Preparation method of bi-component polyurethane pouring sealant for water treatment membrane

A two-component polyurethane, water treatment membrane technology, used in polyurea/polyurethane adhesives, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of insufficient bonding strength, increased production costs, and poor aging resistance. and other problems, to achieve the effect of fast curing speed, improved production efficiency and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment 1 provides a method for preparing a two-component polyurethane potting adhesive for water treatment membranes. The prepared two-component polyurethane potting adhesive has fast curing speed, high tensile and shear strength, excellent bonding performance, and Excellent aging performance and other characteristics. Used for potting and bonding of hollow fiber membranes. The preparation method specifically includes:

[0049] Prepare component A:

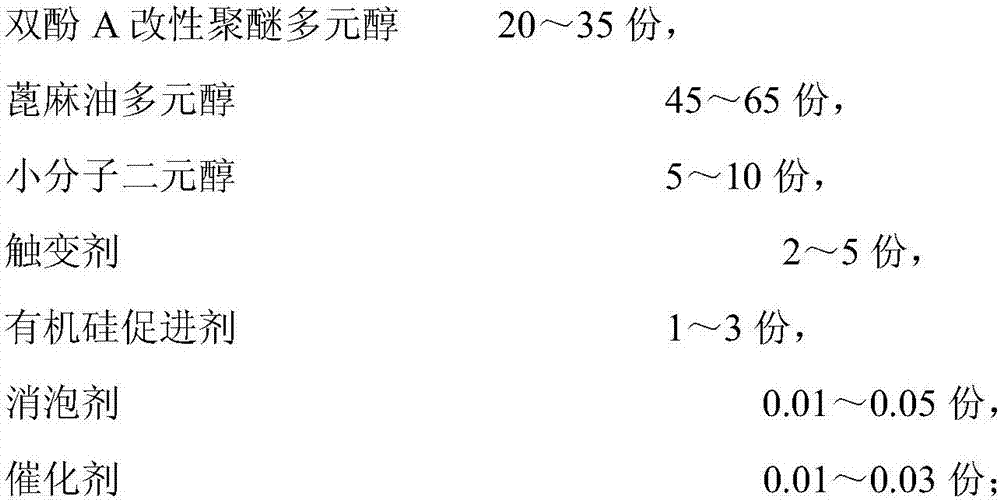

[0050] Get raw materials according to the following ratio:

[0051] In terms of parts by mass, 21 parts by mass of bisphenol A-modified polyoxypropylene trihydric alcohol with a weight average molecular weight of 800 and 65 parts by mass of primary castor oil polyol were added to the synthesis kettle, and the temperature was raised to 110-120°C vacuum dehydration for 2-3 hours while stirring, and the moisture index is controlled below 200ppm; cool down to room temperature and add 10 parts by mass of diethylene gly...

Embodiment 2

[0057] This embodiment 2 provides a preparation method of a two-component polyurethane potting adhesive for water treatment membranes. The prepared two-component polyurethane potting adhesive has a fast curing speed, high tensile and shear strength, excellent bonding performance, and Excellent aging performance and other characteristics. Used for potting and bonding of hollow fiber membranes. The preparation method specifically includes:

[0058] Prepare component A:

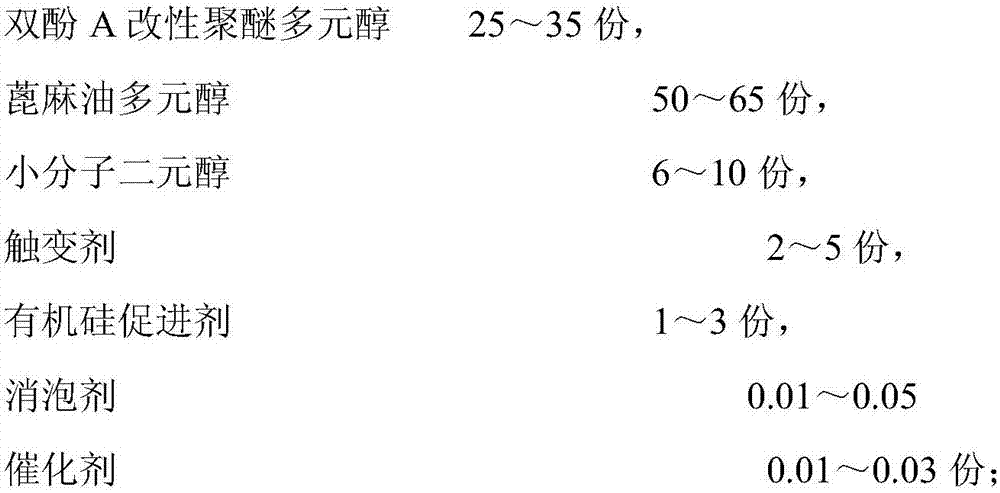

[0059] Get raw materials according to the following ratio:

[0060] In terms of parts by mass, 35 parts by mass of bisphenol A modified polyoxypropylene trihydric alcohol with a weight average molecular weight of 600 and 55 parts by mass of primary castor oil polyol are added to the synthesis kettle, and the temperature is raised to 110-120°C vacuum dehydration for 2-3 hours while stirring, and the moisture index is controlled below 200ppm; cool down to room temperature and add 6 parts by mass of diethylene g...

Embodiment 3

[0066] This embodiment three provides a preparation method of a two-component polyurethane potting adhesive for water treatment membranes. The prepared two-component polyurethane potting adhesive has fast curing speed, high tensile and shear strength, excellent bonding performance, and Excellent aging performance and other characteristics. Used for potting and bonding of hollow fiber membranes. The preparation method specifically includes:

[0067] Prepare component A:

[0068] Get raw materials according to the following ratio:

[0069] In terms of parts by mass, 26 parts by mass of bisphenol A modified polyoxypropylene diol with a weight average molecular weight of 1000 and 60 parts by mass of primary castor oil polyol are added to the synthesis kettle, and the temperature is raised to 110-120°C vacuum dehydration for 2-3 hours while stirring, and the moisture index is controlled below 200ppm; cool down to room temperature and add 8 parts by mass of dipropylene glycol, 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com