Erbium-base lorge-cube non-crystal alloy and making method

An amorphous alloy and bulk technology, which is applied in the field of erbium-based bulk amorphous alloy and its preparation, can solve the problem of rare rare earth-based amorphous alloy, and achieve the effects of low cost, broad application prospect and strong crystallization ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1. Erbium-based bulk amorphous alloy Er 36 Y 20 Al 24 Co 20 Preparation

[0024] After mixing the four components of Er, Y, Al and Co with a raw material purity of 99.9wt% or more (weight percentage) in a molar ratio of 36:20:24:20, the arc is in an argon atmosphere where titanium is adsorbed. The furnace is evenly mixed and smelted 5 times. After cooling, the master alloy ingot of Er-Y-Al-Co quaternary alloy is obtained; then the conventional metal mold casting method is used to re-melt the ingot, using the electric arc furnace The suction casting device sucks the master alloy melt into the water-cooled copper mold, and the composition is Er 36 Y 20 Al 24 Co 20 , A bulk amorphous alloy with a diameter of 8mm.

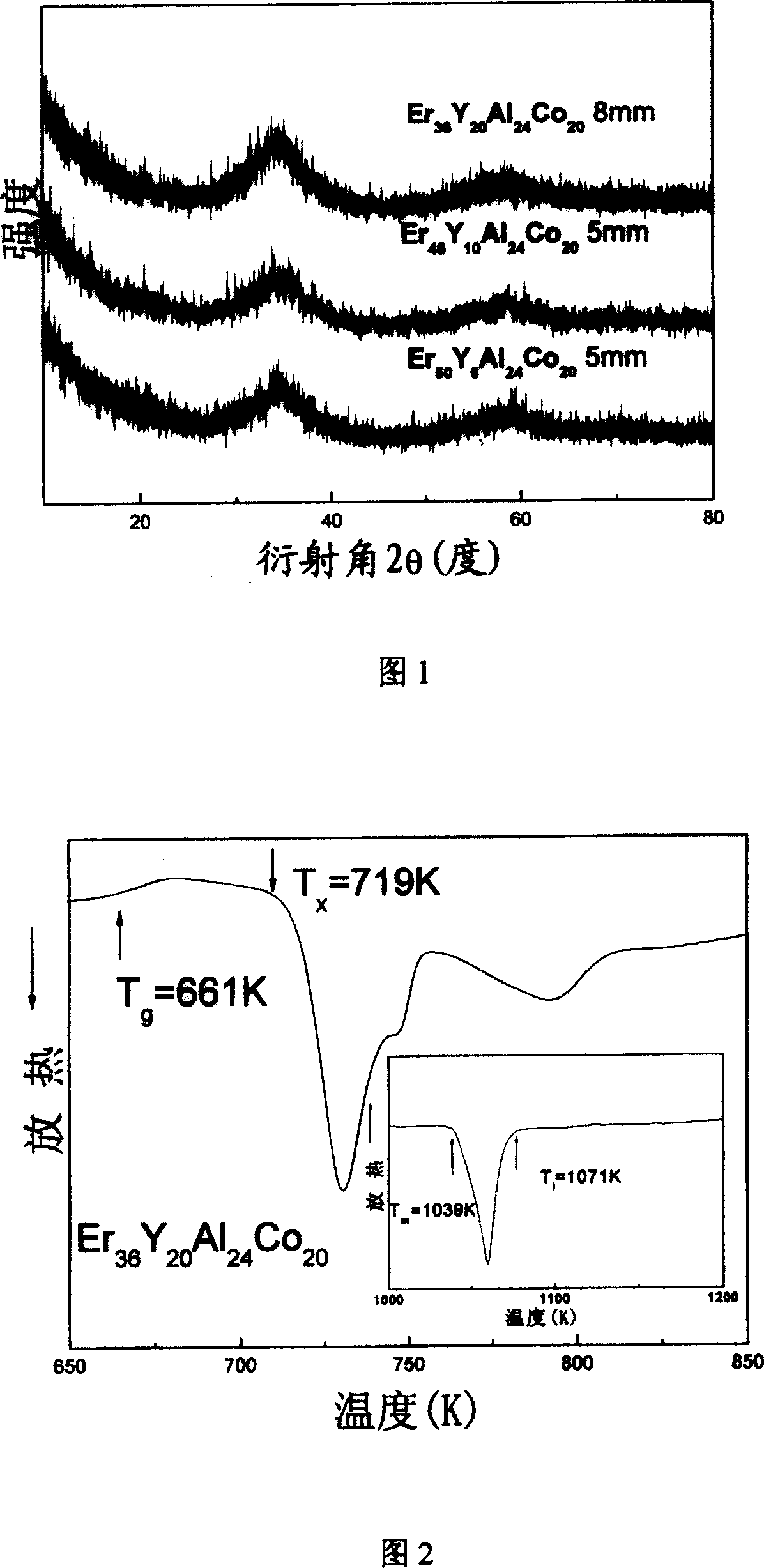

[0025] The X-ray diffraction (XRD) shown in Figure 1 shows that the alloy is a completely amorphous alloy.

