Rare earth-iron-silicon material for magnetic refrigeration, and preparation method and application thereof

A magnetic refrigeration and silicon material technology, applied in magnetic materials, heat exchange materials, chemical instruments and methods, etc., can solve the problems of magnetic refrigeration materials such as the decrease of refrigeration rate, and achieve the effect of strong refrigeration capacity and increased magnetic entropy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: This embodiment is used to illustrate the magnetic refrigeration material and its preparation method provided by the present invention

[0041] 1. Preparation method:

[0042] 1) Weighing materials according to the atomic ratio in the ErFeSi chemical formula, mixing commercially available rare earth metal Er with a purity higher than 99.9% with Fe and Si raw materials, wherein Er is excessively added by 2% (atomic percentage);

[0043] 2) Put the raw materials prepared in step 1) into the electric arc furnace to vacuumize, when the vacuum degree reaches 3×10 -3 Pa, after cleaning twice with pure argon, melt under the protection of pure argon at 1 atmosphere, the melting time is 3 minutes, and the melting temperature is 1600-1650°C;

[0044] 3) Cool the as-cast alloy in a copper crucible, wrap the as-cast alloy with molybdenum foil, and seal it in a vacuum of 5×10 -3 In a Pa quartz tube, it was annealed at 1100°C for 35 days, taken out and quickly quenc...

Embodiment 2

[0053] Example 2: This example is used to illustrate the magnetic refrigeration material provided by the present invention and its preparation method

[0054] 1. Preparation method:

[0055] 1) Weighing materials according to the atomic ratio in the chemical formula of DyFeSi, mixing commercially available rare earth metal Dy with a purity higher than 99.9% with Fe and Si raw materials, wherein Dy is excessively added by 2% (atomic percentage);

[0056] 2) Put the raw materials prepared in step 1) into the electric arc furnace to vacuumize, when the vacuum degree reaches 3×10 -3 Pa, after cleaning twice with pure argon, melt under the protection of pure argon at 1 atmosphere, the melting time is 3 minutes, and the melting temperature is 1600-1650°C;

[0057] 3) Cool the as-cast alloy in a copper crucible, wrap the as-cast alloy with molybdenum foil, and seal it in a vacuum of 5×10 -3 In a Pa quartz tube, it was annealed at 1100°C for 20 days, taken out and quickly quenched...

Embodiment 3

[0064] Example 3: This example is used to illustrate the magnetic refrigeration material provided by the present invention and its preparation method

[0065] 1. Preparation method:

[0066] 1) Weighing materials according to the atomic ratio in the chemical formula of TbFeSi, mixing commercially available rare earth metal Tb with a purity higher than 99.9% with Fe and Si raw materials, wherein Tb is excessively added by 2% (atomic percentage);

[0067] Step 2) and step 3) are identical with embodiment 2.

[0068] 2. Product characterization and performance measurement:

