Hydrogenated NiMn-based alloy magnetic refrigeration material and preparation method and use thereof

A technology based on alloys and magnetic materials, applied in the field of hydrogenated NiMn-based Heusler alloy magnetic refrigeration materials and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

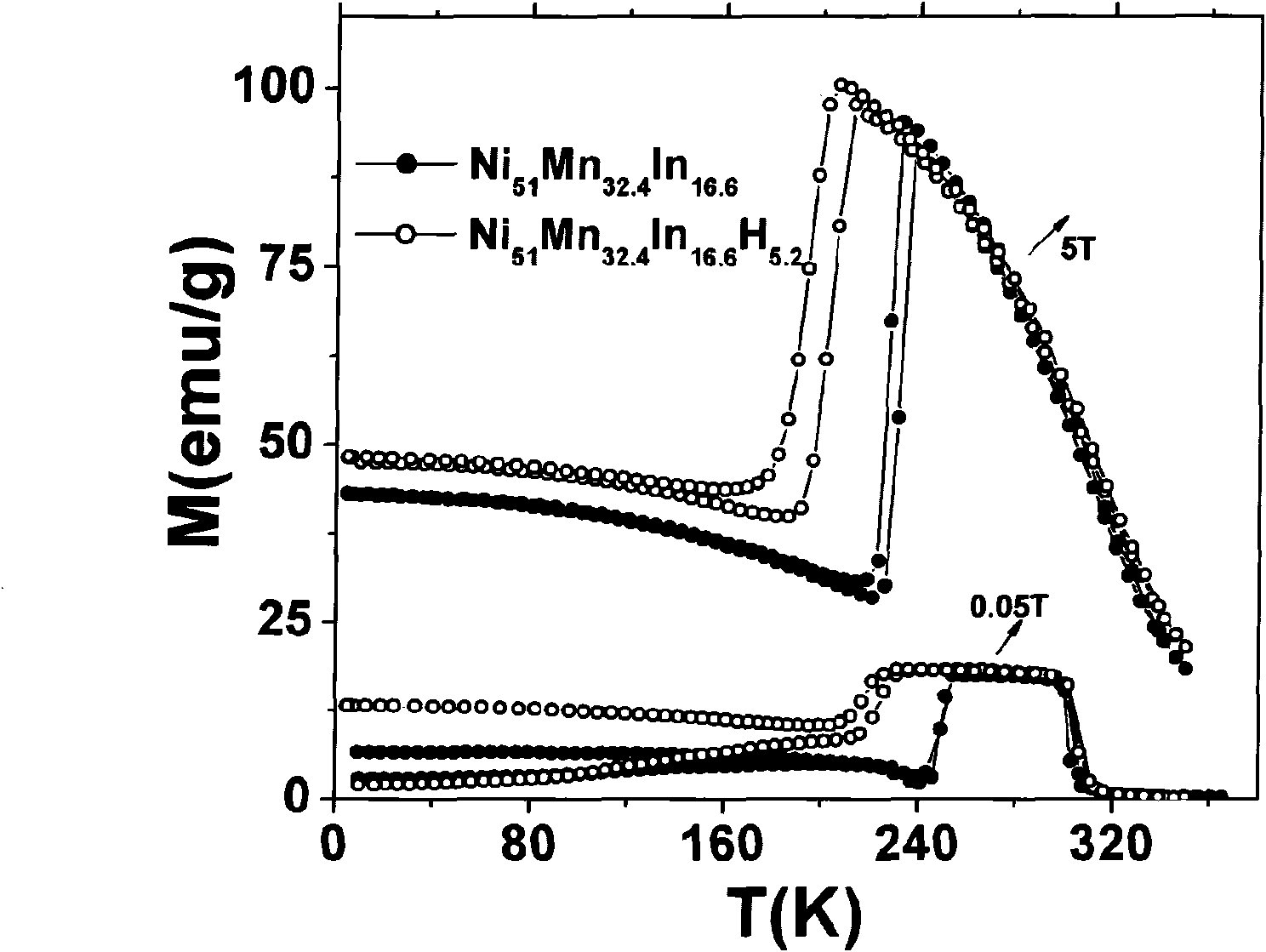

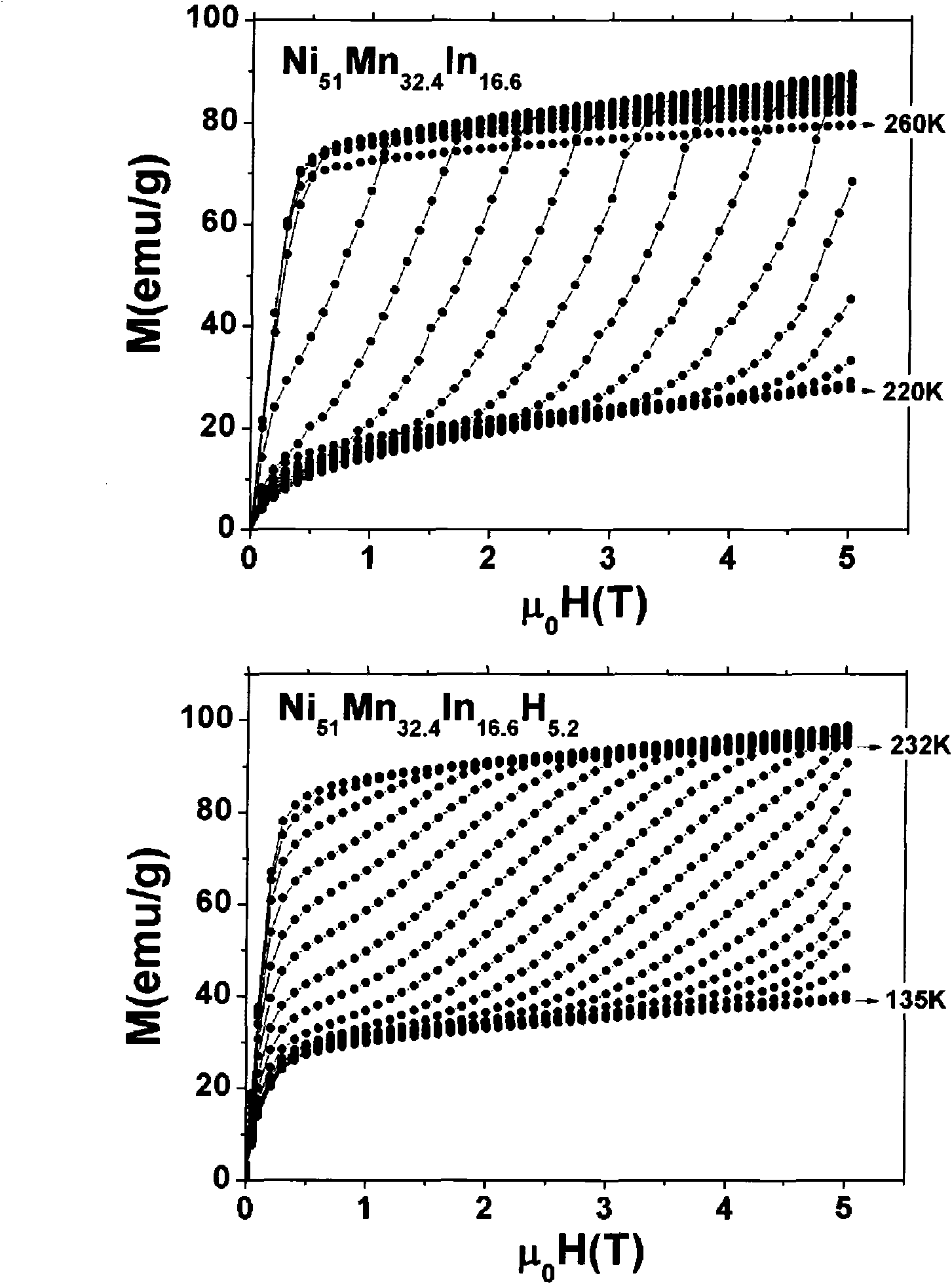

[0074] Embodiment 1 prepares Ni 51 mn 32.4 In 16.6 H 3 Hydride

[0075] This embodiment provides to prepare Ni by chemical formula 51 mn 32.4 In 16.6 h 5.2 The concrete example of hydride, concrete process is:

