Ground-controlled hydraulic pulsing device and application thereof

A hydraulic pulse and ground control technology, applied in vibration generating devices, production fluids, wellbore/well components, etc., can solve problems such as difficulty in adapting to oilfield environment, difficult adjustment of shock frequency, poor applicability, etc., and achieve safe and reliable working performance. , good applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

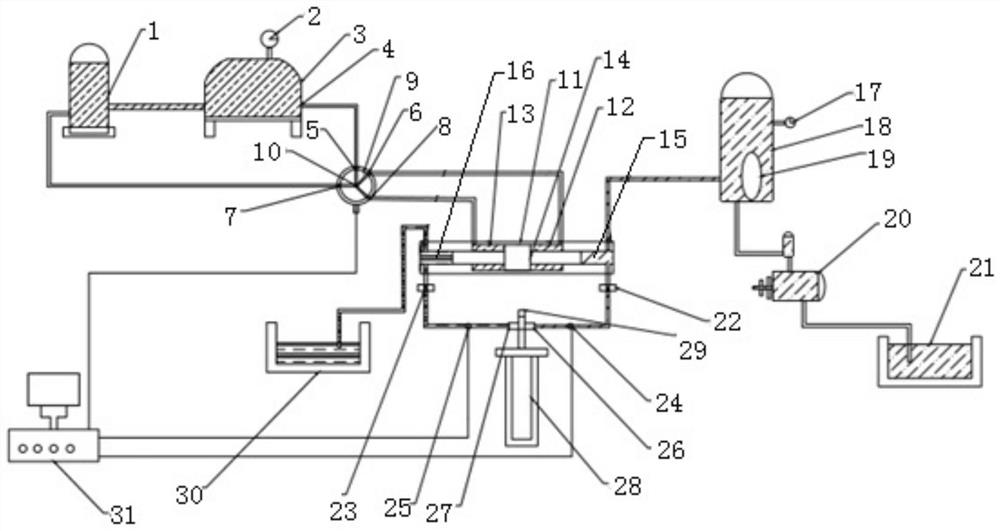

[0037] like figure 1 As shown, this embodiment provides a hydraulic pulse device for ground control, including a frequency conversion servo pulse device and a constant pressure liquid supply device. The frequency conversion servo pulse device includes a hydraulic oil tank 1, a hydraulic pump 3, a frequency conversion servo control valve 9 and a power The converter 11 and the hydraulic oil tank 1 are respectively connected to the oil pressure pump 3 and the frequency conversion servo control valve 9, the oil pressure pump 3 is connected to the frequency conversion servo control valve 9 through the oil pressure pump port 4, and the frequency conversion servo control valve 9 is connected to the power converter 11;

[0038] The constant pressure liquid supply device includes a water storage tank 21, a water injection pump 20 and a pressure accumulator 18. One end of the water injection pump 20 is connected to the water storage tank 21, and the other end is connected to the pressure...

Embodiment 2

[0050] A ground control hydraulic pulse device, the structure is as described in embodiment 1, the difference is that a pressure gauge 17 is arranged on the pressure accumulator 18, and the pressure gauge 17 is connected to the high-pressure air bag 19, which is convenient for observing the pressure in the high-pressure air bag 19, and then By adjusting the liquid capacity in the pressure accumulator 18 to adjust the impact strength of the hydraulic pulse, the pressure in the pressure accumulator 18 is stored as 40MPa.

Embodiment 3

[0052] A ground control hydraulic pulse device, the structure is as described in Embodiment 2, the difference is that the pressure storage of the pressure accumulator 18 is 150MPa, and the pressure gauge 2 is set on the oil pressure pump 3, which is convenient for observing the oil pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com