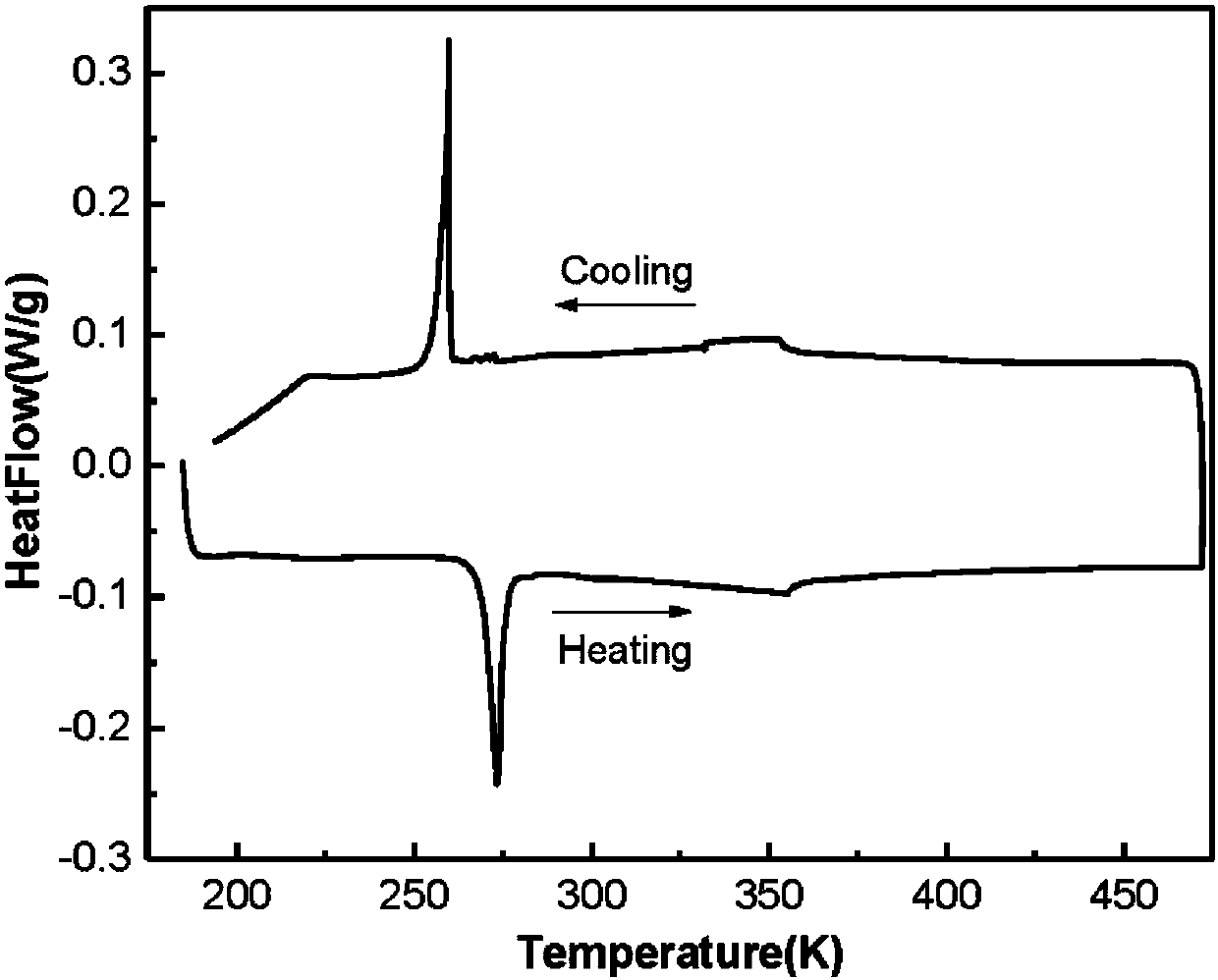

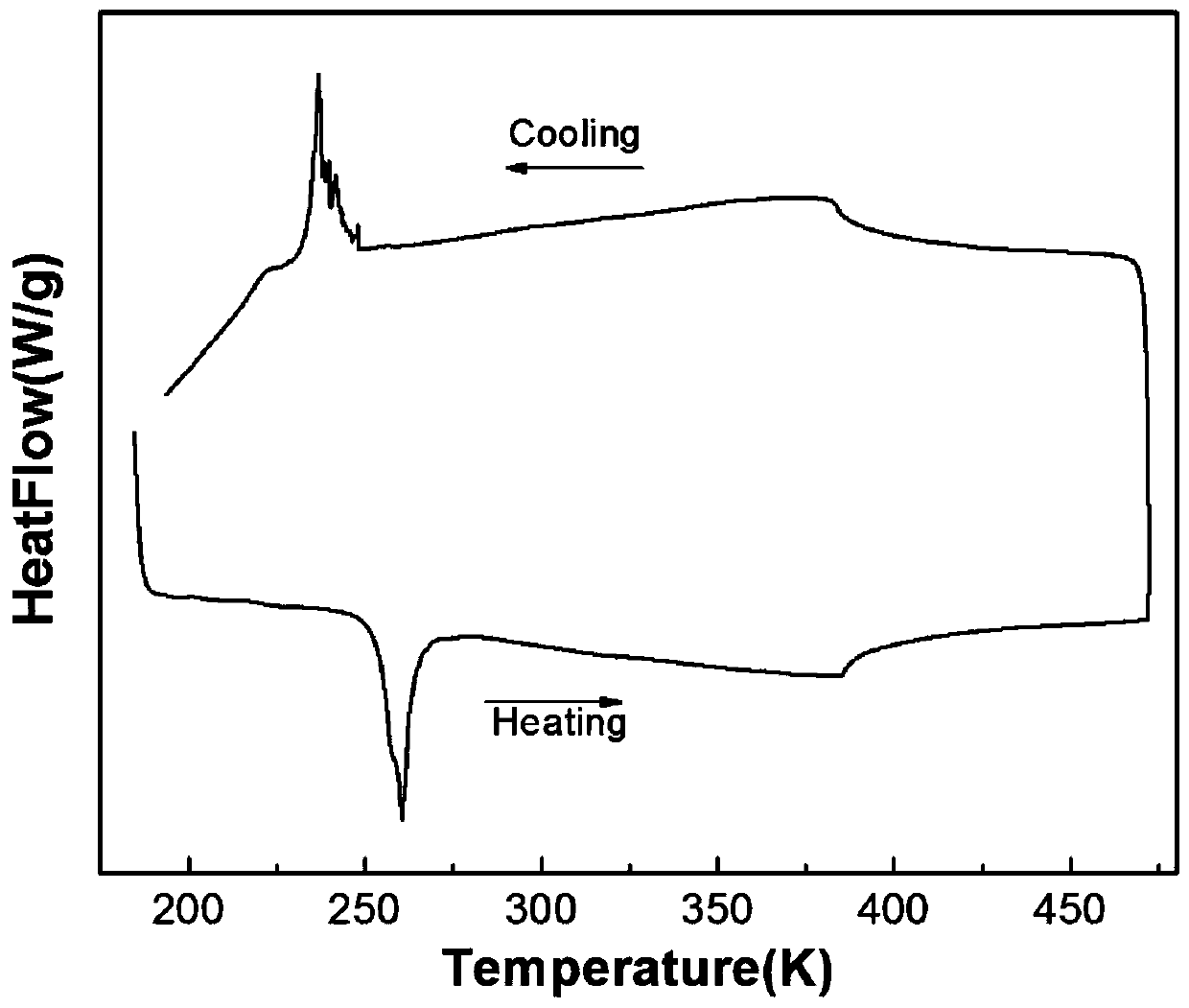

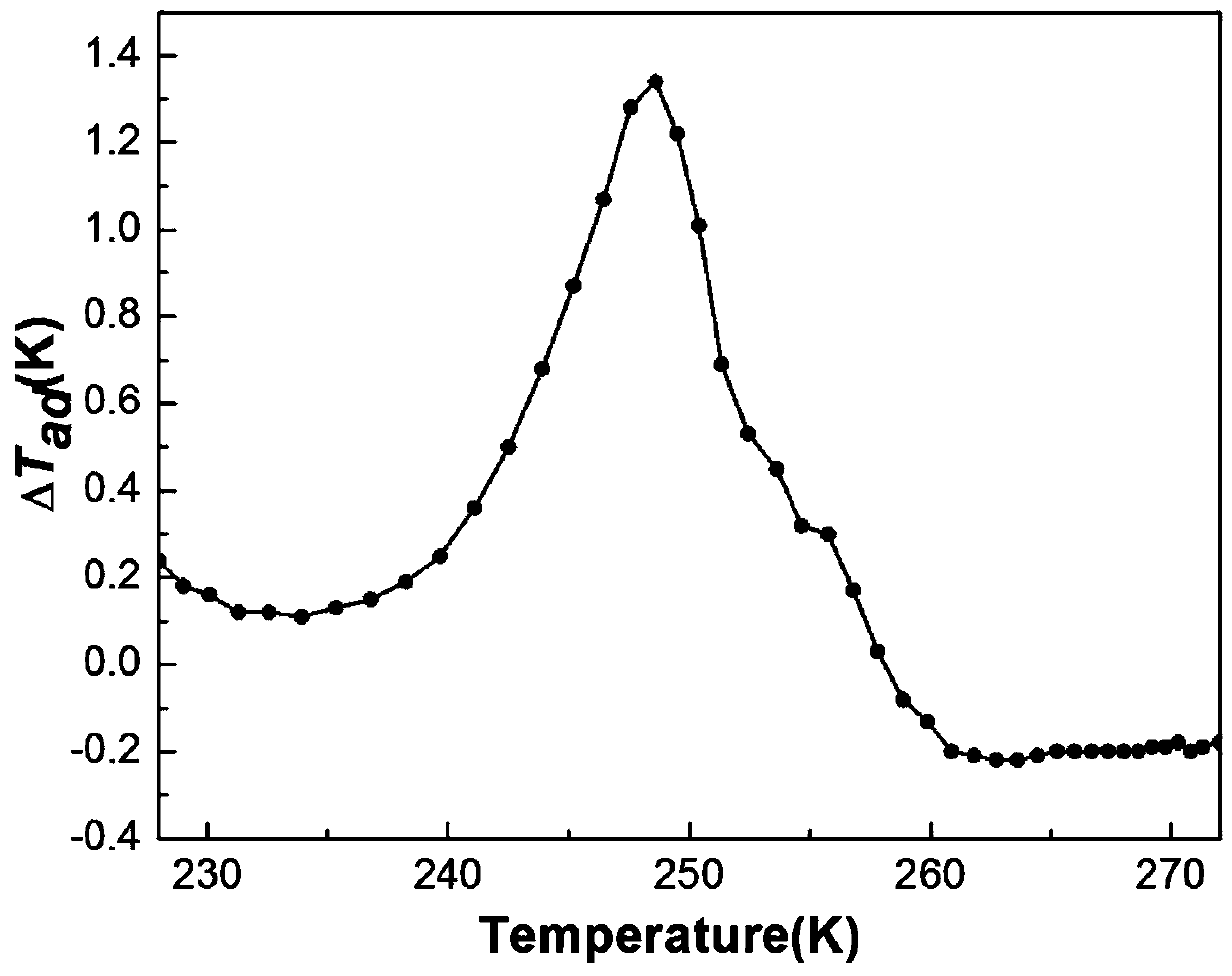

Ni-Mn-In-Co-Cu magnetic refrigeration alloy material and preparation method

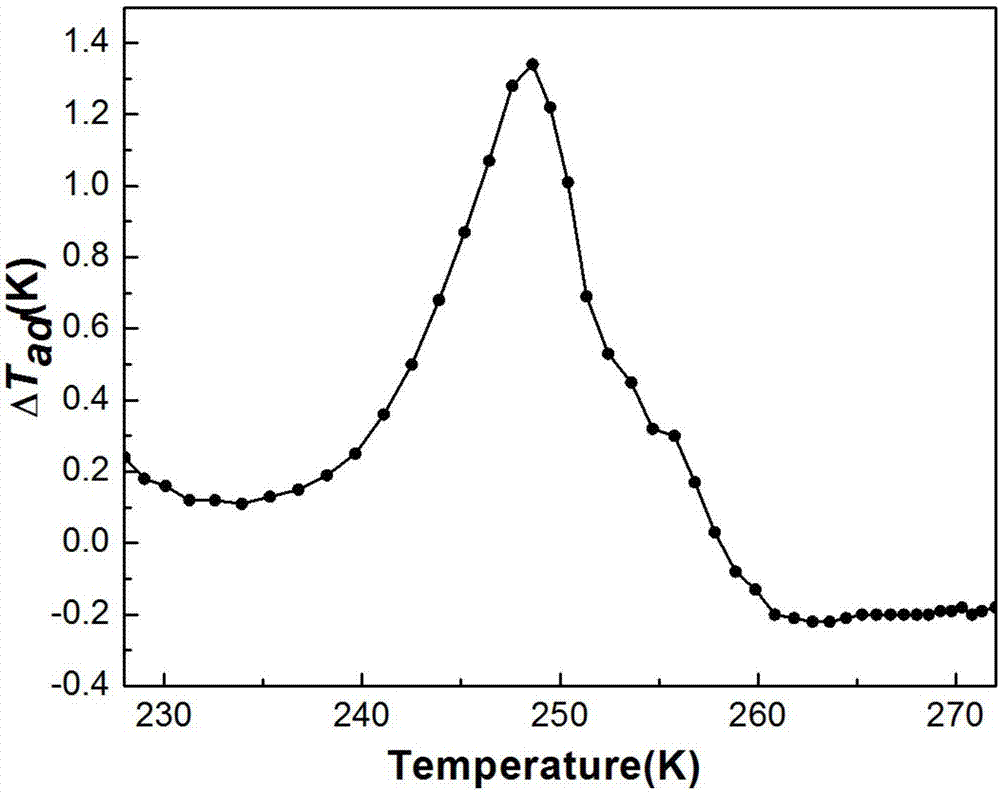

ActiveCN107675063ARealize single temperature zone coolingImprove thermal conductivityInorganic material magnetismIngotWater cooling

The invention provides a Ni-Mn-In-Co-Cu magnetic refrigeration alloy material and a preparation method and belongs to the technical field of magnetic materials. The chemical molecular formula of the Ni-Mn-In-Co-Cu magnetic refrigeration alloy material is Ni46MnxIn14Co3Cuy, and the sum of the mole numbers of the elements in the alloy is 100, wherein 33<=x<=36, and 1<=y<=4. According to the Ni-Mn-In-Co-Cu magnetic refrigeration alloy material and the preparation method, through raw material proportioning and vacuum arc repeated smelting, polycrystal cast ingot is prepared, annealing is conductedunder the high-purity inert gas shielding, rapid water cooling is then conducted, and then the Ni-Mn-In-Co-Cu magnetic refrigeration alloy block blank is prepared. When the alloy block is in a 1.5T magnetic field, the adiabatic temperature change range is 1.01-2.61 K. The magnetic alloy can obtain excellent adiabatic temperature change at nearby the indoor temperature, along with a huge magnetocaloric effect, the magnetic alloy can be used as a magnetic refrigeration work medium, and the magnetic alloy has a high magnetic refrigeration efficiency and a wide temperature domain work range.

Owner:NORTHEASTERN UNIV

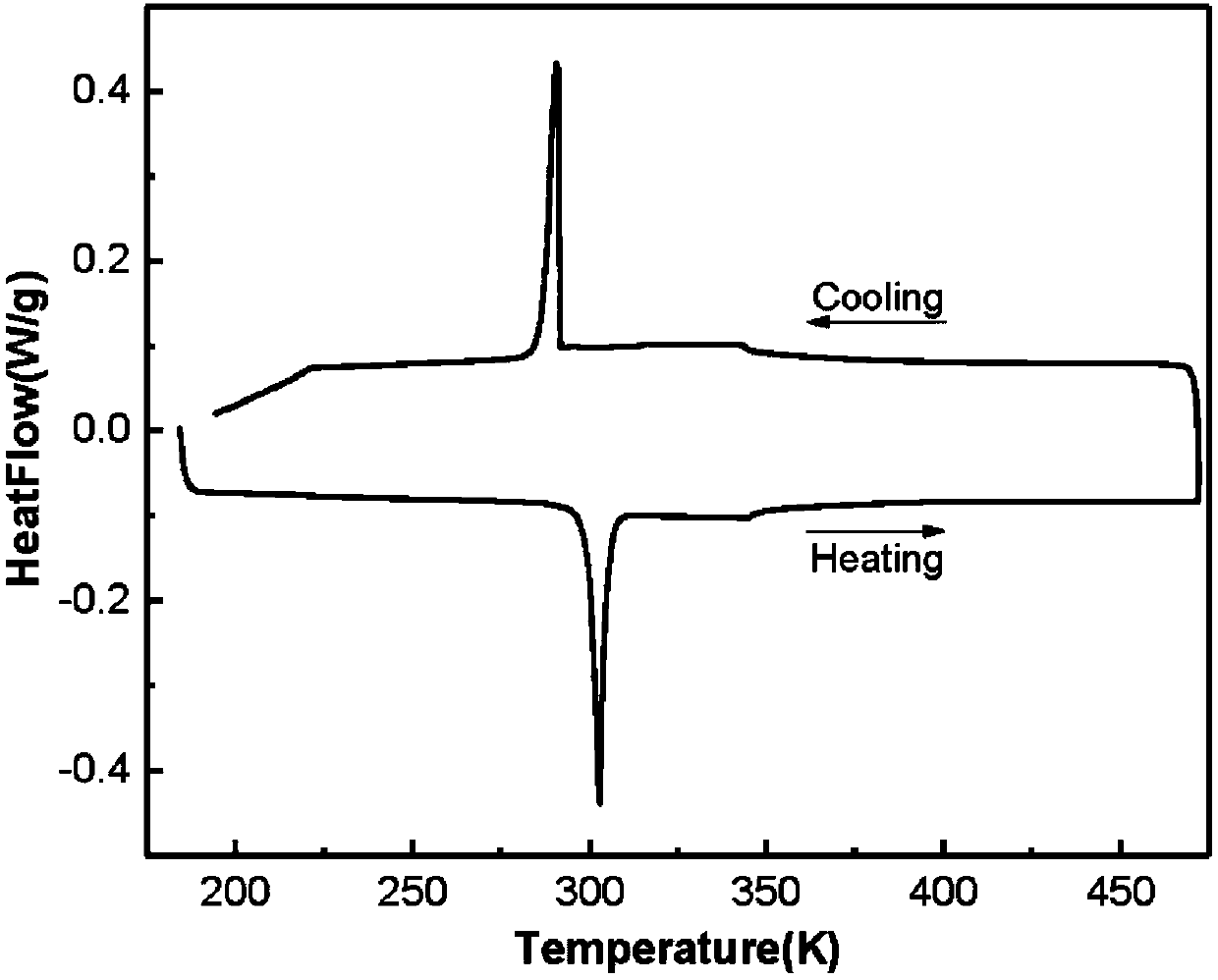

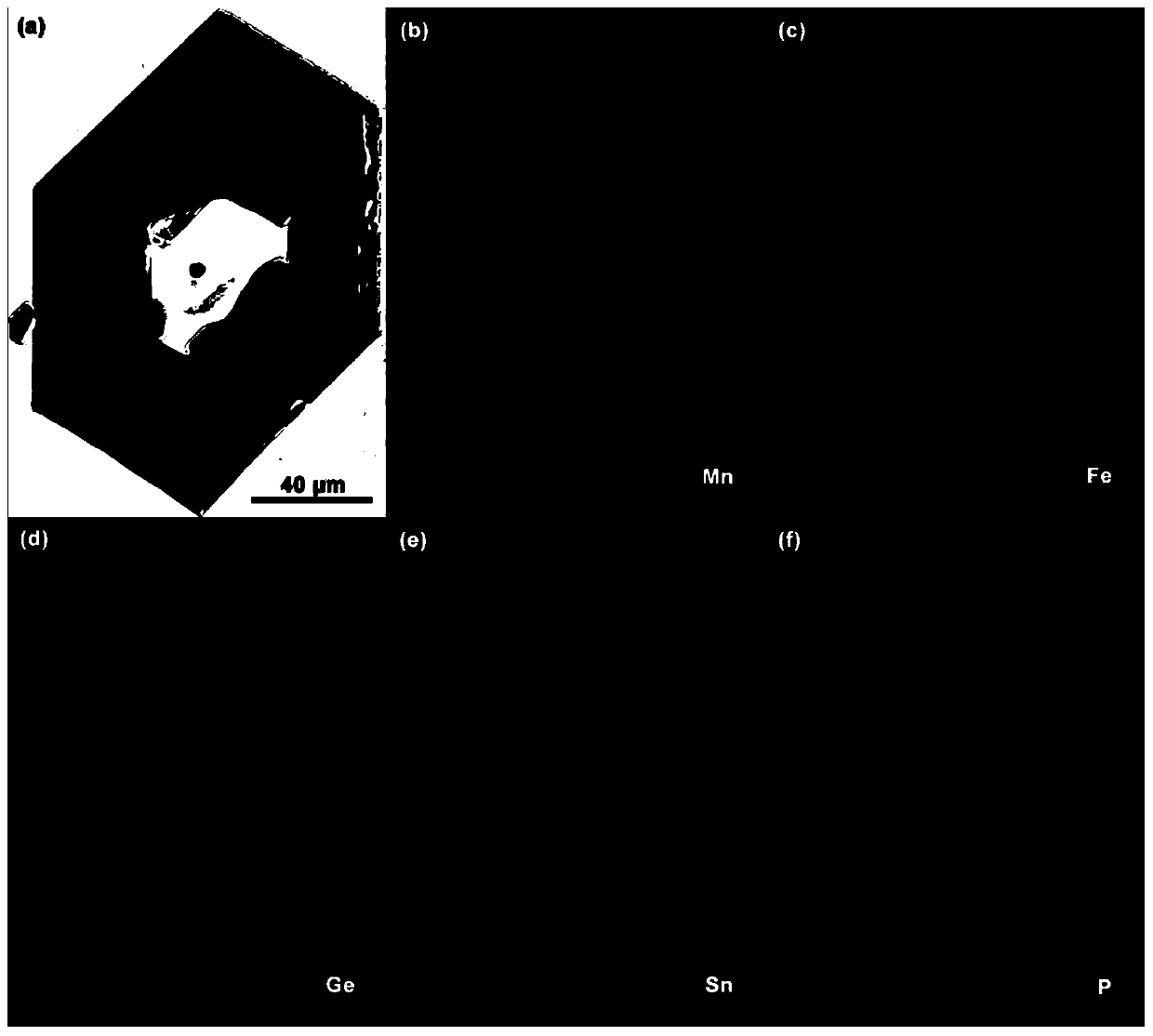

Downfield-driven oriented Mn-Ni-Sn magnetic refrigeration alloy material, and production method of ribbon thereof

