Method for preparing ultrafine activated phosphorusore compound fertilizer

A compound fertilizer and phosphate rock technology, applied in phosphate fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of complex process, long production cycle, unfavorable industrial production, etc., and achieve a short preparation process, low production cost, stable and long-term fertilizer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

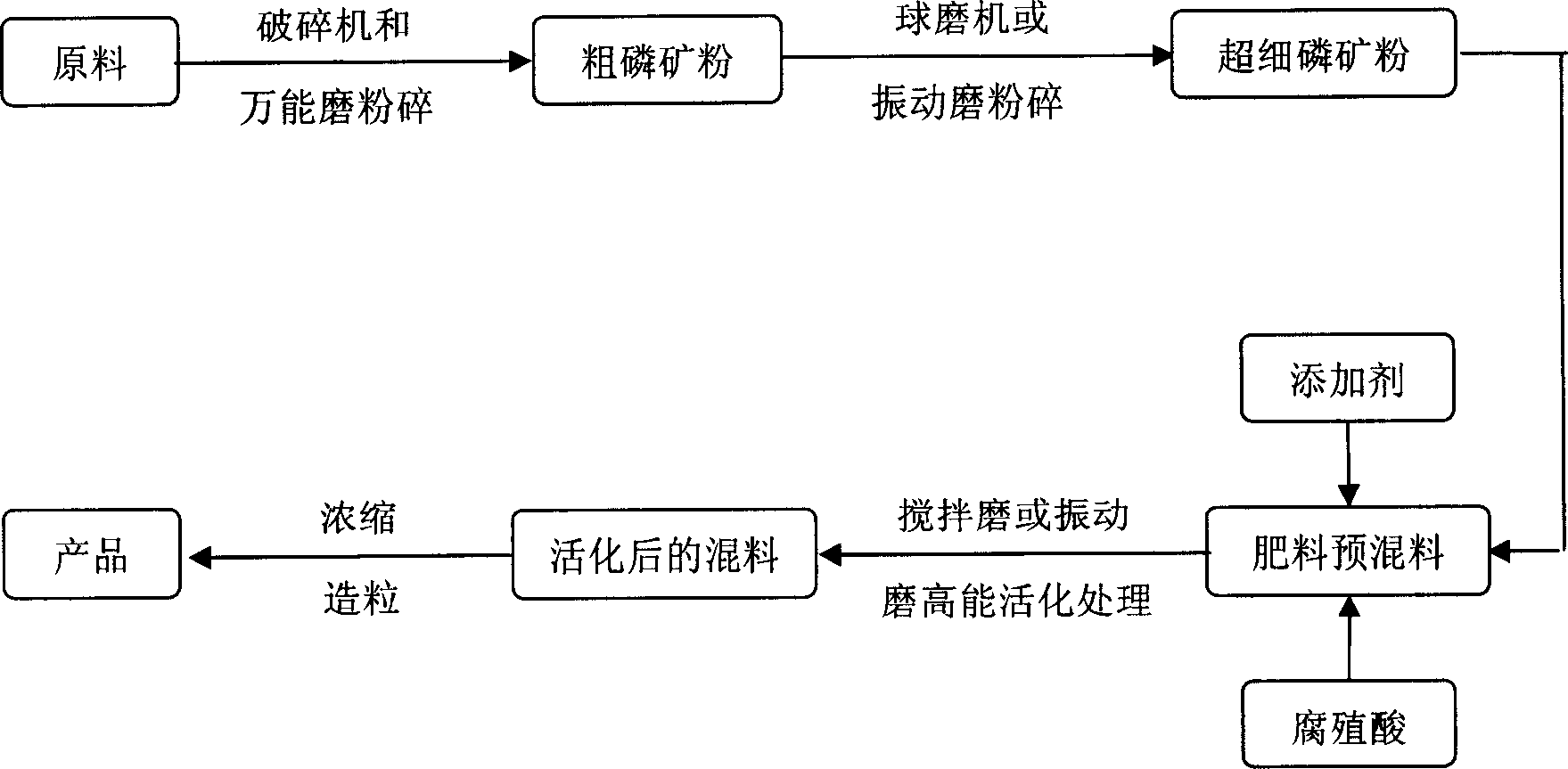

Method used

Image

Examples

Embodiment 1

[0028] Raw materials are medium and low-grade phosphate rocks such as Yunnan phosphate rock, and the raw phosphate rock is crushed into coarse phosphate rock powder (100% through 80 mesh sieve) with a crusher and a universal mill without beneficiation. . Use a ball mill to pulverize the coarse phosphate rock powder until D90 is 21um, mix 270kg (90%) phosphate rock powder with 30kg (10%) humic acid, and then add kg (5%) of phosphorus-solubilizing microorganisms. The mixed materials were added to the stirring mill for processing, the rotating speed of the stirring mill was 300 rpm, and the processing time was 30 minutes. Then concentrate and granulate to obtain the phosphate rock powder fertilizer product.

Embodiment 2

[0030] Raw materials are medium and low-grade phosphate rocks such as Yunnan phosphate rock, and the raw phosphate rock is crushed into coarse phosphate rock powder (100% through 80 mesh sieve) with a crusher and a universal mill without beneficiation. . Use a vibrating mill to pulverize the coarse phosphate rock powder until D90 is 17um, mix 225kg (75%) of phosphate rock powder with 60kg (20%) of humic acid, then add 12kg (4%) of zeolite and 3kg (1%) of phosphorus-solubilizing microorganisms . The mixed material is added to a vibrating mill for processing, the rotating speed of the vibrating mill is 100 rpm, and the processing time is 5 hours. Then concentrate and granulate to obtain the phosphate rock powder fertilizer product.

Embodiment 3

[0032] Raw materials are medium and low-grade phosphate rocks such as Yunnan phosphate rock, and the raw phosphate rock is crushed into coarse phosphate rock powder (100% through 80 mesh sieve) with a crusher and a universal mill without beneficiation. . Use a vibrating mill to pulverize the coarse phosphate rock powder until D90 is 17um, mix 285kg (95%) of phosphate rock powder with 14.7kg (4.9%) of humic acid, and then add 0.3kg (0.1%) of zeolite. The mixed material is added to a vibrating mill for processing, the rotating speed of the vibrating mill is 300 rpm, and the processing time is 0.2 hours. Then concentrate and granulate to obtain the phosphate rock powder fertilizer product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com