Ytterbium-based bulk amorphous alloy and preparation method thereof

An amorphous alloy and bulk technology, which is applied in the field of ytterbium-based bulk amorphous alloy and its preparation, can solve problems such as limiting the industrial application of amorphous materials, and achieves low critical cooling rate, strong crystallization ability and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, ytterbium-based bulk amorphous alloy Yb 65 Zn 20 Mg 15 preparation of

[0030] After the three components of Yb, Zn and Mg with a raw material purity of more than 99.9wt.% (weight percentage) are prepared in a molar ratio of 65:20:15, the raw materials are placed in a quartz tube and placed in a high Frequency induction furnace. Use a vacuum pump to evacuate to 3.0×10 -3 Above Pa, after filling with an appropriate amount of high-purity argon, heat it with a high-frequency coil and small current until it melts. When the electromagnetic stirring is uniform, spray casting into the copper mold, you can get the composition of Yb 65 Zn 20 Mg 15 , a bulk amorphous alloy with a diameter of 1 mm.

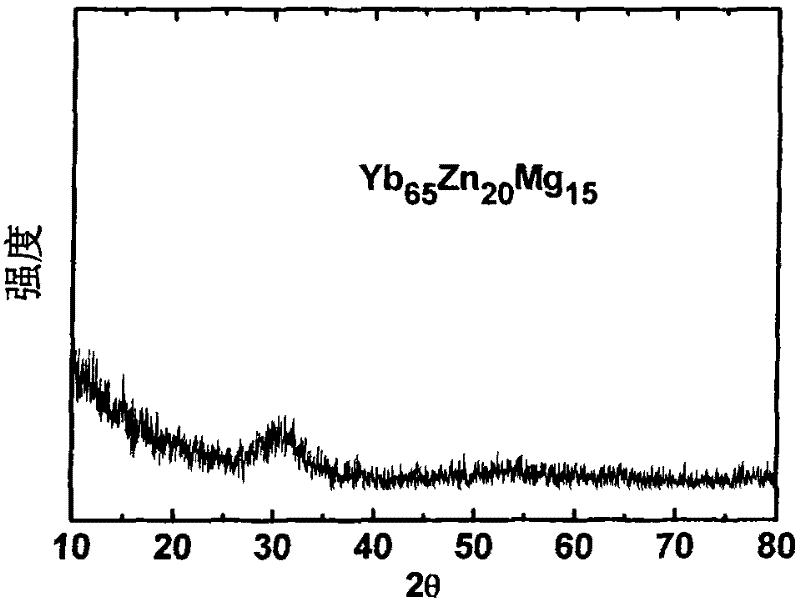

[0031] like figure 1 The X-ray diffraction (XRD) shown, it can be seen that the alloy is a completely amorphous alloy.

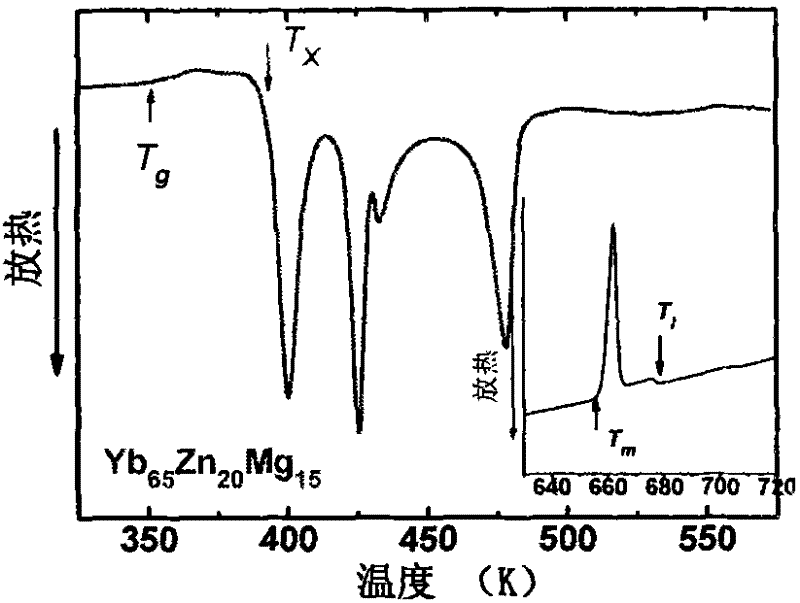

[0032] figure 2 for Yb 65 Zn 20 Mg 15 The thermal analysis (DSC) diagram of the ytterbium-based bulk amorphous alloy, as can be seen fr...

