Mn-Fe-P-Si magnetic refrigeration material and preparation method thereof

A technology of mn-fe-p-si and magnetic refrigeration materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of active powder chemical properties, increased raw material costs, easy oxidation, etc., to achieve low price, The effect of low cost and large magnetic entropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

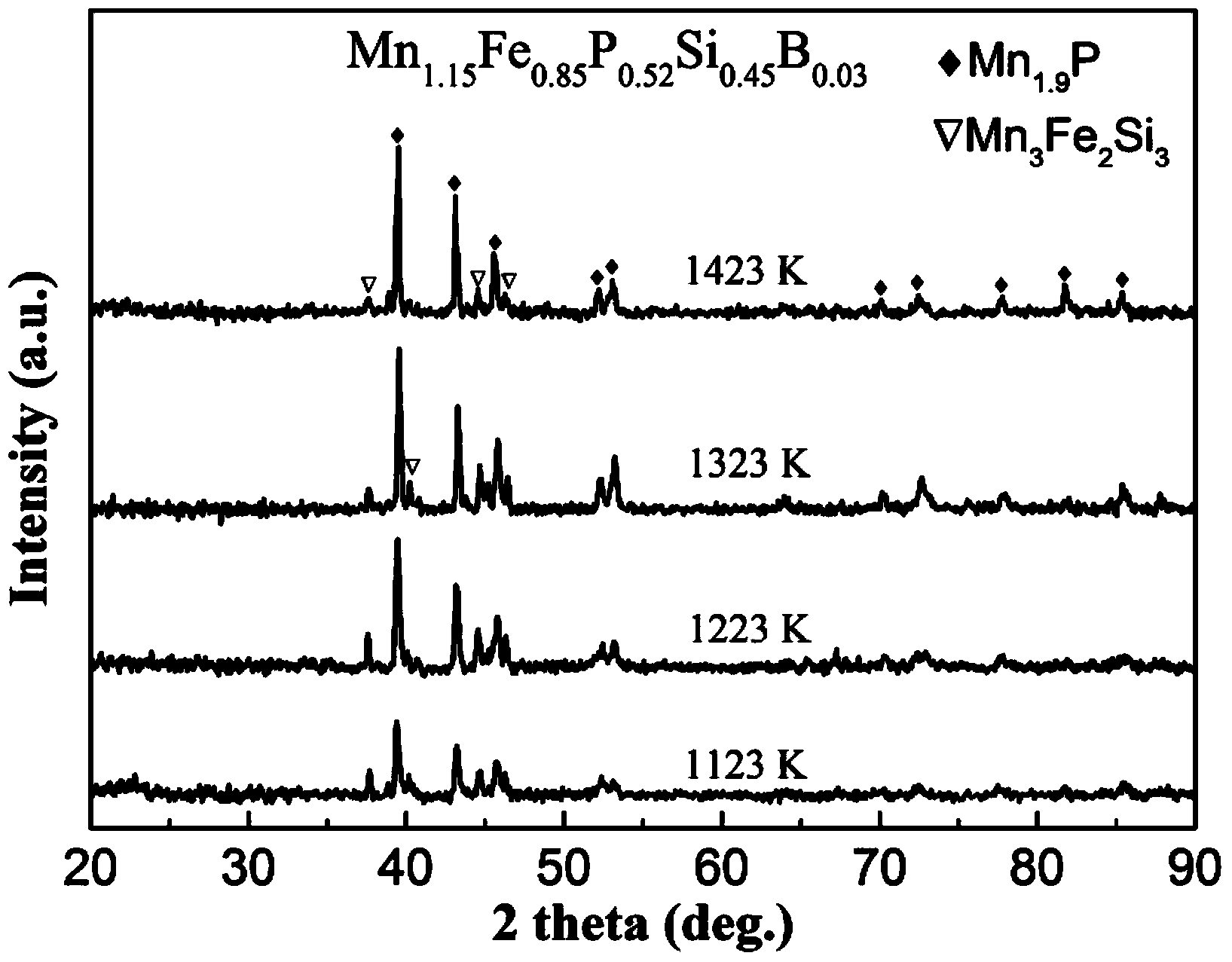

Image

Examples

Embodiment 1

[0039] A kind of Mn-Fe-P-Si magnetic refrigeration material, its preparation method is as follows:

[0040] (1) Press Mn sheet, Fe block, FeP block, Si block and B block by Mn 1.15 Fe0.85 P 0.52 Si 0.45 B 0.03 The atomic proportions of the alloy. Among them, the masses of Mn sheet, Fe block, FeP block, Si block and B block are 4.758g, 0.287g, 4.439g, 0.906g, 0.023g respectively, and four parts are weighed;

[0041] (2) Put the prepared raw materials into the vacuum electric arc furnace and evacuate to 5×10 -3 Below Pa, fill it with high-purity argon gas of 0.03-0.05MPa, and use arc melting to make alloy ingots. In order to ensure that the components are mixed evenly, the sample is turned over after each melting, and the melting is repeated 5 times;

[0042] (3) After the alloy ingot described in the step (2) is removed from the surface oxide skin, it is crushed, and 5 g of the alloy ingot is taken and loaded into a quartz tube having a small hole at the lower end. Insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com