Ni-Fe-Mn-Al alloy material and preparation method thereof

A technology of ni-fe-mn-al and alloy materials, which is applied in the field of Ni-Fe-Mn-Al alloy magnetic refrigeration materials and its preparation, can solve the problems of no magnetocaloric effect, low magnetization, and limited applications, and achieve The effects of non-toxic thermal conductivity, good performance stability, good mechanical properties and molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

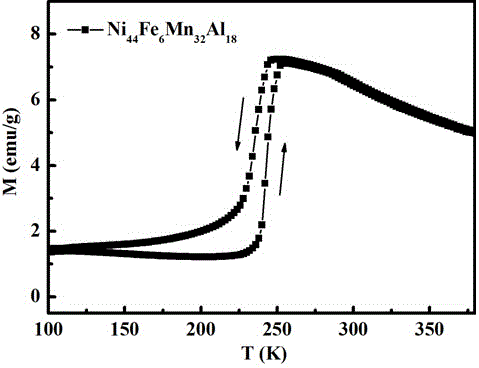

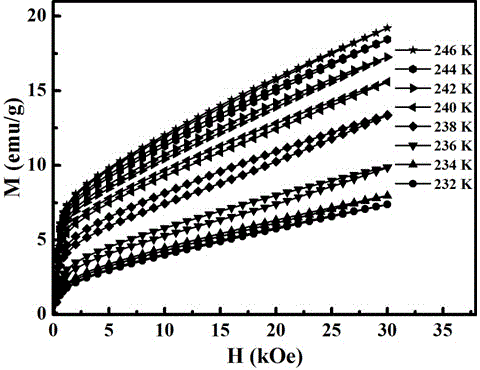

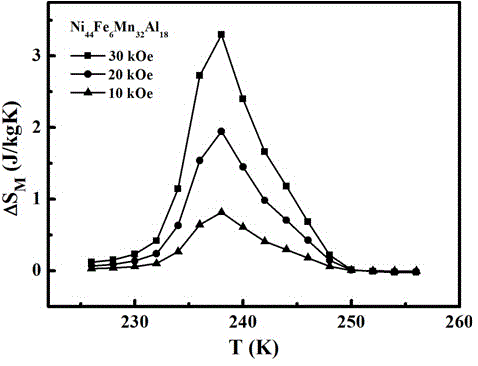

[0027] The preparation composition of this embodiment is Ni 44 Fe 6 mn 32 al 18 The subscripts of each element represent the atomic number percentage content of the corresponding element in the alloy. Specifically include the following steps:

[0028] (1) Press Ni 44 Fe 6 mn 32 al 18 Chemical formula ingredients, respectively weighing Ni, Fe, Mn, Al metal raw materials with a purity of 99.9%; the atomic percentages are: Ni is 44%, Fe is 6%, Mn is 32%, and Al is 18%;

[0029] (2) Put the weighed raw materials into a water-cooled crucible, and draw a vacuum to 1×10 -3 When the Pa is below, argon gas is introduced to generate an arc, the melting current is 200A, each sample is turned over 3 times, and a total of 4 times of melting is used to ensure uniform composition;

[0030](3) The smelted ingot sample was sealed in a vacuum quartz tube, annealed at 1100 ° C for 72 hours, and then quenched in cold water to achieve a highly ordered arrangement of atoms to obtain Ni 44...

Embodiment 2

[0035] Preparation composition is Ni 42 Fe 8 mn 32 Al 18 Alloy Blocks:

[0036] (1) Press Ni 42 Fe 8 mn 32 Al 18 Chemical formula ingredients, respectively weighing Ni, Fe, Mn, Al metal raw materials with a purity of 99.9%; the atomic percentages are: Ni is 42%, Fe is 8%, Mn is 32%, and Al is 18%;

[0037] (2) Put the weighed raw materials into a water-cooled crucible, and draw a vacuum to 1×10 -3 When the Pa is below, argon gas is introduced to generate an arc, the melting current is 300A, each sample is turned over 3 times, and a total of 4 times of melting is used to ensure uniform composition;

[0038] (3) Seal the smelted ingot sample in a vacuum quartz tube, anneal at 1150°C for 72 hours, then put the quartz tube into cold water for quenching to achieve a highly ordered arrangement of atoms, and obtain a magnetic alloy polycrystalline ingot ;

[0039] (4) The prepared polycrystalline samples were cut into smaller sizes by wire electric discharge cutting, and va...

Embodiment 3

[0041] Preparation composition is Ni 46 Fe 4 mn 32 Al 18 Alloy bulk material: except that the composition of the sample is Ni 46 Fe 4 mn 32 Al 18 , the atomic percentages are respectively: 46% for Ni, 4% for Fe, 32% for Mn, and 18% for Al; The martensitic transformation temperature and magnetic entropy change values of the samples are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com