Rare earth tin-based low-temperature magnetic refrigeration material and preparation method thereof

A low-temperature magnetic refrigeration, tin-based technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of complex single crystal preparation technology, unfavorable mass production, cumbersome preparation process, etc., to achieve abundant reserves, low cost, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A rare-earth tin-based low-temperature magnetic refrigeration material, the preparation method of which is as follows:

[0030] Step 1: Press Ho and Sn according to Ho 5 sn 4 (atomic ratio) ratio batching; The sample gross weight is 10g, and wherein Ho, Sn are respectively 6.346g, 3.654g.

[0031] Step 2: Put the raw materials prepared in Step 1 into the electric arc furnace, and evacuate to 10 -3 Pa, after cleaning the furnace with high-purity argon, fill it with high-purity argon slightly lower than 1 atmosphere (about 0.1MPa), and repeatedly smelt it for 4 times under the protection of high-purity argon, and obtain a button-shaped casting with uniform composition after cooling. ingot;

[0032]Step 3: Wrap the smelted ingot with tantalum foil, place it in a high-vacuum induction heating annealing furnace, anneal at 1573K for 24 hours, and then cool with the furnace.

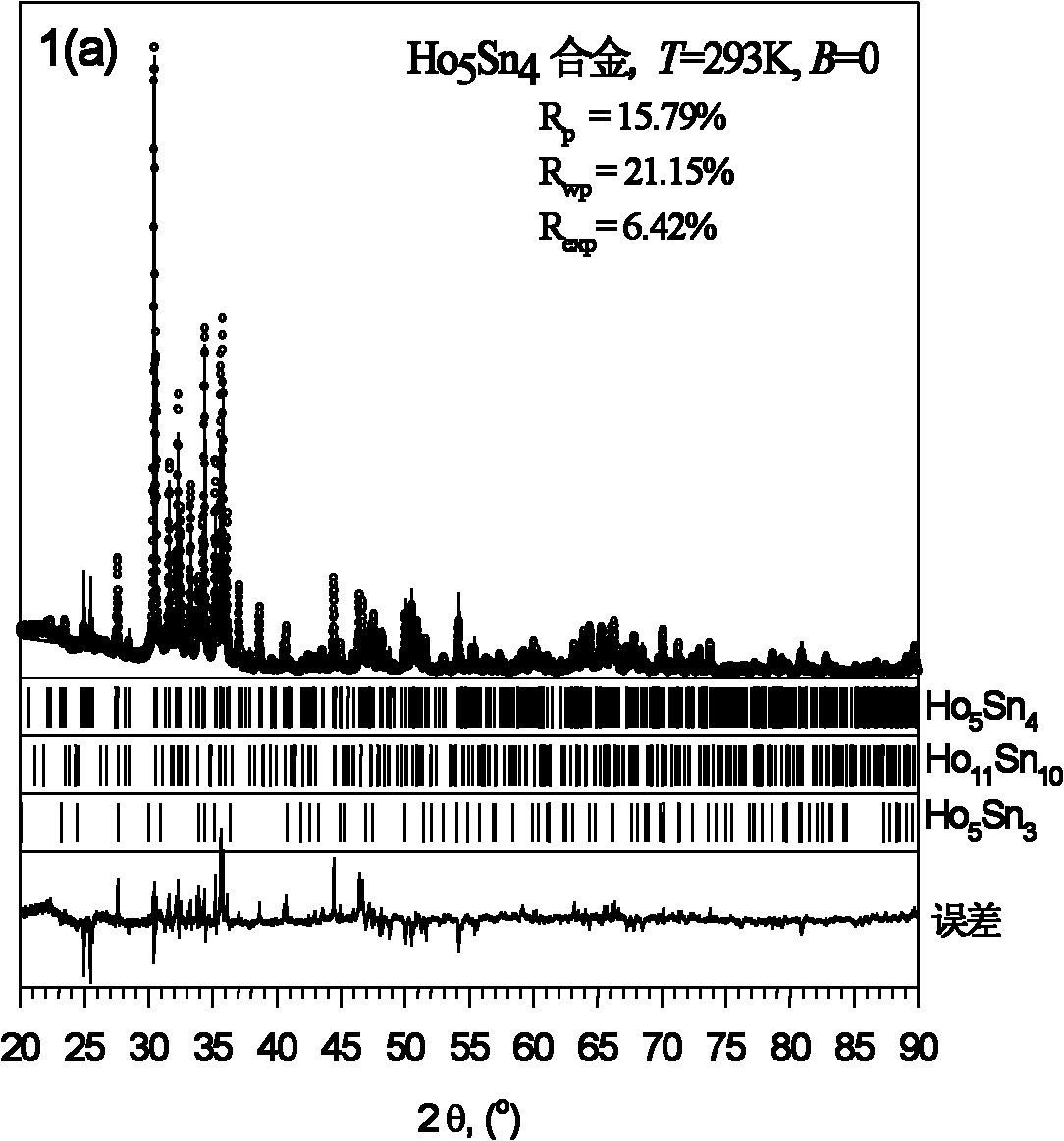

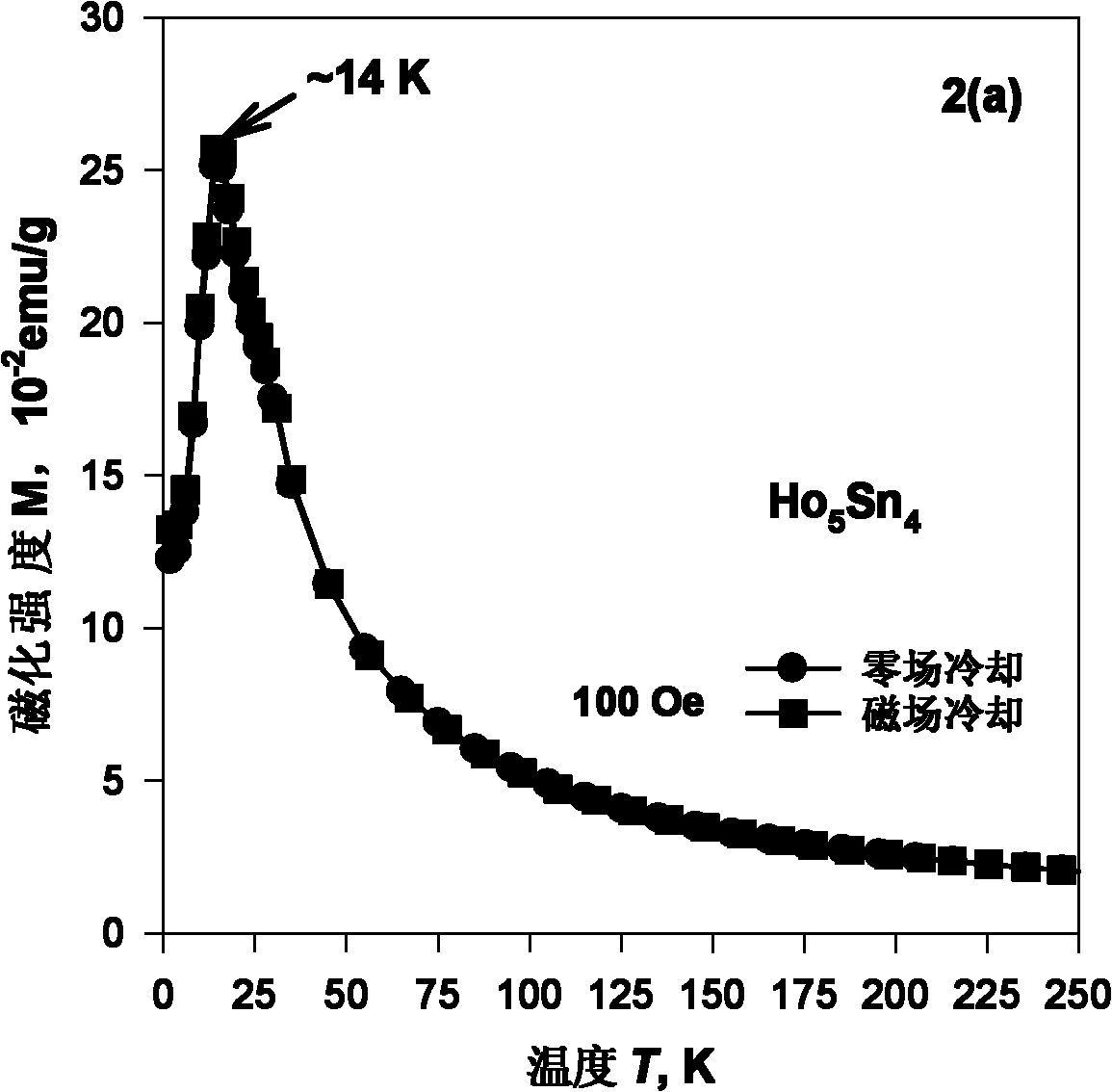

[0033] X-ray diffraction of the samples thus prepared proved that the alloy consisted of three ph...

Embodiment 2

[0038] A rare-earth tin-based low-temperature magnetic refrigeration material, the preparation method of which is as follows:

[0039] Step 1: Press Er and Sn by Er 5 sn 4 (atomic ratio) ratio batching; The sample gross weight is 10g, and wherein Er, Sn are 6.378g, 3.622g respectively.

