Method for producing white carbon black and active carbon by using residual rice hull ash after gasification

A technology of rice husk ash and white carbon black, which is applied in the direction of silicon oxide and silicon dioxide, can solve the problems of limited activated carbon raw materials, increased total workload, low concentration of water glass, etc., and achieves good impregnation absorption performance and labor-intensive The effect of reducing the amount and making the process easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

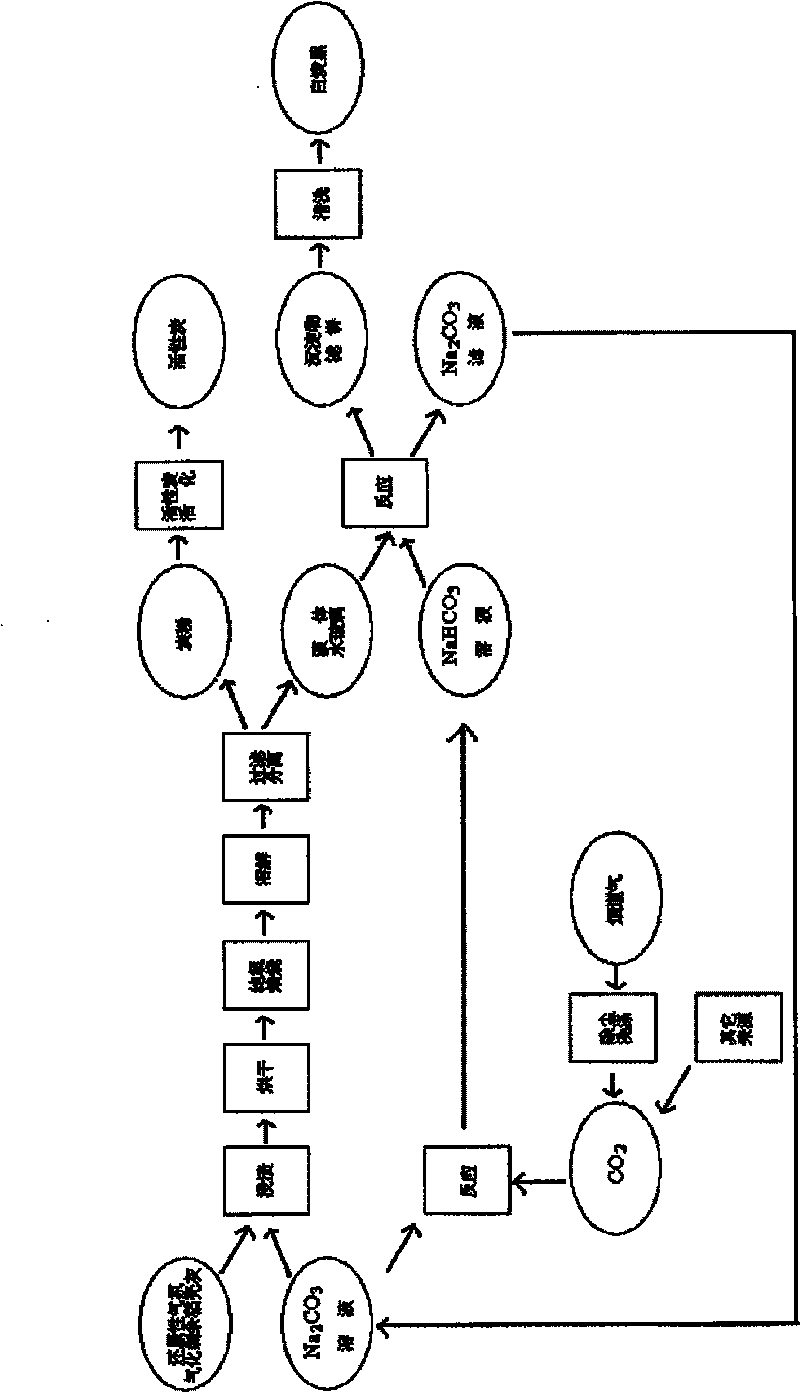

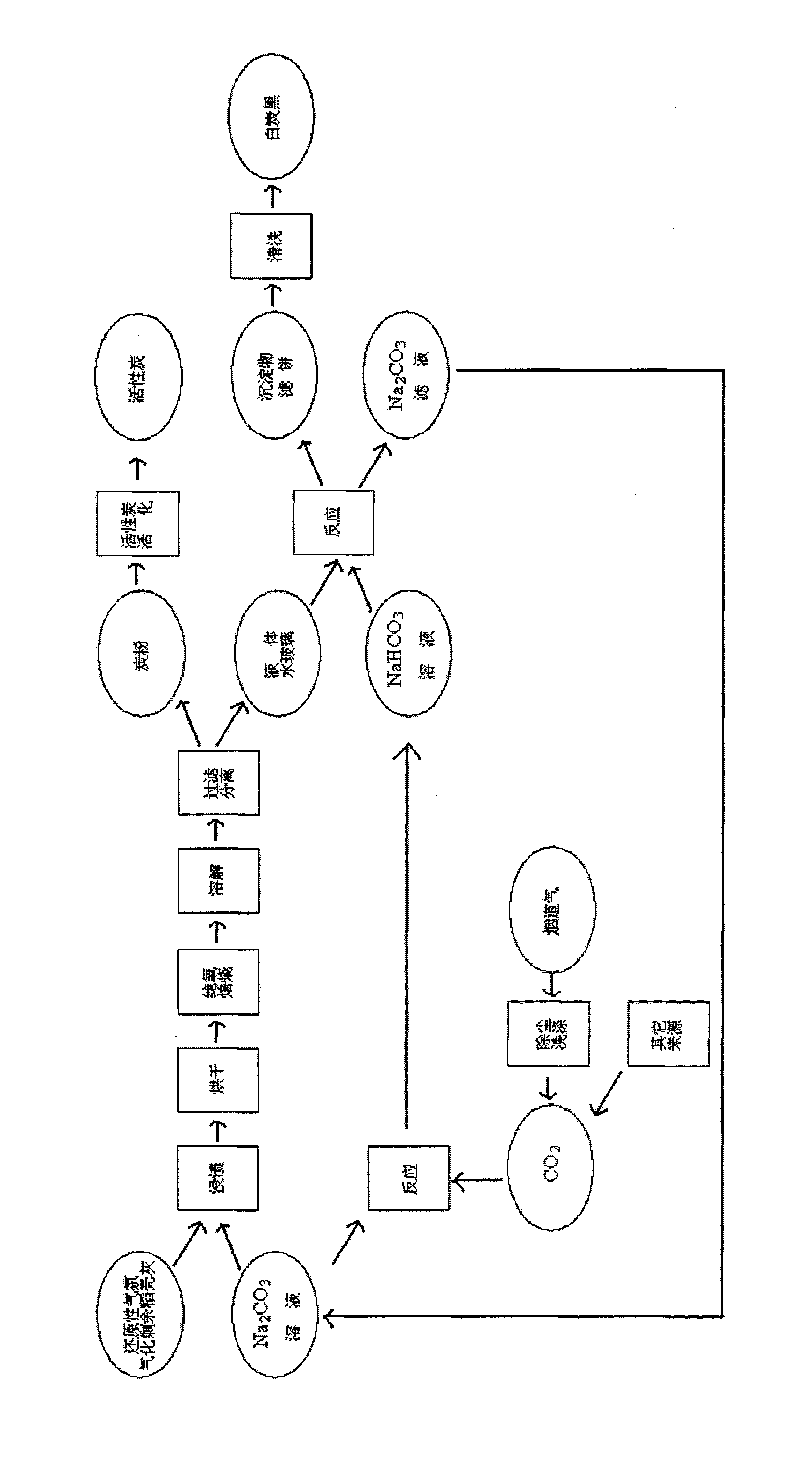

Method used

Image

Examples

Embodiment 1

[0034] Take 3000 grams of remaining rice husk ash after gasification and power generation, and use 5.25 liters of weight percent concentration of 19.4% Na 2 CO 3 The solution impregnates the rice husk ash until the alkaline solution permeates evenly therein, then it is dried, and after drying, it is roasted at 900° C. for 3 hours in an anoxic roaster. Obtain powdered water glass and carbon powder mixture. Add water, stir and dissolve for 2 hours under the condition of 1.0MPa (temperature 180° C.), after decompression and temperature reduction, the modulus of liquid water glass obtained after filtration is 2.06, and the concentration by weight is 12.6% (SiO 2 The weight percent concentration is 8.4%, Na 2 O weight percent concentration is 4.2%). The filter residue is carbon powder after cleaning and drying, the carbon content is about 90%, and the specific surface is about 620m 2 / g, is the raw material for preparing activated carbon, after further activation processing, hi...

Embodiment 2

