Thulium-based metal glass, preparation method and application thereof

A base metal and glass technology, applied in the field of magnetic refrigeration and material science, to achieve the effect of improving efficiency, large magnetocaloric effect, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

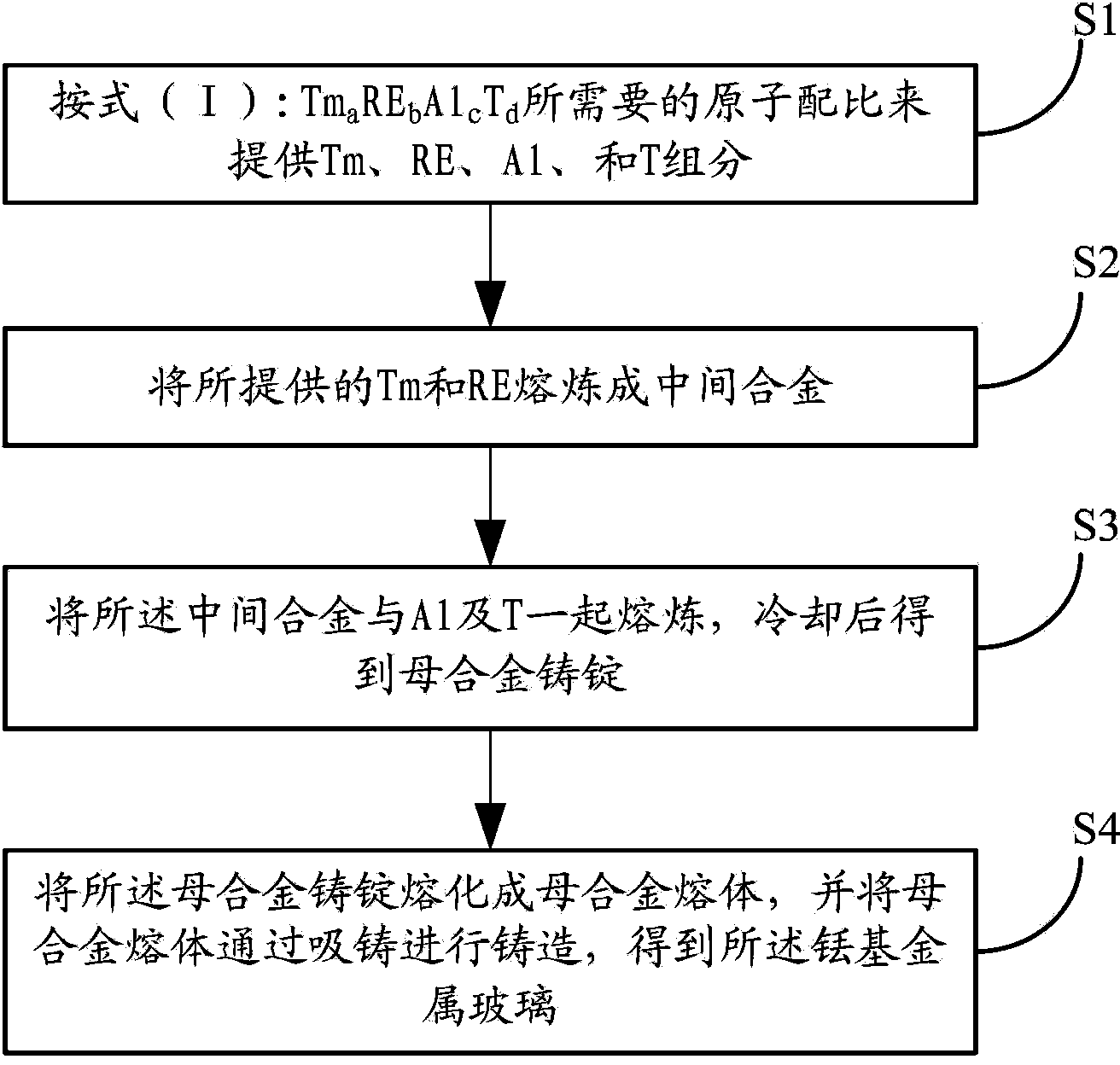

[0052] Such as figure 1 Shown, its specific preparation method comprises the following steps:

[0053] S1: Tm, RE, Al, and T components are provided according to the atomic ratio required by the formula (I).

[0054] S2: Smelting the provided Tm and RE into a master alloy.

[0055] S3: melting the master alloy together with Al and T, and obtaining a master alloy ingot after cooling.

[0056] S4: melting the master alloy ingot into a master alloy melt, and casting the master alloy melt by suction casting to obtain the thulium-based metallic glass.

[0057] Therefore, according to the preparation method of the thulium-based metallic glass according to the embodiment of the present invention, the critical cooling rate required for the preparation is low, the preparation method is simple, and the prepared thulium-based metallic glass has good thermal stability, strong oxidation resistance and corrosion resistance.

