Brine refinement technique

A brine refining and process technology, applied in the field of brine preparation technology, can solve problems such as increased refining cost, and achieve the effects of eliminating saturation, reducing consumption and avoiding scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

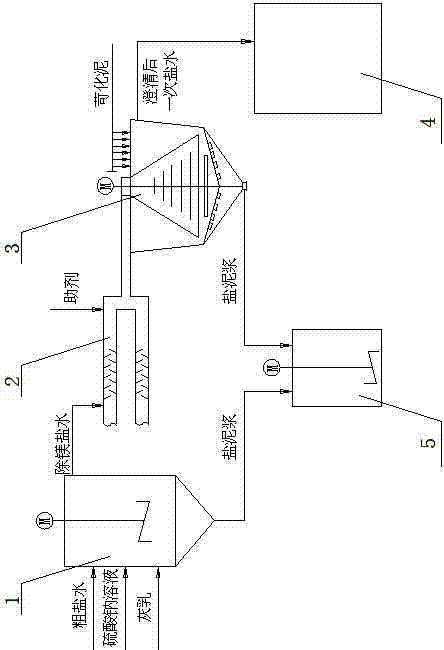

[0017] A kind of brine refining process, see attached figure 1 , Primary reactor 1, Launder 2, Primary clarification tank 3, Primary brine buffer tank 4, Primary mud washing buffer tank 5.

[0018] Add 1500 m of crude brine to primary reactor 1 3 / h, at the same time, according to the content of magnesium ions in the refined brine, gray milk is added to a sub-reactor 1 in a molar ratio of 1:1, and the rough brine is first mixed with gray milk Ca(OH) 2 Reaction to remove magnesium; according to the total amount of calcium and magnesium ions in the crude brine and gray milk mixture, add sodium sulfate solution into the primary reactor at a molar ratio of 1:1, so that the crude brine, gray milk and sodium sulfate are in the reactor internal mixing reaction.

[0019] Calcium equivalent to the magnesium in crude brine is added to the brine after m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com