Method and device for recycling waste clear liquid produced in process for producing sodium carbonate by ammonia-soda process

A cyclic recovery and waste clear liquid technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of energy waste, high production cost, low thermal efficiency, low production efficiency, etc. Achieve the effect of eliminating chemical pollution, low production cost and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

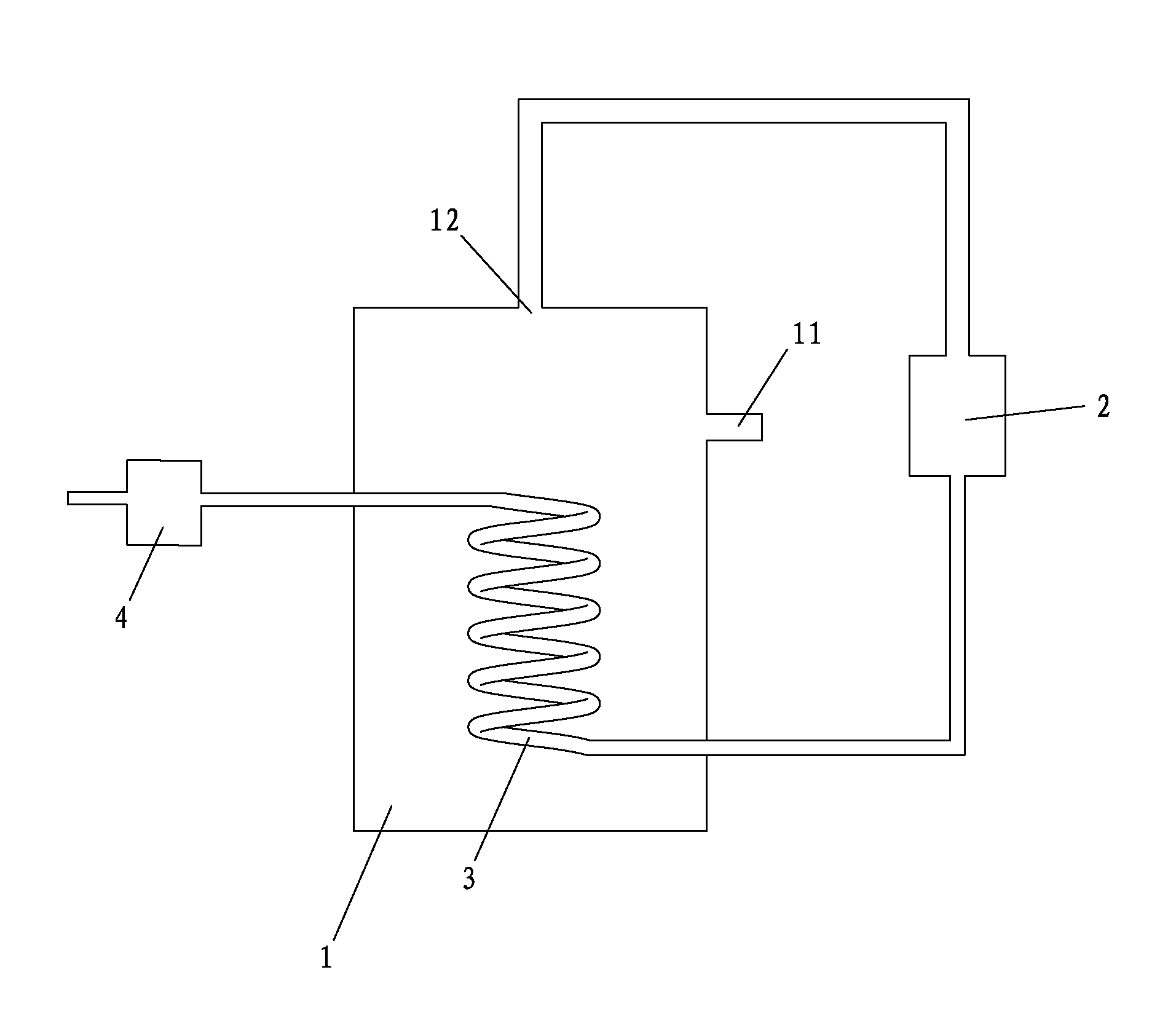

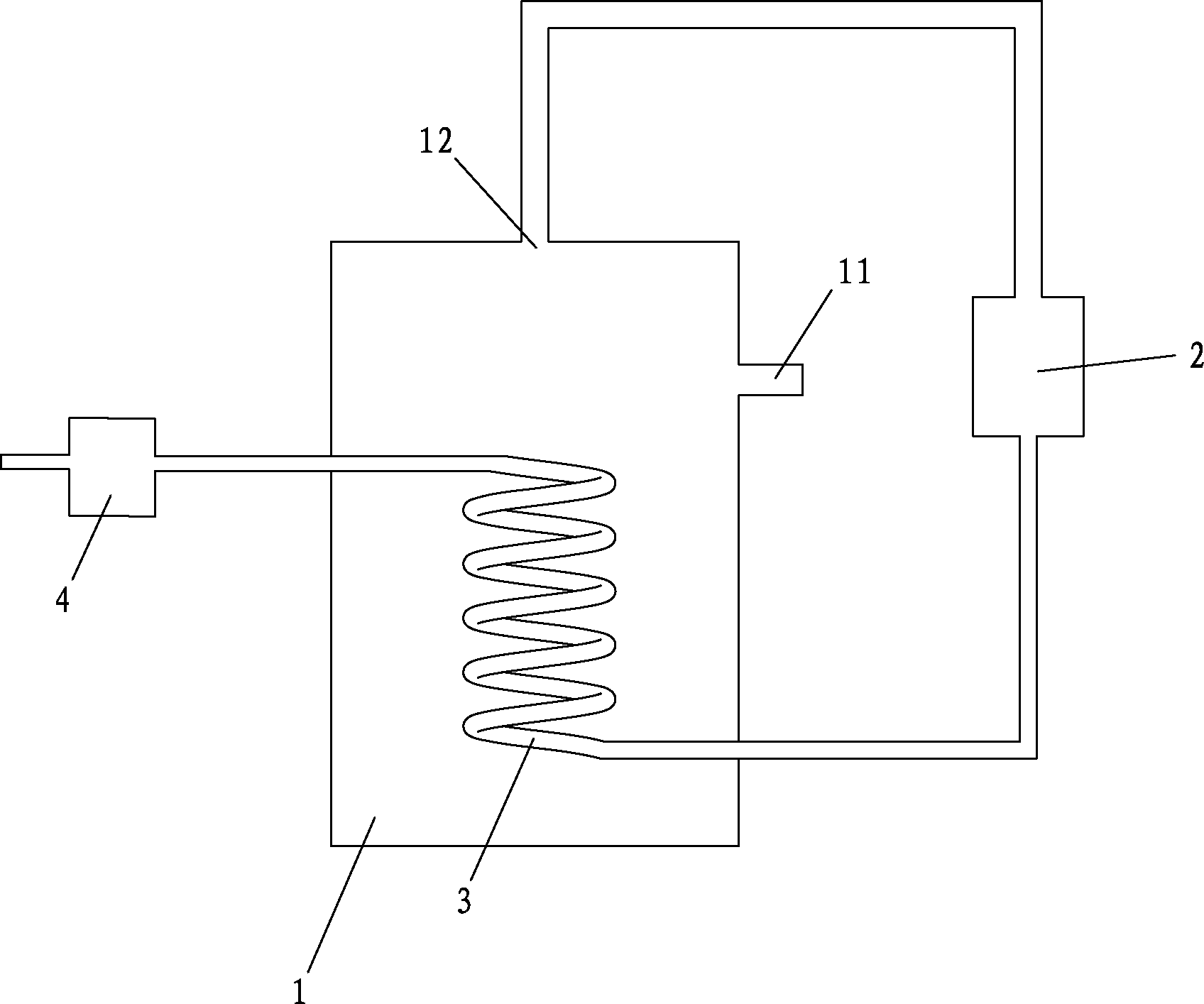

[0041] like figure 1 Shown, the recycling method of the waste clear liquid that ammonia-alkali method of the present invention produces soda ash produces may further comprise the steps:

[0042] Step A, drain the waste clear liquid obtained after clarification and deslagging treatment of 10 cubic meters of distillation waste liquid produced by the ammonia-soda factory to produce soda ash into the waste liquid tank 1; or pass the distillation waste liquid produced by the ammonia-soda factory to produce soda ash The first-stage settler separates the suspended solids therein to obtain the waste liquid and drain it into the waste liquid tank 1;

[0043] Step B, start the compression device 2 to form a negative pressure in the waste liquid tank 1, use the compression device 2 to pressurize the gas and liquid to achieve heat exchange, heat up the waste clear liquid and generate waste liquid vapor, and recycle to obtain distilled water products;

[0044] Step C. When the water evapo...

Embodiment 2

[0055] like figure 1 Shown, the recycling method of the waste clear liquid that ammonia-alkali method of the present invention produces soda ash produces may further comprise the steps:

[0056] Step A, drain the waste clear liquid obtained after clarification and deslagging treatment of 10 cubic meters of distillation waste liquid produced by the ammonia-soda factory to produce soda ash into the waste liquid tank 1; or pass the distillation waste liquid produced by the ammonia-soda factory to produce soda ash The first-stage settler separates the suspended solids therein to obtain the waste liquid and drain it into the waste liquid tank 1;

[0057] Step B, start the compression device 2 to form a negative pressure in the waste liquid tank 1, use the compression device 2 to pressurize the gas and liquid to achieve heat exchange, heat up the waste clear liquid and generate waste liquid vapor, and recycle to obtain distilled water products;

[0058] Step C. When the water evapo...

Embodiment 3

[0069] like figure 1 Shown, the recycling method of the waste clear liquid that ammonia-alkali method of the present invention produces soda ash produces may further comprise the steps:

[0070] Step A, the distillation waste liquid that the 10 cubic meters of ammonia-soda factory produces soda ash produces the waste clear liquid that obtains after clarification and deslagging treatment and drains in waste liquid tank 1; Or the distillation waste liquid that ammonia-soda factory produces soda ash produces through The first-stage settler separates the suspended solids therein to obtain the waste liquid and drain it into the waste liquid tank 1;

[0071] Step B, start the compression device 2 to form a negative pressure in the waste liquid tank 1, use the compression device 2 to pressurize the gas and liquid to achieve heat exchange, heat up the waste clear liquid and generate waste liquid vapor, and recycle to obtain distilled water products;

[0072]Step C. When the water eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com