[0058] Specifically, formula (I) RE represents one or more rar...

Embodiment 1

[0071] The thulium-based metallic glass was prepared by using Tm, Ho, Co and Al with a raw material purity of 99.9 wt% or more and a molar ratio of 39:16:20:25.

[0072] First of all, after the four components are distributed in proportion, Tm and Ho are melted into a uniform master alloy in an electric arc furnace in an argon atmosphere adsorbed by titanium, and then mixed with Co and Al and melted, and then obtained after cooling The master alloy ingot of Tm-Ho-Co-Al quaternary alloy is cast; then the ingot is re-melted using the conventional metal mold casting method, and the master alloy melt is sucked into the water-cooled copper mold by using the suction casting device in the electric arc furnace , you can get a Tm with a diameter of 3mm 39 Ho 16 co 20 Al 25 Cylindrical metallic glass samples.

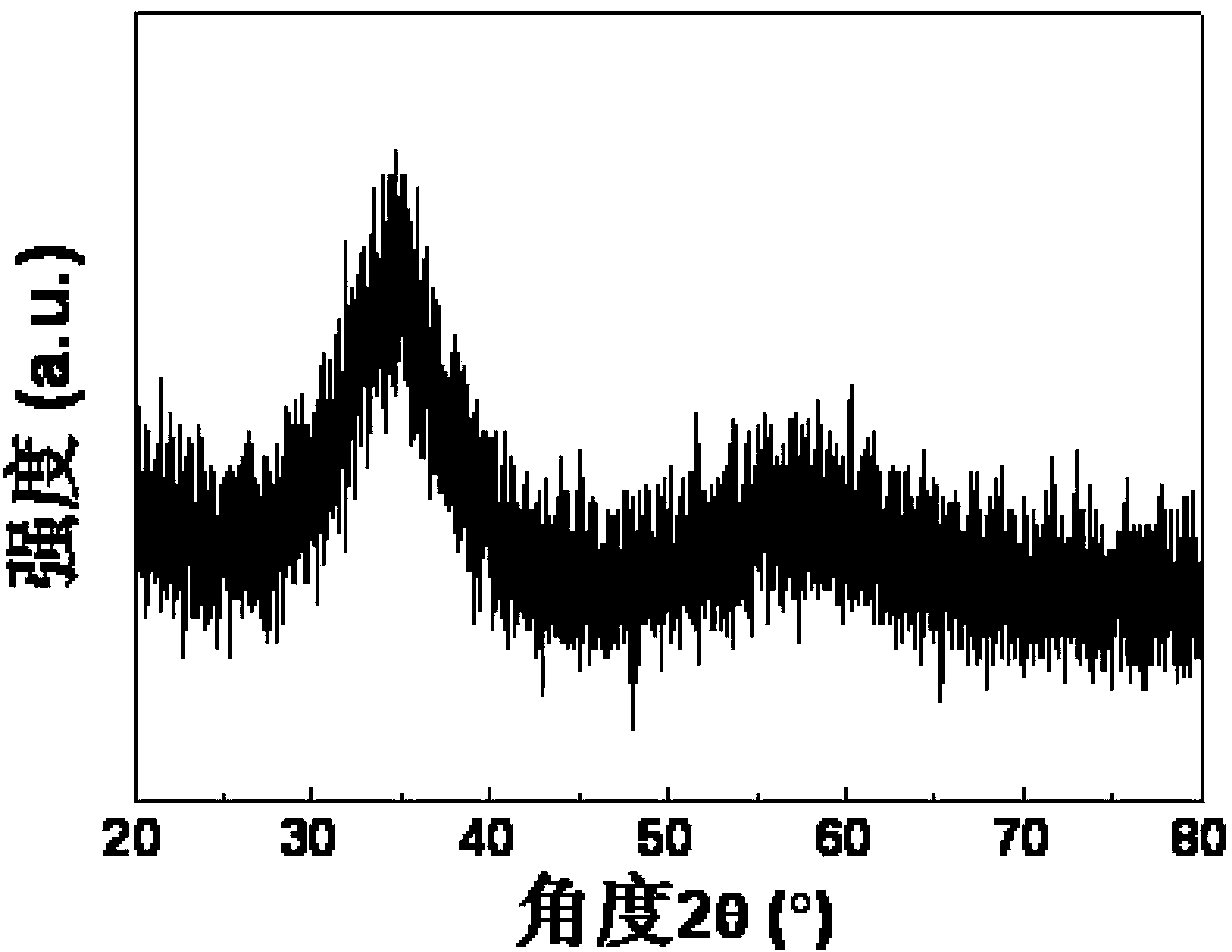

[0073] by such as figure 2 The X-ray diffraction (XRD) image of the alloy shown is visible as a single diffuse scattering peak, confirming that the cylindrical sample is a ...

