Method for preparing high-purity dihydrate gypsum whiskers by using industrial byproduct calcium chloride

A technology of dihydrate gypsum whiskers and calcium chloride, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems affecting the development of salt chemical enterprises, adverse effects of groundwater, occupation of land resources, etc., and achieve large Market demand and practical significance, conducive to large-scale promotion and application, and the effect of low process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

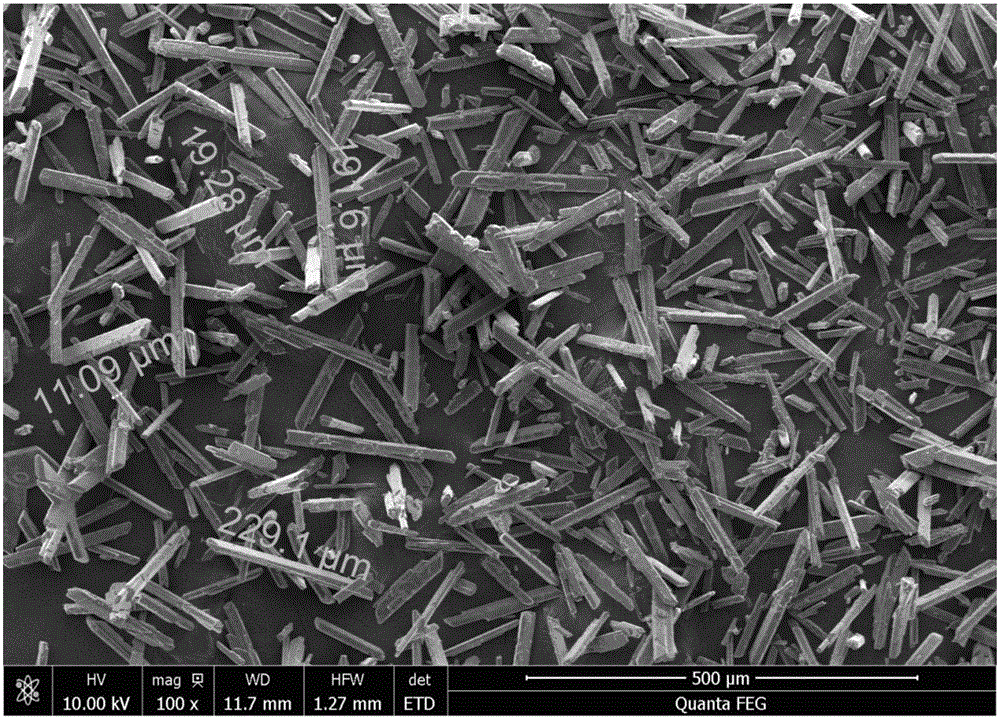

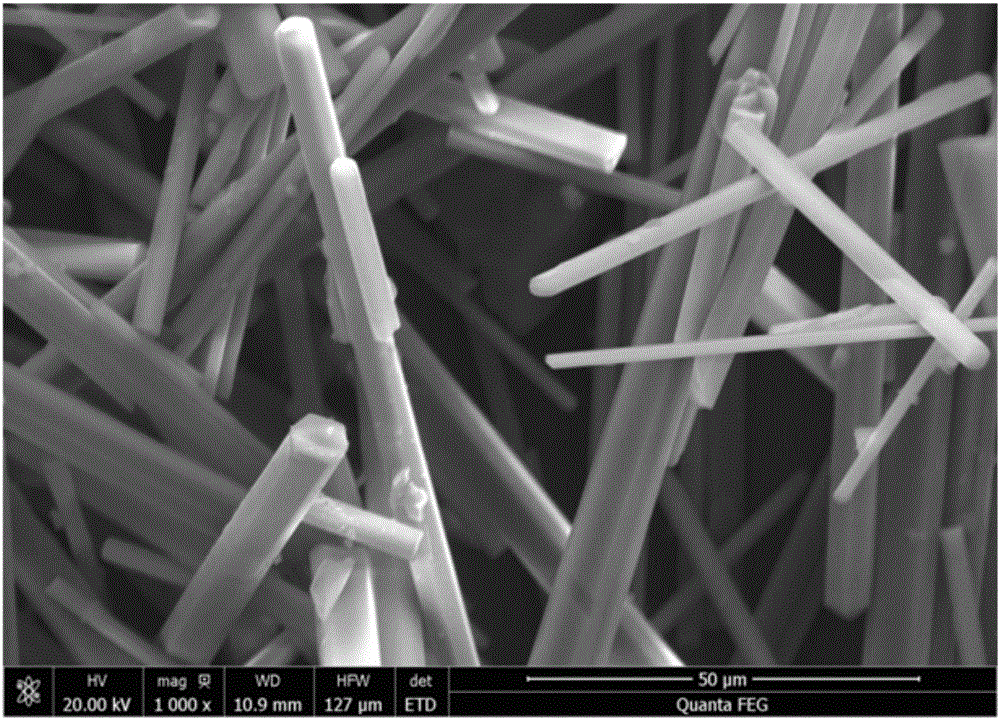

[0024] The method for preparing high-purity dihydrate gypsum whiskers is characterized in that comprising the following steps:

[0025] 1) Preparation of reaction mother liquor: the "ammonia-alkali method" industrial by-product calcium chloride slurry (after testing, containing CaCl 2 Concentration is 32.4wt%, impurity ion content is 3.7wt%) is placed in the hydrothermal reaction kettle, is prepared as the calcium chloride solution of concentration 10wt%, is heated to 30 ℃, adds nucleation promoter (CaCl 2 0.01% nano-silica of the solution quality), crystal form control agent (CaCl 2 1% KCl of the solution quality), the reaction mother liquor is obtained;

[0026] 2) Hydrothermal synthesis of dihydrate gypsum whiskers: Add 40°C sodium sulfate solution (prepared from industrial sodium sulfate with a purity of 98% and a concentration of 5wt%) to the reaction mother liquor obtained in step 1), and the addition time is 5 minutes, so that The molar ratio of calcium chloride to so...

Embodiment 2

[0029] The method for preparing high-purity dihydrate gypsum whiskers is characterized in that comprising the following steps:

