Circulation radiator, and manufacturing method and components thereof

A technology for circulating heat dissipation and components, which is applied in electrical components, electric solid devices, semiconductor devices, etc., and can solve the problems of large heat sinks, increased cost, and limited heat transfer distance of heat pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

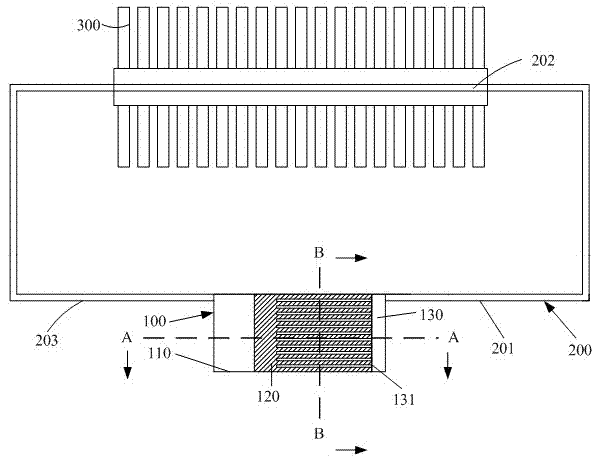

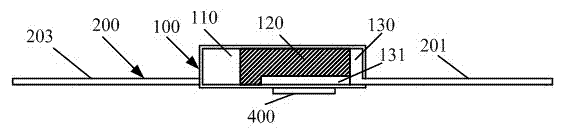

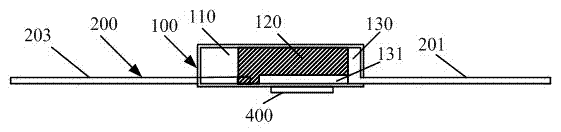

[0042] like Figure 8 As shown, a specific implementation of the manufacturing method of the circulating cooling device includes:

[0043] In the step of making capillary structure, a demoulding mold having at least one convex strip is inserted into the cavity with openings at both ends, and the cavity is filled with metal powder and / or nano-carbon powder and completely covers the convex strip of the demoulding mold. Sintering and extrusion of metal powder and / or nano-carbon powder to form a capillary structure;

[0044] In the demoulding step, the demoulding mold is pulled out, so that the capillary structure separates the cavity into a liquid storage cavity and an evaporation cavity having at least one steam channel;

[0045] Installation steps, connect one end of the pipeline with the liquid storage chamber or capillary structure, and connect the other end with the evaporation chamber, install the heat dissipation mechanism on the surface of the pipeline, and inject workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com