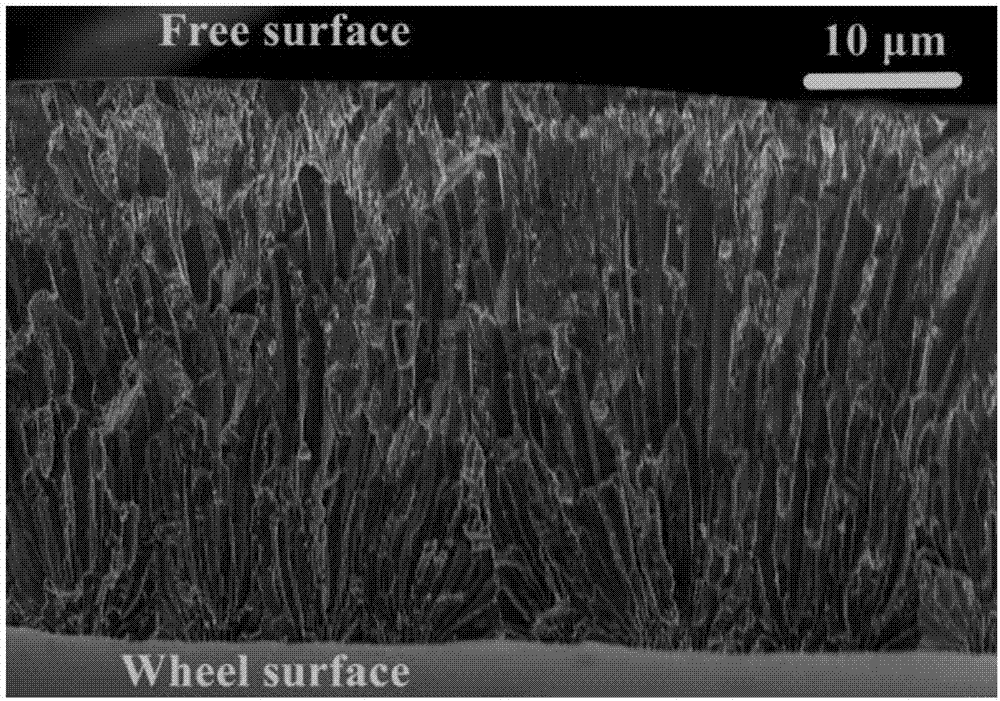

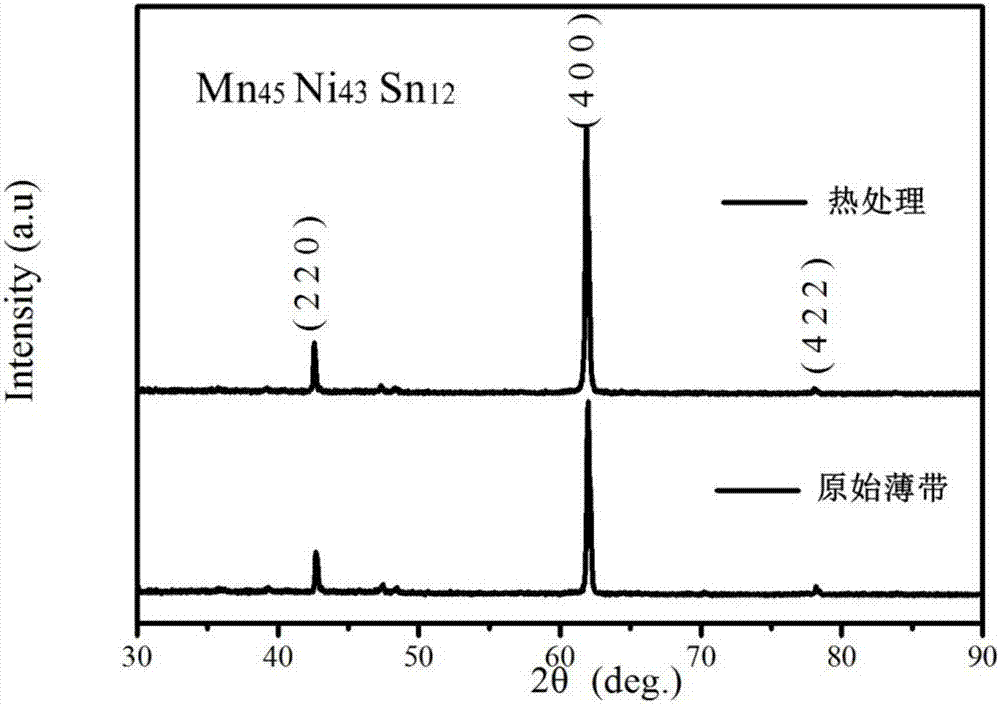

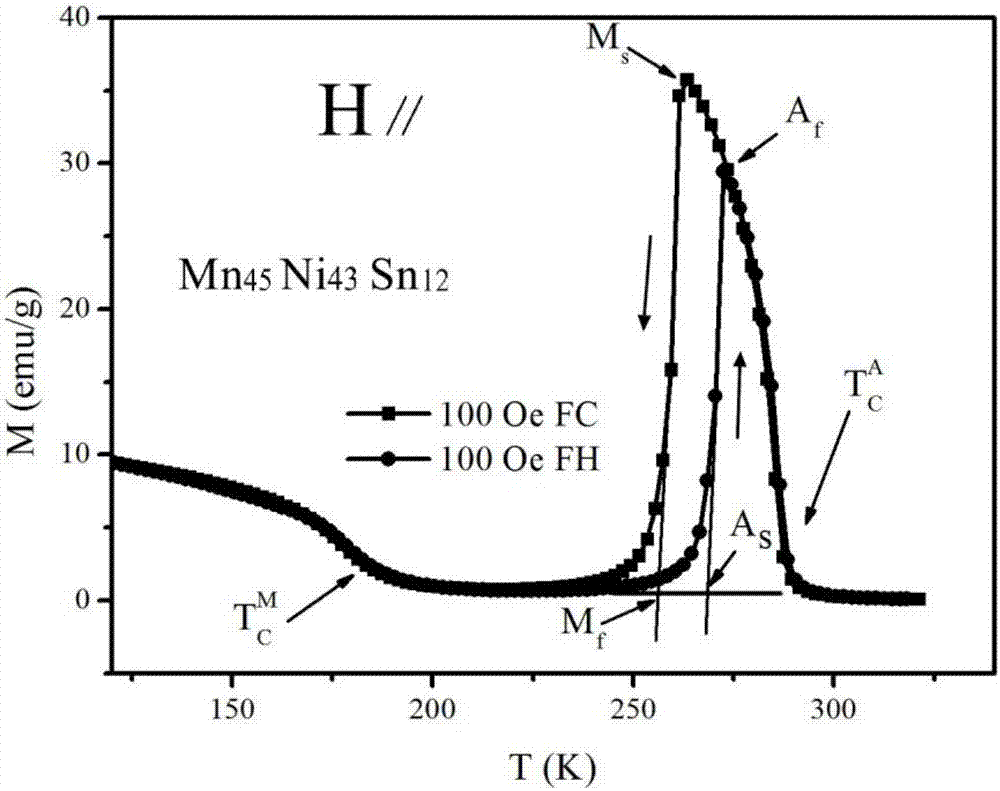

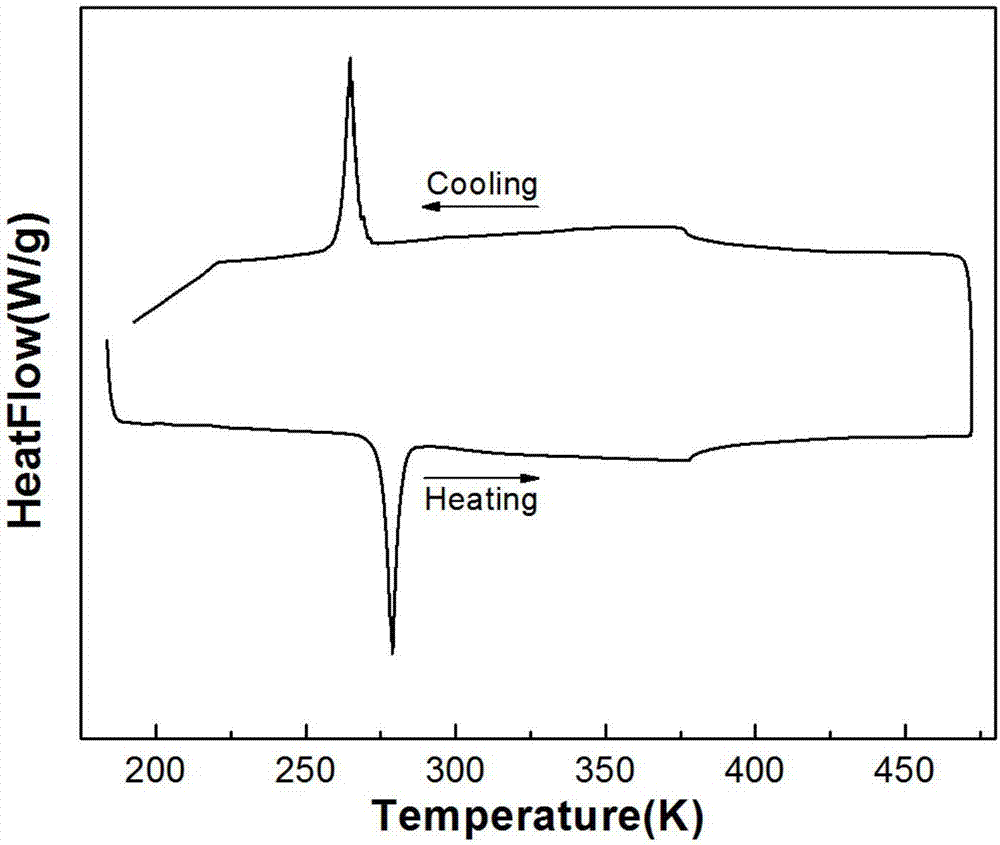

ActiveCN106917030AImprove cooling effectReduce the effect of hysteresis lossInorganic material magnetismInductances/transformers/magnets manufactureHysteresisRare earth

The invention relates to a downfield-driven oriented Mn-Ni-Sn magnetic refrigeration alloy material, and a production method of a ribbon thereof, and belongs to the technical field of magnetic refrigeration alloy materials and ribbons thereof. The technical problem of reduction of the hysteresis loss of the magnetic refrigeration material through using a large externally applied magnetic field of magnetic refrigerating machines is solved, so the prepared magnetic refrigeration alloy material is widely used in a common rare earth permanent magnet range of 8-12 kOe, the material has a large refrigeration capacity at a temperature near room temperature, and the hysteresis loss influence is effectively reduced. The chemical molecular formula of the Mn-Ni-Sn magnetic refrigeration alloy material is MnxNiySnz, wherein x, y and z are the molar ratios of elements, x is not less than 43.0 and not more than 47.0, y is not less than 41.0 and not more than 45.0, z is not less than 10.0 and not more than 13.0, and the value of x + y + z is 100. The production method comprises the following steps: proportioning raw materials, preparing polycrystalline cast ingots, preparing a Mn-Ni-Sn magnetic refrigeration alloy ribbon blank through a melt fast quenching technology, preparing the Mn-Ni-Sn magnetic refrigeration alloy ribbon, and finally preparing a Mn-Ni-Sn magnetic refrigeration alloy ribbon sample.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

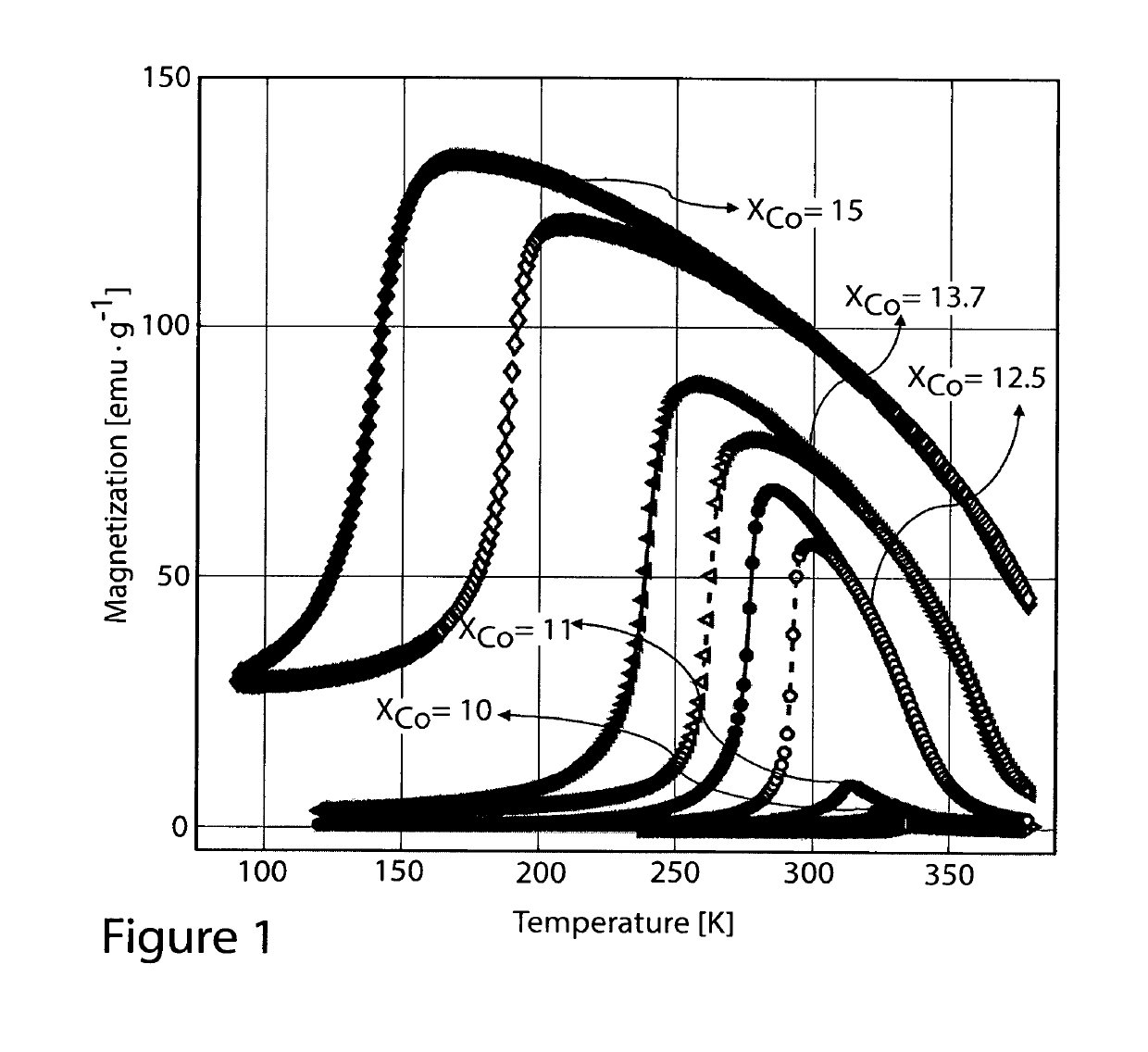

Highly tunable, inexpensive and easily fabricated magnetocaloric materials

PendingUS20190214169A1Large magnetocaloric effectImproved mechanical integrityInorganic material magnetismStructural transitionAlloy composition

A method is provided of making a magnetocaloric alloy composition comprising Ni, Co, Mn, and Ti, which preferably includes certain beneficial substitutional elements, by melting the composition and rapidly solidifying the melted composition at a cooling rate of at least 100 K / second (Kelvin / second) to improve a magnetocaloric property of the composition. The rapidly solidified composition can be heat treated to homogenize the composition and annealed to tune the magneto-structural transition for use in a regenerator.

Owner:IOWA STATE UNIV RES FOUND

Rare earth high-entropy bulk amorphous alloy with magnetothermal effect and preparation process thereof