[0030] 1) Preparation of reaction mother liquor: the "ammonia-alkali method" industrial by-product calcium chloride slurry (after testing, containing CaCl 2 Concentration is 37.3wt%, impurity ion content is 2.6wt%) is placed in the hydrothermal reaction kettle, is prepared as the calcium chloride solution of concentration 30wt%, is heated to 45 ℃, then adds nucleation accelerator (CaCl 2 0.1% silica fume of solution mass), crystal form control agent (CaCl 2 2% K of solution mass 2 SO4 ), prepare reaction mother liquor;

[0031] 2) Hydrothermal synthesis of dihydrate gypsum whiskers: Add 45°C sodium sulfate solution (prepared from industrial sodium sulfate with a concentration of 10wt%) to the reaction mother liquor obtained in step 1), and the addition time is 10min, so that calcium chloride and sulfuric acid The molar ratio of sodium is 1.15:1, s...

Embodiment 3

[0034] The method for preparing high-purity dihydrate gypsum whiskers is characterized in that comprising the following steps:

[0035] 1) Preparation of reaction mother liquor: the "ammonia-alkali method" industrial by-product calcium chloride slurry (after testing, containing CaCl 2 Concentration is 44.6wt%, impurity ion content is 2.9wt%) is placed in the hydrothermal reaction kettle, and preparation concentration is the calcium chloride solution (adjusting its concentration by heating evaporation concentration method) of 50wt%, is heated to 60 ℃, then adds Nucleation accelerator (CaCl 2 0.15% of the solution mass dihydrate gypsum fine powder, the particle size is 0.1-50μm), crystal form control agent (KCl and K 2 SO 4 1:1 mixture by mass, accounting for CaCl 2 4% of the solution quality), prepared reaction mother liquor;

[0036] 2) Hydrothermal synthesis of dihydrate gypsum whiskers: Add 50°C sodium sulfate solution (prepared from industrial sodium sulfate with a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com