Method for preparing sodium carbonate from sodium sulfate

A process method, sodium sulfate technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal carbonates, etc., can solve the problems of salt loss environment, inability to utilize sodium sulfate in ammonia-alkali process, pollution, etc. Economic benefits, the effect of reducing waste water discharge and reducing discharge pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

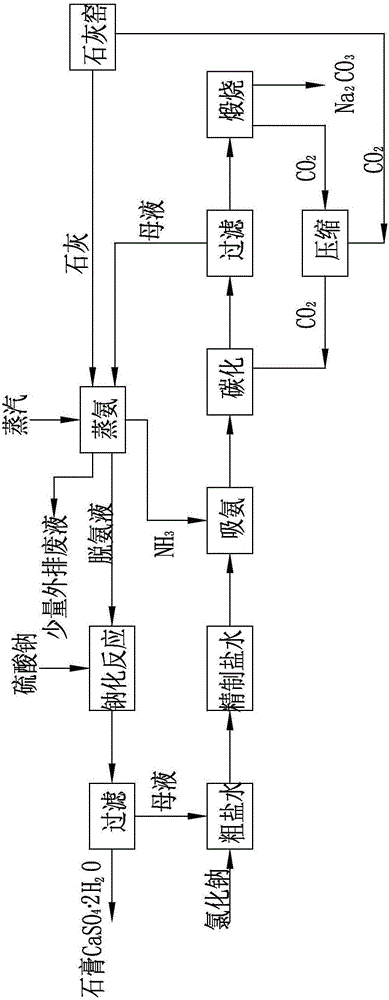

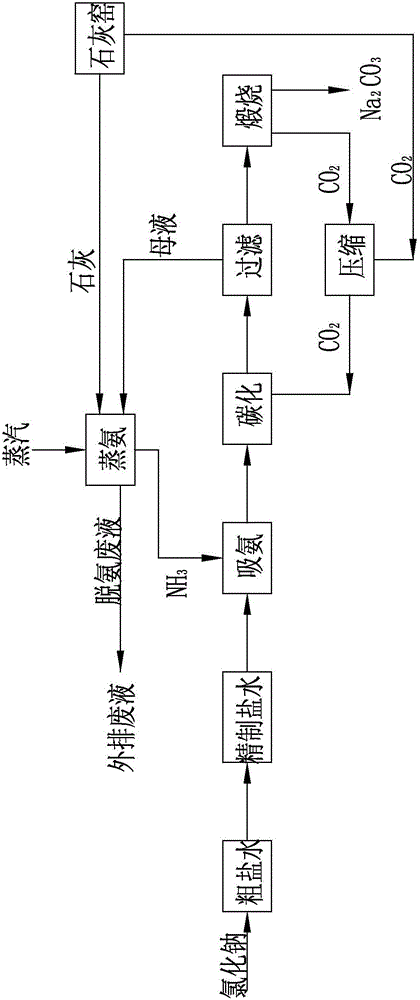

[0010] A process method for preparing soda ash with sodium sulfate, the specific process is:

[0011] It uses sodium sulfate and limestone as the main raw materials, chloride ions and ammonia as intermediate media in the process, and the main products are sodium carbonate and gypsum.

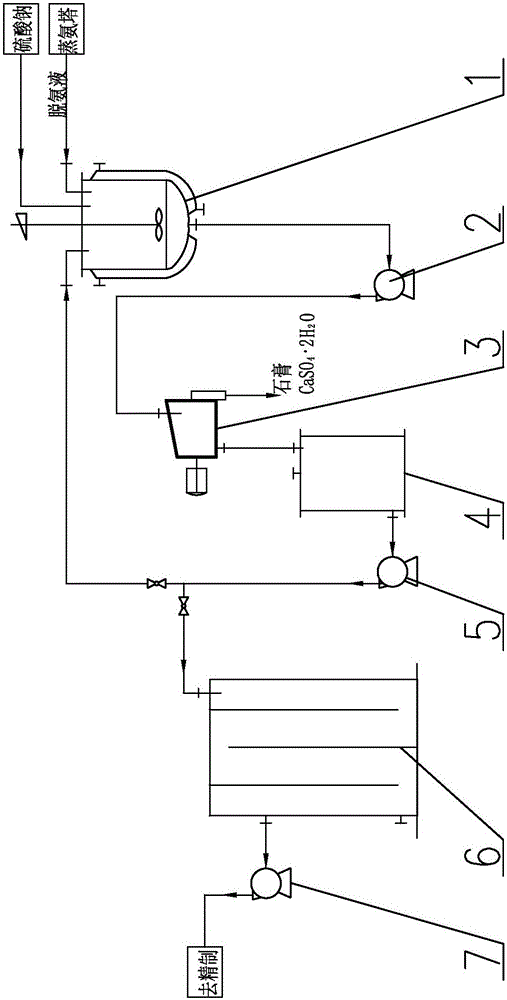

[0012] On the basis of the existing ammonia-soda production system, the sodiumization reaction of sodium sulfate and calcium chloride and the filtration and separation of gypsum are added to realize the process of producing soda ash with sodium sulfate as a raw material. The main by-products are gypsum (CaSO 4 . 2H 2 O).

[0013] Sodium reaction equation:

[0014] Na 2 SO 4 +CaCl 2 +2H 2 O=2NaCl+CaSO 4 .2H 2 O↓ (precipitation)

[0015] Reaction equation of ammonia absorption carbonization:

[0016] NaCl+NH 3 +H 2 O+CO 2 =NaHCO 3 +NH 4 Cl

[0017] Deamination reaction equation:

[0018] 2NH 4 Cl+Ca(OH) 2 = 2NH 3 +2H 2 O+CaCl 2

[0019] In the ammonia-soda soda process, the main components of the mother liquo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com