Single-crystal-like heterojunction room-temperature magnetic refrigeration material with large magnetic entropy change and wide working temperature zone and preparation process thereof

A kind of magnetic refrigeration material, single crystal-like technology, applied in the direction of magnetic material, polycrystalline material growth, single crystal growth, etc., can solve the problems of high processing cost of magnetic working medium, difficult processing, unfavorable popularization of magnetic refrigeration technology, etc. Actual cooling power and efficiency, effect of wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

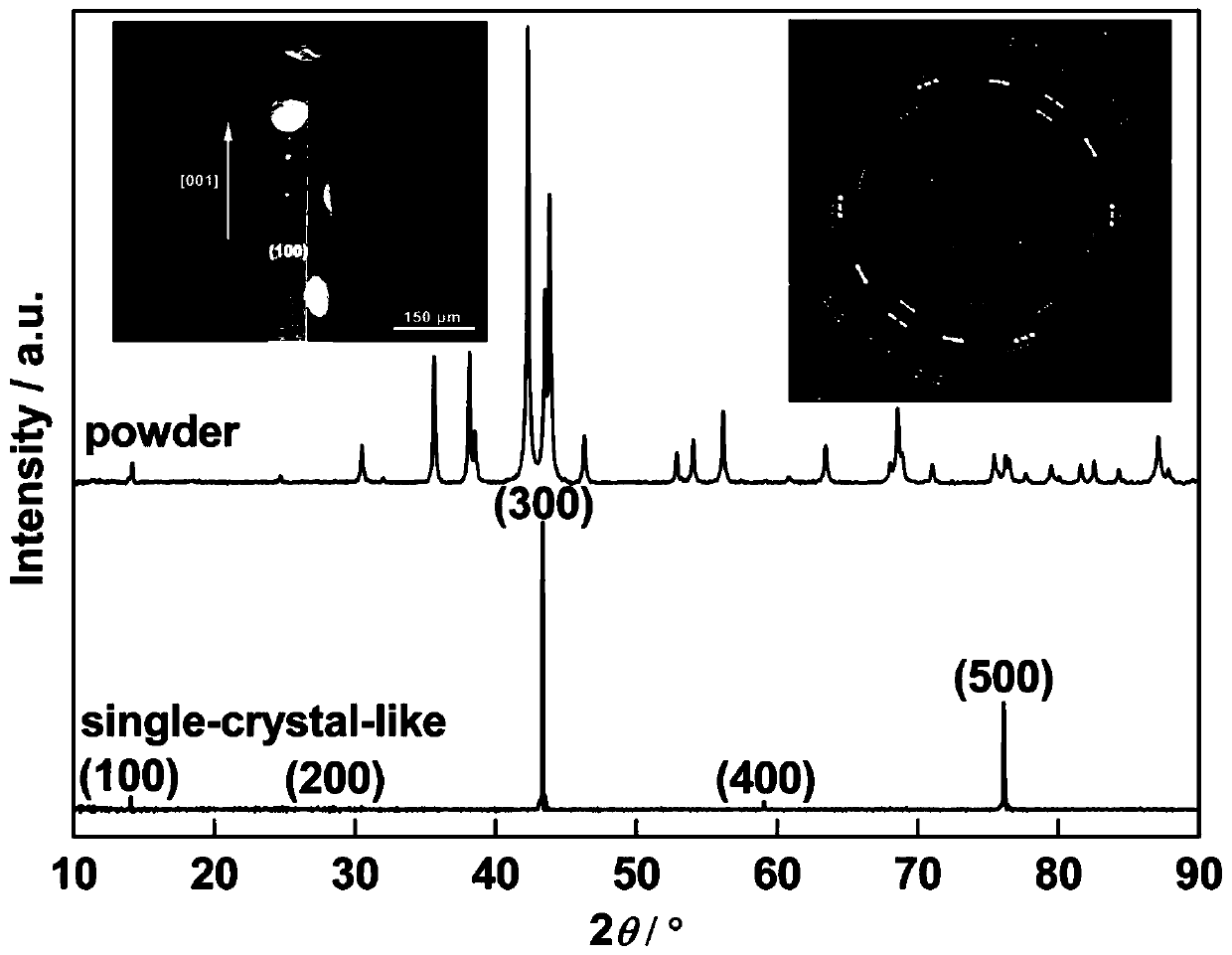

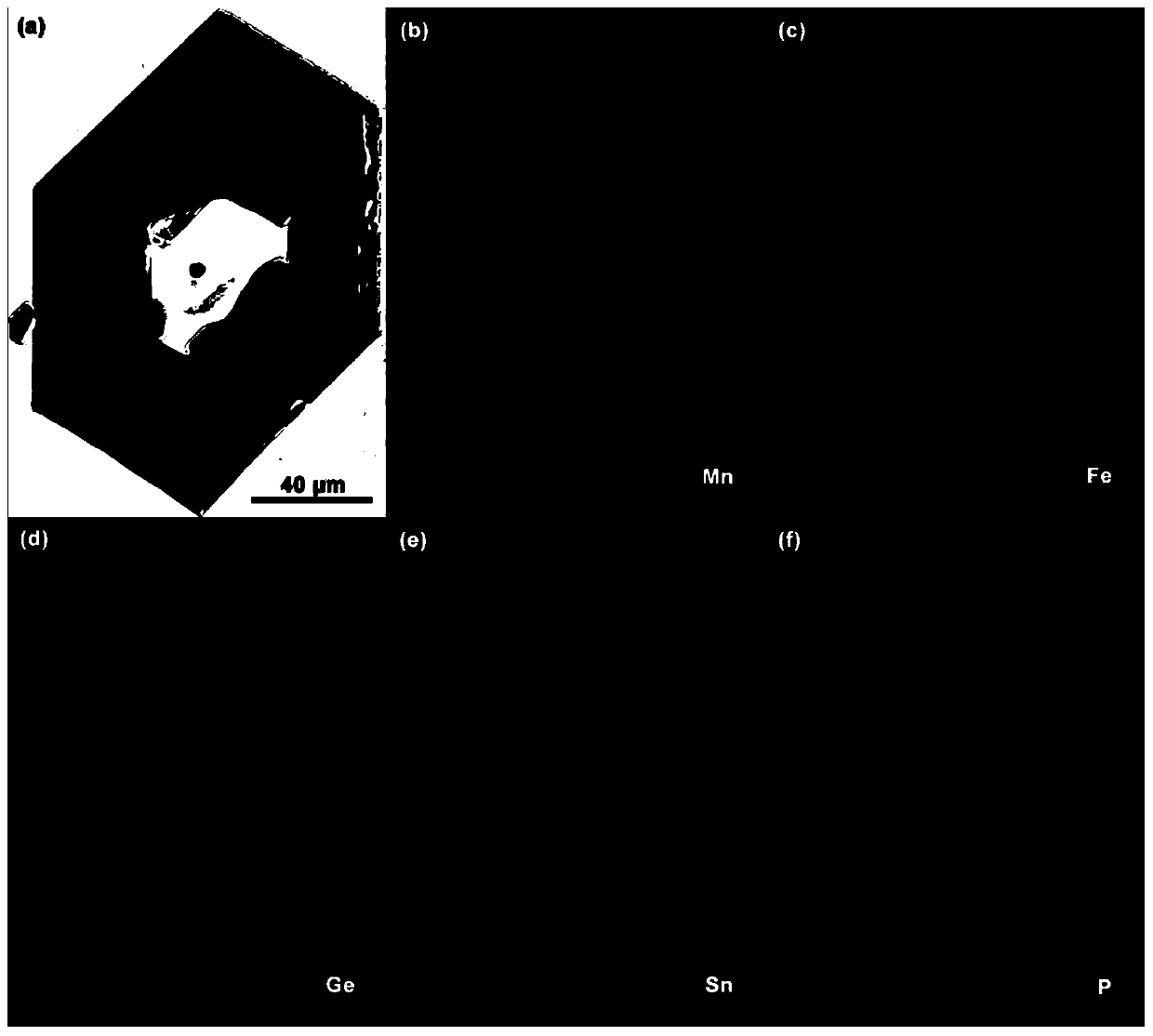

[0021] Example 1. Using 99.99% of Mn and Fe blocks, 99.9999% of red P and 99.999% of Ge blocks and Sn balls as raw materials, according to Mn 1.15 Fe 0.85 P 0.74 Ge 0.26 sn 12 The formula is batched, mixed and loaded with Al 2 o 3 The crucible was sealed in a quartz tube filled with Ar gas. Put the sealed quartz tube into the muffle furnace, heat it from room temperature to 1173K and keep it warm for 7 days, then slowly cool down to 573K at a cooling rate of 5K / h, then take out the quartz tube from the muffle furnace and pour the molten metal upside down Sn, filtered through quartz wool until completely cooled. The quasi-single crystal wrapped by Sn was taken out and soaked in a dilute hydrochloric acid solution with a concentration of 10% (mass fraction) for 1 to 2 weeks, then the solution was filtered off and the separated quasi-singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com