A preparation method of la0.7ca0.25sr0.05mno3 ferromagnetic film

A technology of ferromagnetic thin film and ethylene glycol methyl ether is applied in the field of preparation of thin film materials, which can solve the problems of poor ferromagnetic properties, high sintering temperature and low density of thin films, and achieve enhanced ferromagnetic properties, low sintering temperature, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

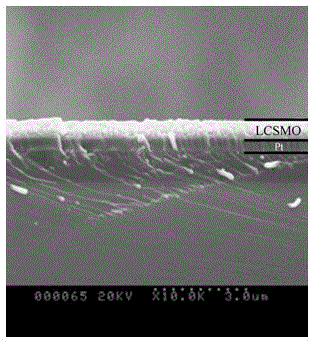

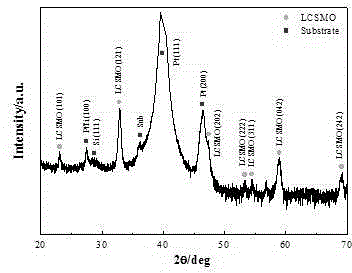

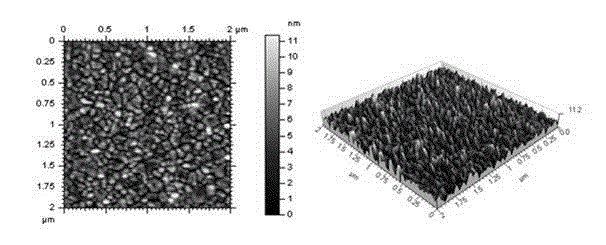

Image

Examples

Embodiment 1

[0027] ①, according to the chemical formula La 0.7 Ca 0.25 Sr 0.05 MnO 3 , respectively weigh 2.42g of lanthanum nitrate, 0.18g of calcium acetate, 0.08g of strontium nitrate and 1.96g of manganese acetate according to the molar ratio of 0.7:0.25:0.05:1;

[0028] ②. Add lanthanum nitrate to a mixed solution of 2mL glacial acetic acid and 10mL ethylene glycol methyl ether, wherein the molar ratio of glacial acetic acid to ethylene glycol methyl ether is 1:5-10, and The molar ratio of the mixed solution of alcohol methyl ether is 1:6~11, and stirred at room temperature for 30~60min to obtain solution A;

[0029] ③. Add the mixture of calcium acetate and strontium nitrate to the mixed solution of 2mL glacial acetic acid and 10mL ethylene glycol methyl ether, wherein the molar ratio of glacial acetic acid and ethylene glycol methyl ether is 1:5~10, The molar ratio of the mixture to the mixed solution of glacial acetic acid and ethylene glycol methyl ether is 1:6~11, and then h...

Embodiment 2

[0037] ①, according to the chemical formula La 0.7 Ca 0.25 Sr 0.05 MnO 3 , respectively weigh 2.42g of lanthanum nitrate, 0.18g of calcium acetate, 0.08g of strontium nitrate and 1.96g of manganese acetate according to the molar ratio of 0.7:0.25:0.05:1;

[0038] ②. Add lanthanum nitrate to a mixed solution of 2mL glacial acetic acid and 15mL ethylene glycol methyl ether, wherein the molar ratio of glacial acetic acid to ethylene glycol methyl ether is 1:5-10, and The molar ratio of the mixed solution of alcohol methyl ether is 1:6~11, and stirred at room temperature for 30~60min to obtain solution A;

[0039] ③. Add the mixture of calcium acetate and strontium nitrate to the mixed solution of 2mL glacial acetic acid and 15mL ethylene glycol methyl ether, wherein the molar ratio of glacial acetic acid and ethylene glycol methyl ether is 1:5-10, The molar ratio of the mixture to the mixed solution of glacial acetic acid and ethylene glycol methyl ether is 1:6~11, and then h...

Embodiment 3

[0048] ①, according to the chemical formula La 0.7 Ca 0.25 Sr 0.05 MnO 3 , respectively weigh 2.42g of lanthanum nitrate, 0.18g of calcium acetate, 0.08g of strontium nitrate and 1.96g of manganese acetate according to the molar ratio of 0.7:0.25:0.05:1;

[0049] ②. Add lanthanum nitrate to a mixed solution of 2mL glacial acetic acid and 17mL ethylene glycol methyl ether, wherein the molar ratio of glacial acetic acid to ethylene glycol methyl ether is 1:5-10, and The molar ratio of the mixed solution of alcohol methyl ether is 1:6~11, and stirred at room temperature for 30~60min to obtain solution A;

[0050] ③. Add the mixture of calcium acetate and strontium nitrate to the mixed solution of 2mL glacial acetic acid and 17mL ethylene glycol methyl ether, wherein the molar ratio of glacial acetic acid and ethylene glycol methyl ether is 1:5-10, The molar ratio of the mixture to the mixed solution of glacial acetic acid and ethylene glycol methyl ether is 1:6~11, and then h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com