[0040] Step 2: Put the raw materials prepared in Step 1 into the electric arc furnace, and evacuate to 10 -3 Pa, after cleaning the furnace with high-purity argon, fill it with high-purity argon slightly lower than 1 atmosphere (about 0.1MPa), and repeatedly smelt it for 4 times under the protection of high-purity argon, and obtain a button-shaped casting with uniform composition after cooling. ingot;

[0041] Step 3: Wrap the smelted ingot with tantalum foil, place it in a high-vacuum induction heating annealing furnace, anneal at 1573K for 24 hours, and then cool with the furnace.

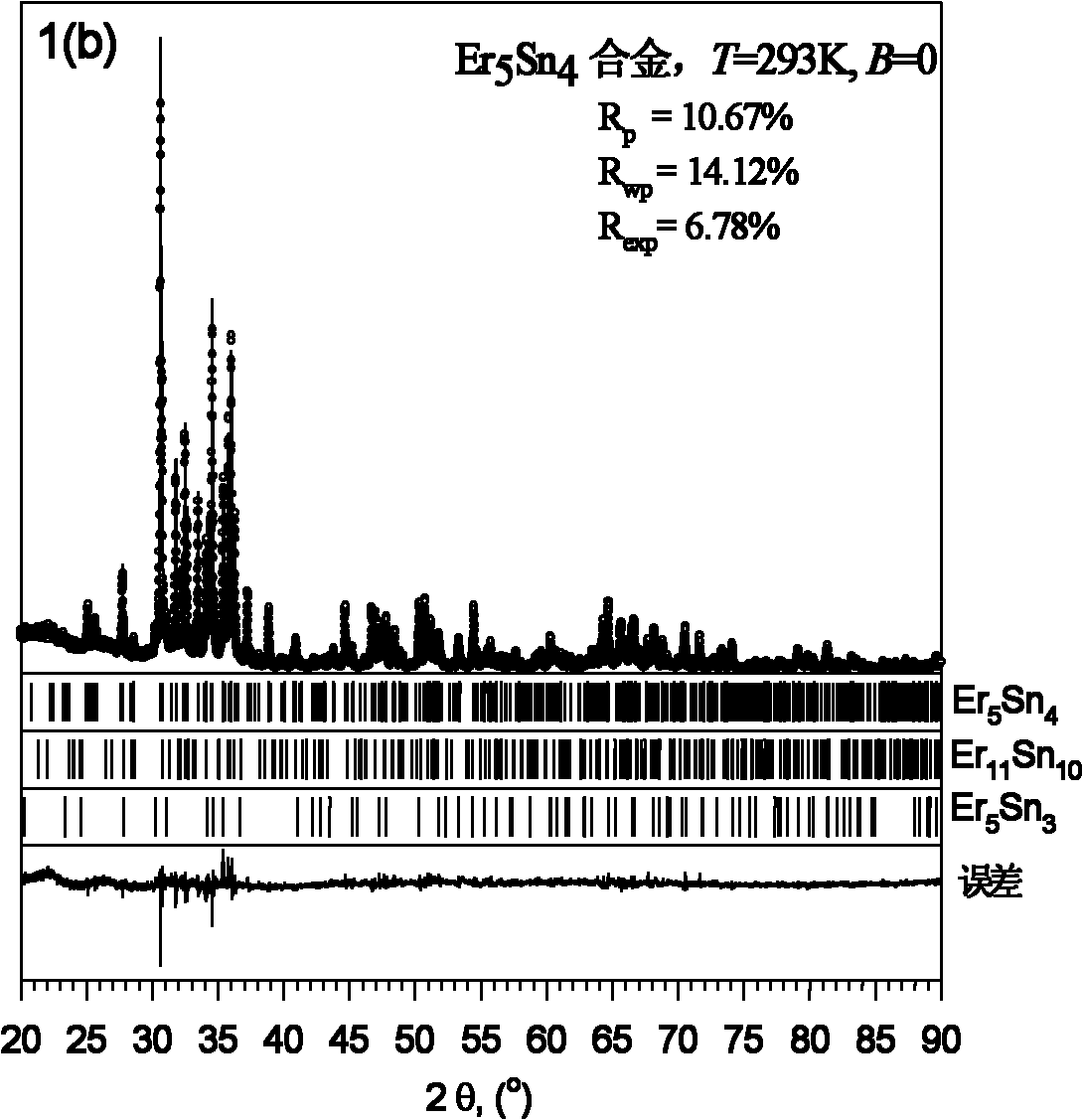

[0042] X-ray diffraction of the samples thus prepared proved that the alloy consisted of three phases, nam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com