Embodiment 2

[0033] Embodiment 2, ytterbium-based bulk amorphous alloy Yb 64 Zn 20 Mg 15 Cu 1 preparation of

[0034] After the four components of Yb, Zn, Mg and Cu with a raw material purity of more than 99.9wt.% (weight percent) are prepared in a molar ratio of 64:20:15:1, the raw materials are placed in a quartz tube and placed Into the high frequency induction furnace. Use a vacuum pump to evacuate to 3.0×10 -3Above Pa, after filling with an appropriate amount of high-purity argon, heat it with a high-frequency coil and small current until it melts. When the electromagnetic stirring is uniform, spray casting into the copper mold, you can get the composition of Yb 64 Zn 20 Mg 15 Cu 1 , a bulk amorphous alloy with a diameter of 2 mm.

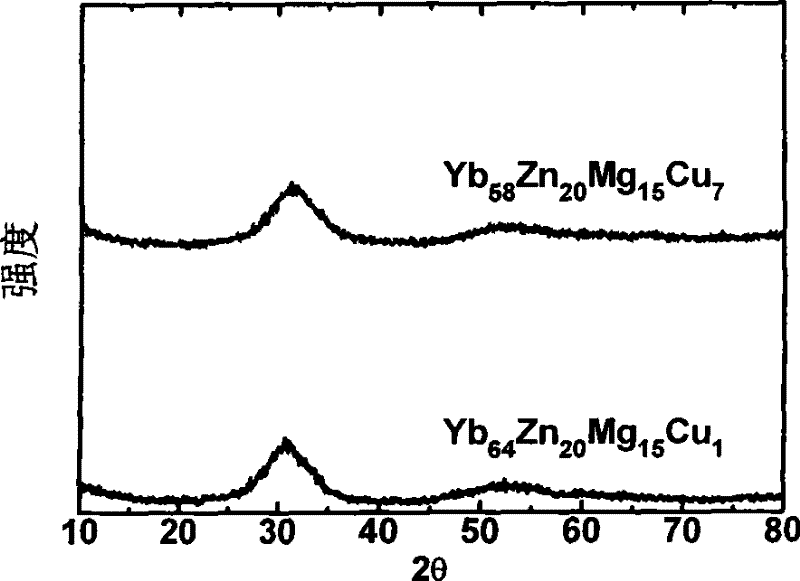

[0035] like image 3 The X-ray diffraction (XRD) shown shows that the alloy is a completely amorphous alloy.

[0036] Figure 4 for Yb 64 Zn 20 Mg 15 Cu 1 The thermal analysis (DSC) diagram of the ytterbium-based bulk amorphous alloy, as c...

Embodiment 3

[0037] Embodiment 3, ytterbium-based bulk amorphous alloy Yb 58 Zn 20 Mg 15 Cu 7 preparation of

[0038] After the four components of Yb, Zn, Mg and Cu with a raw material purity of more than 99.9wt% (weight percentage) are prepared in a molar ratio of 58:20:15:7, the raw materials are placed in a quartz tube and put into High frequency induction furnace. Use a vacuum pump to evacuate to 3.0×10 -3 Above Pa, after filling with an appropriate amount of high-purity argon, heat it with a high-frequency coil and small current until it melts. When the electromagnetic stirring is uniform, spray casting into the copper mold, you can get the composition of Yb 58 Zn 20 Mg 15 Cu 7 , a bulk amorphous alloy with a diameter of 2 mm.

[0039] like image 3 The X-ray diffraction (XRD) shown shows that the alloy is a completely amorphous alloy.

[0040] Figure 5 for Yb 58 Zn 20 Mg 15 Cu 7 The thermal analysis (DSC) diagram of the ytterbium-based bulk amorphous alloy, as can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com