Embodiment 2~9

[0078] Each thulium-based metallic glass was prepared in the same preparation method as in Example 1 according to the composition shown in Table 1.

[0079] X-rays show that this series of alloys have a completely amorphous structure, such as Figure 8 shown.

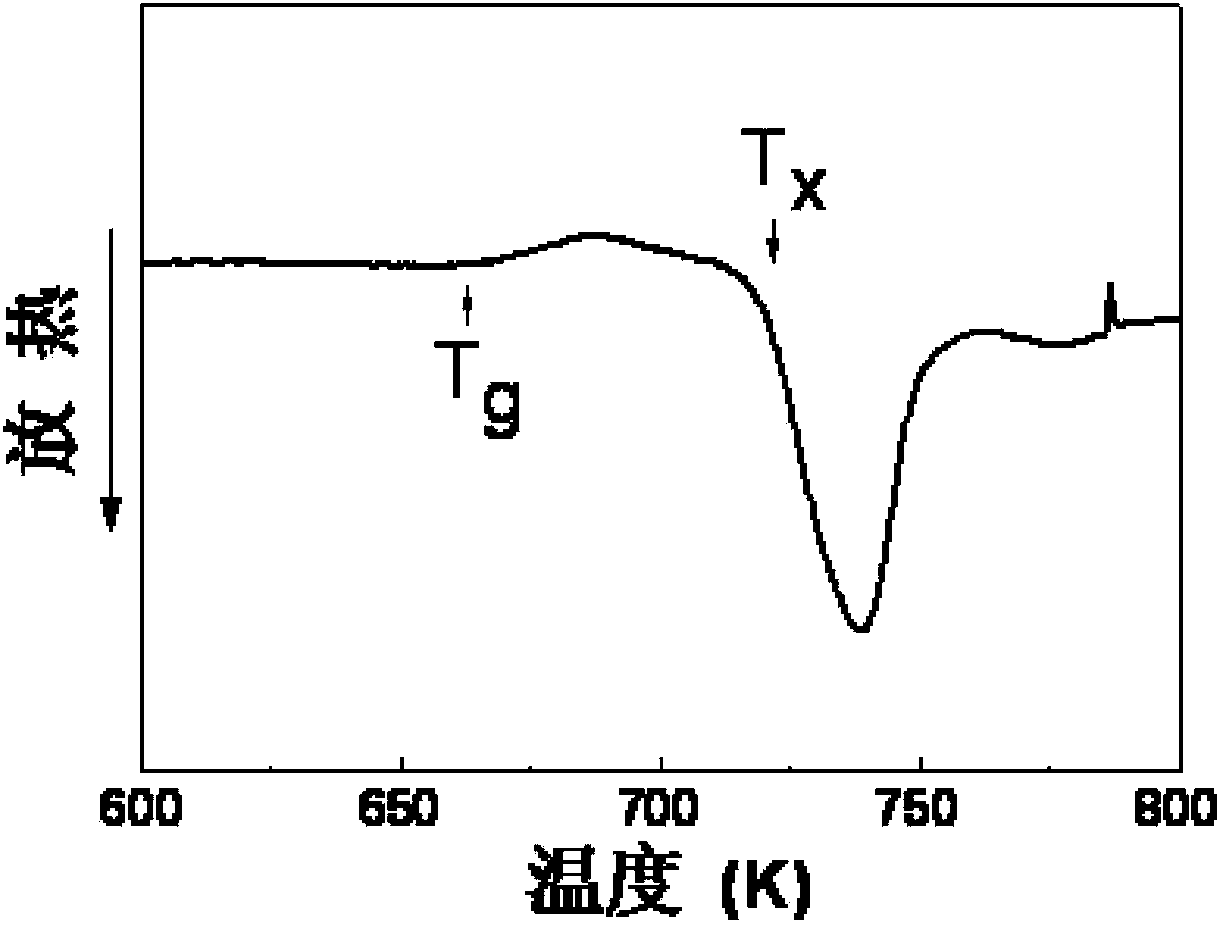

[0080] Depend on Figure 9 It can be seen from the DSC curves of this series of alloys that there are glass transition temperature, initial crystallization temperature and wide supercooled liquid phase region in this series of alloys, and with the change of the added rare earth elements, the corresponding thermodynamic parameters also change. changes happened. Depend on Figure 8 and Figure 9 It can be seen that the series of alloys obtained in the present invention have a complete amorphous structure and good glass-forming ability, and the adjustment of thermodynamic parameters and glass-forming ability can be realized through composition adjustment.

[0081] Figure 10 to Figure 17 The curves of magnetic entrop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com