Amorphous composite not containing Fe, Co and Ni and preparation method and application of amorphous composite

An amorphous composite material and nanocrystalline technology, applied in the field of magnetic refrigeration materials, can solve the problems of limited practical application, high rare earth content, high cost, etc., achieve excellent magnetocaloric performance, simple and easy preparation method, and reduce the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

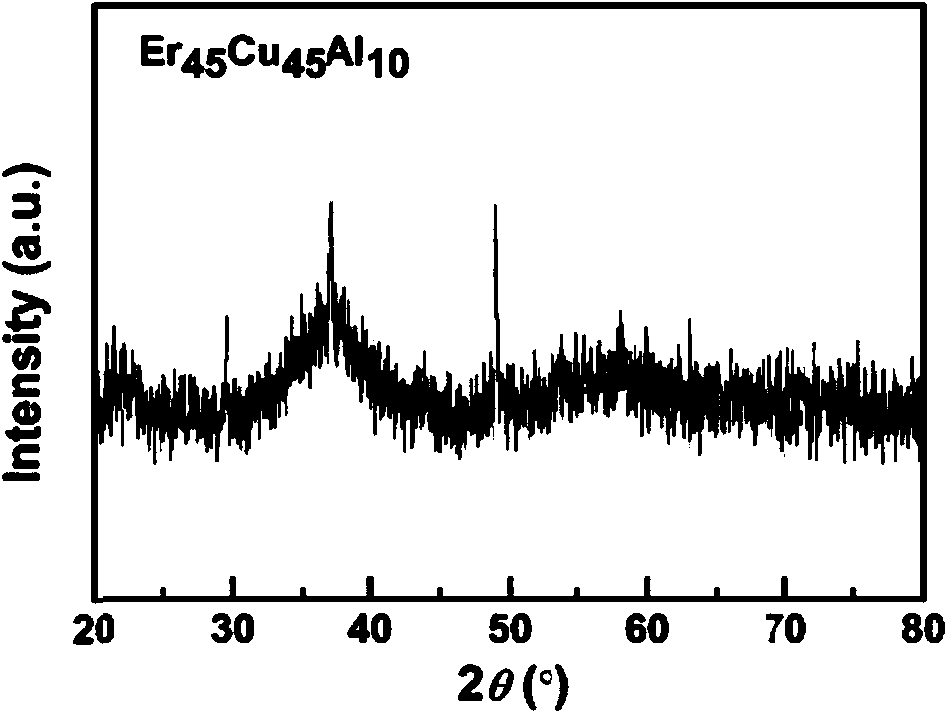

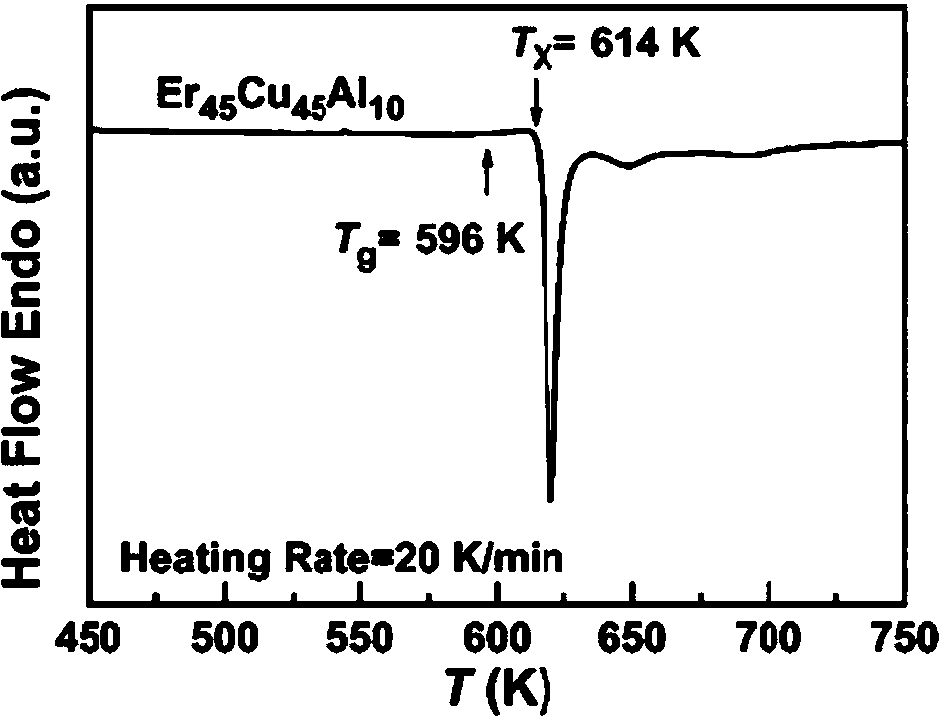

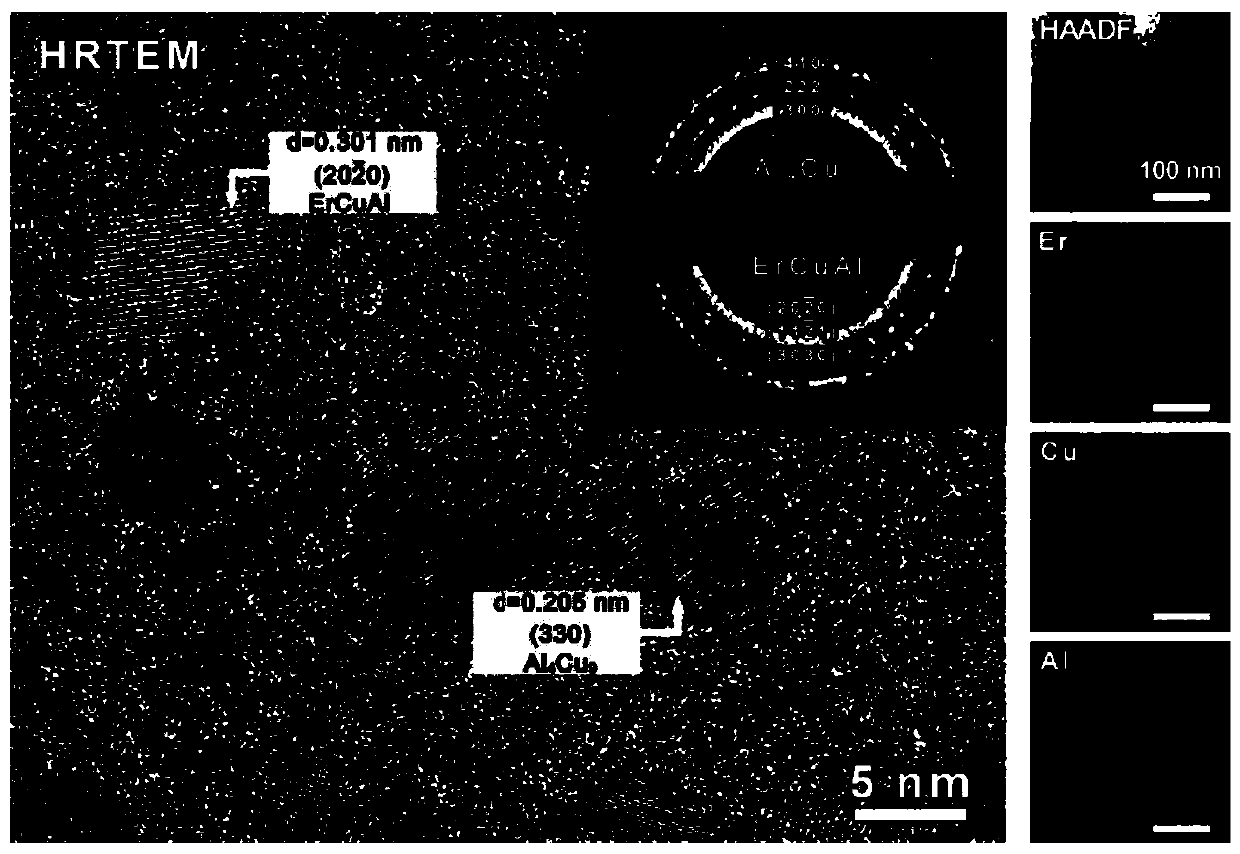

[0042] Preparation of Er 45 Cu 45 al 10 Amorphous composite materials.

[0043] In this embodiment, the amorphous composite material is composed of Er, Cu and Al with an atomic ratio of 45:45:10.

[0044] The Er 45 Cu 45 al 10 The preparation method of the amorphous composite material is as follows:

[0045] According to the molecular formula of the chemical composition, Er, Cu and Al with a raw material purity of more than 99.9wt% are prepared according to the atomic ratio of 45:45:10, and the electric arc furnace (the electric arc furnace is first evacuated to 3 × 10 -3 Pa, then filled with argon to 5×10 4 Pa) mixed evenly and smelted for more than three times, after cooling, the ternary alloy Er 45 Cu 45 al 10 The master alloy ingot is cast; and then the master alloy ingot is melted in an argon gas with an intermediate frequency power supply using a vacuum stripping device. When the melting is complete and the composition is uniform, the molten metal is sprayed to...

Embodiment 2

[0054] Preparation of Er 40 Cu 40 al 20 Amorphous composite materials.

[0055] In this embodiment, the amorphous composite material is composed of Er, Cu and Al with an atomic ratio of 40:40:20.

[0056] The Er 45 Cu 45 al 10 The preparation method of the amorphous composite material is as follows:

[0057] According to the molecular formula of the chemical composition, after the Er, Cu and Al with a raw material purity of more than 99.9wt% are prepared according to the atomic ratio of 40:40:20, the electric arc furnace (the electric arc furnace is first evacuated to 3 × 10 -3 Pa, then filled with argon to 5×10 4 Pa) mixed evenly and smelted for more than three times, after cooling, the ternary alloy Er 40 Cu 40 al 20 The master alloy ingot is cast; and then the alloy ingot is melted in an argon gas with an intermediate frequency power supply by using a vacuum stripping device. When the melting is completely uniform, the molten metal is sprayed to a speed of 30m / s t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com