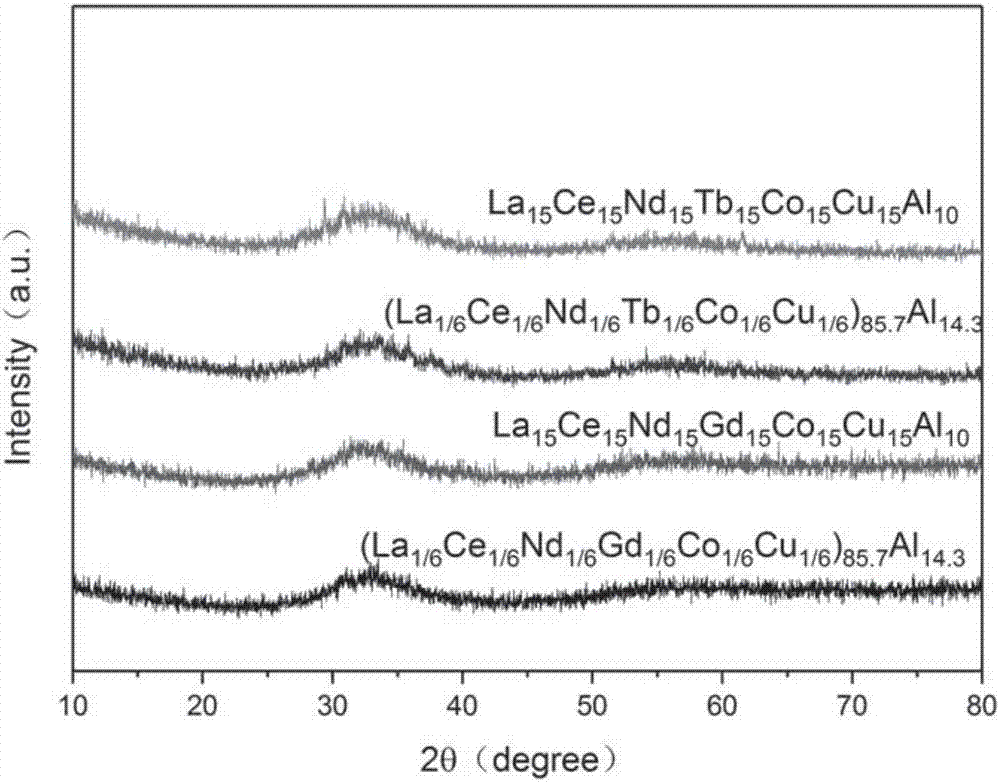

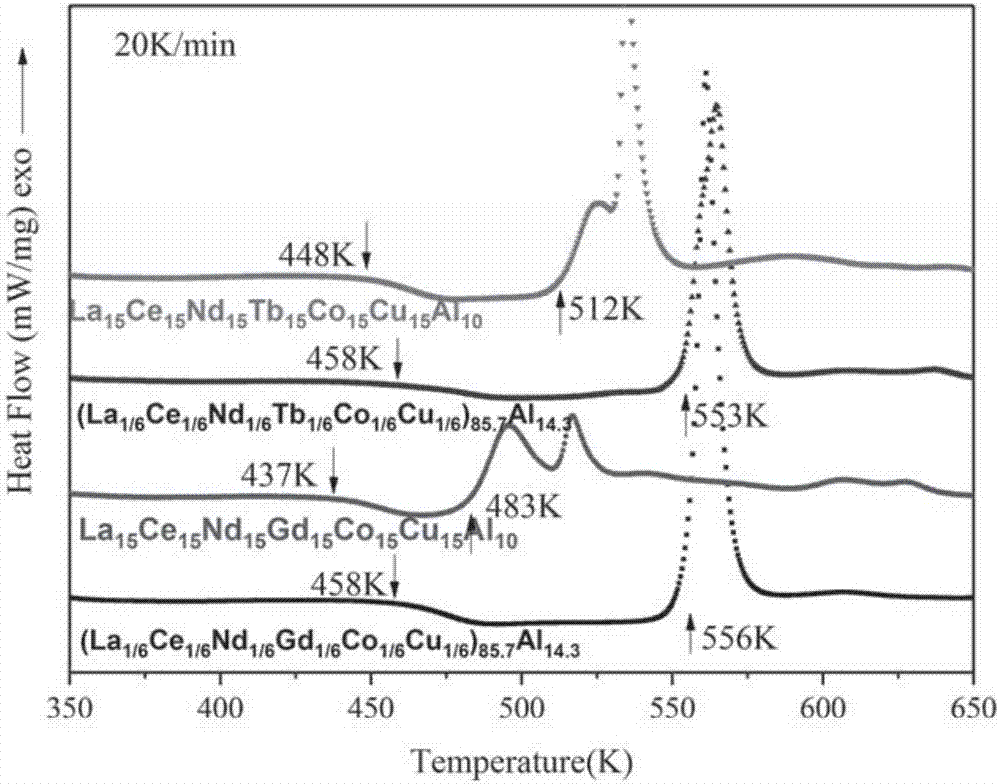

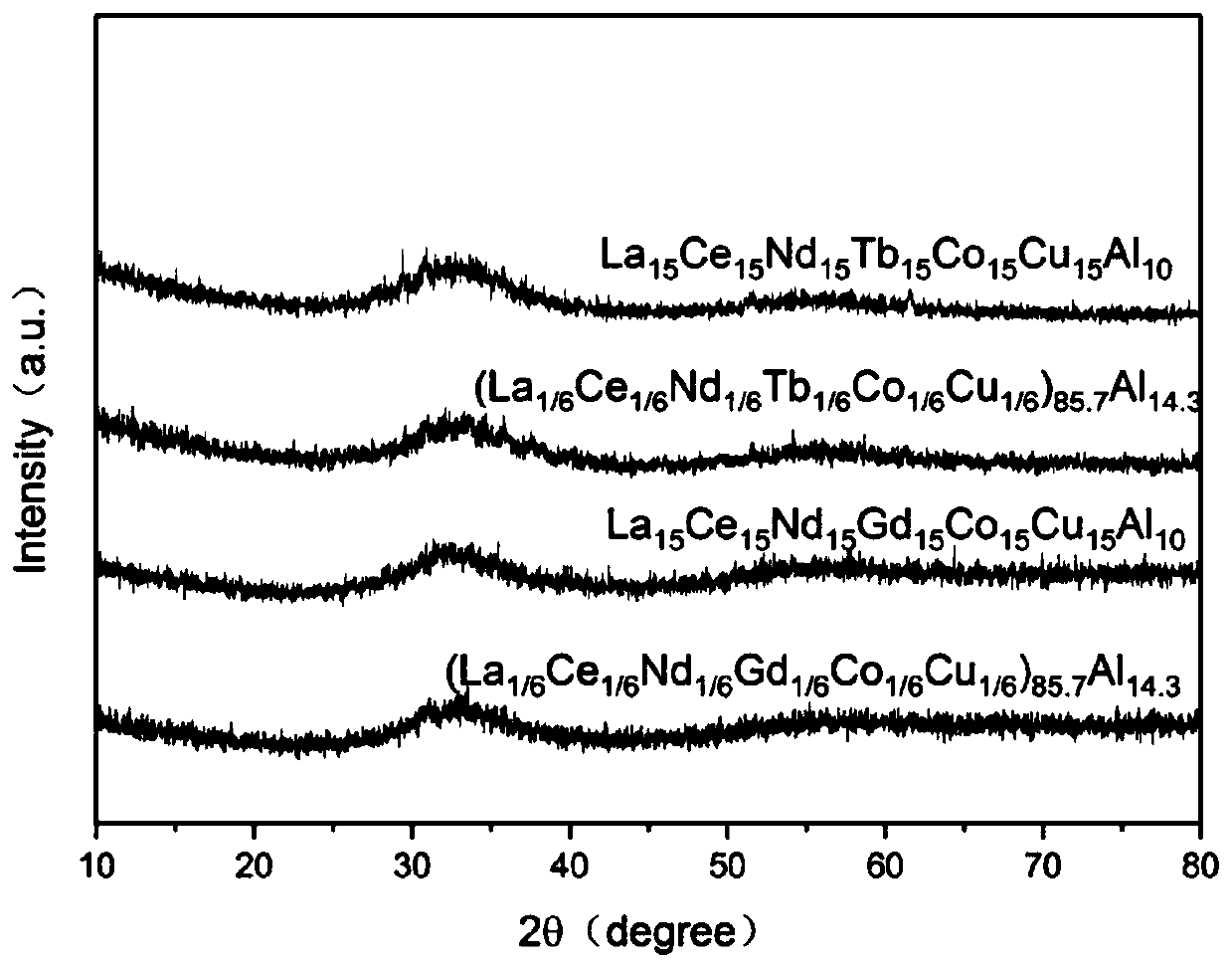

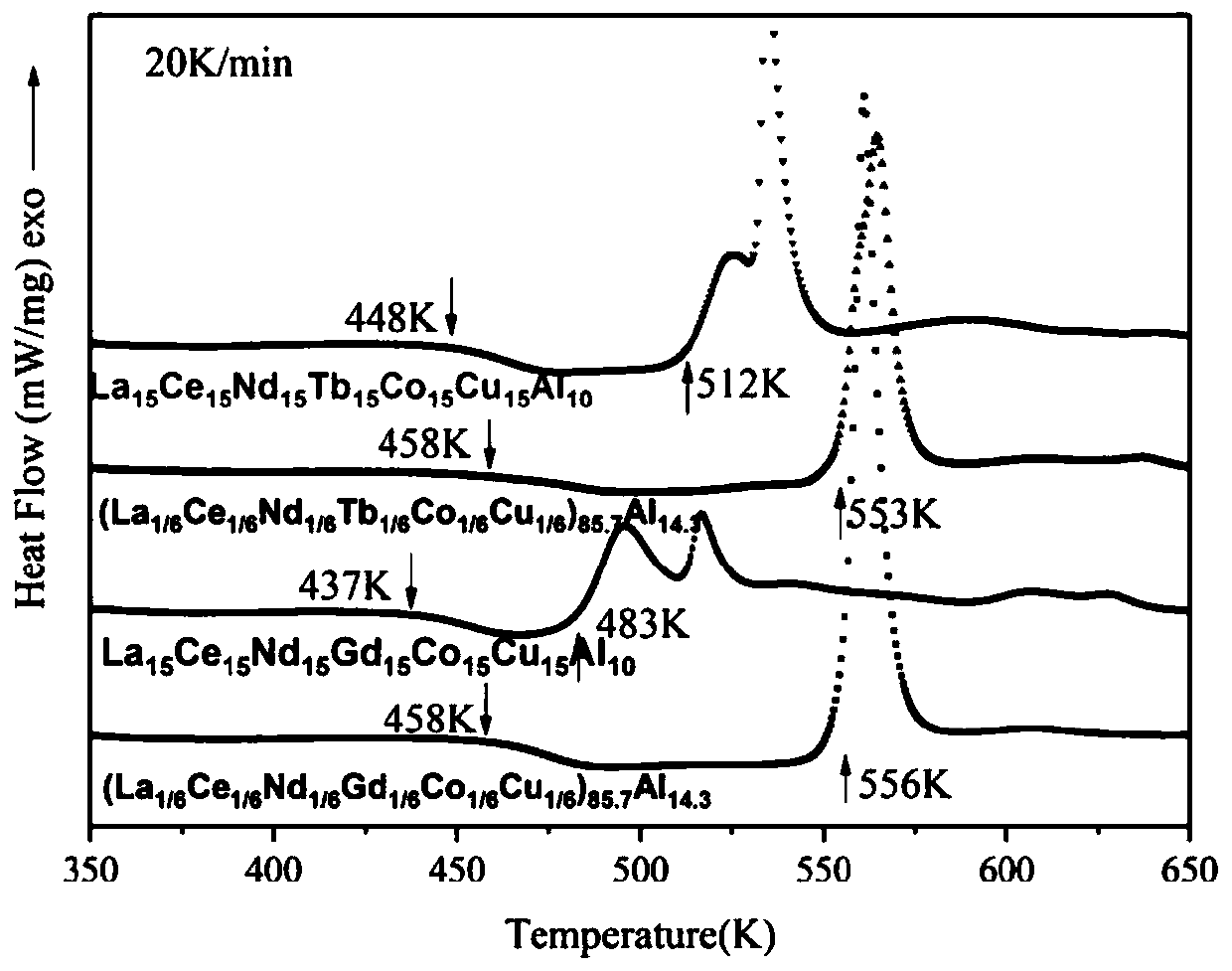

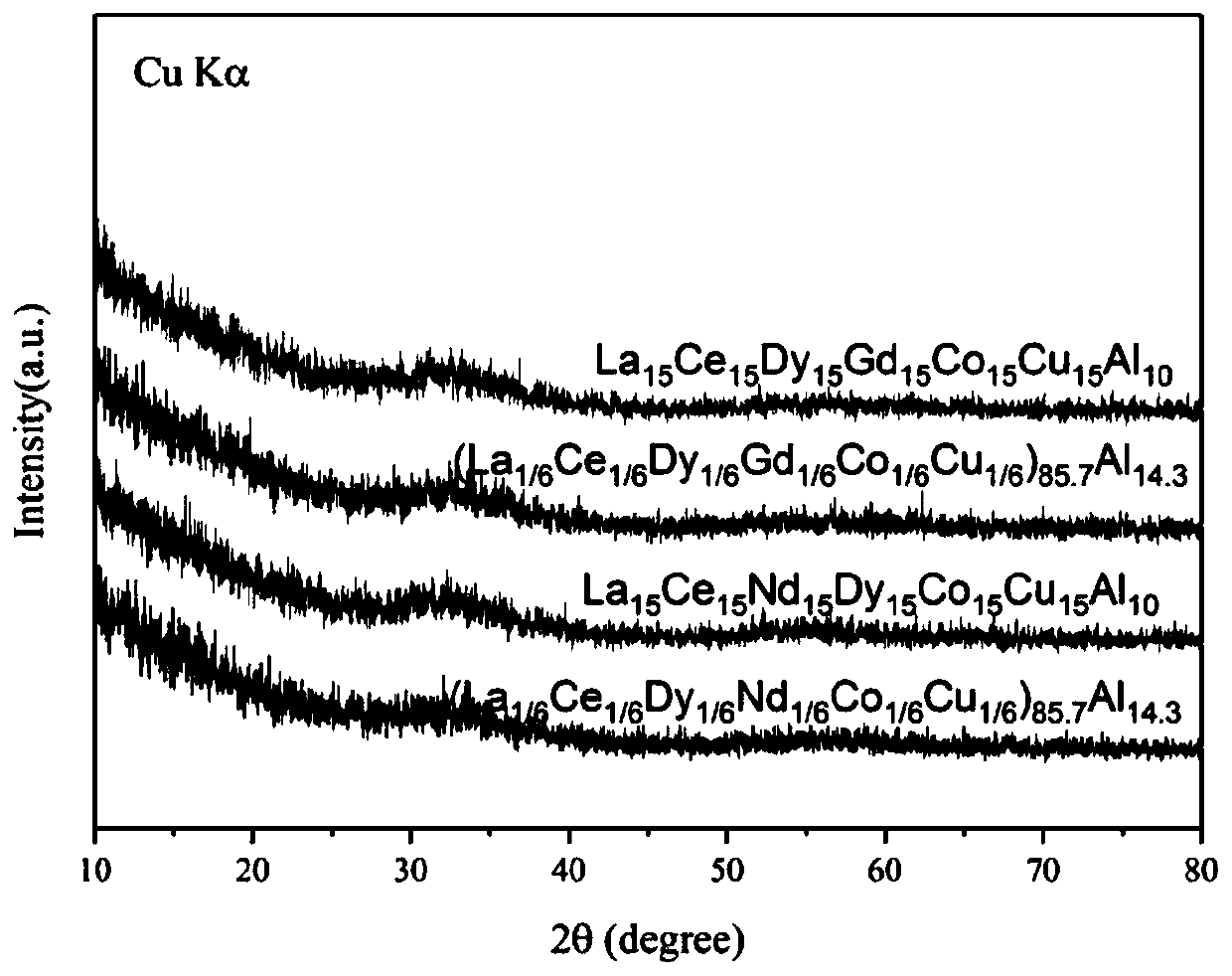

ActiveCN107058911AGood Amorphous Formation AbilityMeet size requirementsMagnetic materialsHeat-exchange elementsMain group elementAmorphous phase

The invention relates to a rare earth high-entropy bulk amorphous alloy with a magnetothermal effect and a preparation process thereof. The rare earth high-entropy bulk amorphous alloy comprises an amorphous phase with the volume fraction not lower than 95%. The ratio of various elements is an equal atomic ratio or a near equal atomic ratio. The components of the alloy mainly comprise La, Ce, Nd, Tb, Gd and Dy, transitional elements of Cu and Co, and the III main group element Al. The components of the alloy can be illustrated in formulas as shown in the specification. By adoption of the technical scheme, the rare earth bulk high-entropy amorphous alloy has good heat stability, excellent magnetothermal performance and application prospects in the field of magnetic refrigerating functional materials and structural materials compared with other component-based high-entropy amorphous alloys.

