Method for removing chloride ions in waste alkaline residues

A waste alkali residue and chloride ion technology, applied in chemical instruments and methods, magnetic separation, solid separation and other directions, can solve the problems of inability to achieve large-scale comprehensive reuse, large chloride ion content, etc., and achieve low energy consumption, Simple process and equipment, high dechlorination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

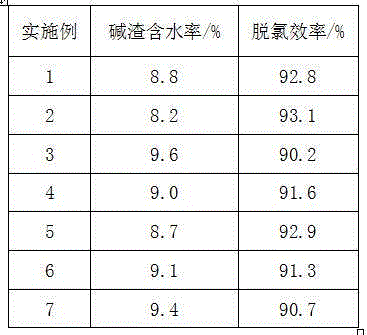

Examples

Embodiment 1

[0022] The waste alkali slag is pretreated by mechanical rolling, so that more than 90% of the waste alkali slag has a particle size of ≤1mm. Mix the waste caustic slag and magnetic iron powder evenly according to the mass ratio of 100:1, add a static magnetic field of 4000Gauss, add water 4 times the mass of the spent caustic soda slag, fully stir for 0.5h, carry out water elution of chlorine, and then stand for separation to obtain Precipitate and supernatant, the precipitation is air-dried for 4 days until the water content is <10%, and the magnetic iron powder is removed with a magnet to obtain the dechlorinated alkali slag.

Embodiment 2

[0024] The waste alkali slag is pretreated by mechanical rolling, so that more than 90% of the waste alkali slag has a particle size of ≤1mm. Mix the waste caustic slag and magnetic iron powder evenly according to the mass ratio of 100:1.2, add a static magnetic field of 5000Gauss, add water 5 times the mass of the spent caustic slag, fully stir for 0.5h, carry out water washing to remove chlorine, and then stand for separation to obtain Precipitate and supernatant, the precipitation is air-dried for 5 days until the water content is <10%, and the magnetic iron powder is removed with a magnet to obtain the dechlorinated alkali slag.

Embodiment 3

[0026] The waste alkali slag is pretreated by mechanical rolling, so that more than 90% of the waste alkali slag has a particle size of ≤1mm. Mix the waste caustic slag and magnetite evenly according to the mass ratio of 100:1.2, add a static magnetic field of 4000Gauss, add water 4 times the mass of the spent caustic slag, fully stir for 0.5h, carry out water washing to remove chlorine, and then stand and separate to obtain Precipitate and supernatant, the precipitation is air-dried for 4 days until the water content is <10%, and the magnetite is removed with a magnet to obtain the dechlorinated alkali slag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com