Silicon-based miniature loop heat pipe cooler

A loop heat pipe and cooler technology, applied in the field of silicon-based micro loop heat pipe coolers, can solve the problems of increased heat load and uneven heating of microelectronic chips, achieve safe and reliable working performance, reduce working medium flow resistance, The effect of increasing the heat transfer limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

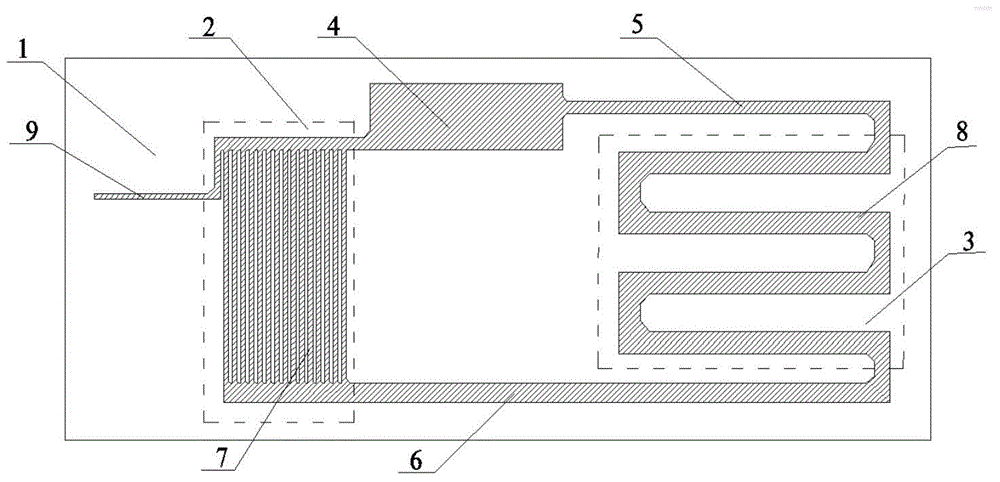

[0030] A silicon-based micro-loop heat pipe cooler includes a semiconductor silicon chip 1 and a heat-resistant borosilicate glass chip 11 bonded together, and the semiconductor silicon chip 1 can be integrated with a semiconductor microelectronic chip. Such as figure 1 As shown, the surface of the silicon wafer 1 in contact with the borosilicate glass wafer 11 is etched with an evaporator 2, a condenser 3, a liquid compensator 4, a liquid phase channel 5, a vapor phase channel 6 and vacuum / injection Liquid channel 9. Both ends of the evaporator 2 and the condenser 3 are respectively connected through a liquid phase channel 5 and a vapor phase channel 6 to form a closed loop. The liquid storage chamber 4 is located on the liquid phase channel 5 , close to the evaporator 2 . The condensation serpentine channel 8 is composed of several U-shaped channels arranged at equal intervals and connected. The number of U-shaped channels is suitable to be 2-8, and the channel hydraulic ...

Embodiment 2

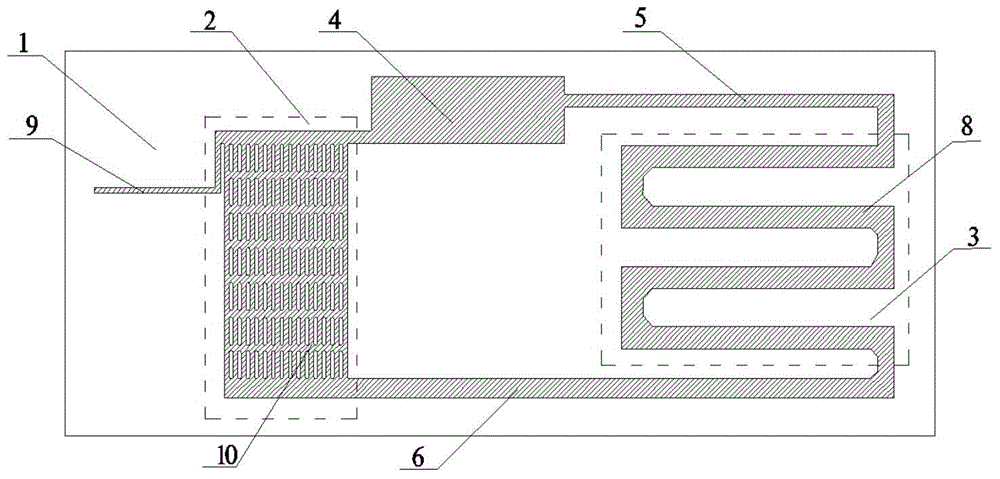

[0035] Such as figure 2 As shown, the difference from Embodiment 1 is the tiny channel structure of the evaporator 2 . In this embodiment, the micro-channel structure of the evaporator 2 is composed of micro-rib array capillary structures 10 . The micro-rib array capillary structure 10 is composed of a plurality of micro-ribs arranged in an array and etched on the silicon wafer, and micro-channels are formed between the micro-ribs. The width of the micro-ribs is 100-300 μm, the length is 400-1200 μm, the distance between two columns of micro-ribs is 50-300 μm, and the distance between two rows of micro-ribs is 50-300 μm. The cross-section of the micro-ribs is rectangular, triangular or circular, and the array arrangement of the micro-ribs is straight or forked.

[0036] Specifically, in this embodiment, the microrib array capillary structure 10 is arrayed in a straight line, including 15 rows arranged horizontally and 7 rows vertically, the width of the rectangular microrib...

Embodiment 3

[0038] On the basis of Embodiment 1 or Embodiment 2, in this embodiment, the cross-sectional dimensions of the liquid phase channel 5 and the vapor phase channel 6 change linearly along the channel direction, wherein the liquid phase channel 5 is from the liquid compensator 4 to the direction of the condenser 3 decreases linearly, while the vapor phase channel 6 increases linearly from the evaporator 2 to the condenser 3. The cross-sectional area of the liquid phase channel 5 decreases linearly from the liquid storage chamber 4 to the condenser 3, the channel width decreases from 600 μm to 300 μm, and the corresponding channel hydraulic diameter decreases from 300 μm to 240 μm; while the width of the vapor phase channel 6 is reduced by The increase from 500 μm to 1000 μm corresponds to an increase in the hydraulic diameter of the channel from 285.7 μm to 333.3 μm. After the above adjustments, it is beneficial to enhance the spontaneous capillary movement effect of the vapor-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com