Owner:UNIV OF SCI & TECH BEIJING

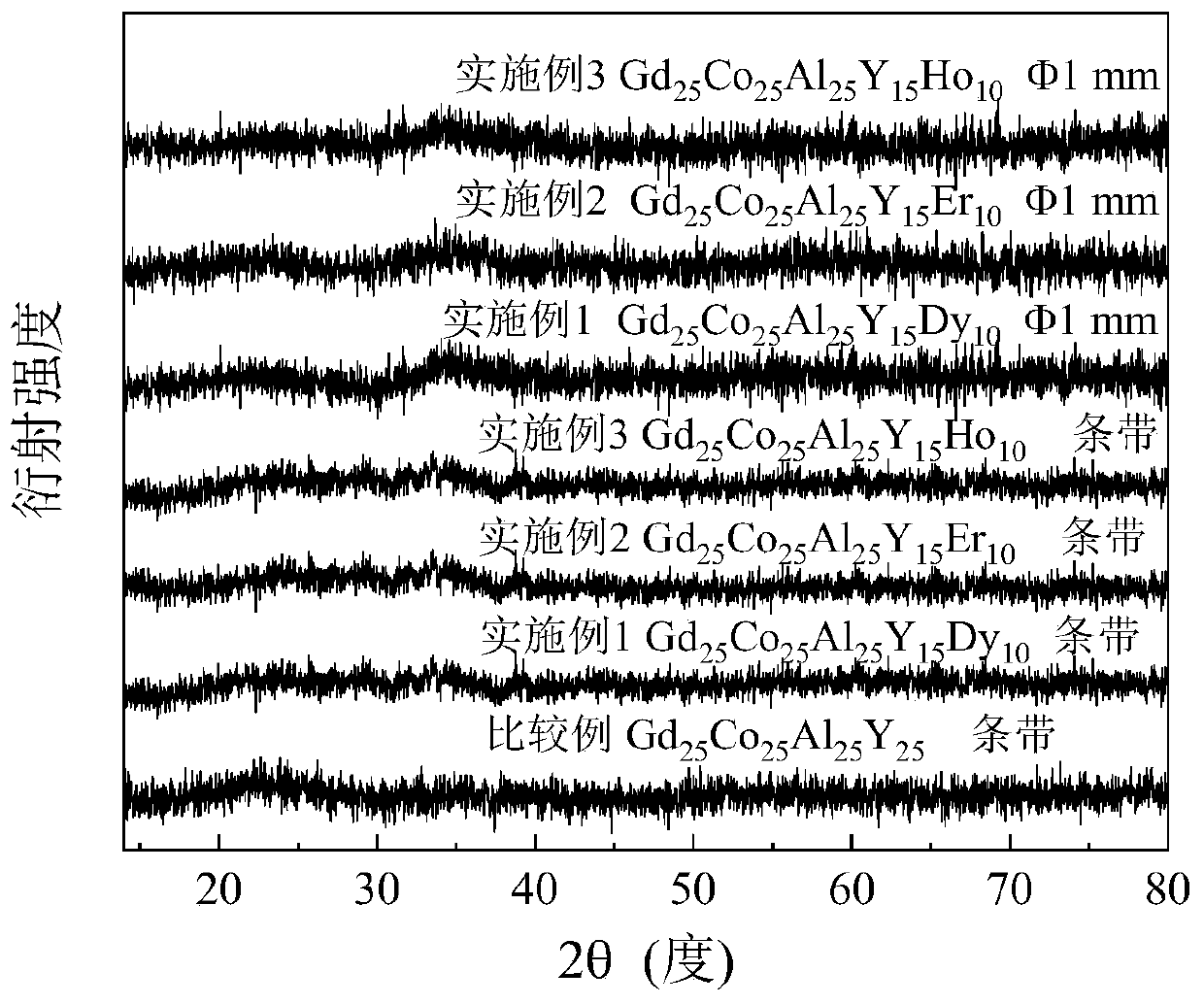

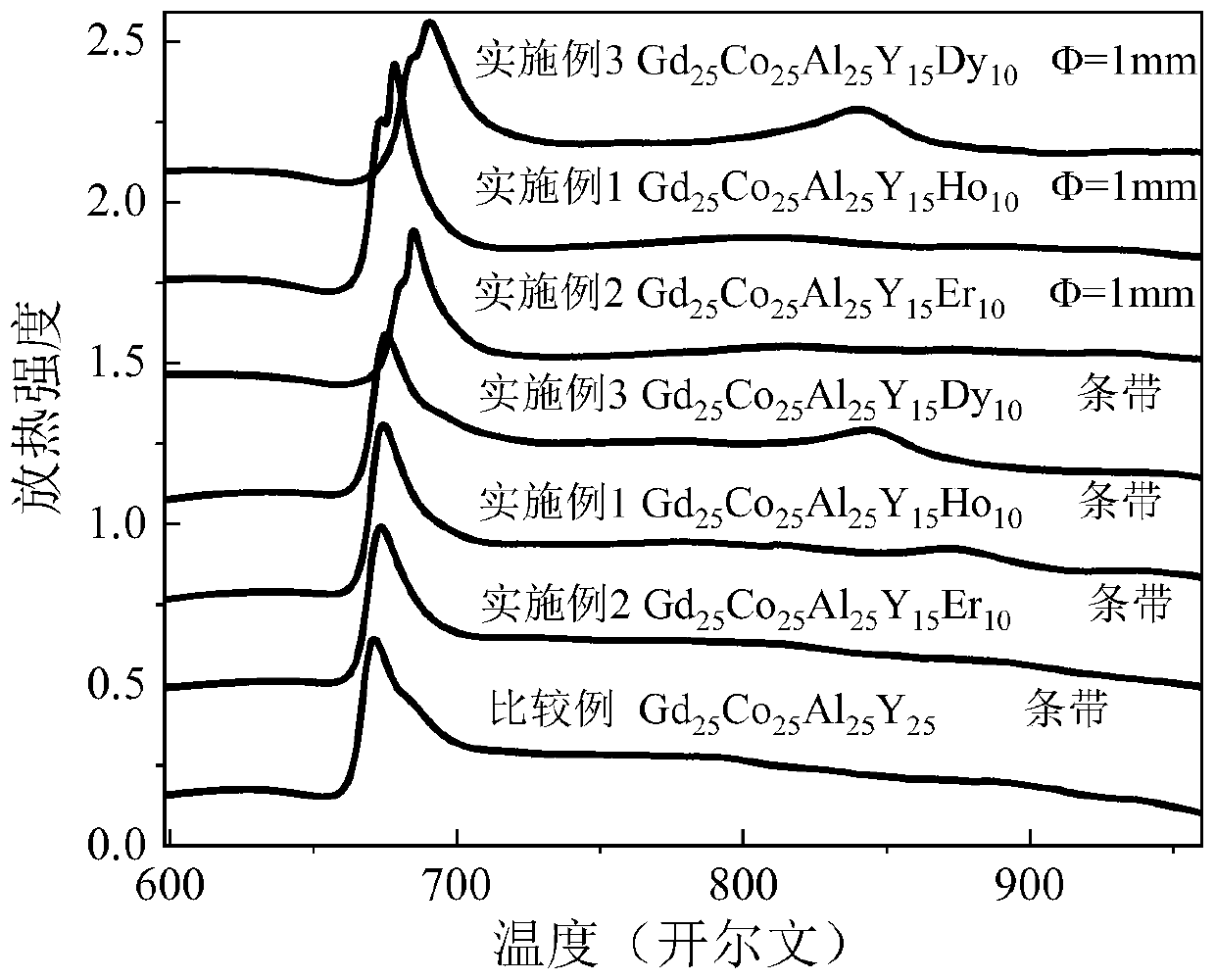

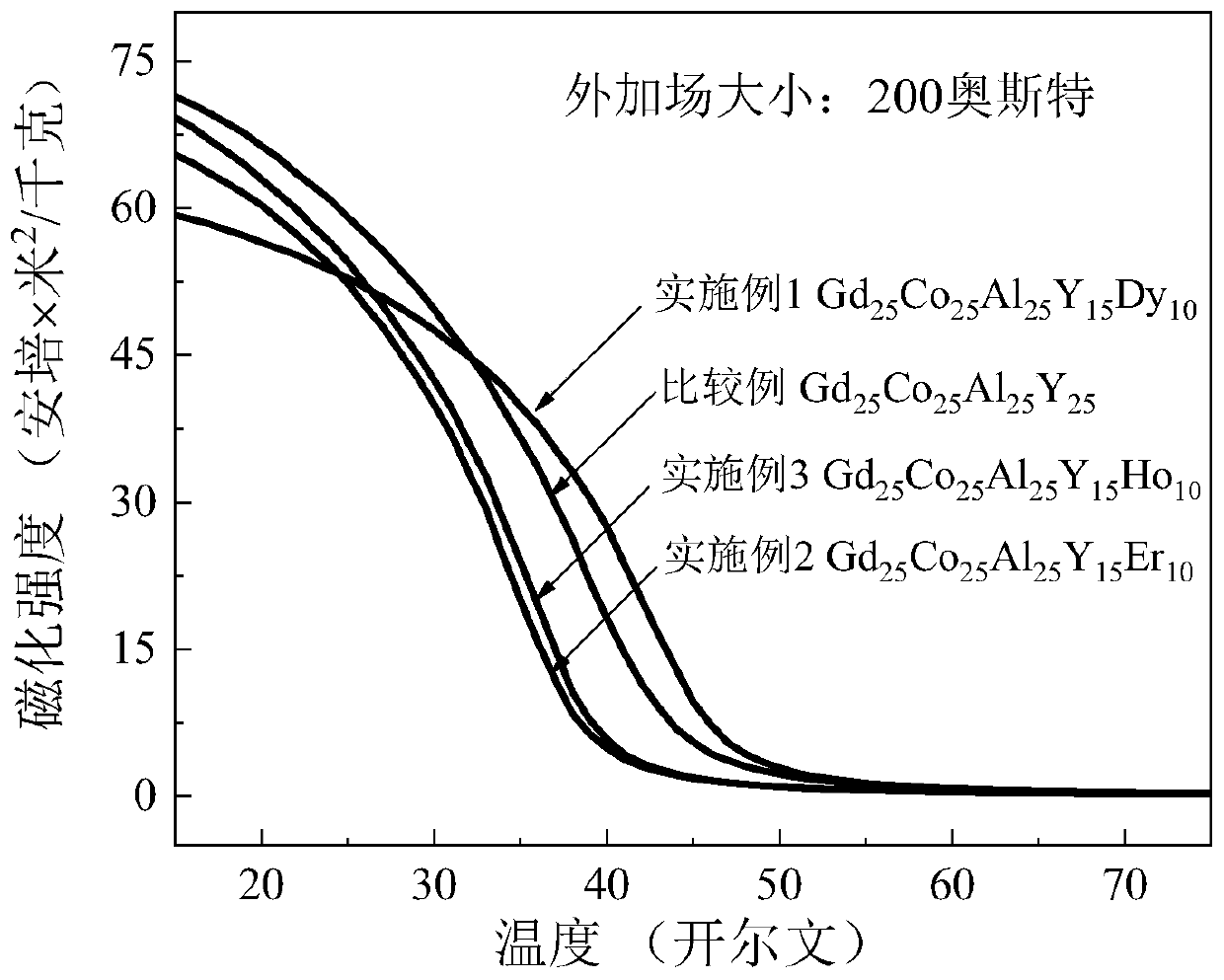

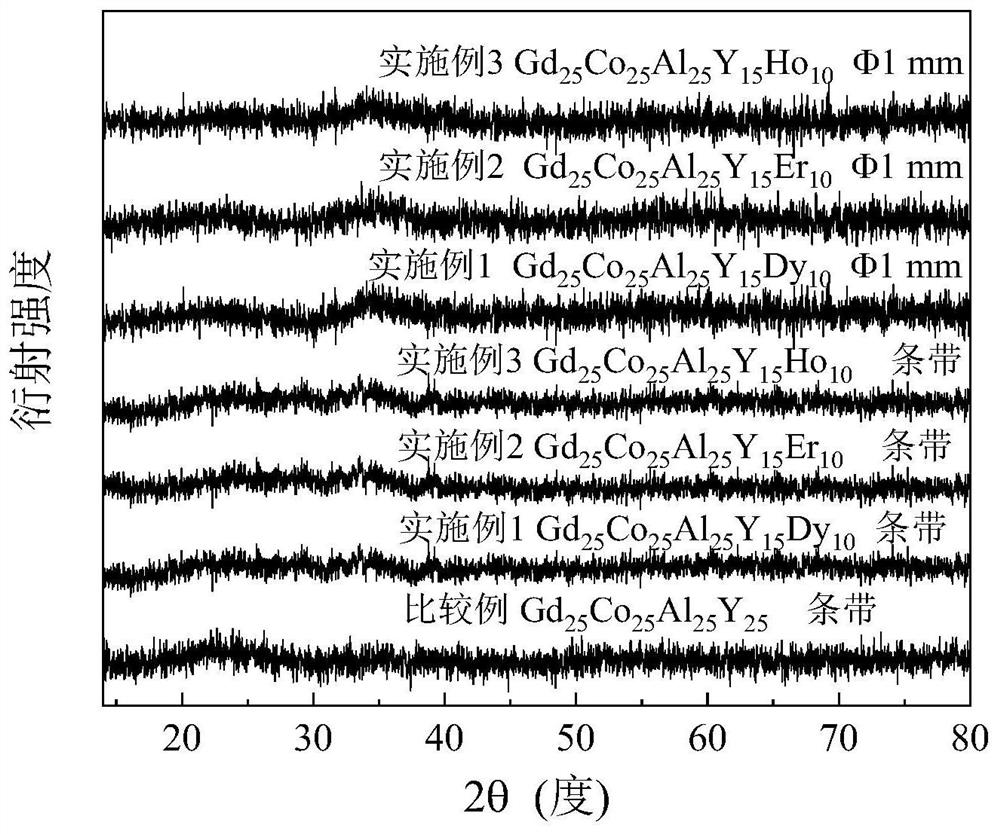

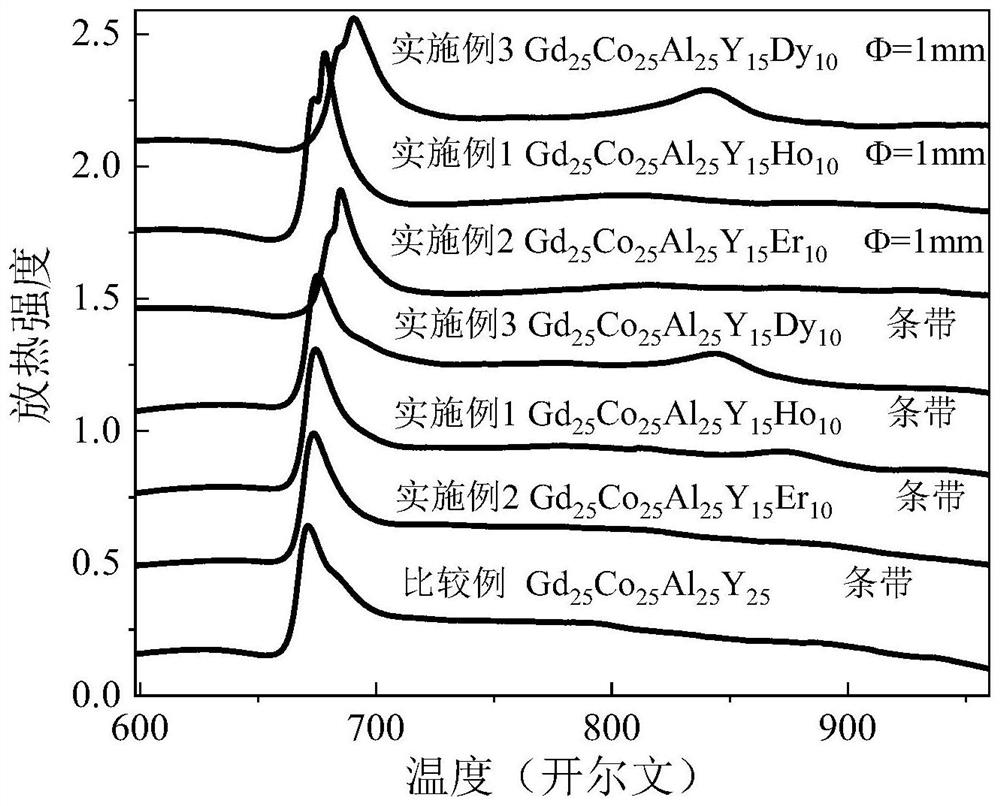

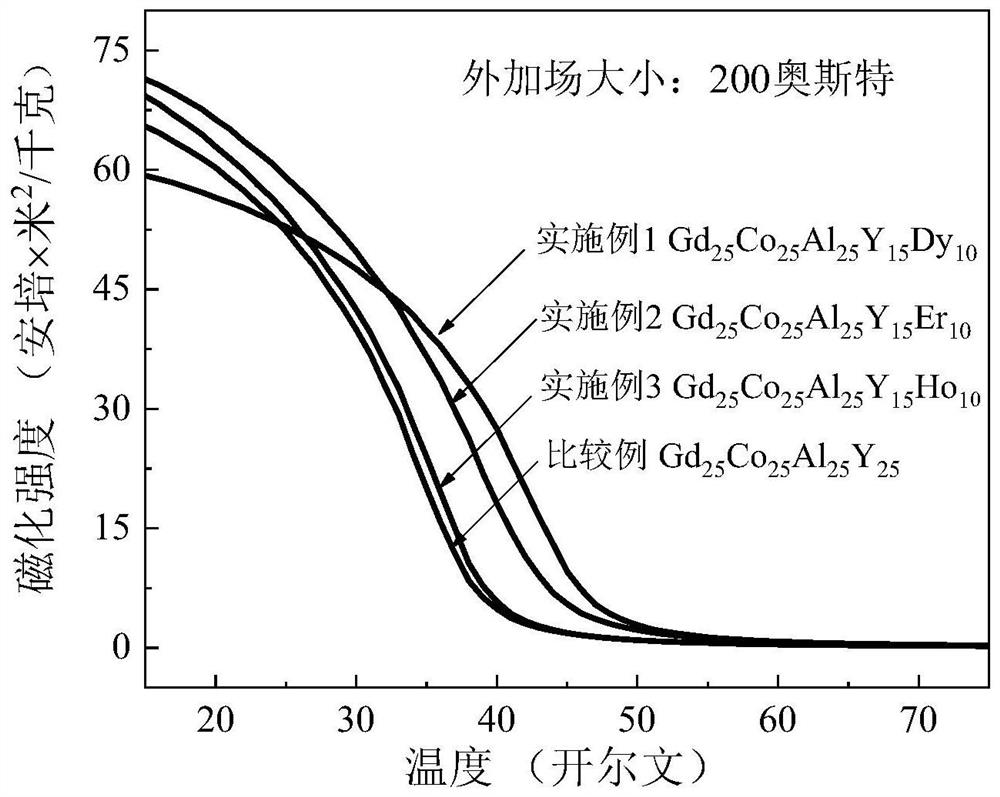

Rare-earth-based high-entropy amorphous alloy high in magnetocaloric effect and preparation method thereof

The invention discloses a rare-earth-based high-entropy amorphous alloy material high in magnetocaloric effect. The molecular formula of the rare-earth-based high-entropy amorphous alloy is GdaCobAlcYdMe, wherein a, b, c, d and e represent the atom percentage content of the corresponding element, a is larger than or equal to 24.8 and smaller than or equal to 25, b is larger than or equal to 8 andsmaller than or equal to 25.4, c is larger than or equal to 24.8 and smaller than or equal to 25.4, d is larger than or equal to 5 and smaller than or equal to 15, e is larger than or equal to 10 andsmaller than or equal to 20, a+b+c+d+e is equal to 100, and M is one of Dy, Er and Ho. On the basis of a GdCoAly high-entropy amorphous alloy, M is used for replacing Y, the high-entropy amorphous alloy high in magnetocaloric effect is obtained, the alloy is stable in magnetocaloric performance, the magnetic variation temperature range is wide, and elements likely to volatile or oxidize are not included. In addition, the completely amorphous structure of the high-entropy amorphous alloy needs no crystallization heat treatment, the preparation process is simple, and the high-entropy amorphous alloy material has good magnetocaloric performance and has good application prospects in the technical field of magnetic refrigeration.

Owner:SOUTHEAST UNIV

Ni-Co-Mn-In-Ge magnetic refrigeration alloy material and preparing method thereof

ActiveCN107881394ALarge magnetocaloric effectRealize single temperature zone coolingInorganic material magnetismMagnetic refrigerationVacuum arc

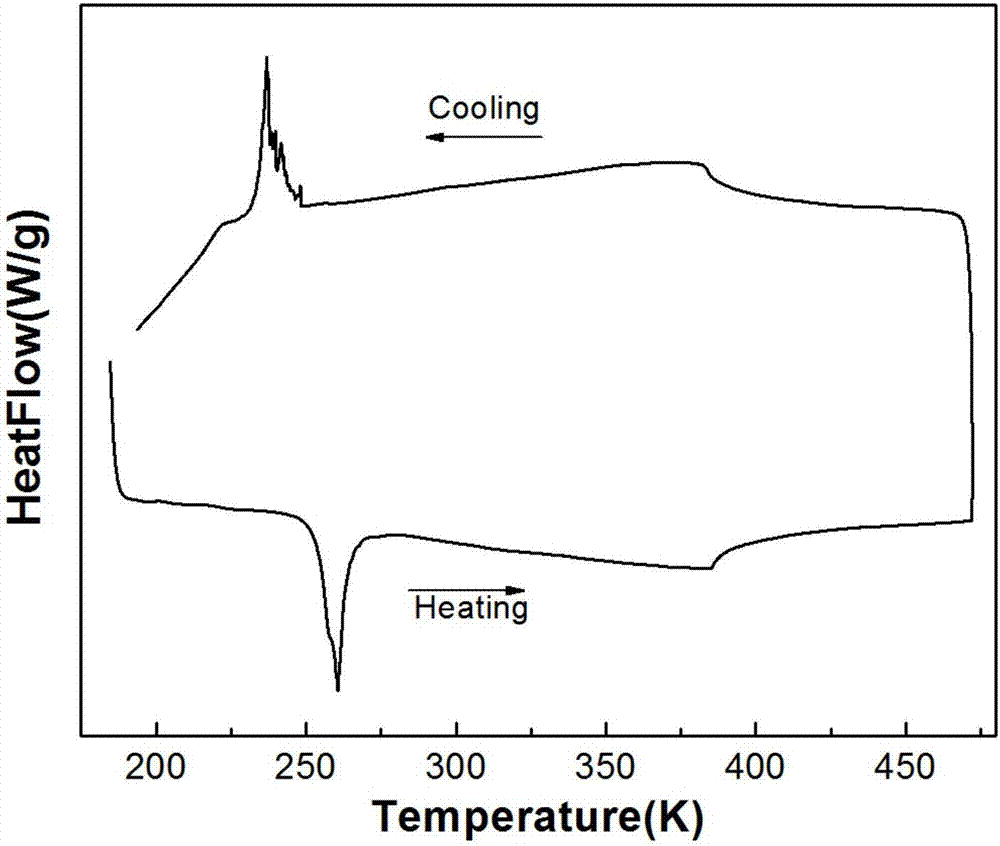

A Ni-Co-Mn-In-Ge magnetic refrigeration alloy material and a preparing method thereof belong to the technical field of magnetic refrigeration materials. The chemical molecular formula of the Ni-Co-Mn-In-Ge magnetic refrigeration alloy material is Ni45Co5Mn36.5In<13.5-x>Gex, and the molar number sum of elements in the alloy is 100, wherein x is greater than or equal to 1 and smaller than or equal to 4. In the invention, a poly-crystal ingot is prepared through raw material proportioning and vacuum arc repeated smelting, annealing is carried out under high-purity inert gas protection, and then,rapid water-cooling is carried out, so that a blocky blank of the Ni-Co-Mn-In-Ge magnetic refrigeration alloy is prepared. Under a 1.5T external magnetic field, through a heating magnetizing mode, theadiabatic temperature change range of the alloy block is 1.34-2.69K. The magnetic alloy material can have large adiabatic temperature change near a room temperature, and can be used as a magnetic refrigerating working medium in the working range of a wide temperature range with a great magnetothermal effect.

Owner:NORTHEASTERN UNIV

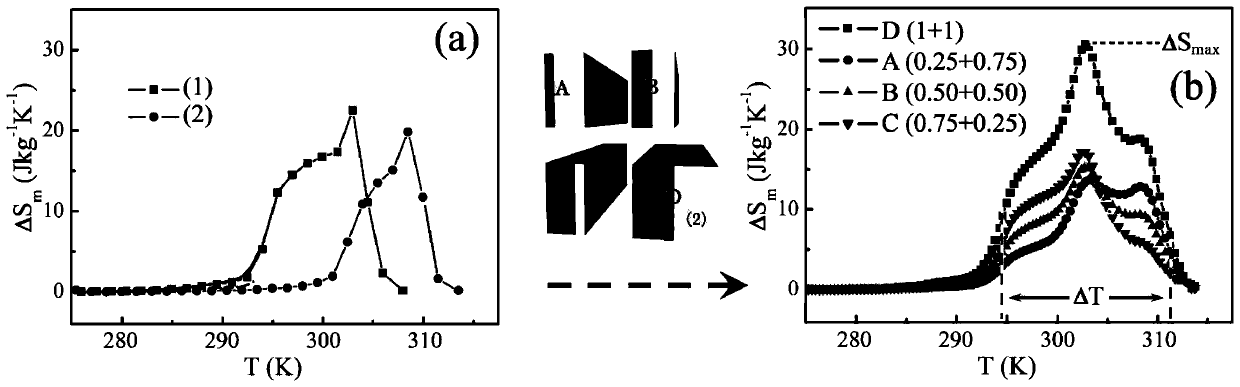

Temperature-graded magnetic heating material and preparation method thereof

ActiveCN109913816AImprove the magnetocaloric effectLarge magnetocaloric effectVacuum evaporation coatingSputtering coatingMagnetic heatingWorking temperature

The invention belongs to the field of magnetic refrigeration, and particularly relates to a temperature-graded magnetic heating material and a preparation method thereof. The temperature-graded magnetic heating material comprises a Ni50Mn37Sn13 alloy film layer and a Ni50Mn35In15 alloy film layer. The phase change temperature of the Ni50Mn37Sn13 alloy film layer ranges from 295 K to 305 K. The phase change temperature of the Ni50Mn35In15 alloy film layer ranges from 301 K to 310 K. The thickness ratio of the Ni50Mn37Sn13 alloy film layer to the Ni50Mn35In15 alloy film layer is 1:3 to 3:1. According to the temperature-graded magnetic heating material and the preparation method thereof, by carrying out gradient design and preparation on the magnetic heating material, the work temperature zone of an existing magnetic heating material can be expanded, and the magnetic heating effect of the material can be improved; and a design rule and a regulating and control mechanism of the magnetic heating material are set up, and the gradient magnetic heating temperature material is pushed to develop towards application.

Owner:上海利鑫生物科技有限公司

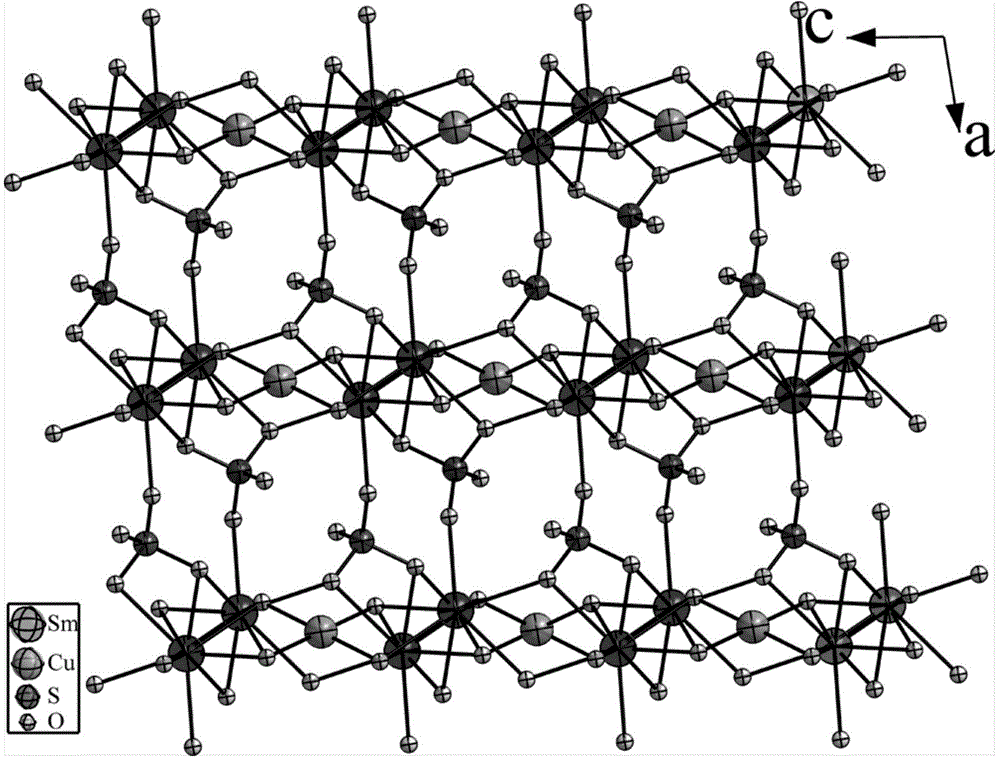

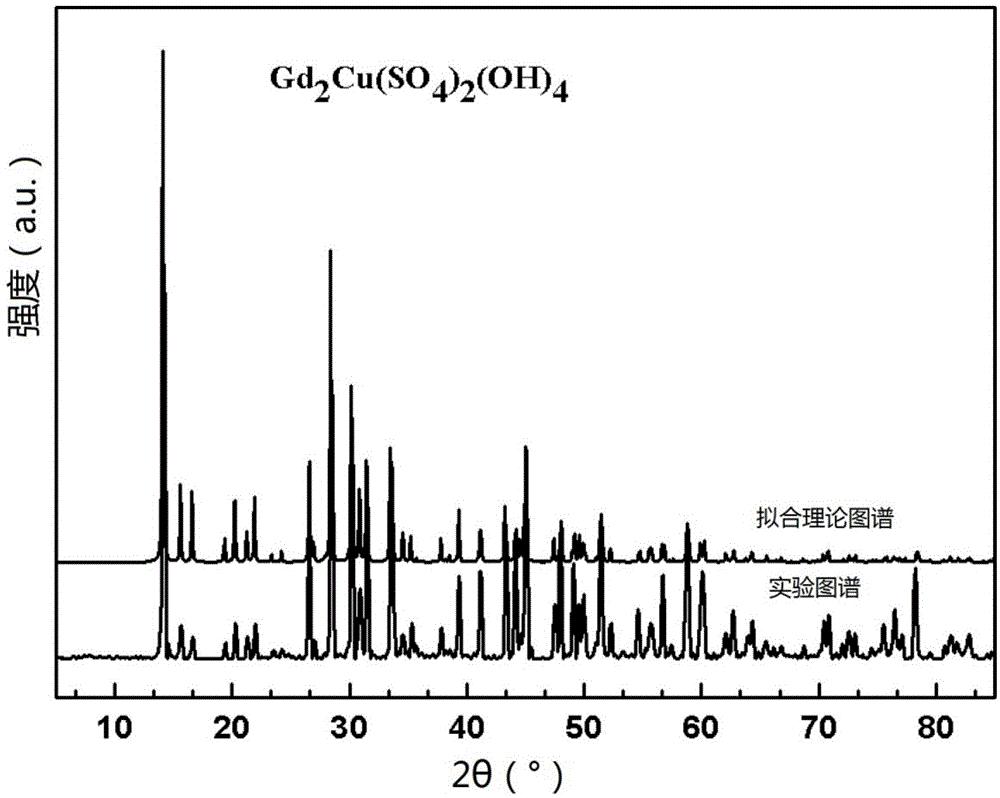

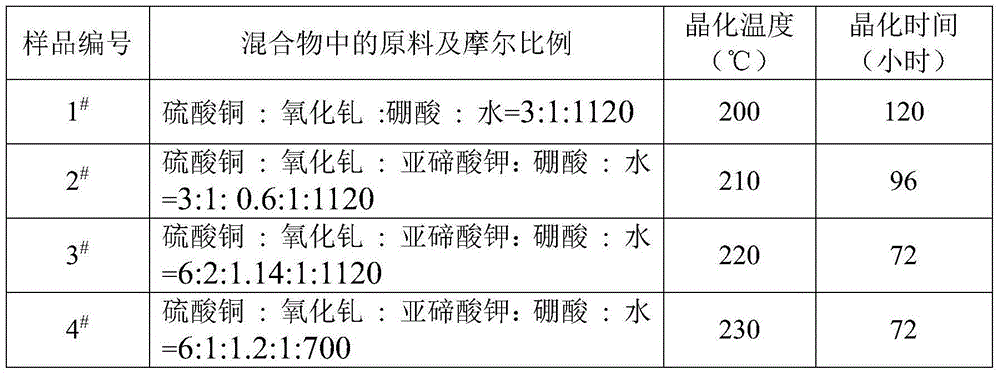

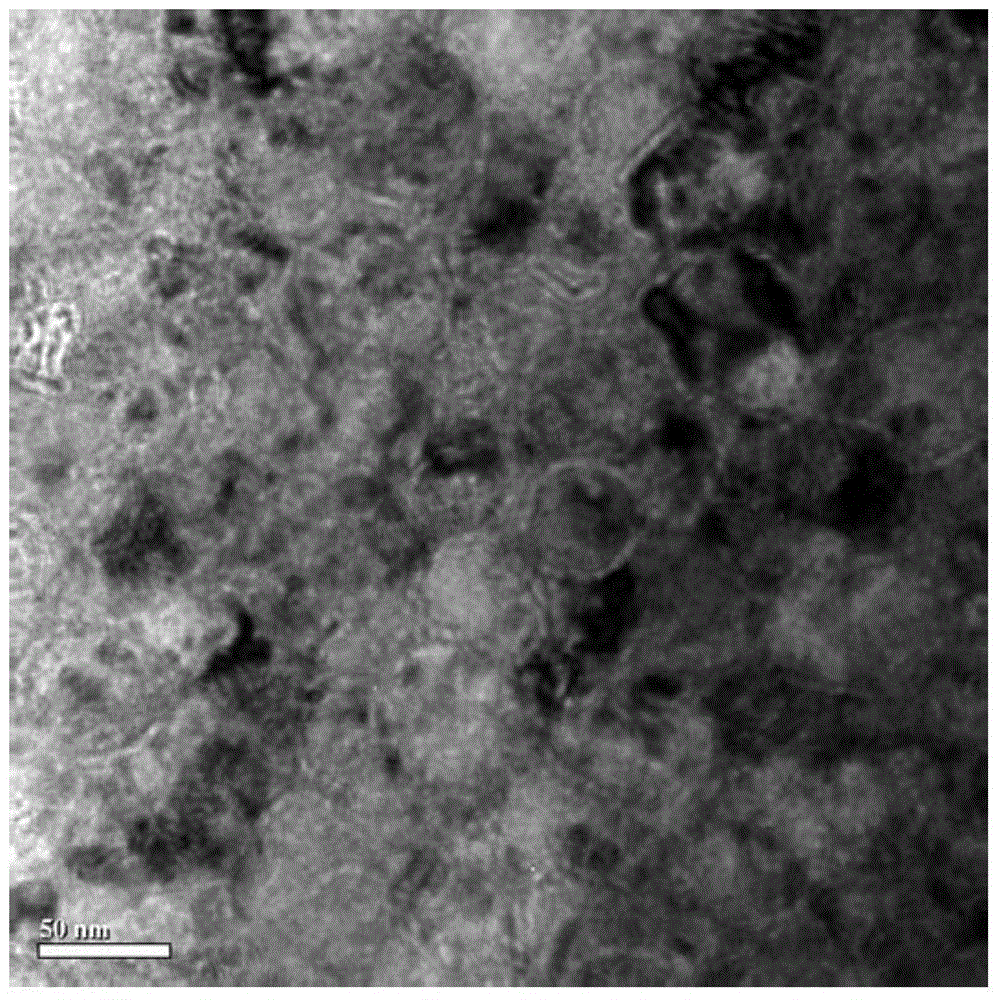

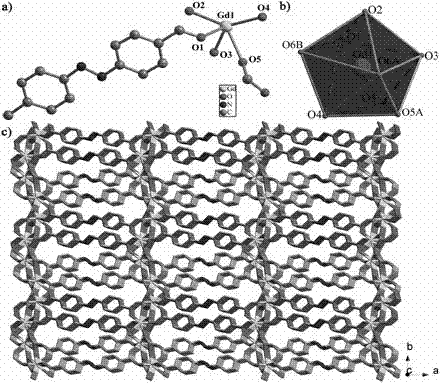

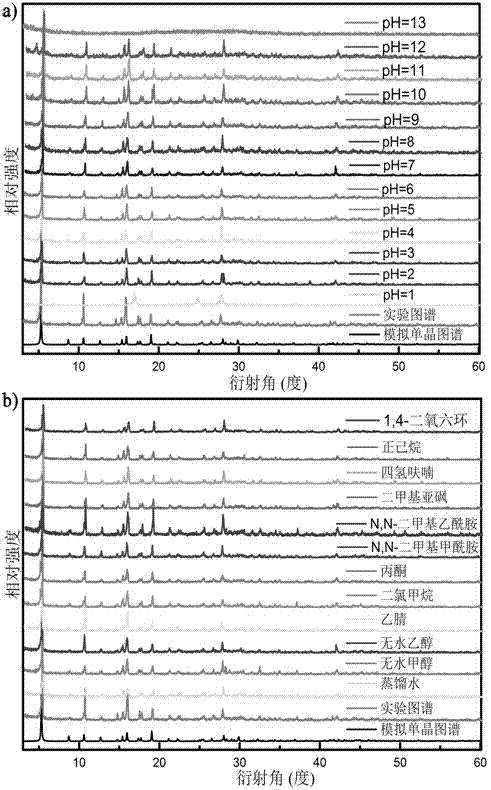

Crystal material, preparation method thereof and magnetic refrigerating material applying crystal material