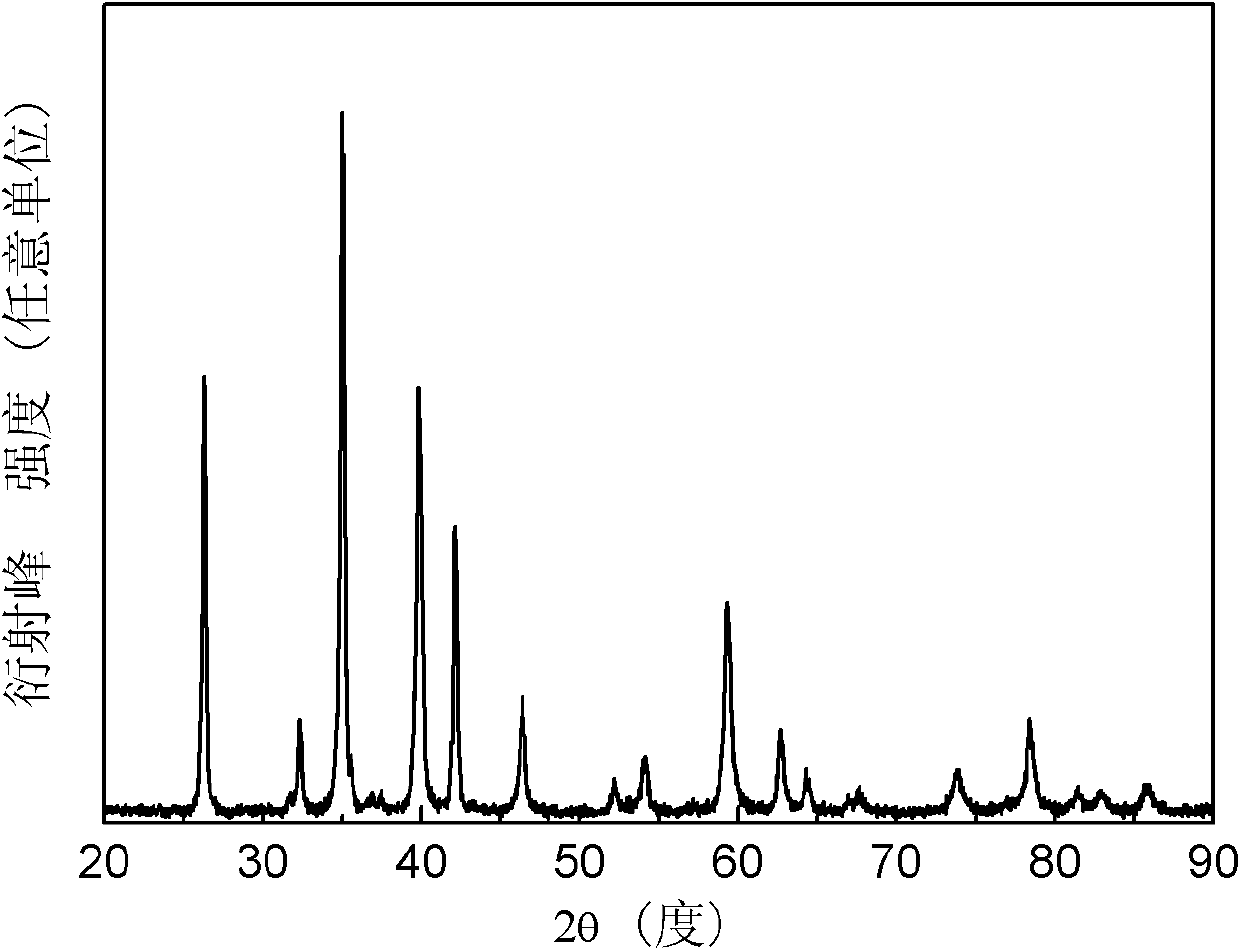

[0069] The room temperature X-ray diffraction spectrum of the compound obtained in this embodiment is as follows: Figure 11 As shown, the results show that TbFeSi forms a single-phase CeFeSi-type tetragonal crystal structure, its space group is P4 / nmm, and the lattice parameter is α=β=γ=90°.

