Plasma processing apparatus

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of etching hole shape change, distortion, semiconductor device product yield reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

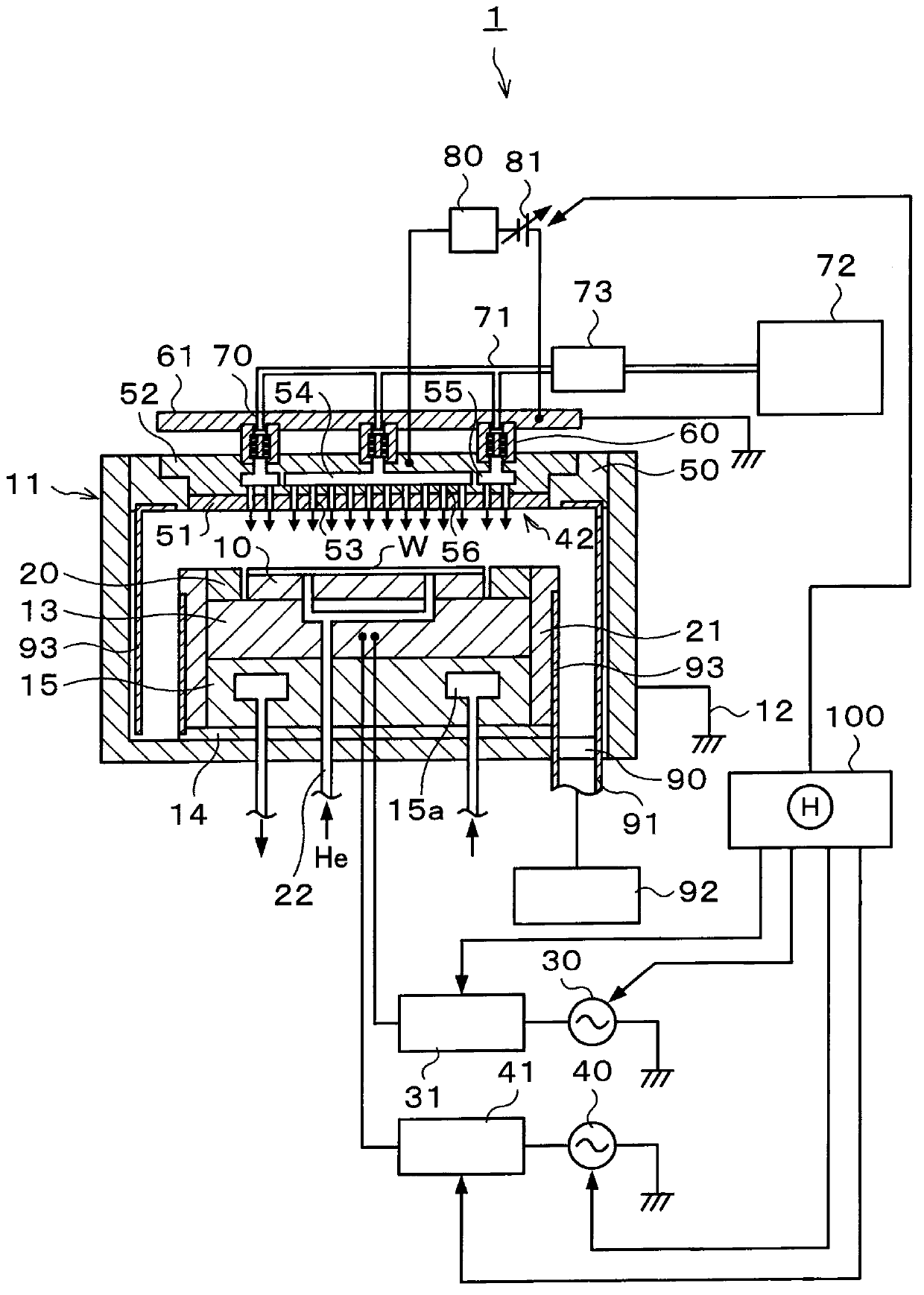

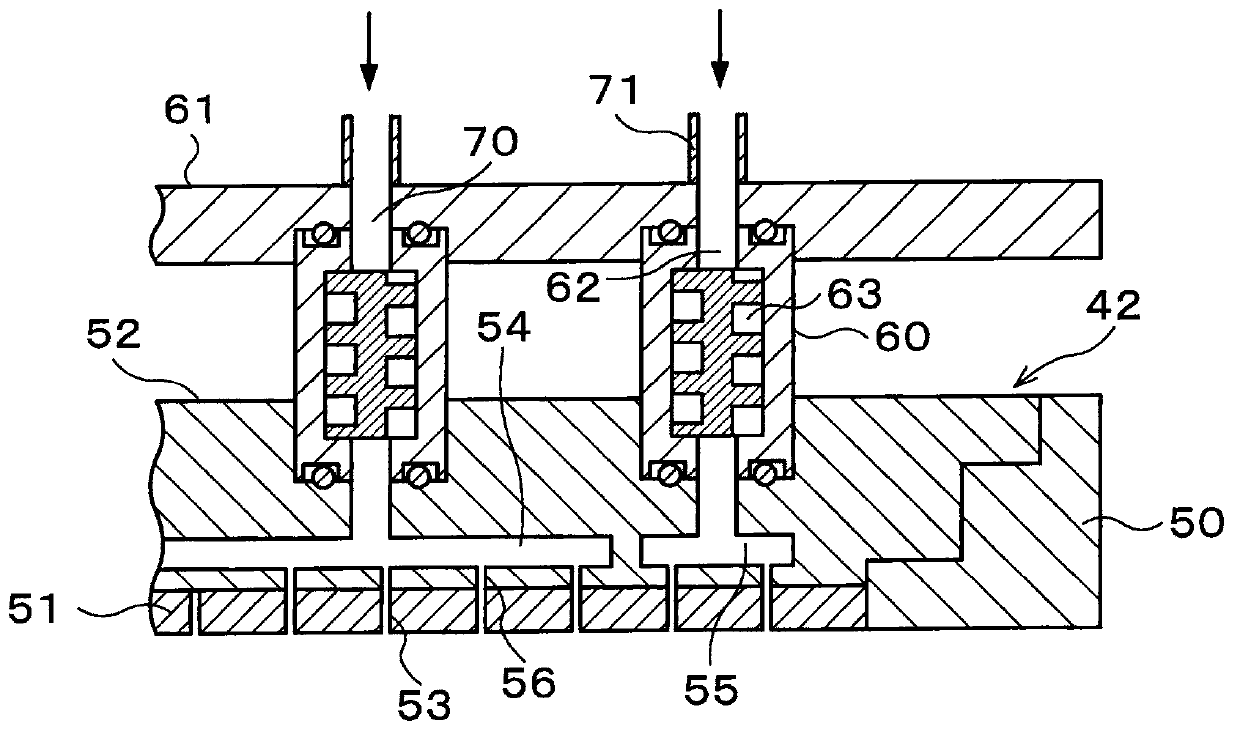

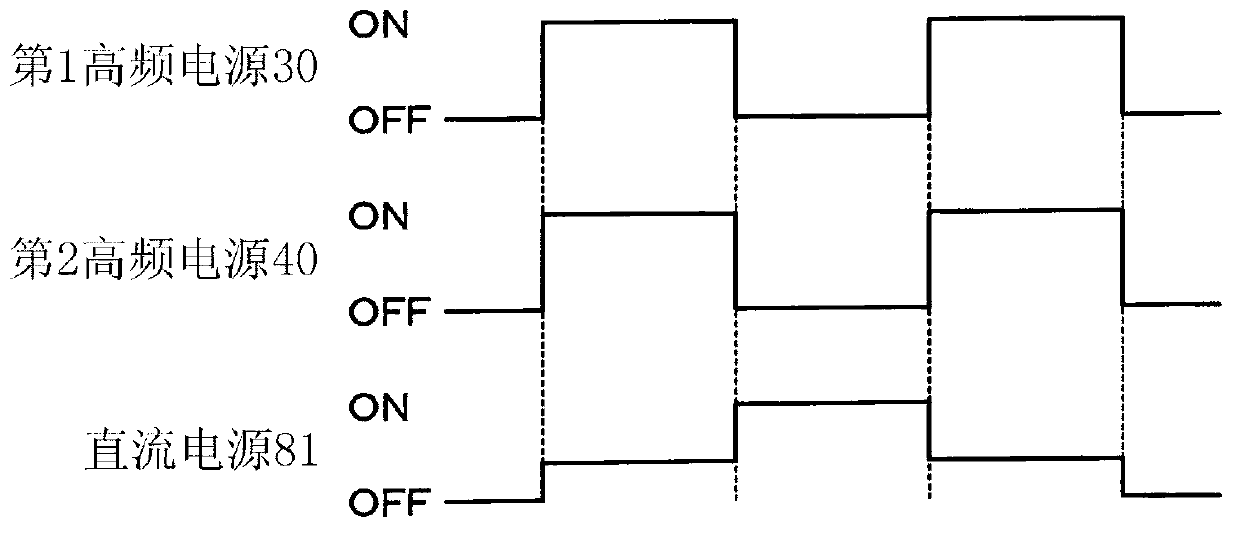

[0031] Next, an example of an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a vertical cross-sectional view showing a schematic configuration of the plasma processing apparatus 1 according to the embodiment of the present invention. The plasma processing apparatus 1 of the present embodiment is, for example, a parallel plate type plasma etching processing apparatus.

[0032] The plasma processing apparatus 1 has a substantially cylindrical processing container 11 provided with a wafer chuck 10 for holding a wafer W serving as a silicon substrate. The processing container 11 is electrically connected to a ground line 12 to be grounded. Electrodes (not shown) are provided inside wafer chuck 10 , and wafer W can be sucked and held by electrostatic force generated by applying a DC voltage to the electrodes.

[0033]The lower surface of wafer chuck 10 is supported by susceptor 13 as a lower electrode. The base 13 is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com