Cobalt-manganese-tin-based alloy material and preparation method thereof

An alloy material, cobalt-manganese-tin-based technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of restricting the development and application of materials, and achieve the goal of avoiding thermal hysteresis effect, broad application prospects, and large magnetocaloric effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

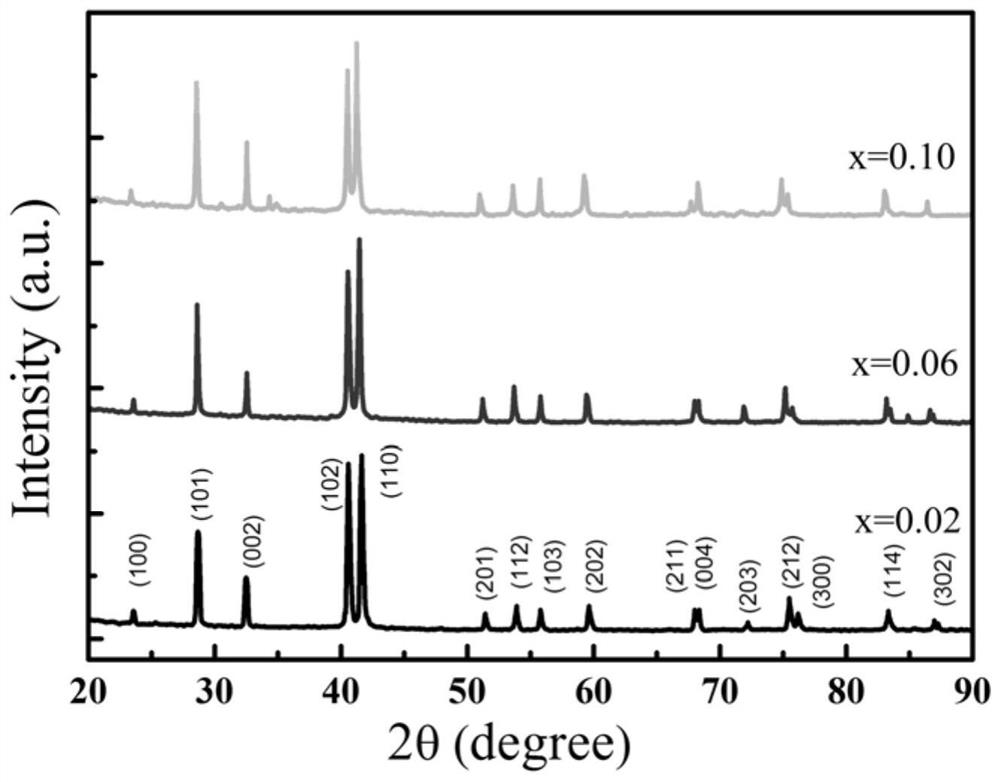

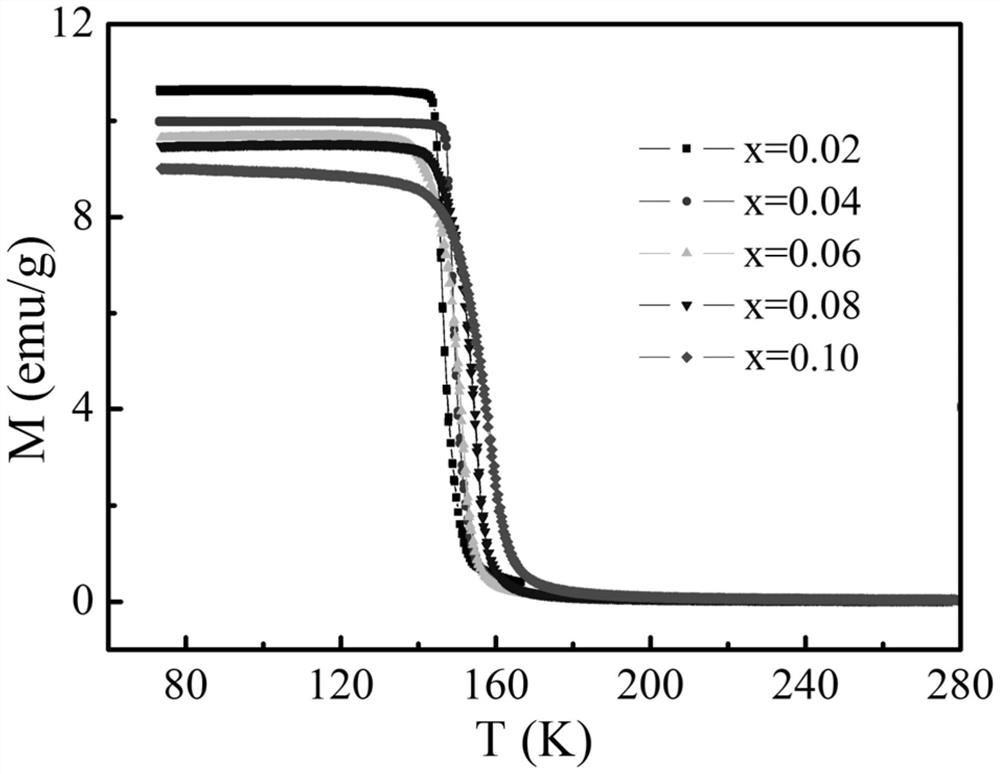

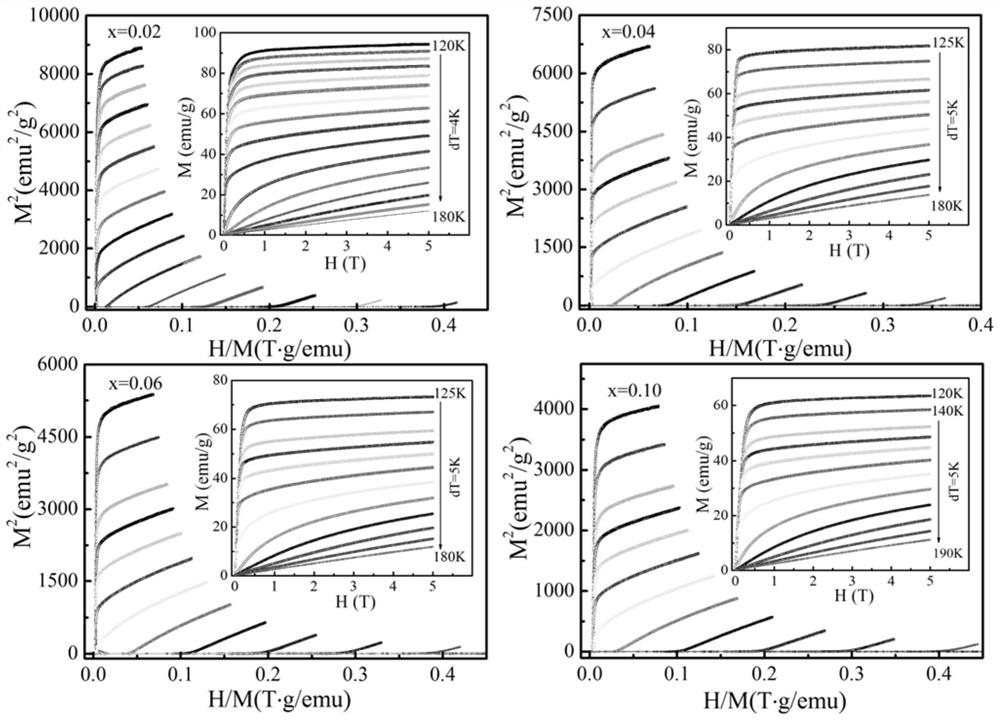

[0022] Example 1: Cobalt (purity: 99.99%), manganese (purity: 99.6%), tin (purity: 99.999%) elemental metals were weighed according to the molar ratio of 0.98:1.02:1, and placed in a vacuum electric arc furnace. Before arcing and smelting, first use a mechanical pump to evacuate the furnace cavity to a vacuum degree lower than 2 Pa, and then turn on the molecular pump to evacuate to a furnace cavity vacuum degree lower than 10 Pa. -4 Pa. Then pass into high-purity argon (99.999%) to clean the furnace chamber until the vacuum degree of the furnace chamber is 1 atmosphere (0.8atm), and then vacuumize to 10 -4 Pa, repeat the above steps three times. Use 30A current to start the arc, then move the electrode to the top of the sample, keep the distance between the electrode and the sample at 0.5-1cm, slowly adjust the current to 80A until the sample is completely melted and form an alloy, then reduce the current to 60A for 30s, after the end of the current Adjust to zero. After t...

Embodiment 2

[0023] Example 2: Except that the molar addition ratio of cobalt, manganese, and tin components is 0.96:1.04:1, other steps are the same as in Example 1.

Embodiment 3

[0024] Embodiment 3: except that the molar addition ratio of each component of cobalt, manganese, and tin is 0.94:1.06:1, all the other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com