Preparation of spinel catalyst and application thereof to elimination of nitrogen oxides

A technology of nitrogen oxides and catalysts, applied in the field of preparation of high-efficiency denitrification catalysts at low temperatures, can solve the problems of 1D nanomaterials that have not been reported, and achieve the effects of wide industrial application prospects, high resistance to SO2 poisoning, and reduced synthesis costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

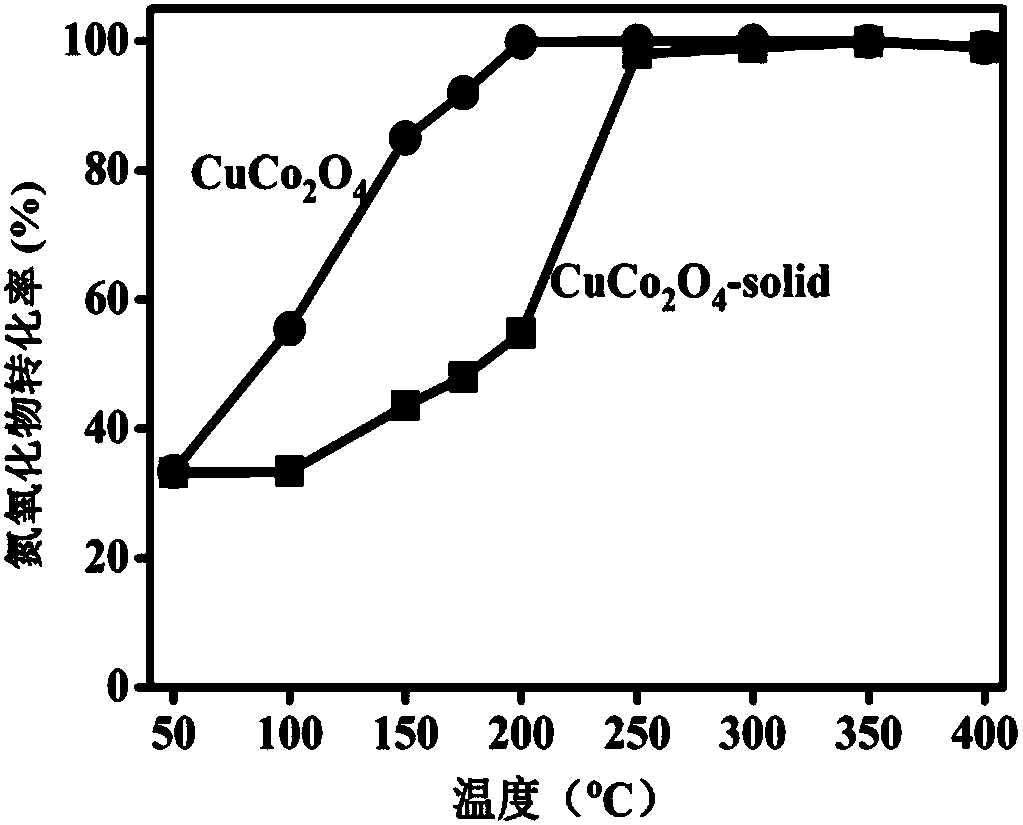

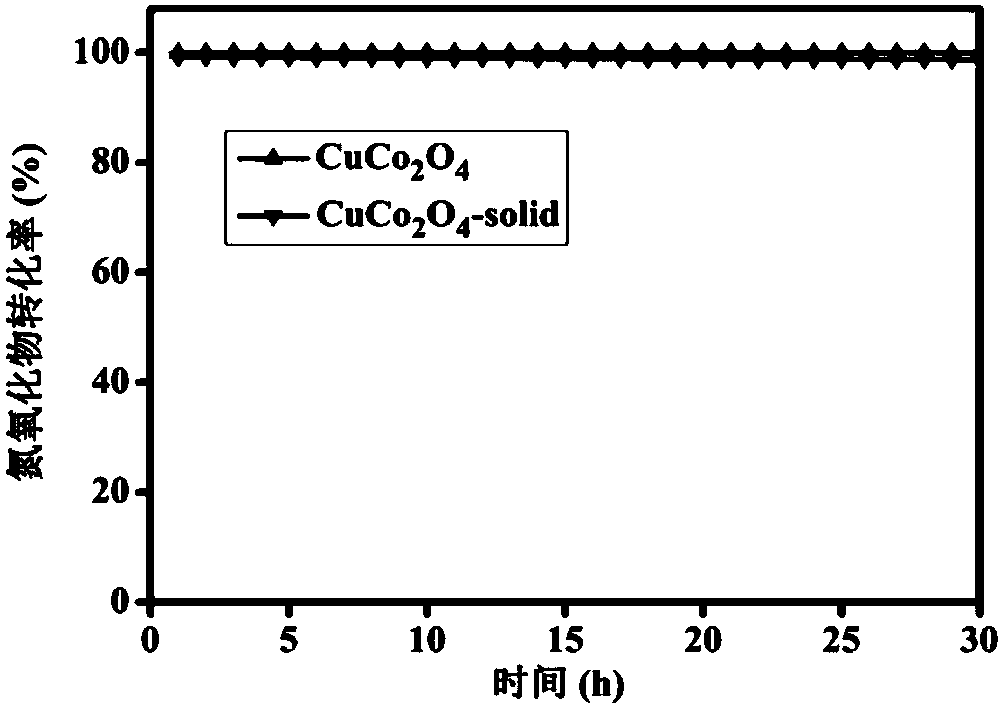

[0027] The present invention will be 0.4mmol Cu(NO 3 ) 2 ·3H 2 O and 0.8mmolCo(NO 3 ) 2 ·6H 2 O was dissolved in 19mL DMF, then 1.44mmolCA and 1.2g PAN were added to the above solution, and stirred at room temperature for 24h. The uniformly stirred solution was passed through an electrospinning device to form one-dimensional nanofibers under the conditions of 22kV and 1mL / h. The collected nanofibers were dried at 100 °C and calcined at 400 °C. The heating rate during the roasting process was 0.5 °C / min. The prepared catalyst was marked as CuCo 2 o 4 .

[0028] NO x Elimination process: take 0.5ml sample and place it in a u-shaped (i.d=8mm) quartz tube, and carry out NO x Determination of reduction performance, space velocity 150,000h -1 , sample, constant temperature reduction of NO at 50-400°C x , gas volume composition is 294ppm NO, 350ppm NH 3 , 3vol%O 2 (Ar balance gas), NO x Conversion by chemiluminescence NO-NO 2 -NO x Analyzer detection (Thermo, 42i-HL)....

Embodiment 2

[0030] The present invention will be 0.4mmol Cu(NO 3 ) 2 ·3H 2 O and 0.8mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 19mL DMF, then 1.44mmol CA and 1.2g PAN were added to the above solution, and stirred at room temperature for 24h. The uniformly stirred solution was passed through an electrospinning device to form one-dimensional nanofibers under the conditions of 22kV and 1mL / h. The collected nanofibers were dried at 100°C and calcined at 400°C. During the calcining process, the heating rate was 10°C / min. The prepared catalyst was marked as CuCo 2 o 4 -solid (such as figure 1 shown). NO x Elimination process: take 0.5ml sample and place it in a u-shaped (i.d=8mm) quartz tube, and carry out NO x Determination of reduction performance, space velocity 150,000h -1 , sample, constant temperature reduction of NO at 50-400°C x , gas volume composition is 294ppm NO, 350ppm NH 3 , 3vol%O 2 (Ar balance gas), NO x Conversion by chemiluminescence NO-NO 2 -NO x Analyzer dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com