Heat pipe and manufacturing method thereof

A production method and heat pipe technology, which are applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of insufficient heat dissipation performance of heat pipes, increase the effective evaporation area, increase the separation frequency, and increase the liquid return resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

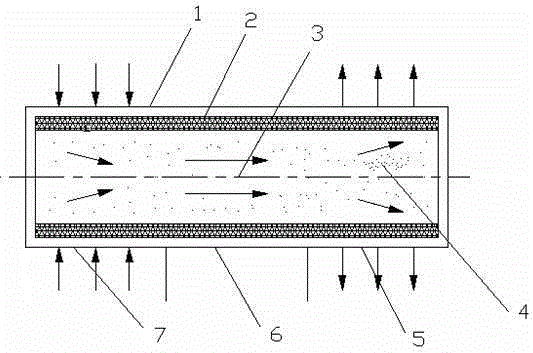

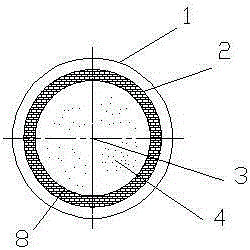

[0014] see figure 1 and figure 2 , the outermost part of the high-efficiency heat pipe of the present invention is the shell 1, and the innermost part is the steam chamber 3. Along the axial direction of the steam chamber 3, the steam chamber 3 is divided into an evaporating section 7, an adiabatic section 6 and a condensing section 5, the middle is an adiabatic section 6, and the two ends are respectively an evaporating section 7, a condensing section 5, an evaporating section 7 and a condensing section 5 The structure is the same. The shell 1 is cylindrical and made of red copper. The inner wall of the shell 1 is close to the capillary liquid-absorbing core layer 2. The capillary liquid-absorbing core layer 2 is composed of porous foam copper liquid-absorbing cores with different pore sizes. The wall thickness of the capillary liquid-absorbing core layer 2 is 0.2~1.0mm , the porosity is 50%~80%. The inner wall of the capillary liquid-absorbing core layer 2 is close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com