Method for producing calcium chloride solution from alkali waste residues produced by ammonia-alkali process

A technology of calcium chloride solution and alkali-making waste residue, applied in chemical instruments and methods, separation methods, calcium/strontium/barium chloride and other directions, can solve the problems of low consumption of alkali residue, high utilization cost and high steam consumption, Achieve the effect of reducing steam consumption and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

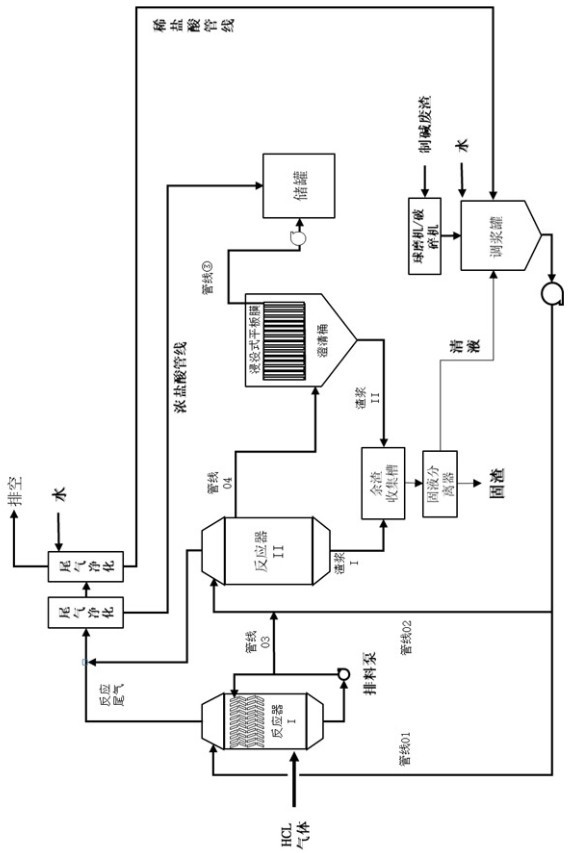

[0024] refer to figure 1 , the device adopted in the present invention includes a crusher, a slurry tank, a reactor I, a reactor II, a clarifier, an immersion filter, a residue collection tank, a solid-liquid separator, a tail gas purification device, a storage tank, and a reactor I. The structure of reactor II, submerged filter, residue collection tank, solid-liquid separator and tail gas purification device is a known technology. The specific connection method is:

[0025] The crusher is connected to the slurry tank. After the slurry tank, the slurry pipeline is divided into two routes. The first route is connected to the reactor I slurry inlet through the first pipeline 01, and the second route is connected to the reactor II slurry through the second pipeline 02. The inlet; the bottom of the reactor I is equipped with a discharge pump, that is, a feed liquid forced circulation pump. After the circulation pump, the slurry pipeline is divided into two routes, the first route...

Embodiment 2

[0035] Embodiment 2 is basically the same as Embodiment 1, the main difference is:

[0036] Hydrogen chloride gas comes from the production process of potassium sulfate by Mannheim method; the bottom of reactor II is equipped with multi-layer rakes for stirring to strengthen and optimize the discharge of slurry at the bottom; The slurry is used for solid-liquid separation; the exhaust gas purification part and the two-stage exhaust gas absorption tower are respectively equipped with independent circulation pumps to optimize and adjust the concentration of hydrochloric acid after absorption; Filtration, control pressure -0.01~-0.1MPa, filtration temperature 40~80℃, flow control at 50~150 L / m 2 .h, when the membrane flux is lower than 50 L / m 2 .h or regularly use dilute hydrochloric acid backwash from the exhaust gas purification device, and use 0.5-1mol / L HCl chemical cleaning when the backwash of the submerged flat membrane cannot restore the flux. The material of the submerg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com