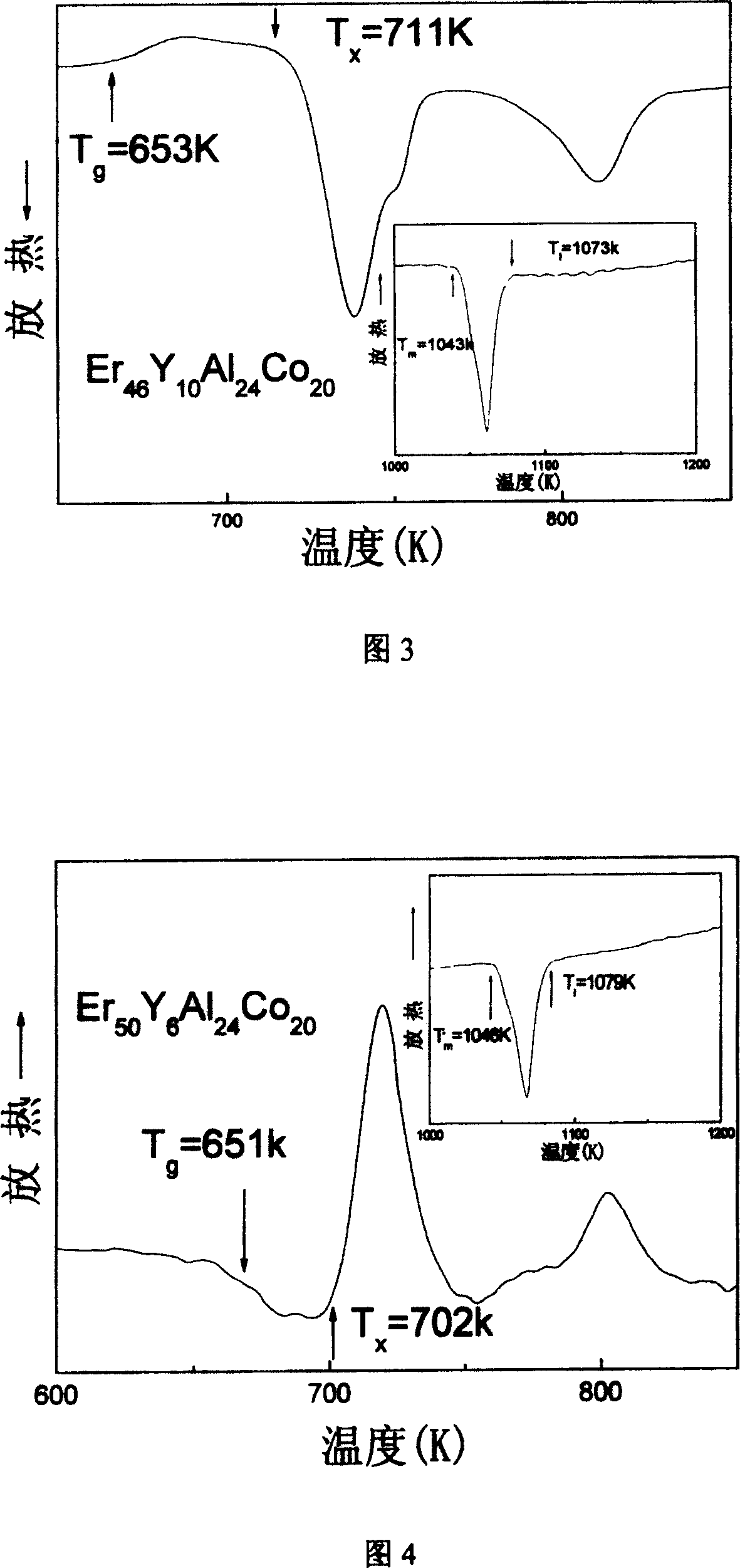

[0026] Figure 2 shows Er 36 Y 20 Al 24 Co 20 The thermal analysis (DTA) diagram of the erbium-based bulk amorphous alloy, as can be seen from the dia...

Embodiment 2

[0027] Example 2. Erbium-based bulk amorphous alloy Er 46 Y 10 Al 24 Co 20 Preparation

[0028] After preparing the four components of Er, Y, Al and Co with a raw material purity of 99.9wt% or more (weight percentage) at a molar ratio of 46:10:24:20, in an electric arc furnace with an argon atmosphere adsorbed by titanium Mix uniformly and repeatedly smelt 6 times, and after cooling, the master alloy ingot of Er-Y-Al-Co quaternary alloy is obtained; then the conventional metal mold casting method is used to re-melt the ingot, using suction casting in the electric arc furnace Device, suck the master alloy melt into the water-cooled copper mold to get the composition Er 46 Y 10 Al 24 Co 20 , A bulk amorphous alloy with a diameter of 5mm.

[0029] The X-ray diffraction (XRD) shown in Figure 1 shows that the alloy is a completely amorphous alloy.

[0030] Figure 3 shows Er 46 Y 10 Al 24 Co 20 The thermal analysis (DSC and DTA) diagrams of erbium-based bulk amorphous alloys can be seen...

Embodiment 3

[0031] Example 3: Erbium-based bulk amorphous alloy Er 50 Y 6 Al 24 Co 20 Preparation

[0032] After preparing the four components of Er, Y, Al and Co with a raw material purity of 99.9wt% or more (weight percentage) at a molar ratio of 50:6:24:20, in an electric arc furnace with an argon atmosphere adsorbed by titanium Mix uniformly and repeatedly smelt 5 times. After cooling, the master alloy ingot of Er-Y-Al-Co quaternary alloy is obtained; then the conventional metal mold casting method is used to re-melt the ingot and use the suction casting in the electric arc furnace Device, suck the master alloy melt into the water-cooled copper mold to get the composition Er 50 Y 6 Al 24 Co 20 , A bulk amorphous alloy with a diameter of 5mm.

[0033] The X-ray diffraction (XRD) shown in Figure 1 shows that the alloy is a completely amorphous alloy.

[0034] Figure 4 shows Er 50 Y 6 Al 24 Co 20 The thermal analysis (DSC and DTA) diagrams of erbium-based bulk amorphous alloys can be seen fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com