Horizontal continuous crystal transformation device, system and method for preparing high-strength gypsum

A technology of high-strength gypsum and crystal transformation, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of non-compliance with the development requirements of green environmental protection, continuous production, low production efficiency, high energy consumption, etc. , to achieve good drying and water removal effects, reduce manpower, and shorten the material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

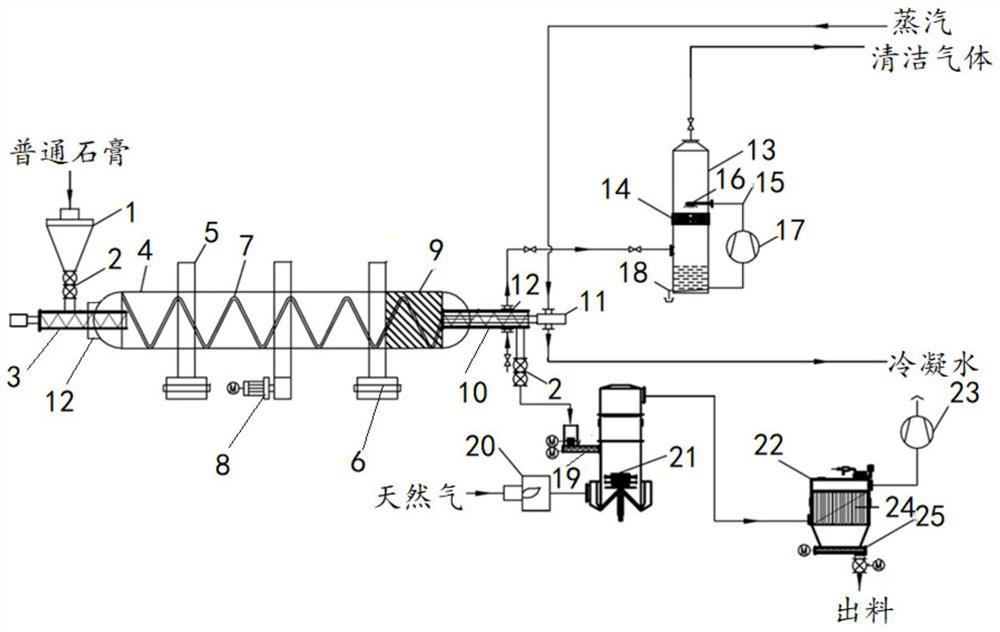

[0037] In one or more embodiments, a horizontal continuous crystallizing device for preparing high-strength gypsum is disclosed, combined with figure 1 , which specifically includes: a horizontal crystal retort 4, the two ends of the horizontal crystal retort 4 are respectively connected to the feed conveying screw 3 and the screw guide device 10 through the high-pressure dynamic and static seals 12, and the feed port of the feed conveying screw 3 and the screw The discharge ports of the material guiding device 10 are respectively connected to the pressure-maintaining discharge valves 2; in this embodiment, the internal pressure of the horizontal crystal bowl 4 is always maintained at 0.3MPA-0.6MPA, and the pressure-holding discharge valve 2 can The internal pressure of the crystal barrel 4 is kept at the same time so that the material feeding does not release pressure; the high-pressure dynamic and static seal 12 mainly plays the role of sealing and maintaining pressure.

[003...

Embodiment 2

[0049] In one or more embodiments, a system for producing high-strength gypsum is disclosed, incorporating figure 1 , which specifically includes: a feeding bin 1, the horizontal continuous crystallizing device described in the first embodiment, a waste gas treatment unit, a flash drying unit and a bag filter unit; wherein, the feeding bin 1 is connected to the horizontal continuous crystallizing device. , The material output of the horizontal continuous crystallizing device is connected to the flash drying unit, the tail gas output of the flash drying unit is connected to the bag filter unit; the waste gas output of the horizontal continuous crystallizing device is connected to the exhaust gas treatment unit.

[0050] In this embodiment, the waste gas treatment unit adopts a washing tower 13 , and the washing tower 13 mainly includes a tower body, a sealing box 14 , a sprinkling main pipe 15 and nozzles 16 , a water pump 17 and a sewage outlet 18 . The nozzle 16 and the seali...

Embodiment 3

[0054] In one or more embodiments, a method for preparing high-strength gypsum is disclosed, which specifically includes the following processes:

[0055] (1) Put a certain amount of ordinary gypsum (β gypsum) at room temperature (CaSO with a general water content of about 15%) 4 -2H 2 (0, and part of the crystallizer) is put into the feeding bin 1 to make it evenly fed, and the pressure-retaining discharge valve 2 is acted upon by gravity to reach the feeding conveying screw 3, and the feeding and conveying screw 3 contains conveying blades, The blades can clean each other, thus preventing the gypsum from sticking to the feed screw wall.

[0056] (2) The ordinary gypsum conveyed by the feeding screw will enter the horizontal crystal retort 4. The pressure maintaining and discharge valves 2 on both sides of the horizontal crystal retort 4 maintain the internal pressure of the crystal revolver, and at the same time prevent the material from being fed. Depressurize. The inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com