Application of liquid waste containing liquid and solid components obtained in process of producing sodium carbonate by ammonia-alkali method in production of saline water in underground caves

A liquid waste, underground cave technology, applied in the application of brine production, the evaluation field of brine production application, can solve the problems of high cost and overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

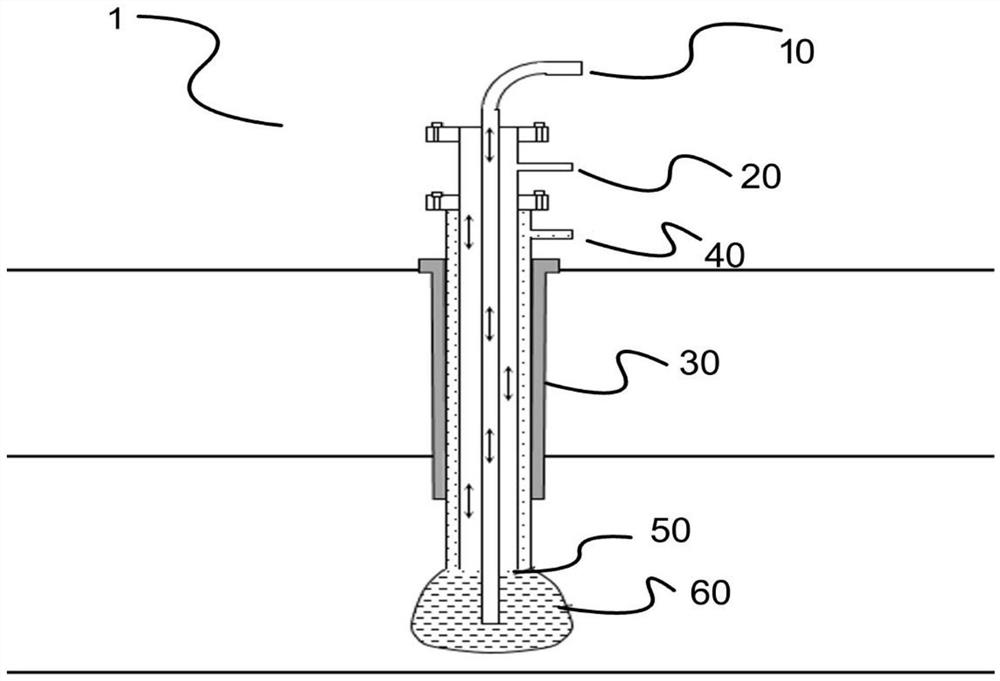

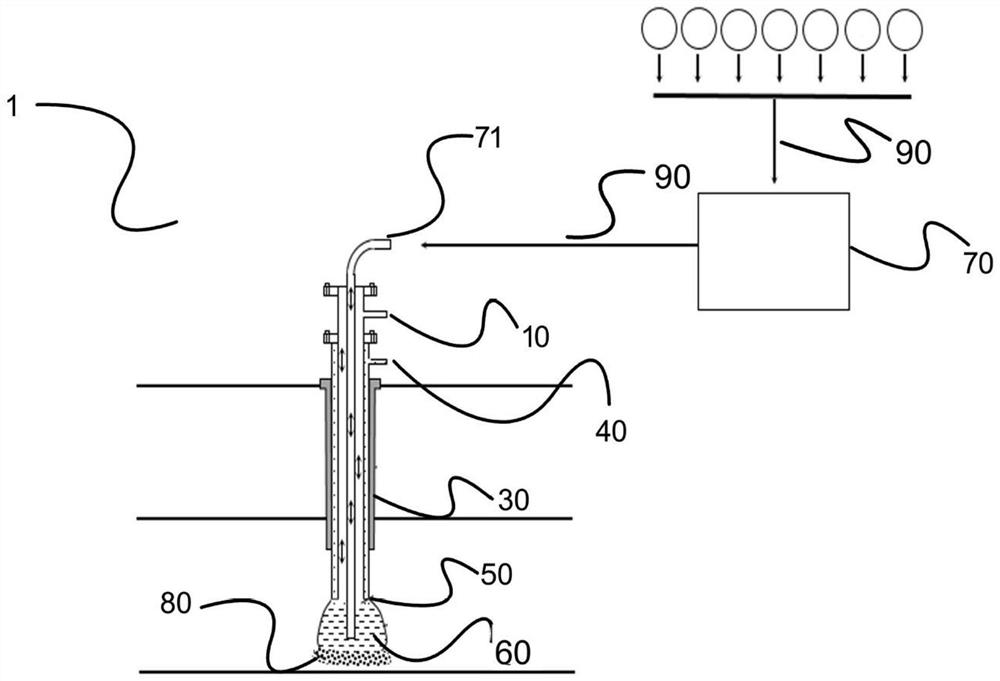

[0043] In this detailed description, the invention relates to the evaluation of liquid waste containing liquid and solid components obtained during the production of soda ash by the ammonia-soda process for the production of brine in underground caverns 1, illustrated by examples, the implementation The examples are just for easier understanding of the present invention, without any limiting effect.

[0044] Liquid wastes containing both liquid and solid components are generated during the application of the ammonia-soda process and generally originate from the following process sections. These craft parts are:

[0045] 1. The saturated brine used in the ammonia-soda method is first passed through calcium hydroxide (hereinafter referred to as milk of lime) and then refined with soda ash. As a result, the calcium (Ca) and magnesium (Mg) contents of the brine are reduced to desired levels. The process is realized in conical strippers and refining tanks.

[0046] Ca 2+ +Na 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com