ActiveCN105714378ALarge magnetocaloric effectImprove the cooling effectPolycrystalline material growthFrom normal temperature solutionsSpace groupCell parameter

The invention discloses a crystal material. The crystal material is characterized in that a molecular formula of the crystal material is fd2Cu(SO4)2(OH)4, the crystal material belongs to a monoclinic system, space group is P21 / c, cell parameters are shown as follows, wherein both alpha and gamma are equal to 90 degrees, beta is equal to 98.3-98.4, and Z is equal to 2. Magnetothermal effect of the crystal material is far greater than DGG, and the crystal material has good refrigerating performance. The invention further discloses a preparation method of the crystal material. The preparation method is simple, suitable for large-scale industrial production and wide in market prospect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

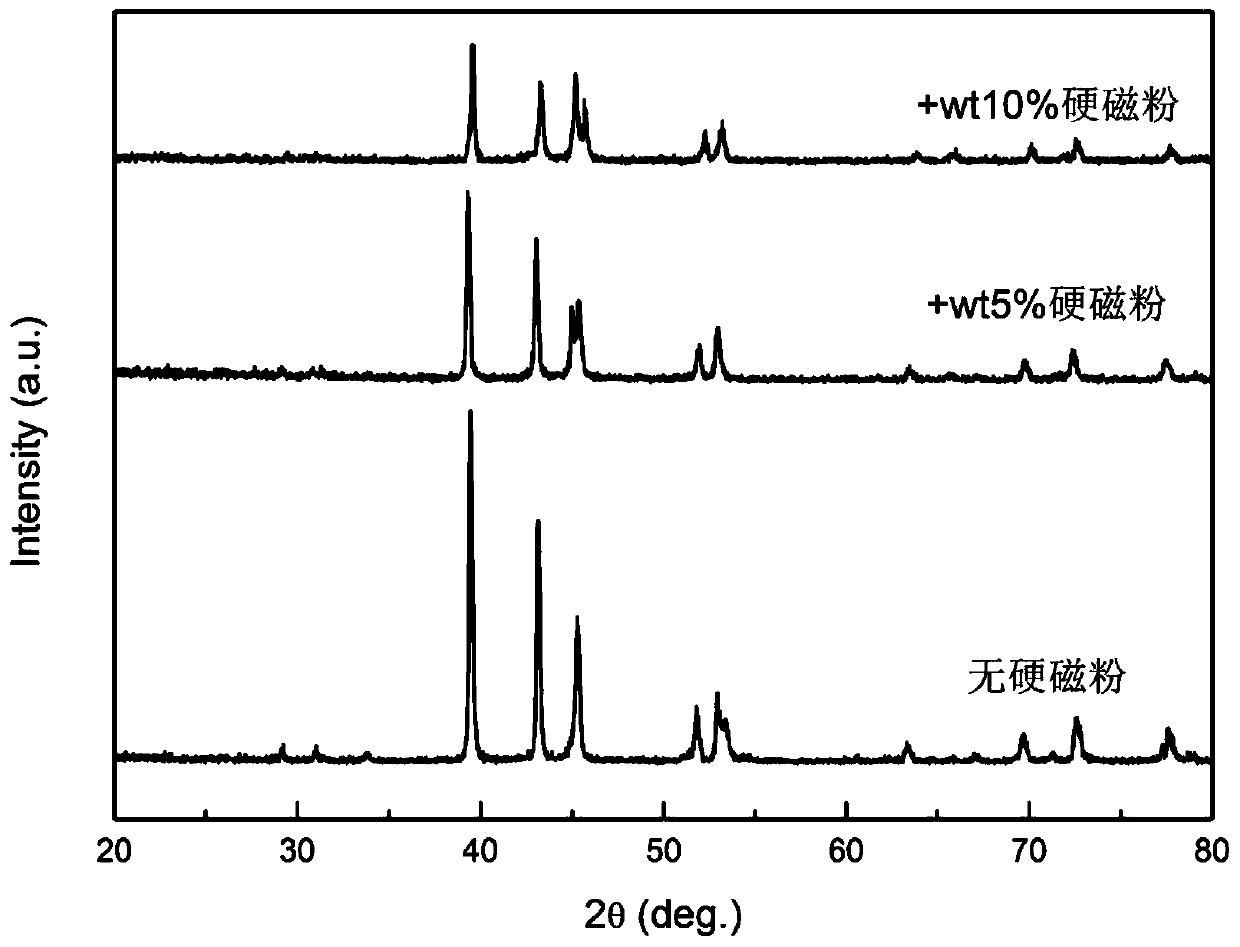

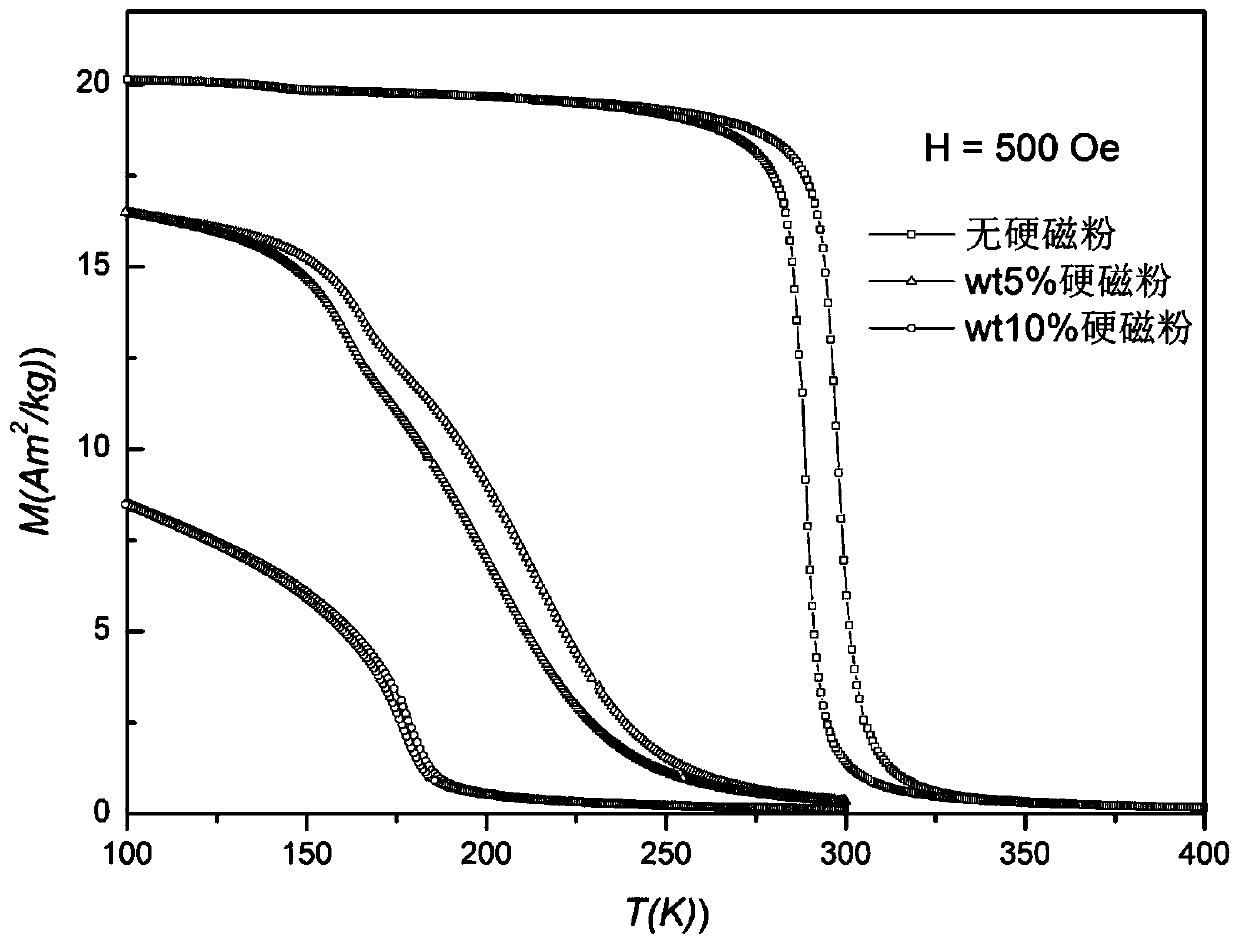

Ferromanganese-based magnetic refrigeration material with low heat stagnation and preparation method and application thereof

ActiveCN110880391ALow thermal hysteresisLow densityInorganic material magnetismHigh densityMixed materials

The invention belongs to the technical field of refrigeration, and discloses a ferromanganese-based magnetic refrigeration material with low heat stagnation and a preparation method and application thereof. The ferromanganese-based magnetic refrigeration material with low heat stagnation is prepared by sintering hard magnetic powder and mixed powder containing manganese and iron. The hard magneticpowder is composed of one or more of neodymium iron boron, samarium cobalt and samarium iron nitrogen hard magnets. The molar ratio of the mixed powder meets the chemical general formula MnxFey-xPaSib, and x is more than or equal to 0.9 and less than or equal to 1.3, y is greater than or equal to 1.9 and less than or equal to 2, a is more than or equal to 0.15 and less than or equal to 0.75, a and b meet the condition that a + b is equal to 1. Through adding hard magnetic powder into a mixed material containing manganese and iron, the block material with low heat stagnation and high density is prepared, the phase change temperature and heat stagnation of the magnetic refrigeration material are effectively changed by adding the hard magnetic powder, the block material with low heat stagnation, large magnetocaloric effect and high density is prepared, and the preparation method is beneficial to being applied to the technical field of room-temperature magnetic refrigeration.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Gadolinium block material and preparation method thereof

ActiveCN104923790ALarge magnetocaloric effectRefined grain sizeHeat-exchange elementsGadoliniumPre treatment

The invention discloses a gadolinium block material and a preparation method thereof. The preparation method comprises the following operation steps that firstly, metal gadolinium powder is used as the raw material and is ground through a mechanical milling method; secondly, the nanoscale gadolinium powder is placed in a die and pre-pressed in a pre-treatment chamber protected by argon; and thirdly, the die is placed in a spark plasma sintering device for sintering, and therefore the gadolinium block material is obtained. The preparation method is simple and practicable and can be used for preparing gadolinium block materials of different grain sizes; the average grain size of the material is adjustable within the range of 20-1000 nanometers, and the corresponding magnetothermal effect of the material within the grain size range is improved along with increase of the grain size of the prepared material.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Alloy magnetocaloric material for magnetic refrigeration at room temperature as well as preparation method and application thereof

ActiveCN107267839ASolve temperature problemsSolve too lowInorganic material magnetismInductances/transformers/magnets manufactureElectric arc furnaceManganese

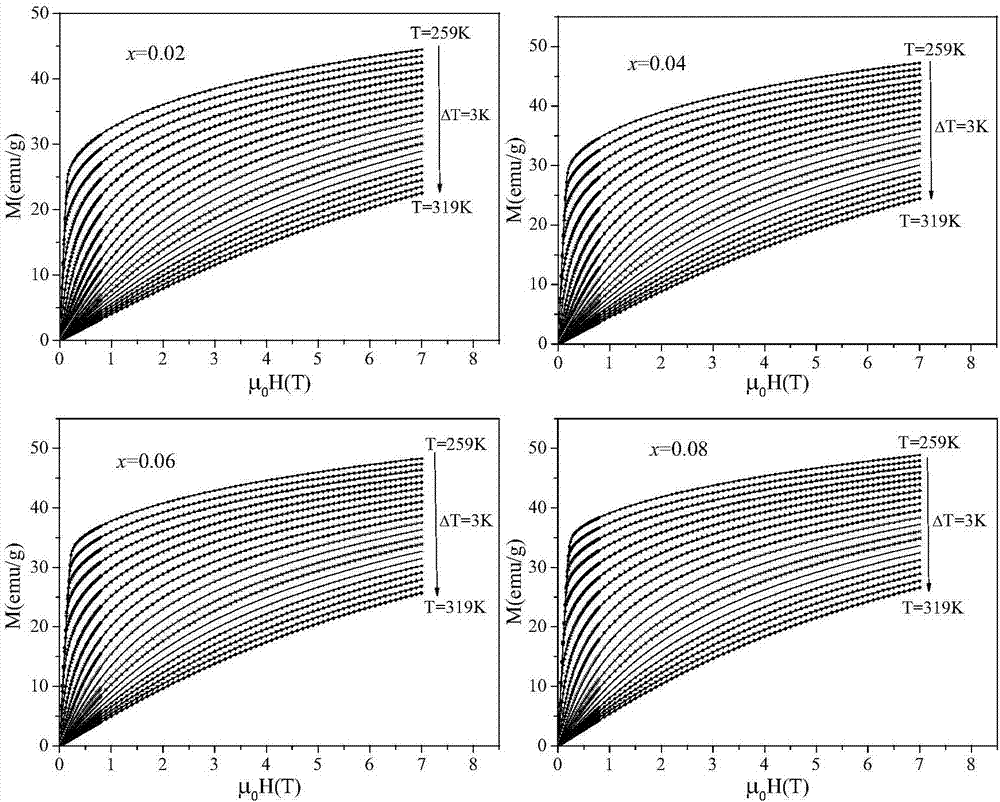

The invention relates to an alloy magnetocaloric material for magnetic refrigeration at a room temperature as well as a preparation method and application thereof. A chemical general formula of the material is MnCo1-xTixGe, wherein x is 0.02 to 0.08; the atomic percentage of a manganese element in the material is 33.3 to 34.4 percent; the atomic percentage of a cobalt element is 32.8 to 33.3 percent; the atomic percentage of a titanium element is 0.6 to 2.7 percent; and the atomic percentage of a germanium element is 30.2 to 32.7 percent. During preparation, reactants are added into a vacuum electric arc furnace; the vacuum electric arc furnace is vacuumized to 10<4> Pa or below, and high-purity argon gas is introduced; samples are melted for 2 to 5 times repeatedly; samples are taken out and cooled, and then put into a high-temperature resistant quartz glass test tube for vacuumizing; the high-purity argon gas is introduced to clean the gas and then put into a furnace type box; and the samples are taken out and annealed to obtain a finished product. Compared with the prior art, the alloy magnetocaloric material disclosed by the invention is a secondary phase change material, and has the characteristics of small heat stagnation and large regulated temperature zones; moreover, the problem of the heat stagnation caused by a primary phase change material can be effectively avoided; and a preparation process has simple steps, the condition controllability is good, and the material has good application prospect.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

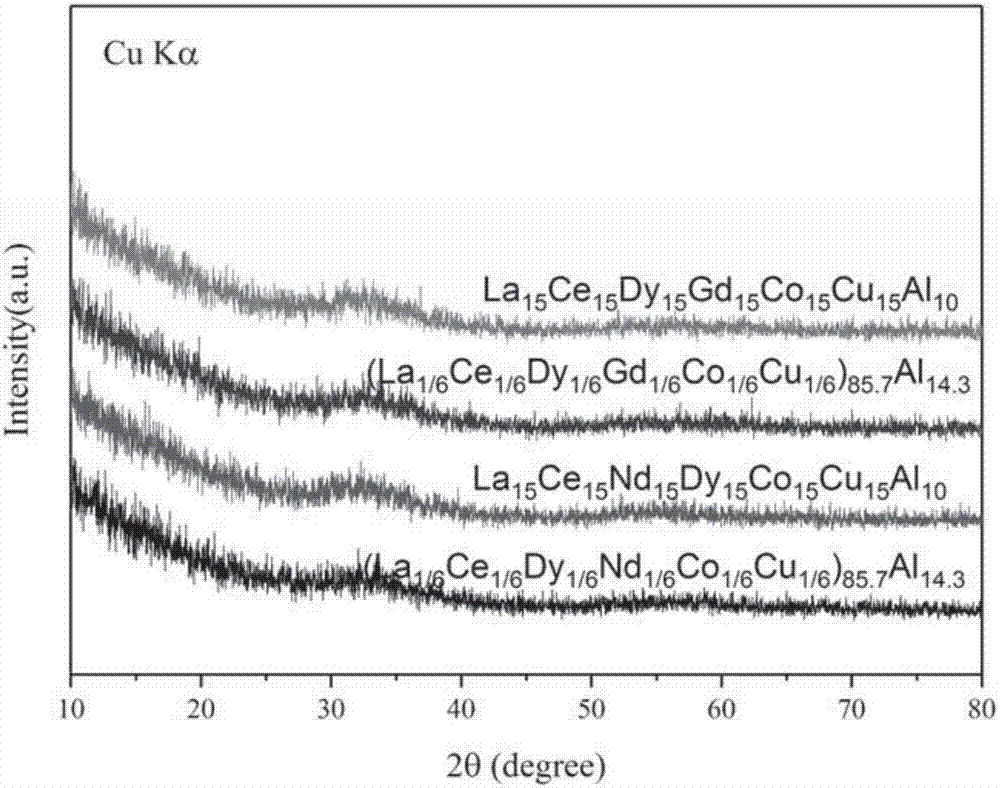

Rare earth high entropy bulk amorphous alloy with magnetocaloric effect and its preparation process

ActiveCN107058911BMeet size requirementsGood Amorphous Formation AbilityMagnetic materialsHeat-exchange elementsMain group elementHeat stability

The invention relates to a rare earth high-entropy bulk amorphous alloy with magnetocaloric effect and its preparation process. The rare-earth high-entropy bulk amorphous alloy contains an amorphous phase with a volume fraction of not less than 95%, and various elements are equal to Atomic ratio or nearly equivalent atomic ratio, the alloy composition mainly includes La, Ce, Nd, Tb, Gd, Dy, as well as transition group elements Cu, Co, and the main group III element Al, and its composition can be expressed by the following formula: (La 1 / 6 Ce 1 / 6 Nd 1 / 6 m 1 / 6 co 1 / 6 Cu 1 / 6 ) y Al x . or (La 1 / 6 Ce 1 / 6 Dy 1 / 6 Q 1 / 6 co 1 / 6 Cu 1 / 6 ) b Al a . Due to the adoption of the above technical solution, the present invention produces a rare earth block high-entropy amorphous alloy. Compared with other component-based amorphous high-entropy amorphous, it has good thermal stability and excellent magnetocaloric properties, and has application prospects in magnetic refrigeration functional materials and structural materials.