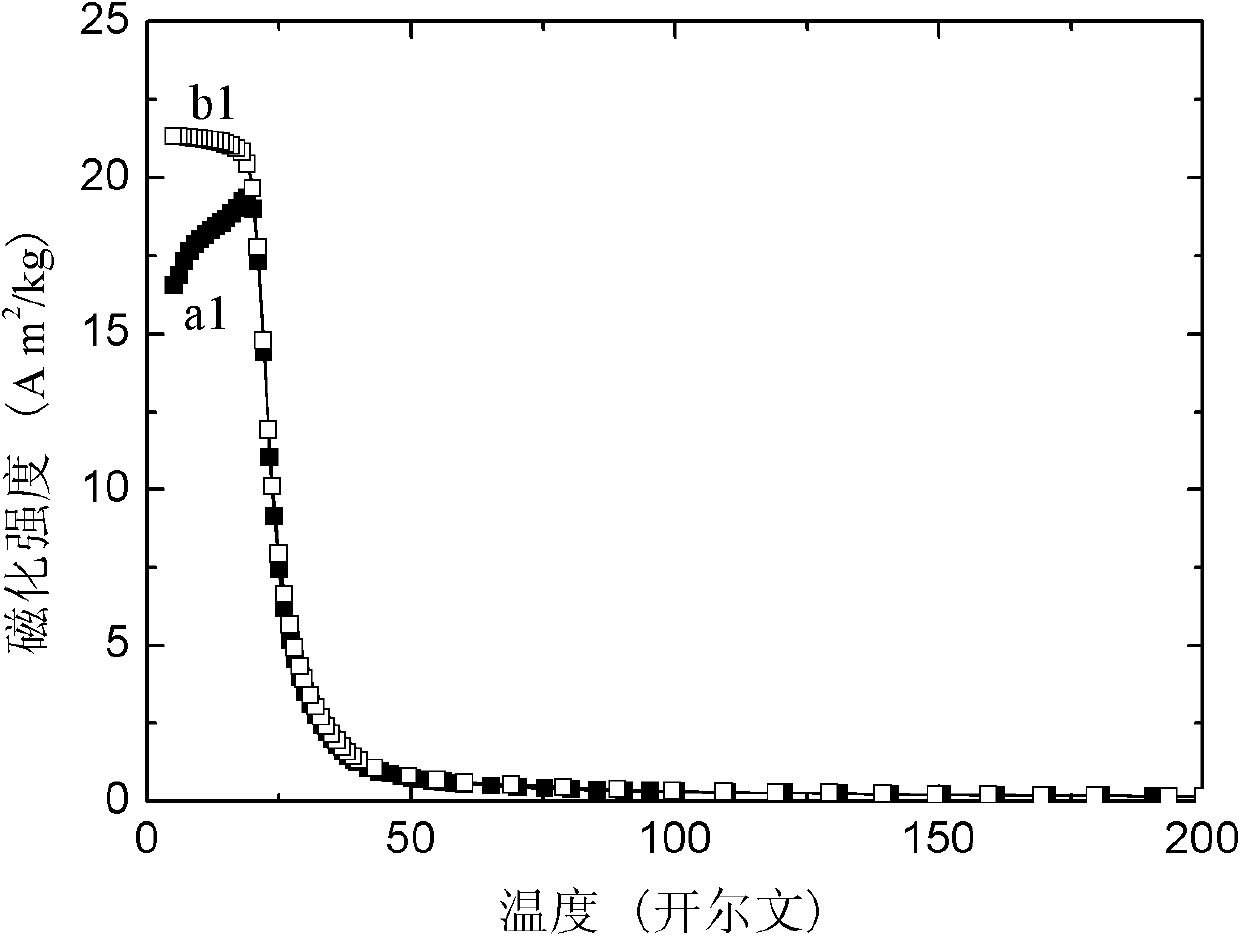

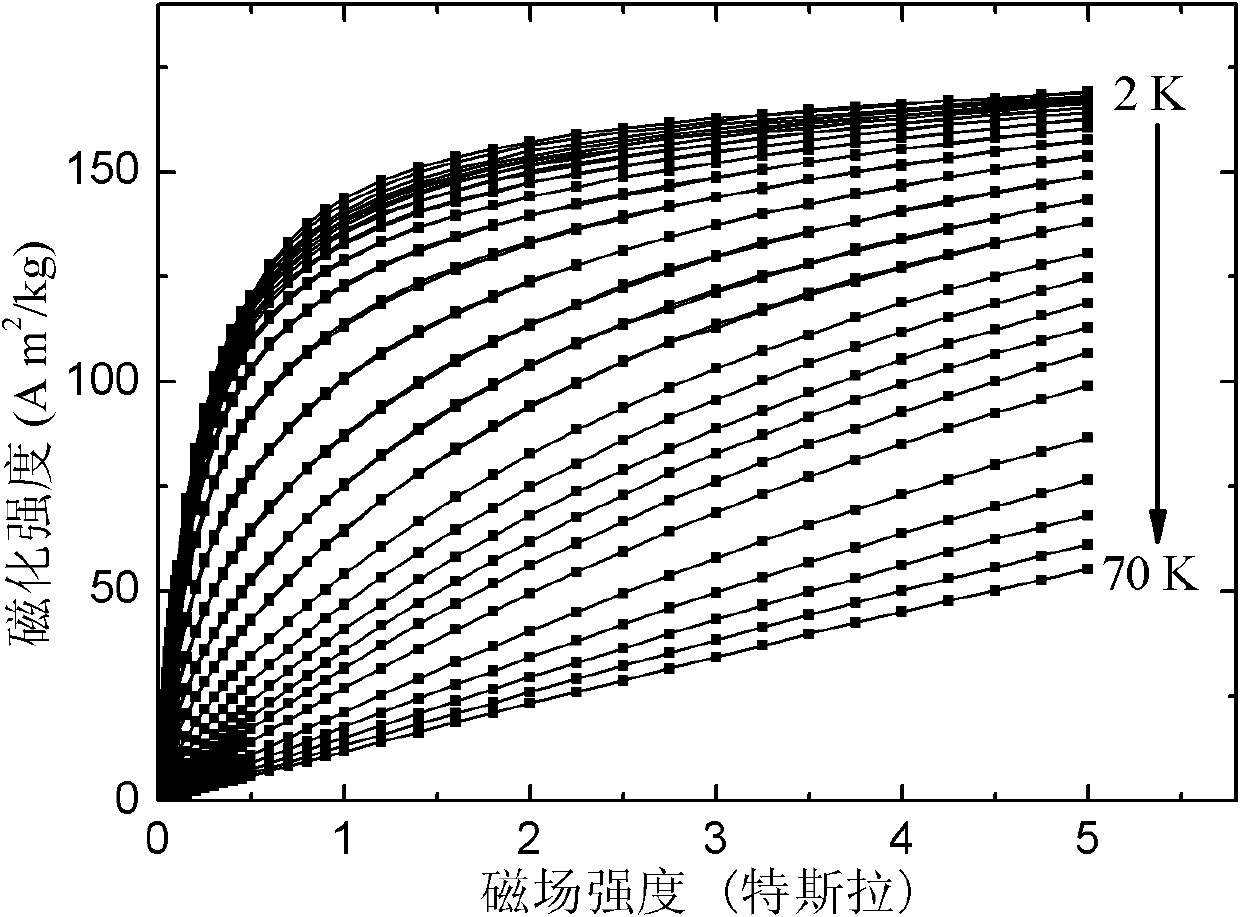

[0070] The TbFeSi of the present embodiment is in the magnetic field strength μ 0 The thermomagnetic (M-T) c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com