Method for making cored building material block by using solidified soda residue soil

A technology of building materials and alkali slag, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of land occupation, incomplete realization of alkali slag soil reduction and harmlessness, and failure to realize resources issues such as utilization, to achieve the effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

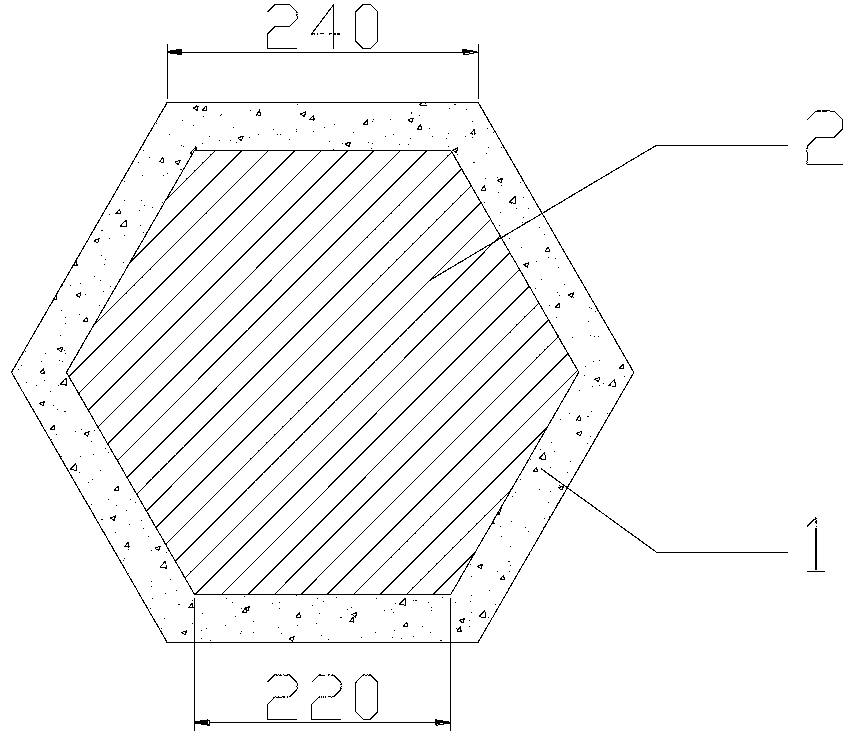

[0046] Adopt method provided by the invention to make floor tile, its plan view is as figure 2 Shown, the mass percent that its various raw material components occupy and production process are:

[0047] The mass percentages of various raw material components are as follows:

[0048] Wet alkali slag: 75%; plasticity index 28.6, moisture content 110%, void ratio 2.97.

[0049] Curing agent 5%: powdered sodium silicate: 4.5%, industrial caustic soda: 0.5%;

[0050] Ordinary Portland cement mortar: 20%; among them, ordinary Portland cement: 3%; sand: 17%.

[0051] Its production process is carried out according to the following steps:

[0052] The first step is to make the core material of solidified alkali dregs. Mix the curing agent and alkali slag evenly, put it into the mold A and fill it evenly, and demould after 3 days of normal curing (curing temperature 40°C, relative humidity 70%). The plane of the mold A is a regular hexagon with a side length of 22cm and a height...

Embodiment 3

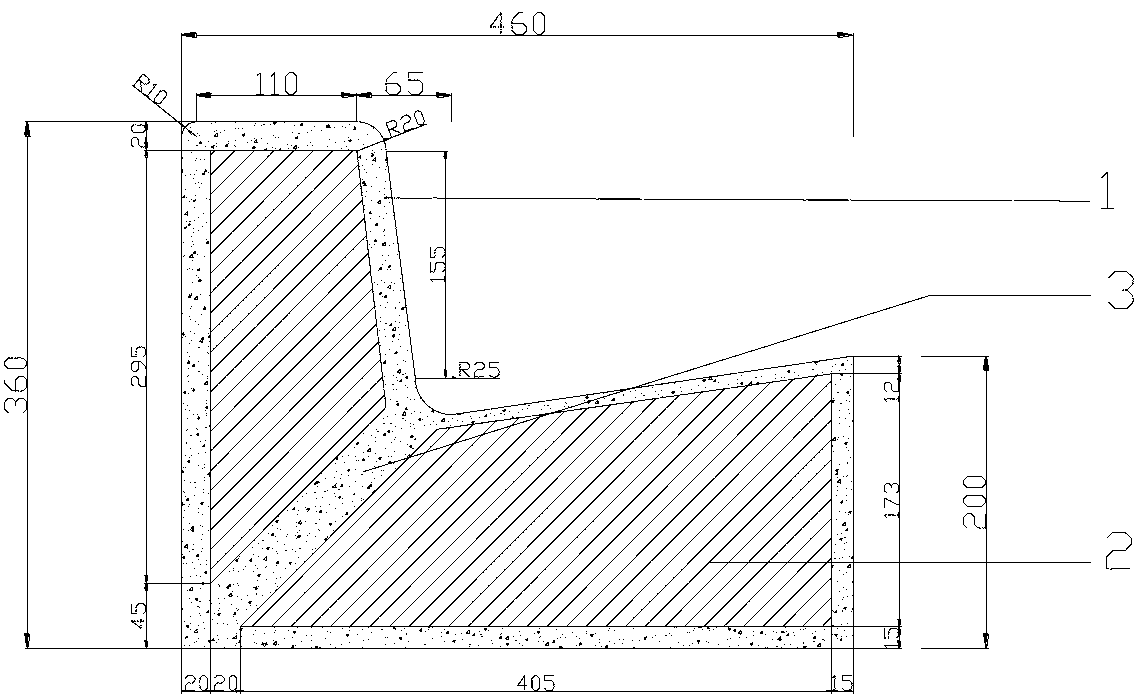

[0071] Adopt method provided by the invention to make revetment brick, its plan view is as Figure 4 Shown, the mass percent that its various raw material components occupy and production process are:

[0072] The mass percentages of various raw material components are as follows:

[0073] Wet alkali slag: 74%; plasticity index 14.5, moisture content 49%, void ratio 2.03.

[0074] Curing agent: 13%; among them, fly ash 9%, ordinary portland cement 4%.

[0075] Fly ash Portland cement polymer concrete 13%; among them, fly ash Portland cement 3%, styrene: 0.5%; fine aggregate: 3%; coarse aggregate: 5.5%; water: 1%.

[0076] Its production process is carried out according to the following steps:

[0077] The first step is to make the solidified alkali residue soil core material. Mix the curing agent and alkali slag evenly, put it into the mold A and fill it evenly, and demould after 4 days of normal curing (curing temperature 40°C, relative humidity 95%). The plane of mold A...

Embodiment 4

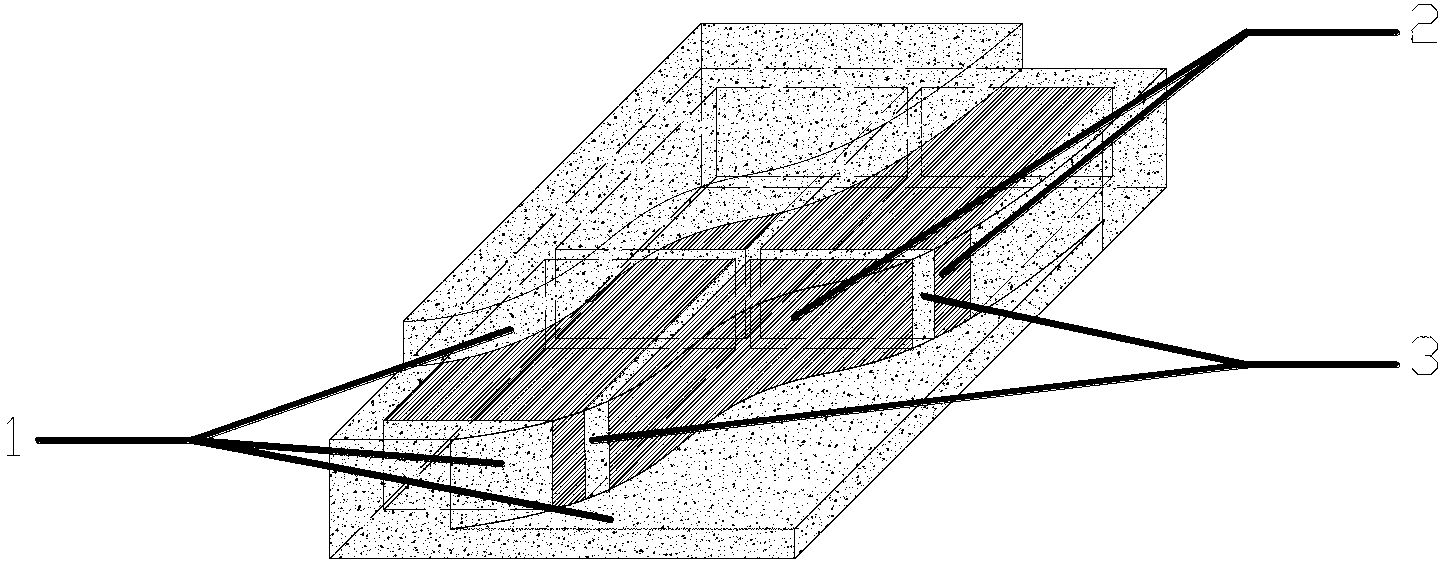

[0083] Adopt the method provided by the invention to make the building block that is used for masonry pool, its front view is as follows Figure 5 Shown, the mass percent that its various raw material components occupy and production process are:

[0084] The mass percentages of various raw material components are as follows:

[0085] Wet alkali slag: 58%; plasticity index: 15.7, moisture content: 40%, void ratio 2.1.

[0086] Curing agent: 9%; among them, granulated blast furnace slag: 1%, metakaolin pozzolan materials: 4%, sodium silicate: 4%.

[0087] Slag Portland cement mortar 33%; Among them, slag Portland cement: 4.5%, sand: 27%; water: 1.5%.

[0088] Its production process is carried out according to the following steps:

[0089] The first step is to make the core material of solidified alkali dregs. Mix the curing agent and alkali slag evenly, put them into the molds A1 and A2 and fill them evenly, and then demould directly. The plane of the mold A1 is a rectangl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com