Owner:UNIV OF SCI & TECH BEIJING

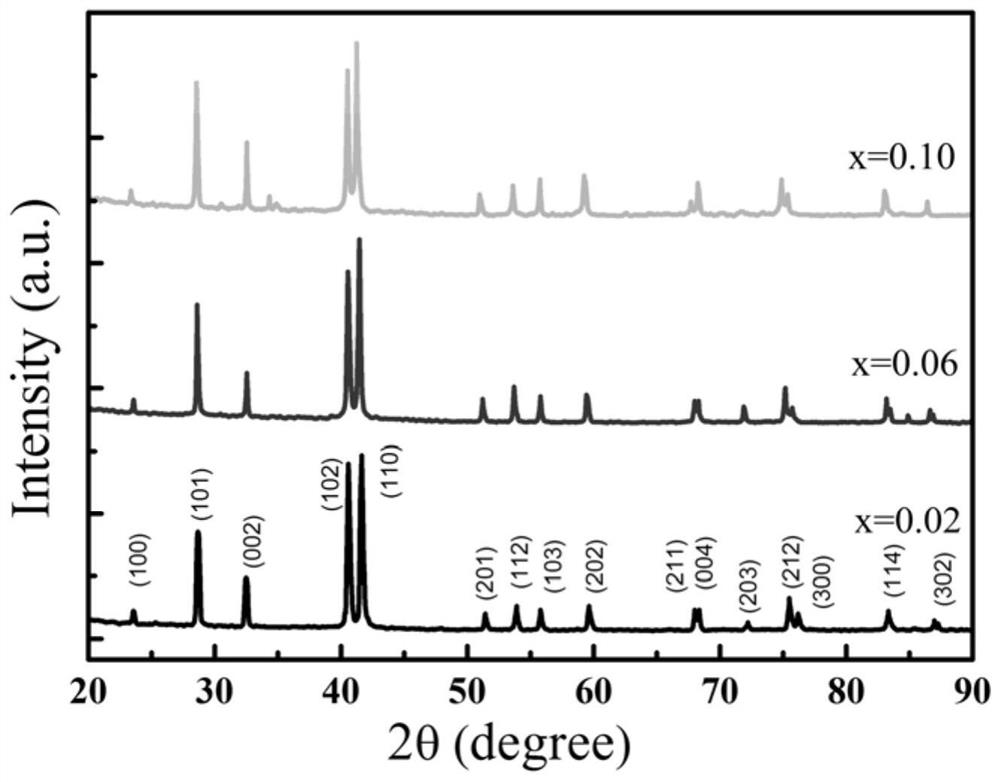

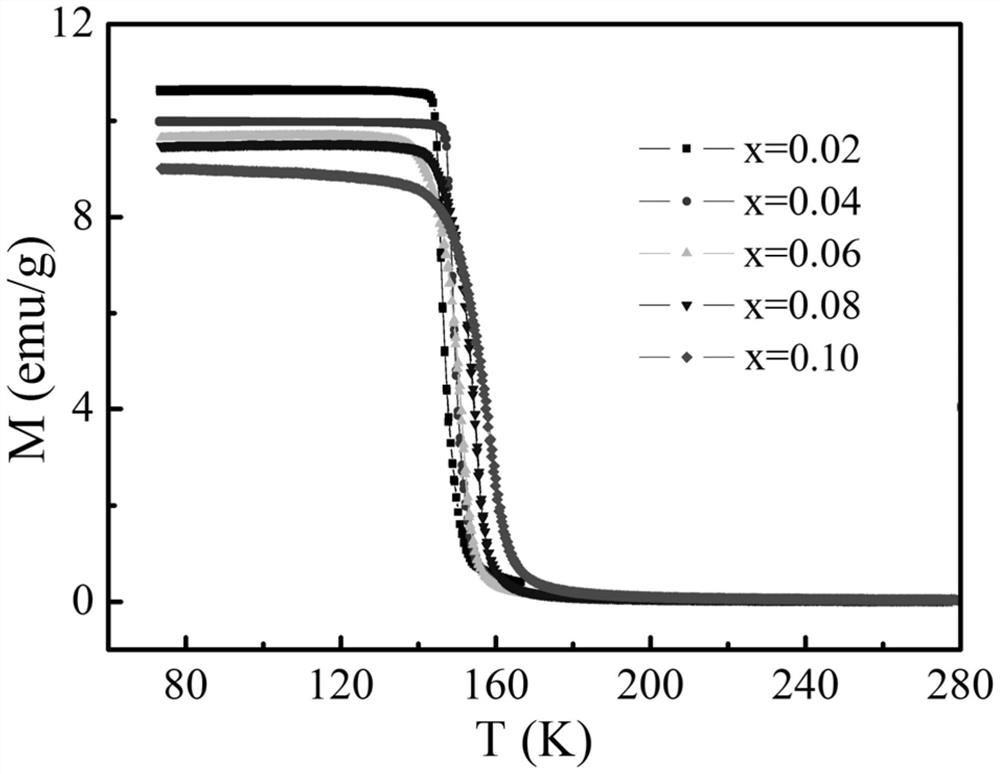

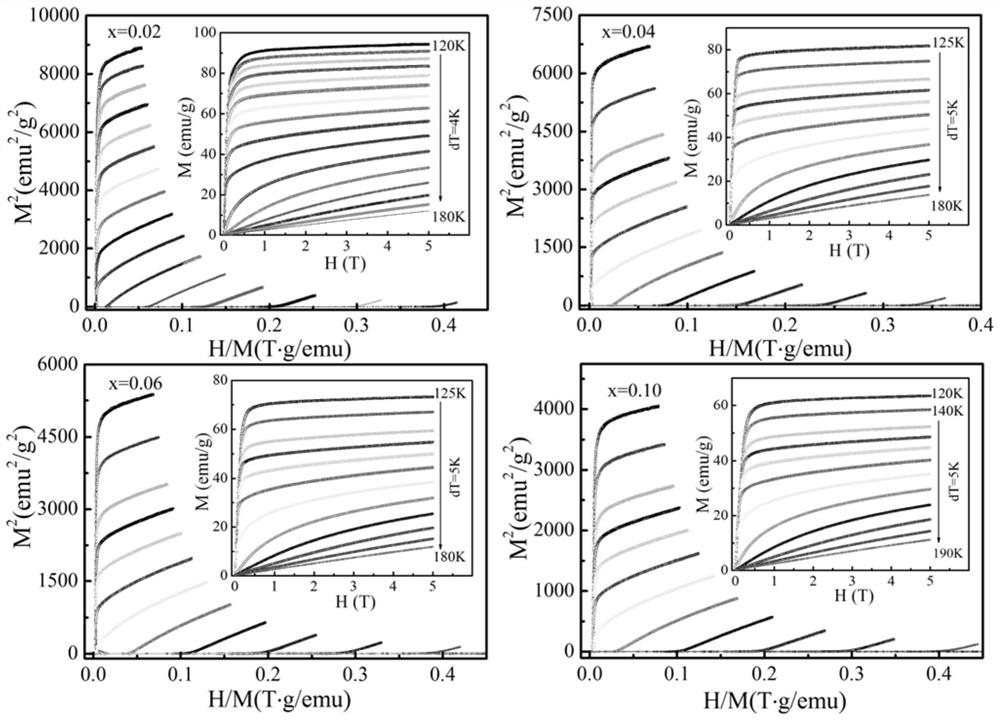

Cobalt-manganese-tin-based alloy material and preparation method thereof

The invention belongs to the field of magnetic refrigeration, and specifically relates to a cobalt-manganese-tin-based alloy material and a preparation method thereof. The molecular formula of the cobalt-manganese-tin-based alloy material is Co 1‑x mn 1+x Sn, where x=0.02‑0.10, its structure is hexagonal. The alloy material overcomes the shortcomings of the small magnetic entropy change half-peak width and large thermal hysteresis of the first-order magnetic phase transition. Its phase transition behavior is a second-order magnetic phase transition, which has a large magnetocaloric effect and avoids Large thermal hysteresis effect. Cobalt-manganese-tin alloy has low cost and broad application prospects, and can be applied to many important fields of the national economy involving refrigeration and cryogenic technology.

Owner:天津市京建建筑防水工程有限公司 +1

A kind of gadolinium block material and preparation method thereof

ActiveCN104923790BLarge magnetocaloric effectRefined grain sizeHeat-exchange elementsMechanical millingGadolinium

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

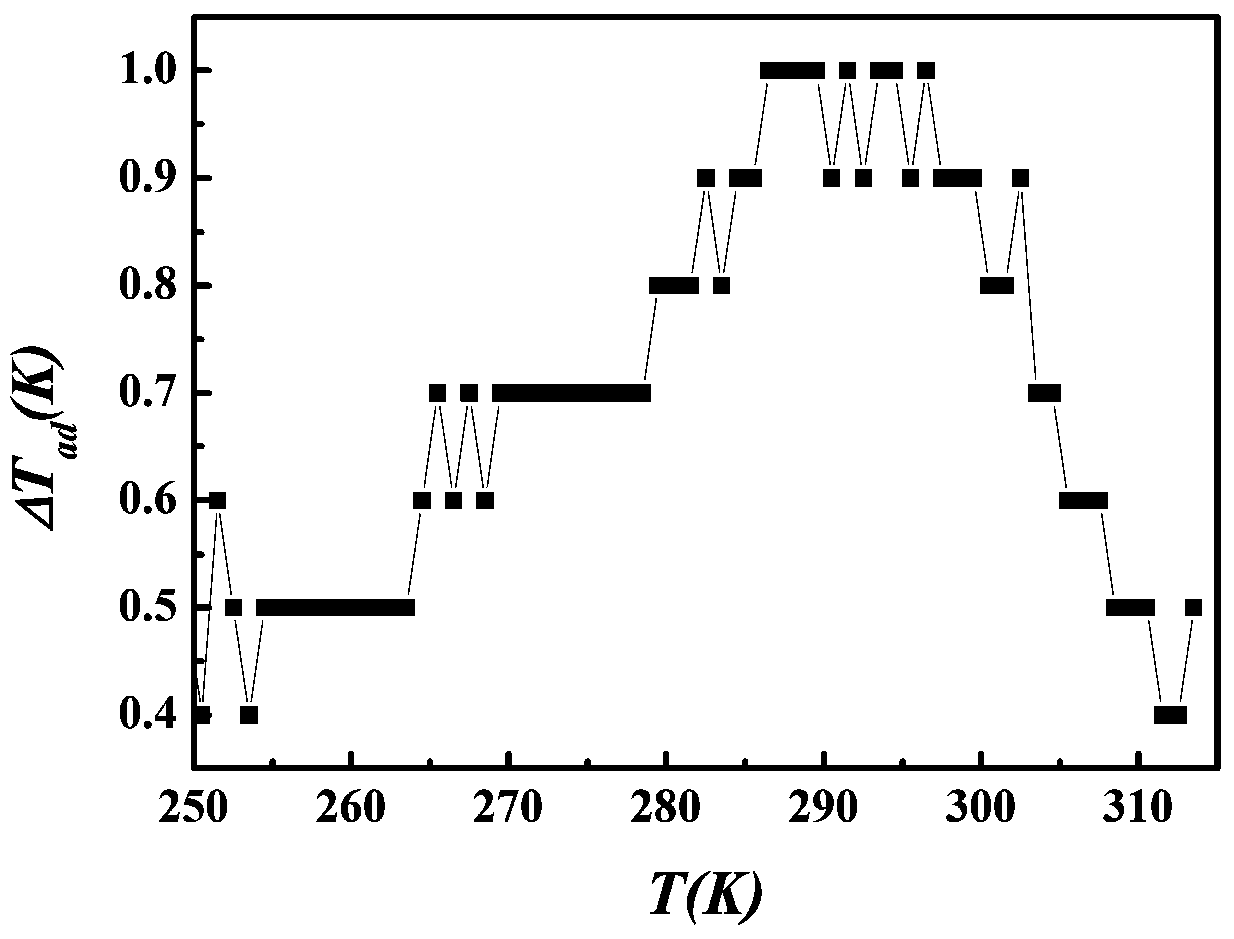

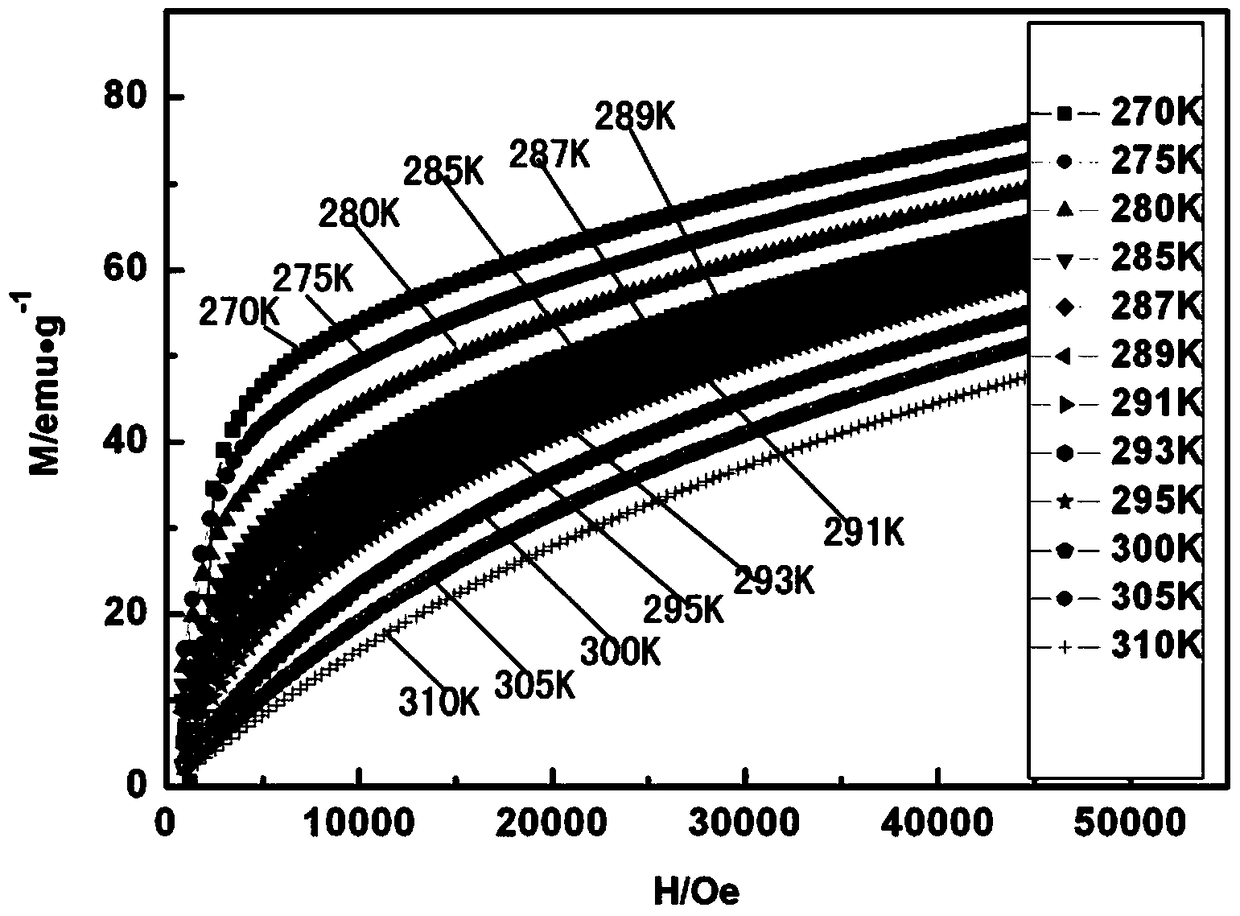

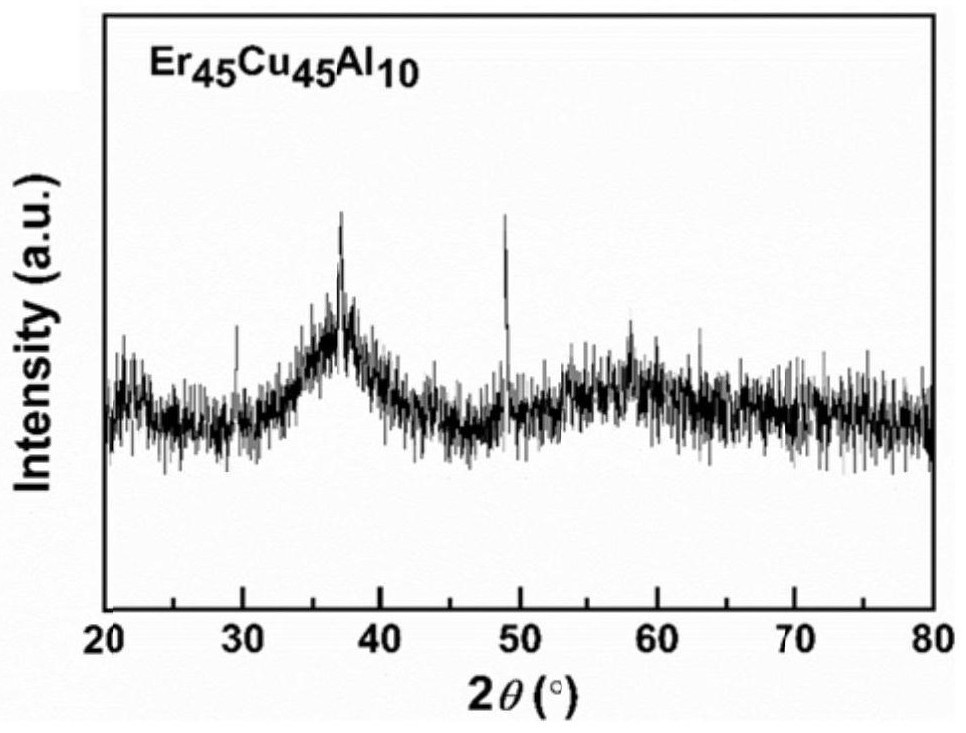

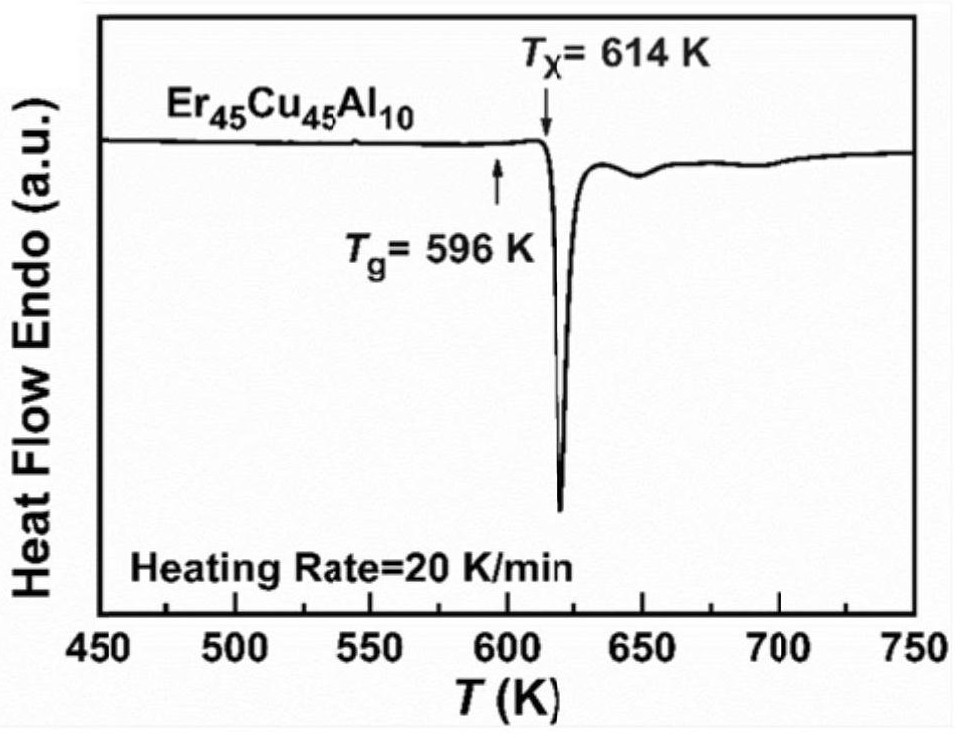

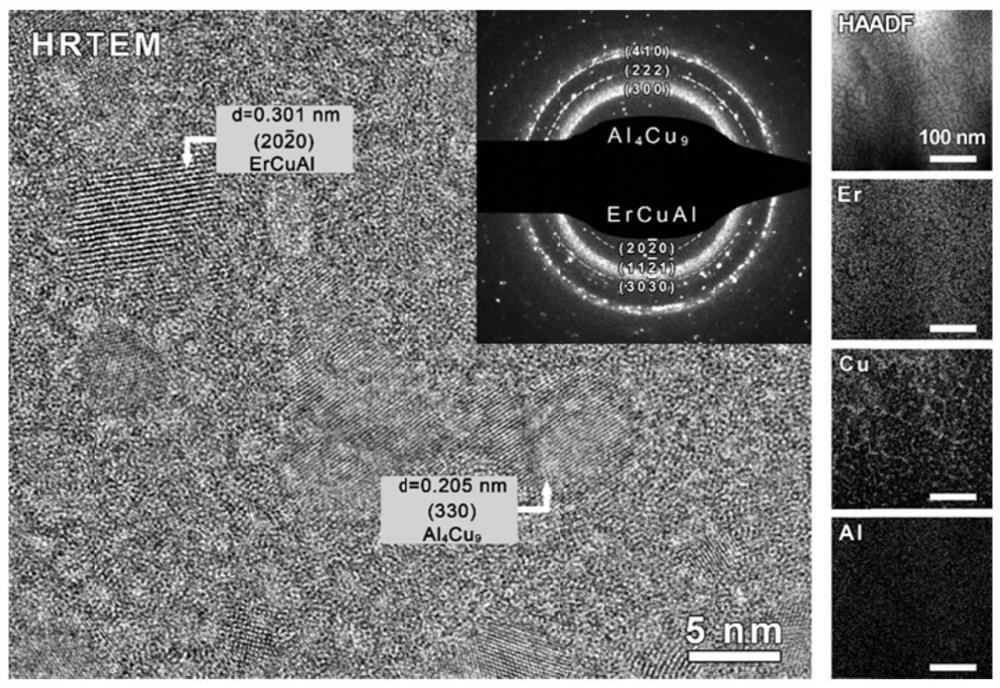

A kind of amorphous composite material not containing Fe, Co, Ni and its preparation method and application

ActiveCN110983207BLarge magnetocaloric effectLarge magnetic entropy changeRare-earth elementElectric arc furnace

The invention discloses an amorphous composite material not containing Fe, Co, Ni, the chemical formula is (Er 0.5 Cu 0.5 ) 100‑x al x , where 10≤x≤20. The present invention also provides the preparation method of the amorphous composite material, comprising the steps of: (1) putting metal Er, Cu and Al in an electric arc furnace in proportion, melting evenly, and obtaining a master alloy ingot after cooling; (2) ) re-melting the master alloy ingot into a master alloy melt, spraying the master alloy melt onto the surface of a rotating copper roller, and quenching to obtain a strip-shaped amorphous composite material. The invention also discloses the application of the amorphous composite material as a magnetic refrigerant material. Because the amorphous composite material of the present invention does not contain elements having strong antiferromagnetic coupling effects with Er such as Fe, Co, Ni, etc., it has more excellent magneto-caloric properties, and can realize larger magneto-caloric properties with less rare earth elements. Magnetocaloric effect, while saving material cost.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

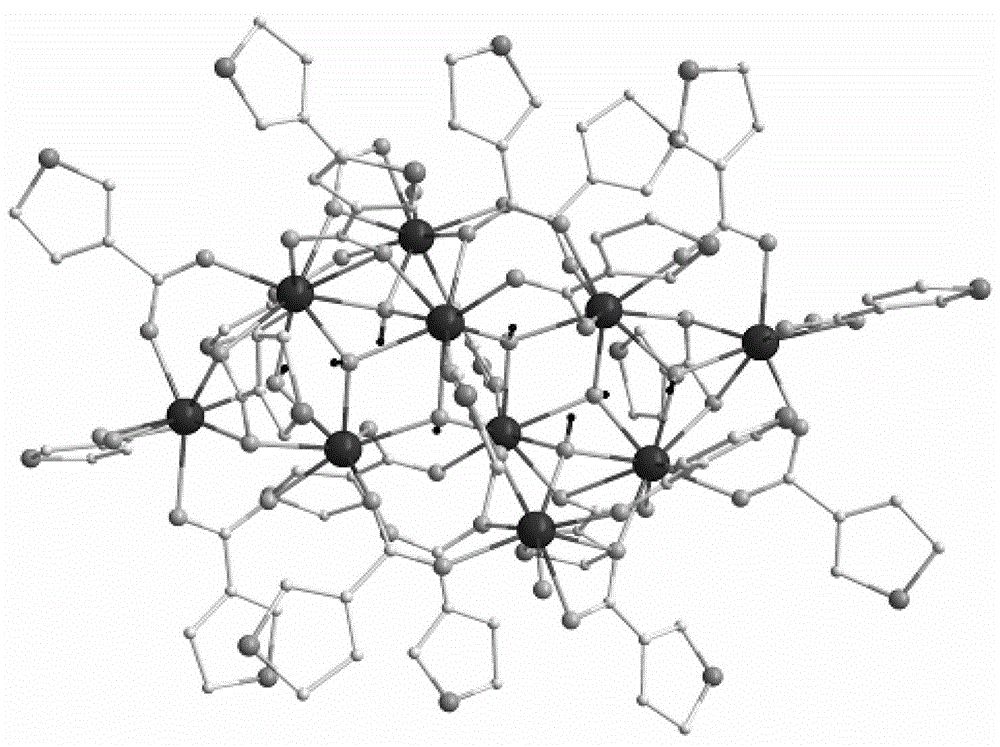

High nuclear gadolinium cluster complex with large magnetocaloric effect and preparation method thereof

InactiveCN102964368BLarge magnetocaloric effectRaw materials are simple and cheapGroup 3/13 element organic compoundsOrganic/organic-metallic materials magnetismSpace groupGadolinium oxide

Owner:NANKAI UNIV

Lanthanum-iron-silicon-based hydride magnetic working fluid, preparation method thereof, and magnetic refrigerator

ActiveCN105957672BLarge magnetocaloric effectHigh strengthInorganic material magnetismRare-earth elementAdhesive

The invention discloses a lanthanum-iron-silicon-based hydride magnetic refrigerant, a preparation method of the lanthanum-iron-silicon-based hydride magnetic refrigerant and a magnetic refrigerator. The chemical formula of the lanthanum-iron-silicon-based hydride magnetic refrigerant is La1-aRa(Fe1-b-cMbSic)13Hd, wherein R represents one or a composition of a plurality types of the following rare earth elements: Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc and Y; a value range of a is 0 to 0.5; M represents one or a composition of a plurality of types of Ti, V, Cr, Mn, Co, Ni, Cu, Zn and Ga; a value range of b is 0.005 to 0.05; a value range of c is 0.069 to 0.162; and a value range of d is 0 to 2. The lanthanum-iron-silicon-based hydride magnetic refrigerant provided by the invention is formed into a block by adopting a hot pressing molding process, introduction of impurity constituents such as an adhesive and the like is avoided, a high thermomagnetic property is kept, the prepared magnetic refrigerant is excellent in mechanical property, the problem of reduction of mechanical properties of pulverization, frangibility and the like of a lanthanum-iron-silicon-based compound after hydrogenation is solved, and performance of the formed magnetic refrigerant can meet the use requirements of the magnetic refrigerator.