[0044] Get 3000 grams (30°C) of remaining rice husk ash after gasification and power generation, and use 4.2 liters of weight percent concentration of 25.5% Na 2 CO 3 The solution (30°C) impregnates the rice husk ash until the alkaline solution permeates evenly therein, and then it is dried. After drying, it is roasted at a temperature of 1150°C in an oxygen-deficient roaster. Obtain powdered water glass and carbon powder mixture. Add water, dissolve and stir for 2 hours at a temperature of 100° C. After filtration, the modulus of the liquid water glass obtained is 2.5, and the concentration by weight is 11.86% (SiO 2 The weight percent concentration is 8.4%, Na 2 O weight percent concentration is 3.46%). The filter residue is carbon powder after cleaning and drying, the carbon content is about 90%, and the specific surface is about 510m 2 / g, is the raw material for preparing activated carbon, after further activation processing, high-quality activated carbon can be obta...

Embodiment 3

[0054] Take 3000 grams of remaining rice husk ash after gasification and power generation, and use 5.7 liters of weight percent concentration of 17.3% Na 2 CO 3 The solution impregnates the rice husk ash until the alkaline solution permeates evenly therein, then it is dried, and after drying, it is roasted at 1100° C. for 3 hours in an anoxic roaster. Obtain powdered water glass and carbon powder mixture. Add water, stir and dissolve for 2 hours under the condition of 1.0MPa (temperature 180° C.), after reducing the pressure and temperature, filter to obtain liquid water glass with a modulus of 3.0 and a concentration of 13.45% by weight (SiO 2 The weight percent concentration is 10.0%, Na 2 O weight percent concentration is 3.45%). The filter residue is carbon powder after cleaning and drying, the carbon content is about 90%, and the specific surface is about 530m 2 / g, is the raw material for preparing activated carbon, after further activation processing, high-quality a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com