Preparation method of feed containing chitin-oligosaccharides

A technology for chitosan oligosaccharide and feed, which is applied in the field of preparing feed containing chitosan oligosaccharide, can solve the problems of dense chitin structure, unfavorable biological decomposition, high energy consumption, etc., and achieves the effects of saving water consumption and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Thaw 100g of frozen prawn heads at room temperature, add 500mL of deionized water, homogenize with a high-speed homogenizer, collect the homogenate of shrimp heads, put it into a steel reaction vessel, and pass in CO 2 Until the container pressure reaches 1.0MPa, the oil bath heating temperature is 200°C, and the heating time is 60min. After heat treatment, concentrate at 60°C and 20mBar until the moisture content of the shrimp head raw material is 30%, add 100g of bran, and sterilize the shrimp head and bran mixture at 121°C for 20 minutes before use.

[0022] Get Bacillus subtilis bacterial classification, inoculate in seed culture medium (25g / L glucose, 25g / L yeast powder, 1g / LKH 2 PO 4 , 0.5g / L NaCl, 0.5g / L MgSO 4 ·7H 2 (0) in a shaker at 37° C. and 200 rpm for 24 hours to obtain a seed culture solution. Inoculate into the sterilized shrimp head bran mixture according to 10% (v / w) inoculum amount, and add appropriate amount of sterile water to adjust the water c...

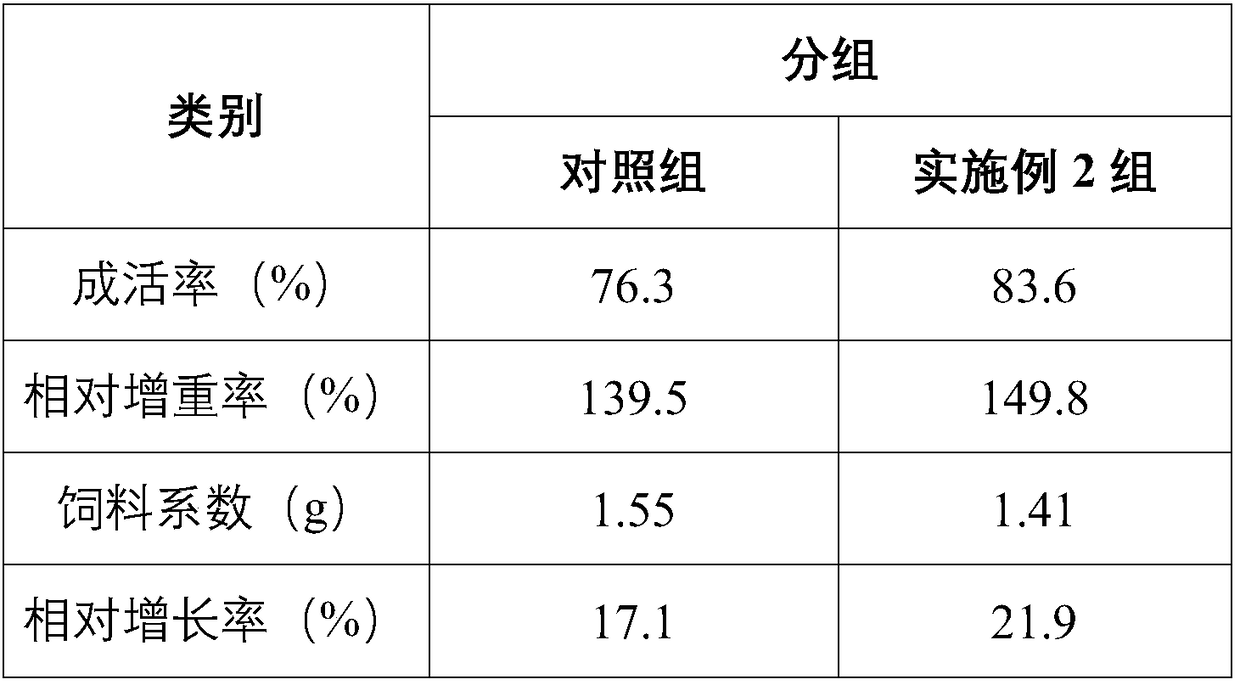

Embodiment 2

[0025] Thaw 100g of frozen prawn heads at room temperature, add 500mL of deionized water, homogenize with a high-speed homogenizer, collect the homogenate of shrimp heads, put it into a steel reaction vessel, and pass in CO 2 Until the container pressure reaches 1.0MPa, the oil bath heating temperature is 200°C, and the heating time is 60min. After heat treatment, concentrate at 60°C and 20mBar until the moisture content of the shrimp head raw material is 30%, add 100g of bran, and sterilize the shrimp head and bran mixture at 121°C for 20 minutes before use.

[0026] Get Bacillus subtilis bacterial classification, inoculate in seed culture medium (25g / L glucose, 25g / L yeast powder, 1g / LKH 2 PO 4 , 0.5g / L NaCl, 0.5g / L MgSO 4 ·7H 2 (0) in a shaker at 37° C. and 200 rpm for 24 hours to obtain a seed culture solution. Inoculate into the sterilized shrimp head bran mixture according to 10% (v / w) inoculum amount, and add appropriate amount of sterile water to adjust the water c...

Embodiment 3

[0029] Thaw 100g of frozen prawn heads at room temperature, add 500mL of deionized water, homogenize with a high-speed homogenizer, collect the homogenate of shrimp heads, put it into a steel reaction vessel, and pass in CO 2 Until the container pressure reaches 1.5MPa, the oil bath heating temperature is 180°C, and the heating time is 60min. After heat treatment, concentrate at 60°C and 20mBar until the moisture content of the shrimp head raw material is 30%, add 100g of bran, and sterilize the shrimp head and bran mixture at 121°C for 20 minutes before use.

[0030] Get Bacillus licheniformis bacterial classification, inoculate in seed culture medium (25g / L glucose, 25g / L yeast powder, 1g / LKH 2 PO 4 , 0.5g / L NaCl, 0.5g / L MgSO 4 ·7H 2 (0) in a shaker at 37° C. and 200 rpm for 24 hours to obtain a seed culture solution. Inoculate into the sterilized shrimp head bran mixture according to 10% (v / w) inoculum amount, and add appropriate amount of sterile water to adjust the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com