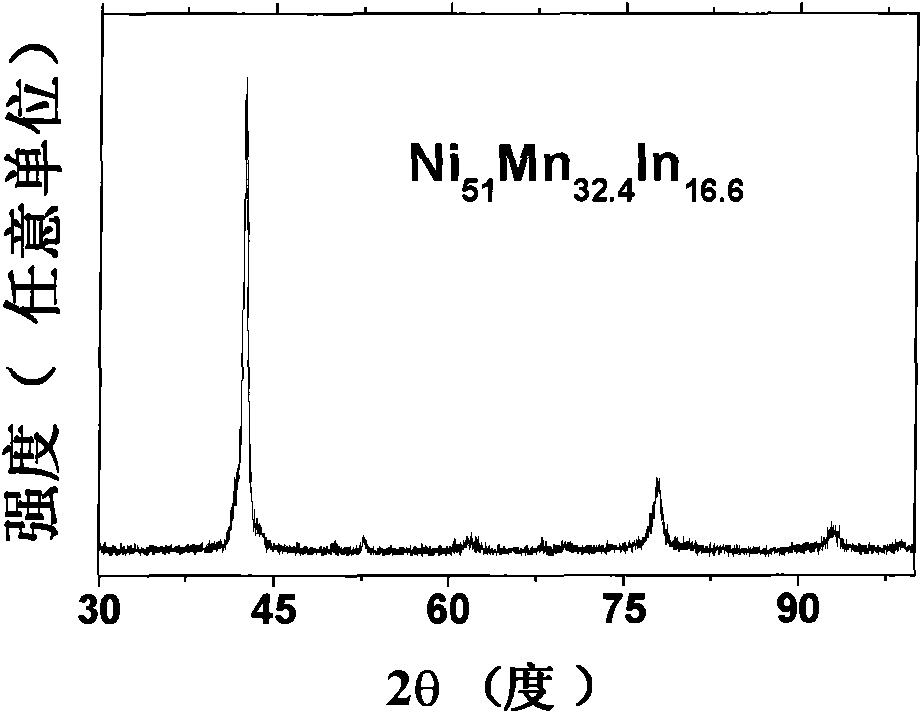

[0076] 1) First, according to the chemical formula Ni 51 mn 32.4 In 16.6 As for ingredients, the purity of raw materials Ni, Mn and In are 99.99wt%, 99.9wt% and 99.99wt% respectively.

[0077] 2) Put the Ni, Mn, In raw materials prepared in step 1) into the electric arc furnace, and vacuumize to 2×10 -3 Pa, clean the furnace cavity twice with high-purity argon gas with a purity of 99.996%, and then fill the furnace cavity with high-purity argon gas with a purity of 99.996% to an atmospheric pressure, start the arc, and repeatedly smelt each alloy ingot 4 times. The temperature is 2000 degrees Celsius. After the smelting is completed, the cast alloy is obtained by cooling in a copper crucible.

[0078] 3) Wrap the cast alloy ingots prepared...

Embodiment 2

[0086] Embodiment 2 prepares Ni 51 mn 32.8 In 16.2 H 1.4 Hydride

[0087] This embodiment provides to prepare Ni by chemical formula 51 mn 32.8 In 16.2 h 1.4 The concrete example of hydride, concrete process is:

[0088] 1) First, according to the chemical formula Ni 51 mn 32.8 In 16.2 As for ingredients, the purity of raw materials Ni, Mn and In are 99.99wt%, 99.9wt% and 99.99wt% respectively.

[0089] 2) Put the Ni, Mn, In raw materials prepared in step 1) into the electric arc furnace, and vacuumize to 2×10 -3 Pa, the furnace cavity is cleaned twice with high-purity argon gas with a purity of 99.996%, and then the furnace cavity is filled with high-purity argon gas with a purity of 99.996% to an atmospheric pressure. The arc is started, and each alloy ingot is repeatedly smelted 4 times at a melting temperature of 2000 degrees Celsius. After smelting, it is cooled in a copper crucible to obtain an as-cast alloy.

[0090] 3) Wrap the cast alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com