Method for preparing engineering soil from alkaline residues by ammonia-alkaline method

A technology of engineering soil and ammonia-alkali method, which is applied in the field of alkali slag treatment, can solve the problems of thick paste mud that is not suitable for separation and treatment costs, high sensitivity, unstable alkali slag components, etc., to improve strength and water stability, reduce Soluble salt content, effect of reducing soluble salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

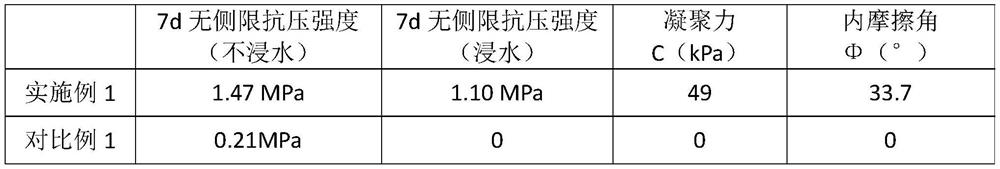

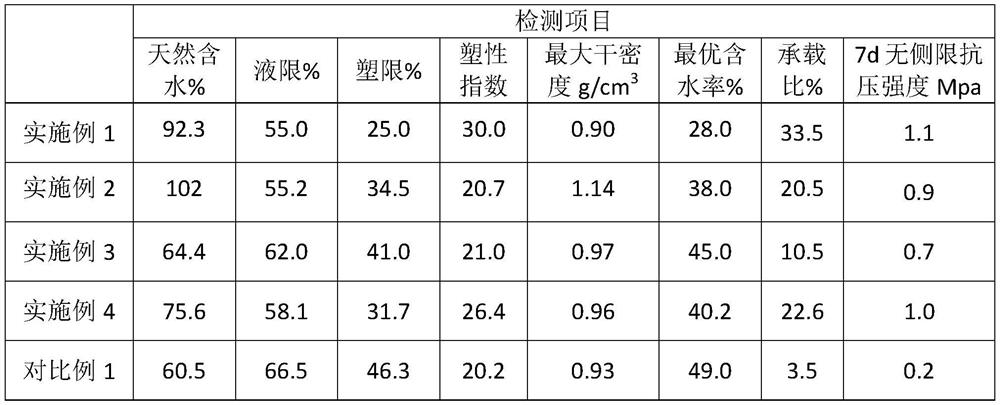

Embodiment 1

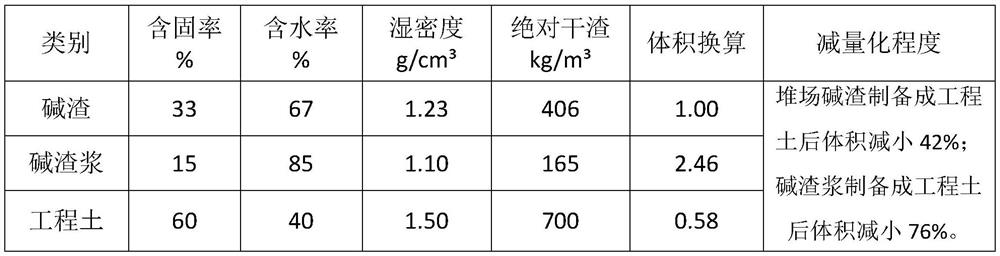

[0020] Use dredgers or hydraulic excavation units to excavate the alkali slag in the yard, and then use the pressure pipeline to transport the alkali slag slurry to the sedimentation tank, and then carry out sediment treatment, concentration treatment, homogenization and modification on the alkali slag, Adjust the mass fraction of alkali slag in the alkali slag slurry to 10-20% in the pool, and then use a plate and frame filter press for dehydration and consolidation. The feeding time of the plate and frame filter press is 30-40 minutes, and the pressing time is 5-8 minutes , and then stacked for 3 to 5 days to obtain engineering soil, and record the parameters in the process of alkali slag treatment, as shown in Table 1;

[0021] Wherein, the specific steps of homogenization modification are: adding calcareous material and pozzolanic active material to the alkali slag after concentrated treatment, stirring evenly, The mass ratio is 5:16:100. Calcareous materials are recorded ...

Embodiment 2

[0025] Use dredgers or hydraulic excavation units to excavate the alkali slag in the yard, and then use the pressure pipeline to transport the alkali slag slurry to the sedimentation tank, and then carry out sediment treatment, concentration treatment, homogenization and modification on the alkali slag, Adjust the mass fraction of alkali slag in the alkali slag slurry to 10-20% in the pool, and then use a plate and frame filter press for dehydration and consolidation. The feeding time of the plate and frame filter press is 30-40 minutes, and the pressing time is 5-8 minutes , and then stacked for 3 to 5 days to obtain engineering soil;

[0026] Wherein, the specific steps of homogenization modification are: adding calcareous material and pozzolanic active material to the alkali slag after concentrated treatment, stirring evenly, The mass ratio is 0:20:100.

Embodiment 3

[0028] Use dredgers or hydraulic excavation units to excavate the alkali slag in the yard, and then use the pressure pipeline to transport the alkali slag slurry to the sedimentation tank, and then carry out sediment treatment, concentration treatment, homogenization and modification on the alkali slag, Adjust the mass fraction of alkali slag in the alkali slag slurry to 10-20% in the pool, and then use a plate and frame filter press for dehydration and consolidation. The feeding time of the plate and frame filter press is 30-40 minutes, and the pressing time is 5-8 minutes , and then stacked for 3 to 5 days to obtain engineering soil;

[0029] Wherein, the specific steps of homogenization modification are: adding calcareous material and pozzolanic active material to the alkali slag after concentrated treatment, stirring evenly, The mass ratio is 15:5:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com