Terbium base noncrystal alloy and its preparing method

An amorphous alloy, terbium-based technology, applied in the field of alloys, can solve the problems of rare earth-based amorphous alloy preparation and performance research, etc., and achieve the effects of simple preparation, good magnetostrictive performance, and good magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1, Tb 56 co 20 al 24 Preparation of Bulk Amorphous Alloy

[0031] Use Tb, Co and Al with a purity of more than 99.9% and a molar ratio of 56:20:24 to prepare a terbium-based bulk amorphous alloy. Melt in the furnace, mix evenly, and obtain the master alloy ingot of Tb-Co-Al ternary alloy after cooling; then use the conventional metal mold casting method to remelt the ingot, and use the suction casting device in the electric arc furnace to The master alloy melt is sucked into the water-cooled copper mold, and the composition is Tb 56 co 20 al 24 The bulk amorphous alloy, whose morphology is as follows figure 1 As shown, the diameter is 3mm.

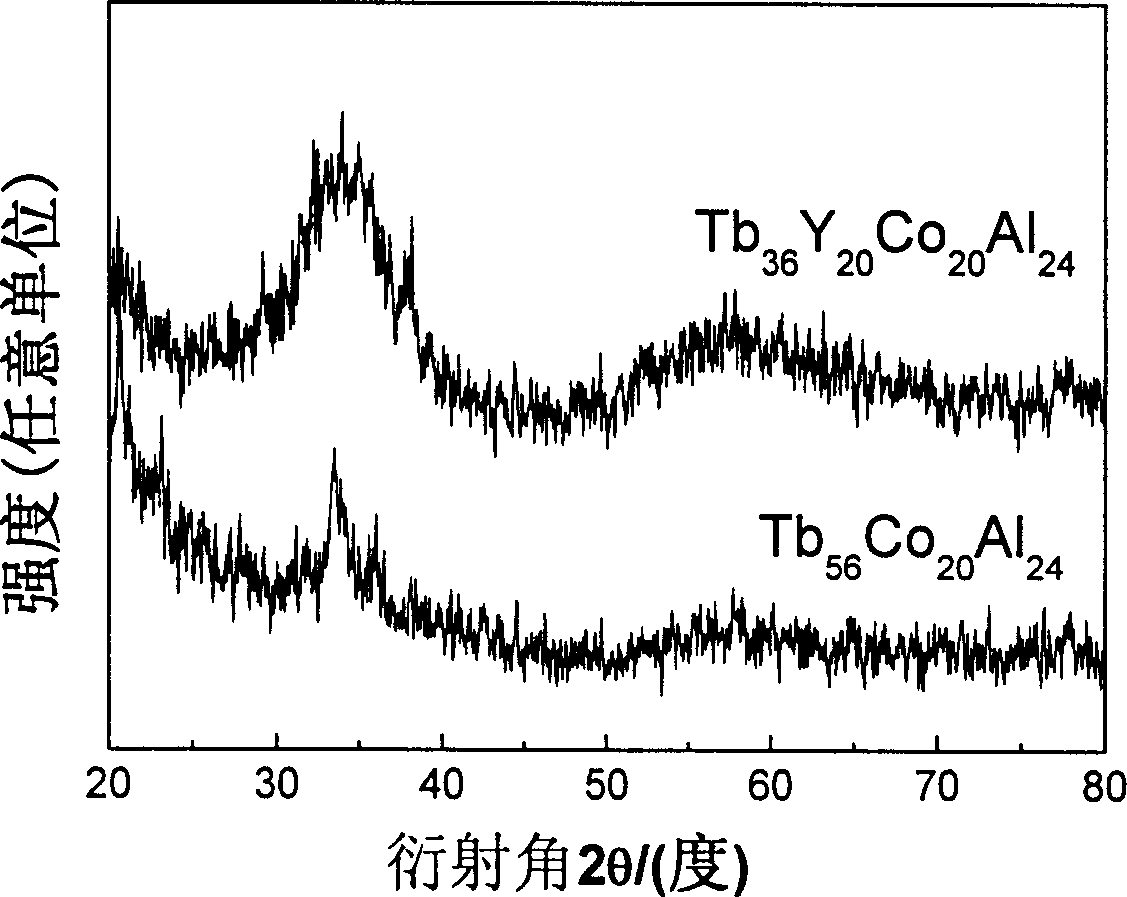

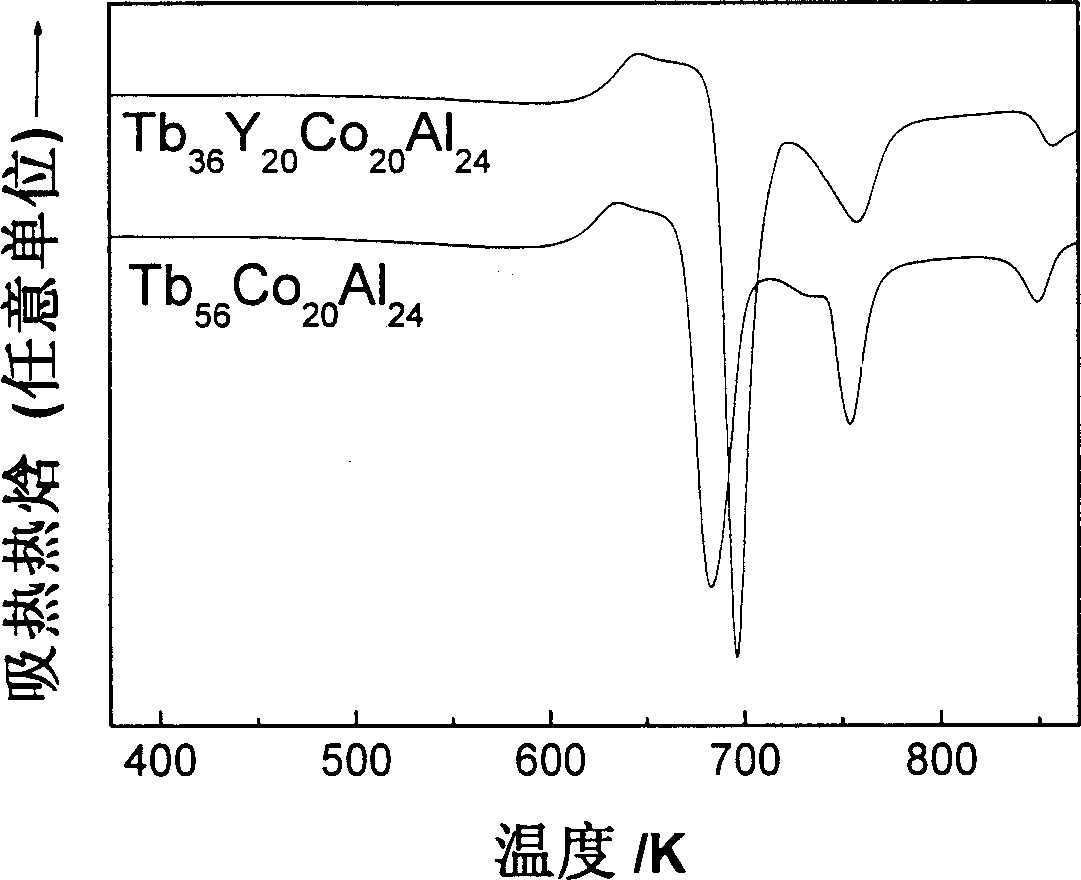

[0032] Such as figure 2 X-ray diffraction (XRD) shown demonstrates that the alloy is nearly completely amorphous. Such as image 3 The thermal analysis (DSC) diagram shown, its glass transition temperature (T g ), crystallization onset temperature (T x ), the width of the subcooling interval (ΔT=T x -T g ) are...

Embodiment 2~13

[0034] Various ratios of terbium-based bulk amorphous alloys were prepared according to the method of Example 1, and their compositions and thermophysical parameters are listed in Table 1.

[0035] Reality

[0036] Note: 1) The heating rate used in the measurement of each component sample in the table is 10K / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com