A kind of preparation method of mnfepsi-based magnetic refrigeration composite material

A composite material and magnetic refrigeration technology, which is applied in refrigerators, refrigeration and liquefaction, and the operation mode of machines, etc., can solve the problems of poor mechanical properties and low thermal conductivity of MnFePSi-based magnetic refrigeration materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] mn 1.24 Fe 0.76 P 0.46 Si 0.54 The preparation process of / Cu magnetic refrigeration composite material:

[0026] 1) Screen out Mn with a particle size of 60-80 μm 1.24 Fe 0.76 P 0.46 Si 0.54 Particles, and then pickling pretreatment with hydrochloric acid alcohol solution;

[0027] 2) Suspend the pickled powder material in a mixed solution of 0.2mol / L copper sulfate and 0.02mol / L sodium citrate, the concentration of the powder material in the solution is 10g / L, dip-plating at room temperature for 90min After that, take it out, wash it with deionized water and alcohol and dry it;

[0028] 3) The material after electroless plating and drying was hot-pressed under vacuum at a hot-pressing temperature of 1000° C., a pressure of 500 MPa, and a hot-pressing time of 5 minutes to obtain a composite magnetic refrigeration material of φ4×10 mm.

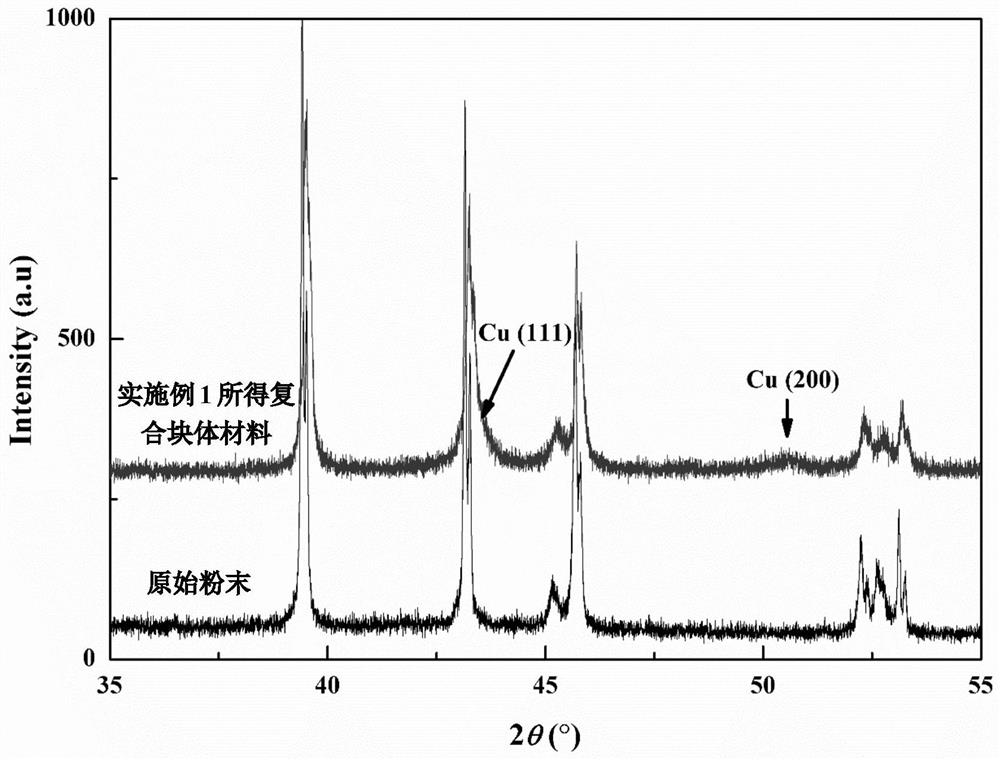

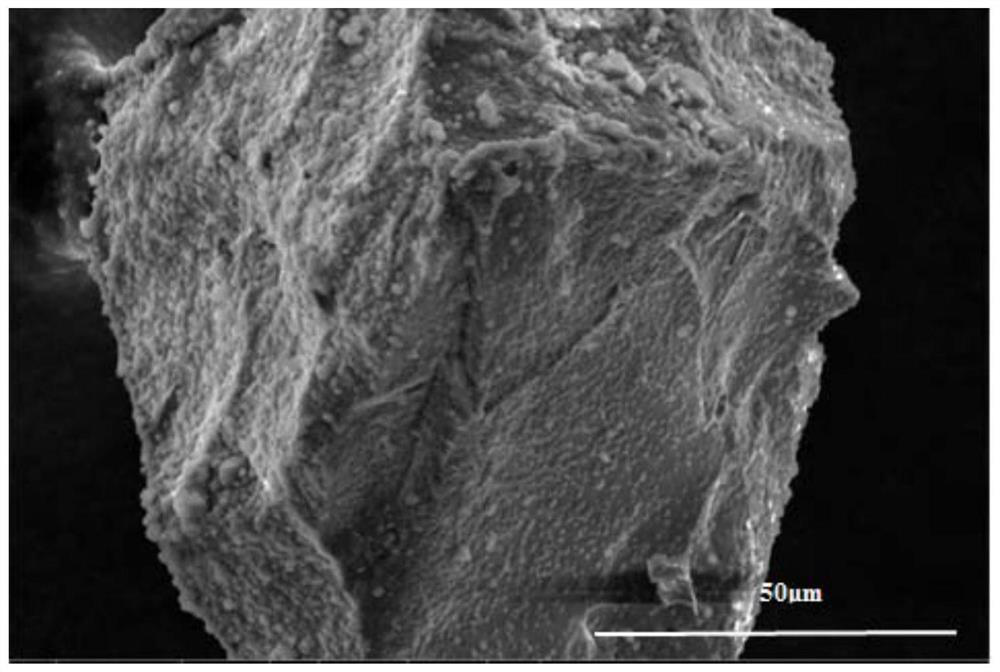

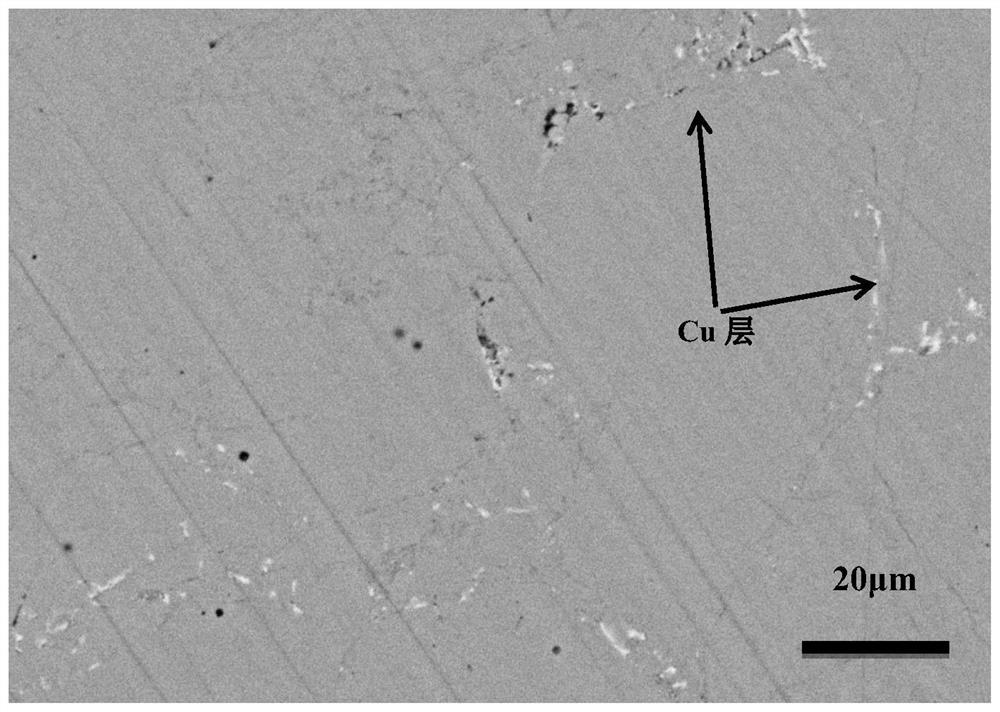

[0029] The Mn obtained in this example 1.24 Fe 0.76 P 0.46 Si 0.54 XRD diffraction patterns of / Cu magnetic refrigeration...

Embodiment 2

[0035] Prepare Mn in the same way as in Example 1 1.24 Fe 0.76 P 0.46 Si 0.54 / Cu magnetic refrigeration composite material, in addition to changing the immersion plating time of electroless copper plating to 360min, changing the hot-pressing temperature to 1100°C, and changing the hot-pressing time to 1min.

[0036]By measuring the isothermal curves under different magnetic fields, it is calculated that the magnetic refrigeration composite material obtained in this embodiment has a magnetic entropy change of 11.4J / kgK when the external magnetic field changes to 2T; the thermal conductivity at room temperature measured by the laser thermal conductivity meter is 8.3W / kgK. mK; the compressive strength measured by the universal testing machine has reached 64MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com