Owner:BAOTOU RES INST OF RARE EARTHS

A kind of ni-co-mn-in-ge magnetic refrigeration alloy material and preparation method

ActiveCN107881394BLarge magnetocaloric effectRealize single temperature zone coolingInorganic material magnetismMagnetic refrigerationMaterials science

A Ni‑Co‑Mn‑In‑Ge magnetic refrigeration alloy material and a preparation method belong to the technical field of magnetic refrigeration materials. The chemical molecular formula of the Ni‑Co‑Mn‑In‑Ge magnetic refrigeration alloy material is Ni 45 Co 5 Mn 36.5 In 13.5‑x Ge x , the sum of the number of moles of elements in the alloy is 100, where 1≤x≤4. This invention prepares polycrystalline ingots through raw material proportioning and vacuum arc smelting multiple times, annealing under the protection of high-purity inert gas, and then rapid water cooling to prepare Ni-Co-Mn-In-Ge magnetic refrigeration alloy blocks. blank. The alloy block of the present invention obtains an adiabatic temperature change range of 1.34-2.69K through heating and magnetization under an external magnetic field of 1.5T. The magnetic alloy material of the present invention can obtain a large adiabatic temperature change near room temperature, accompanied by a huge magnetocaloric effect, and can be used as a magnetic refrigeration working medium in a wide temperature range.

Owner:NORTHEASTERN UNIV LIAONING

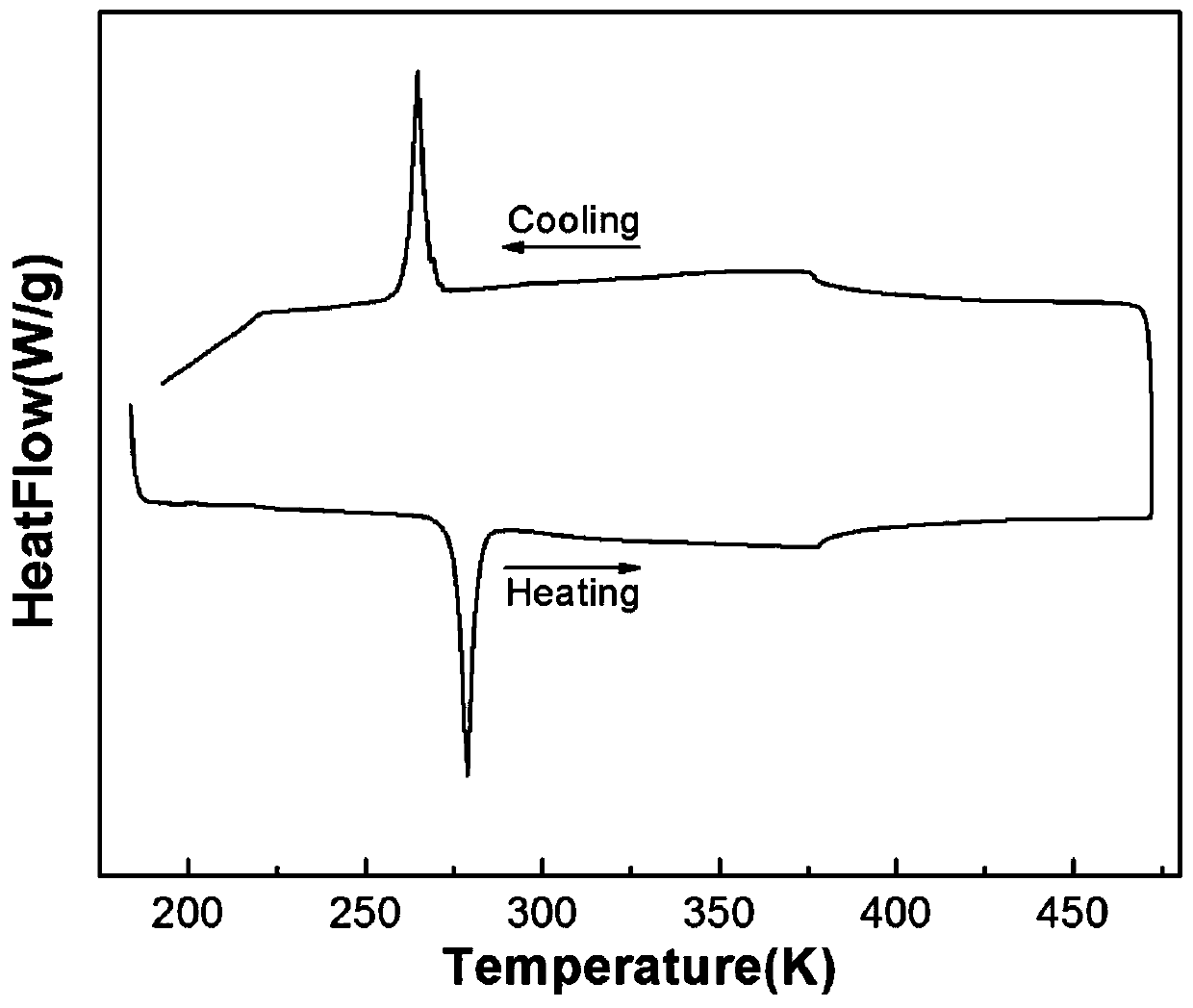

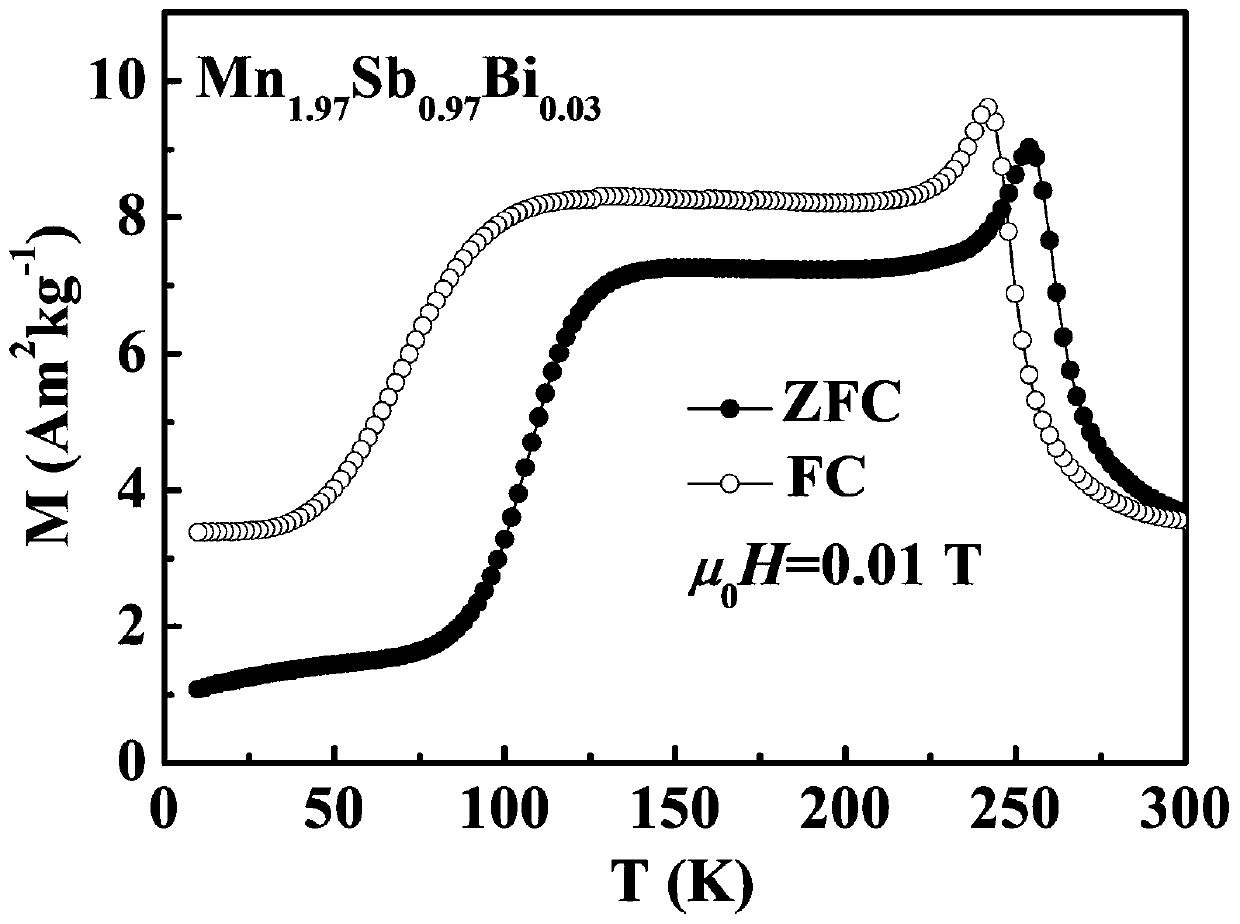

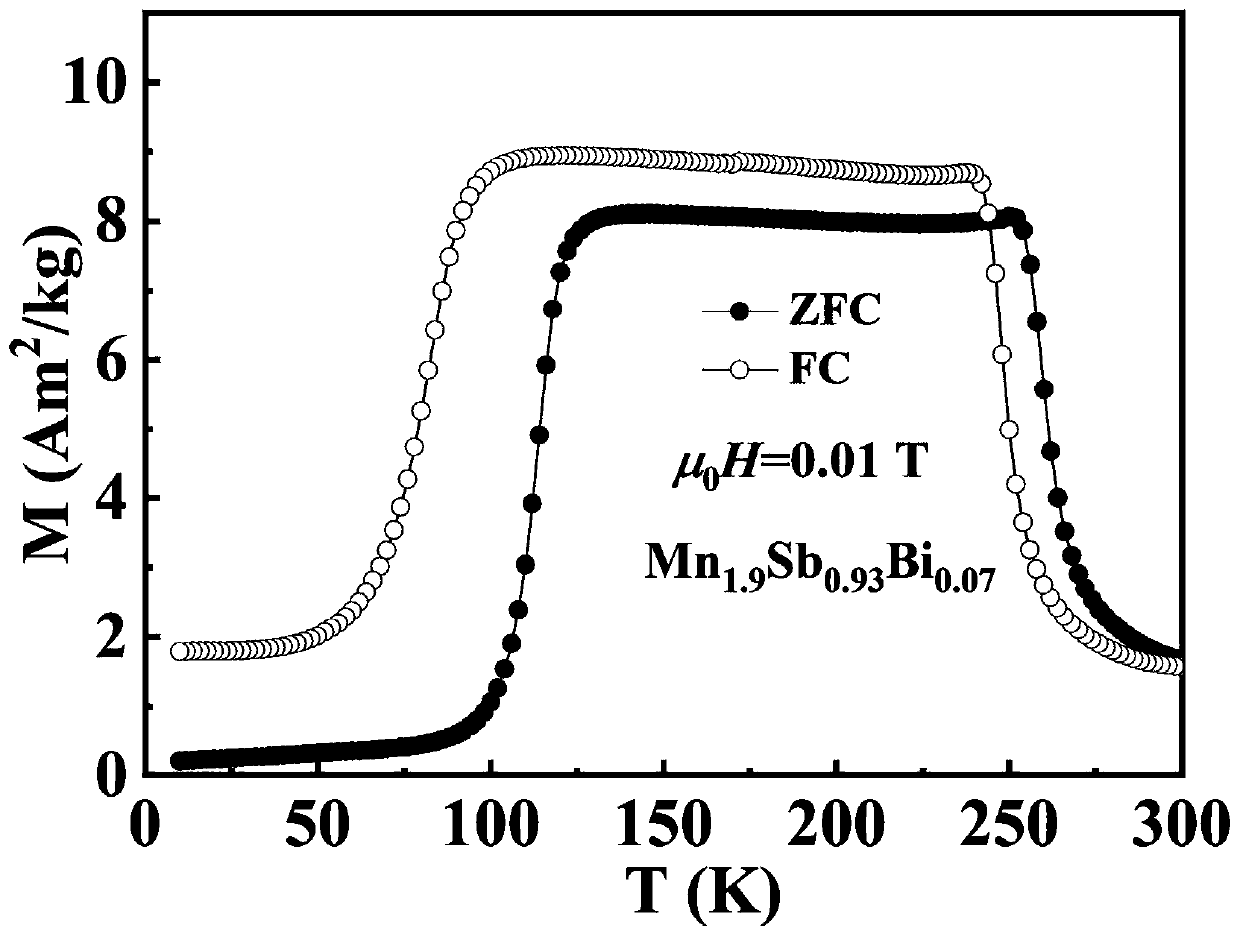

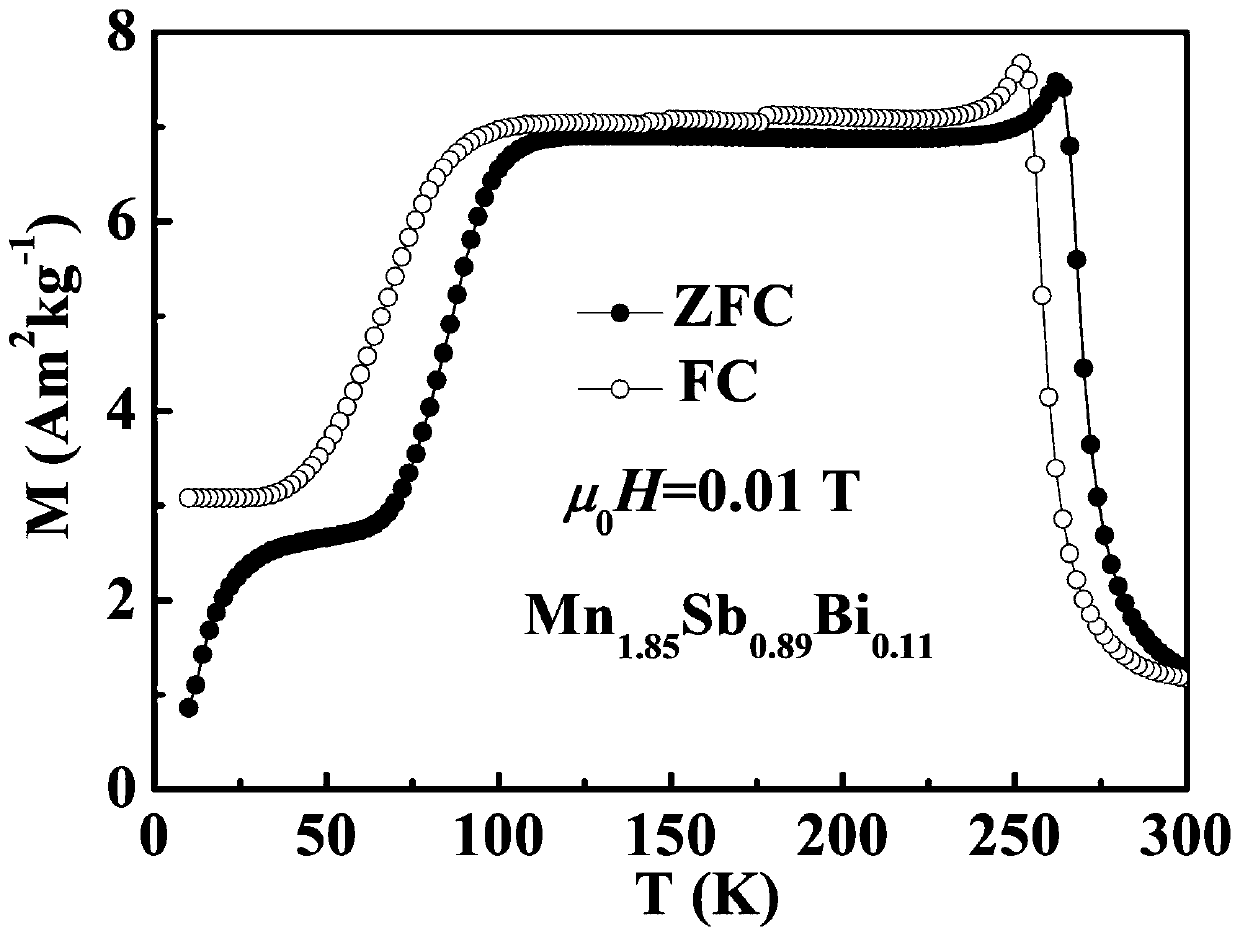

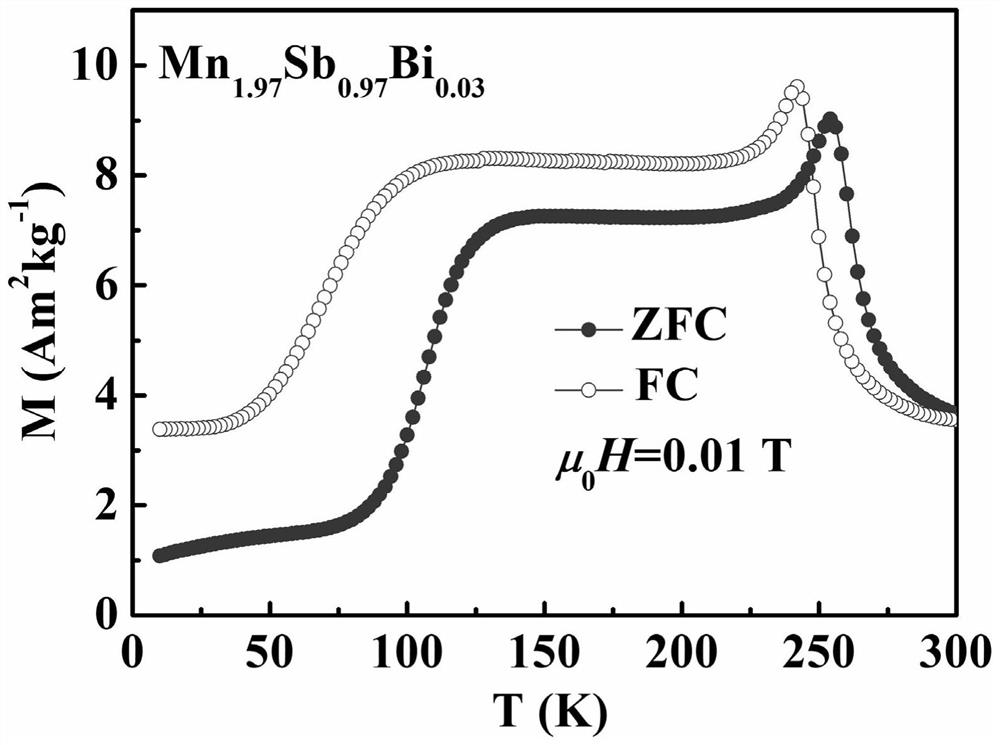

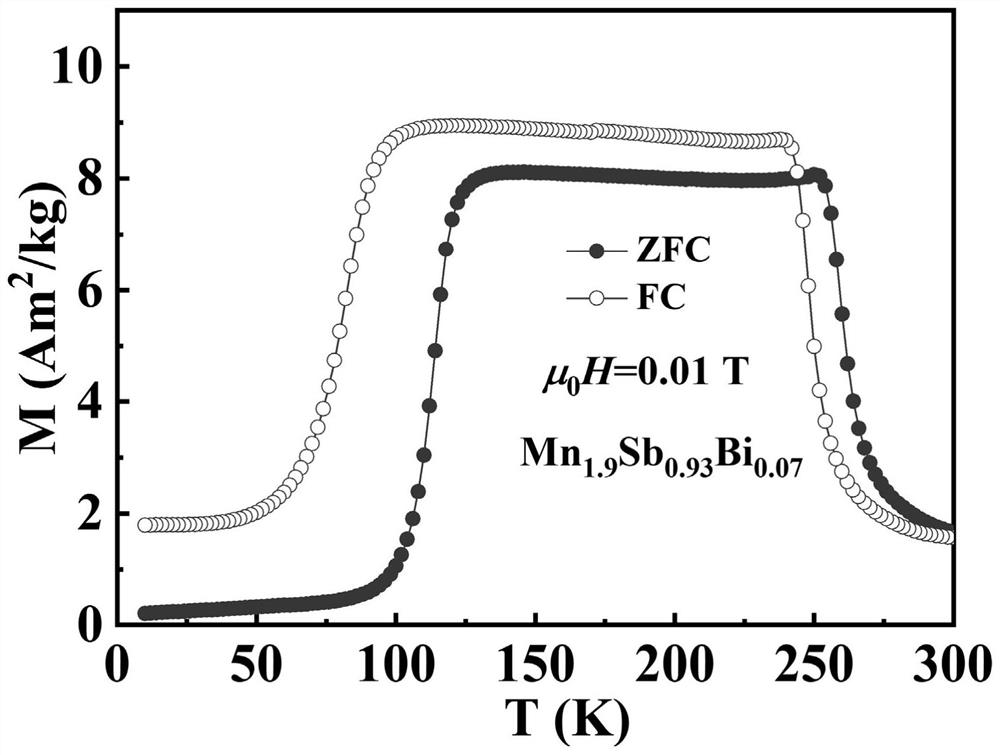

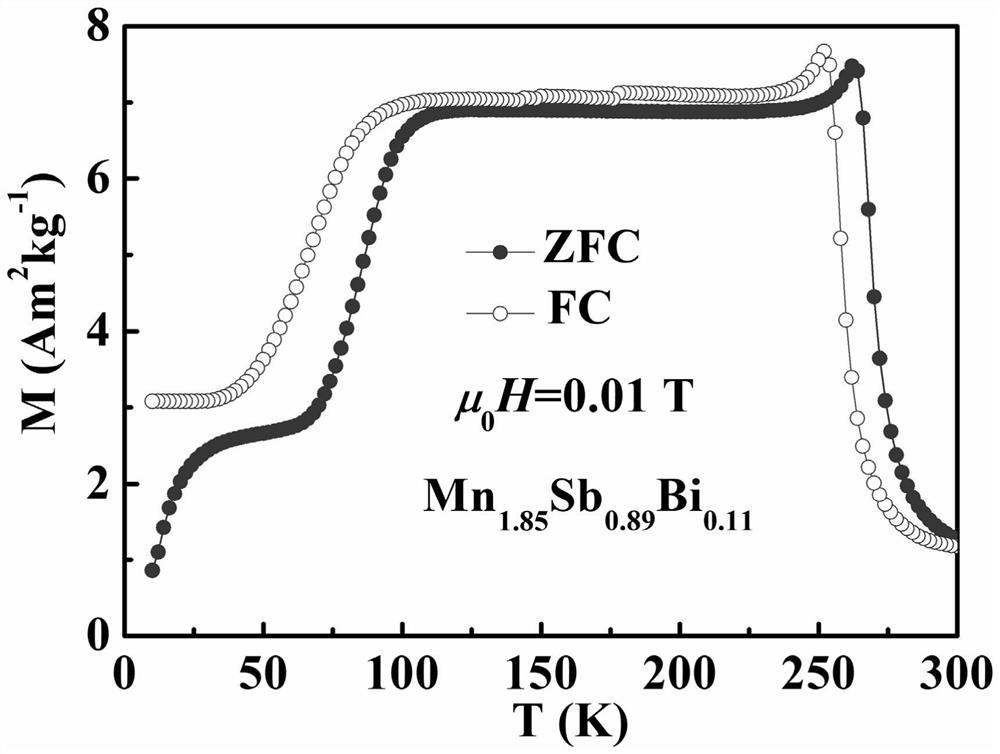

Bi substituted Mn absent Mn2Sb-based alloy and preparation method and application thereof

ActiveCN111575532AHas a first-order magnetoelastic phase transitionExcellent magnetic functional propertiesInorganic material magnetismMagnetic phaseMagneto elastic

The invention relates to the technical field of magnetic phase change materials, and discloses a Bi substituted Mn absent Mn2Sb-based alloy and a preparation method and application thereof. The chemical formula of the Bi substituted Mn absent Mn2Sb-based alloy is Mn2-ySb1-xBix, wherein y is the absence amount of Mn atoms, x is the substitution amount of Bi to Sb, y is larger than 0 and smaller than 1, and x is larger than 0 and smaller than or equal to 0.4. Firstly, primary magnetic phase change is adjusted and controlled and achieved through transition element absence, the Bi substituted Mn absent Mn2Sb-based alloy is prepared with a doping or element substitution method, primary magnetic elastic phase change is adjusted and controlled and achieved in the alloy, rich magnetic functional characters are obtained, the Bi substituted Mn absent Mn2Sb-based alloy can be widely applied to multiple fields such as magnetic refrigeration, magnetic storage, magnetic sensing, energy capture and energy conversion, and the preparation method is simple and convenient, low in energy consumption, low in preparation cost and suitable for industrial production.

Owner:JIANGXI UNIV OF SCI & TECH

A bi-substituted mn-deficient mn 2 Sb-based alloy and its preparation method and application

ActiveCN111575532BHas a first-order magnetoelastic phase transitionExcellent magnetic functional propertiesInorganic material magnetismMagnetic phaseMagneto elastic

Owner:JIANGXI UNIV OF SCI & TECH

Thulium-based metallic glass, preparation method and application

ActiveCN103668008BMagnetic transition temperature range is wideLow critical cooling rateRare-earth elementMagnetic transitions

The invention discloses a thulium-based metallic glass and its preparation method and application. The thulium-based metallic glass is mainly composed of thulium, and its composition is shown in formula (I), wherein, RE means selected from Ce, Pr, Nd, One or more rare earth elements in Sm, Gd, Tb, Dy, Ho and Er; T represents Co or Ni; a, b, c, d represent the atomic percentage of each element, 30≤a≤60, 5≤ b≤30, 20≤c≤25, 15≤d≤25, 50≤a+b≤60 and a+b+c+d=100. According to the thulium-based metallic glass of the present invention, the change of RE and T can modulate the amorphous forming ability on the one hand, and on the other hand can modulate the temperature range in which the magnetic transition of the thulium-based metallic glass occurs, broaden the magnetic transition region, and make it work in a wider range. It has a large magnetocaloric effect in the temperature range. TmaREbAlcTd (I).

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

A kind of gadolinium complex with high stability and high magnetocaloric effect and preparation method thereof

InactiveCN104610327BLarge magnetocaloric effectSimple processGroup 3/13 organic compounds without C-metal linkagesHeat-exchange elementsFiltrationSolvent

Owner:NANKAI UNIV

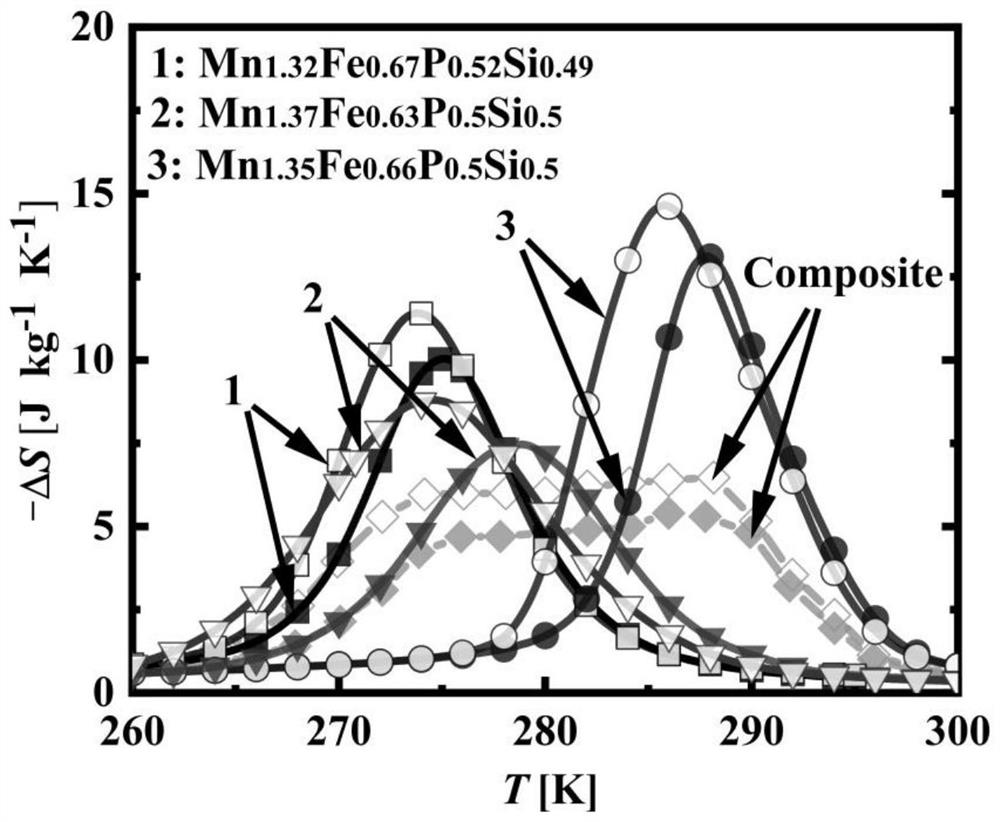

Ferromanganese-based magnetic composite material and design method and manufacturing method thereof

ActiveCN113444942ALarge magnetocaloric effectLarge operating temperature span valueDesign optimisation/simulationMachines using electric/magnetic effectsMagnetic field magnitudeComposite material

The invention discloses a ferromanganese-based magnetic composite material and a design method and manufacturing method thereof. The design method comprises the steps that firstly, relational expressions between the magnetic entropy of the ferromanganese-based magnetic composite material and the applied magnetic field intensity, between the magnetic entropy and temperature, between the magnetic entropy and the molar ratio of multiple layers of ferromanganese-based magnetic materials, between the isothermal magnetic entropy change of the ferromanganese-based magnetic composite material and the applied magnetic field intensity, between the isothermal magnetic entropy change and temperature and between the isothermal magnetic entropy change and the molar ratio of the multiple layers of ferromanganese-based magnetic materials are established; secondly, an equation is established to perform composite optimization on the multiple layers of ferromanganese-based magnetic materials; and thirdly, the molar ratio of each layer of ferromanganese-based magnetic material to all the ferromanganese-based magnetic materials is calculated. The designed ferromanganese-based magnetic composite material can keep a relatively large magnetothermal effect in a relatively wide working temperature range.

Owner:BAOTOU RES INST OF RARE EARTHS

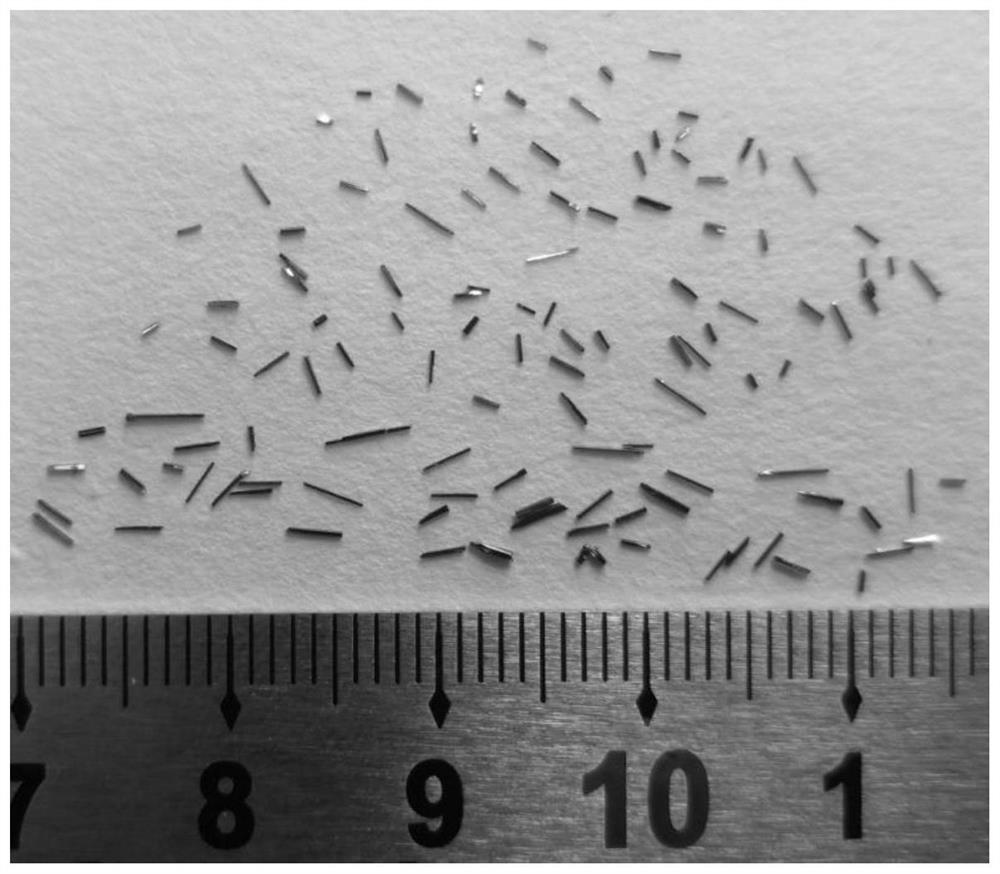

A kind of single crystal heterojunction room temperature magnetic refrigeration material with large magnetic entropy change and wide working temperature range and its preparation process

ActiveCN110556221BIncrease cooling powerImprove cooling efficiencyPolycrystalline material growthInorganic material magnetismHeterojunctionAcid corrosion

Owner:BEIJING UNIV OF TECH

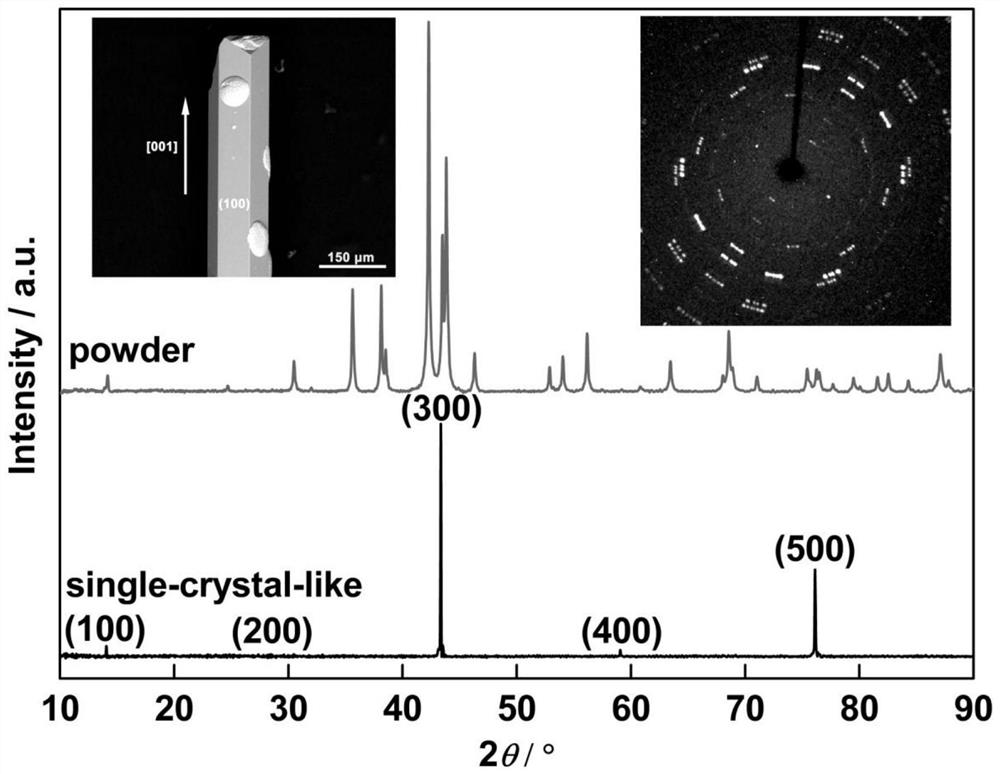

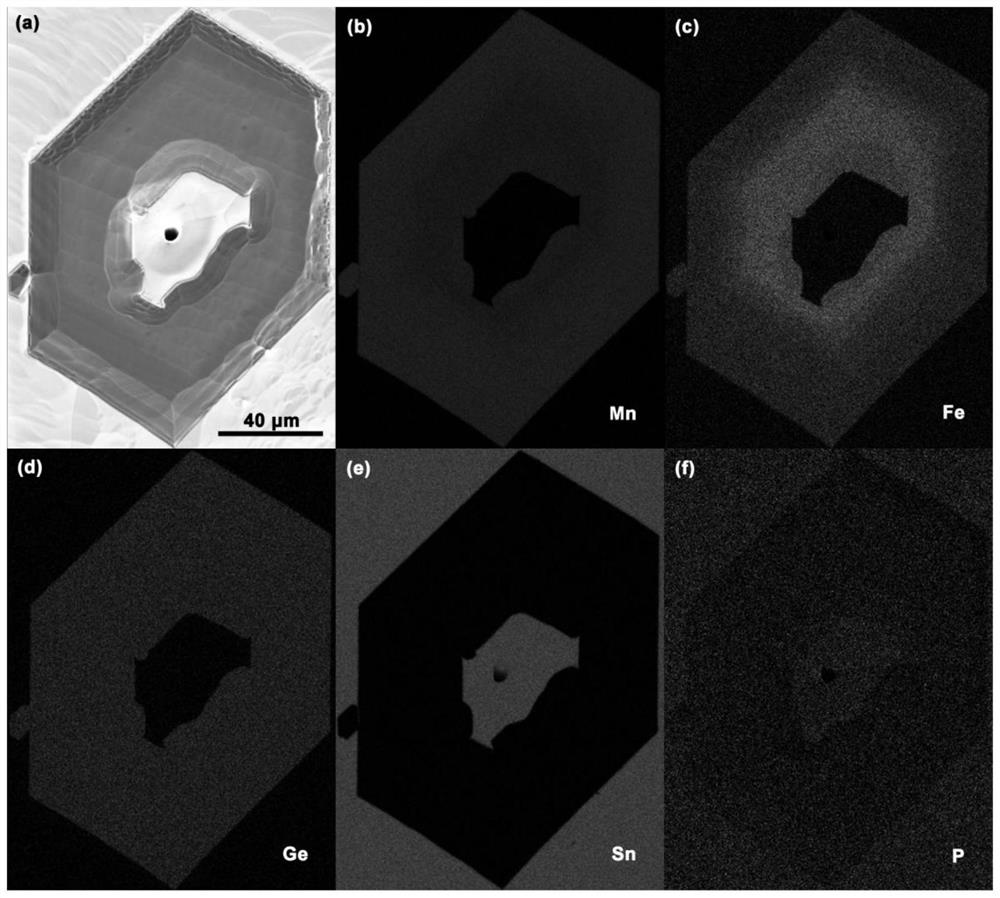

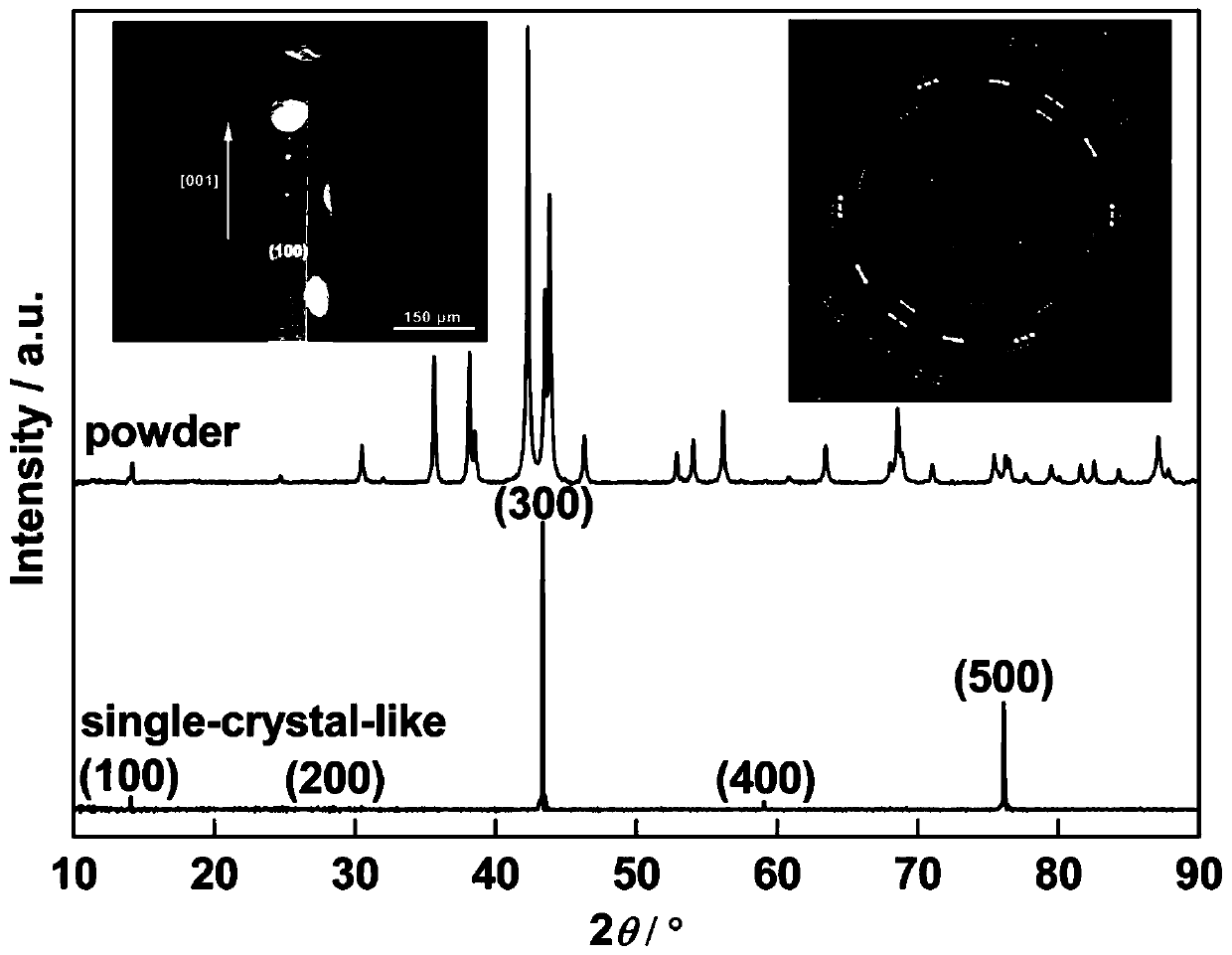

Single-crystal-like heterojunction room-temperature magnetic refrigeration material with large magnetic entropy change and wide working temperature zone and preparation process thereof

ActiveCN110556221ALarge working temperature zoneIncreased actual cooling power and efficiencyPolycrystalline material growthInorganic material magnetismSingle crystalMolten metal

The invention relates to a Mn5Ge3 / (Mn, Fe)5Ge3 single-crystal-like heterojunction room-temperature magnetic refrigeration material with large magnetic entropy change and a wide working temperature zone and a preparation process thereof. Elementary substances Mn, Fe, P, Ge and Sn used as raw materials are mixed according to the component proportion of Mn<2-x>Fe<x>P<1-y>Ge<y>Sn12 (x is greater thanor equal to 0.80 and smaller than or equal to 0.90, and y is greater than or equal to 0.20 and smaller than or equal to 0.26) and packaged in a quartz tube filled with Ar gas. A needle-shaped Mn5Ge3 / (Mn, Fe)5Ge3 single-crystal-like heterojunction room-temperature magnetic refrigeration material with the diameter of about 100-300 microns and the maximum length of 1cm is successfully prepared for the first time through the processes of high-temperature heat preservation, slow cooling, molten metal Sn pouring, acid pickling separation and the like. The room-temperature magnetic refrigeration material has the advantages of large magnetic entropy change, wide working temperature zone, large refrigeration capacity, no need of subsequent processing, acid corrosion resistance and the like, and canbe directly used as a room-temperature magnetic refrigeration working medium.

Owner:BEIJING UNIV OF TECH

A rare earth-based high-entropy amorphous alloy with high magnetocaloric effect and its preparation method

ActiveCN110616386BImprove magnetic propertiesEnhancing the half-width of magnetic entropy changeMagnetic refrigerationMaterials science

The invention discloses a rare earth-based high-entropy amorphous alloy material with high magnetocaloric effect, and its molecular formula is Gd a co b Al c Y d m e , where a, b, c, d, and e represent the atomic percentages of the corresponding elements, and 24.8≤a≤25.4, 24.8≤b≤25.4, 24.8≤c≤25.4, 5≤d≤15, 10≤e≤ 20, a+b+c+d+e=100, wherein M is one of Dy, Er or Ho. On the basis of GdCoAlY high-entropy amorphous, M element is used to replace Y element to obtain a high-entropy amorphous alloy with high magnetocaloric effect. sexual element. Moreover, the patented high-entropy amorphous alloy has a completely amorphous structure without crystallization heat treatment, and the preparation process is simple. It is a high-entropy amorphous alloy with good magnetocaloric properties and good application prospects in the field of magnetic refrigeration technology. alloy.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com